Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Wright flow Classic+

- Page 1 NSTALLATION PERATION AINTENANCE ANUAL Range of Pumps...

-

Page 2: Table Of Contents

Installation, Operation & Maintenance Manual For The Classic+ Range Of Rotary Lobe Pumps Safety Information. Risk assessment relating to the use of Wright Flow Technologies Limited. Classic+ rotary lobe pumps and pump units in potentially explosive atmospheres. Introduction. General. Wright Flow Technologies Limited Distributors. - Page 3 4.2.1 CP40 Front Cover and Rotor Removal 4.2.2 CP40 Rotorcase Removal 4.2.2.1 CP40 Rotorcase Removal for Pumps fitted with Single Un-flushed Mechanical Seals and O-Ring Seals 4.2.2.2 CP40 Rotorcase Removal for Pumps Fitted with Single Flushed or Double Flushed Mechanical Seals. 4.2.4 CP40 Gearbox Assembly 4.2.5...

- Page 4 Classic+ Packed Gland Seals 6.4.1 General Procedures For Fitting Packed Gland Seals Packed Gland Seals - CP10, CP20, CP30 and CP40 Series Pumps 6.5.1 Packed Gland Seal Removal 6.5.2 Packed Gland Seal Replacement 6.5.3 Flushed Packed Gland Seal Removal 6.5.4 Flushed Packed Gland Seal Replacement Packed Gland Seals - CP50 Series Pumps.

-

Page 5: Safety Information

Safety Information. INCORRECT INSTALLATION, OPERATION, OR MAINTENANCE OF EQUIPMENT MAY CAUSE SEVERE PERSONAL INJURY OR DEATH AND/OR EQUIPMENT DAMAGE AND MAY INVALIDATE THE WARRANTY. THIS INFORMATION MUST BE READ FULLY BEFORE BEGINNING INSTALLATION, OPERATION, OR MAINTENANCE AND MUST BE KEPT WITH THE PUMP. - Page 6 The mounting of the pump or pump unit should be solid and stable. Pump orientation must be considered in relation to drainage/cavity ventilation requirements. Once mounted, shaft drive elements must be checked for correct alignment. Rotate pump shaft by at least one full revolution to ensure smoothness of operation.

- Page 7 DO NOT attempt any maintenance or disassembly of the pump or pump unit without first ensuring that: The pump is fully isolated from the power source (electric, hydraulic, pneumatic). The pumping chamber, pneumatic relief valve and any shaft seal support system are depressurised and purged. Any temperature control devices (jackets, heat-tracing, etc) are fully isolated, that they are depressurised and purged, and components are allowed to reach a safe handling temperature.

-

Page 8: Risk Assessment Relating To The Use Of Wright Flow Technologies Limited

Risk assessment relating to the use of Wright Flow Technologies Limited. Classic+ rotary lobe pumps and pump units in potentially explosive atmospheres. Note:- For a feature to be suitable for an application, The feature must be fit for its designated purpose and also suitable for the environment where it is to be installed. -

Page 9: Introduction

Introduction. General. Classic+ rotary lobe pumps are manufactured by Wright Flow Technologies Limited, a unit of the IDEX Corporation. This manual includes all the necessary information for the Classic+ and should be read prior to beginning installation, operation, or maintenance. -

Page 10: Cleaning

–10° and 40°C (14° F and 105° F). Further to the above, if the pump is not intended for installation or use within 18 months or more then refer to Wright Flow Technologies Limited, or the Wright Flow Technologies Limited authourised distributor for storage recommendations. -

Page 11: Atex Information

2.5.1 ATEX Information ATEX Pump Requirements Please be aware that mechanical seals are a source of heat and must never be allowed to run dry. We would recommend provision be made to ensure that there is a flow of fluid around the pump seals at all times. If there is a risk of the supply being interrupted, we would recommend that the flush on the seals be fitted with a flow detection device. -

Page 12: Pump Model And Serial Number

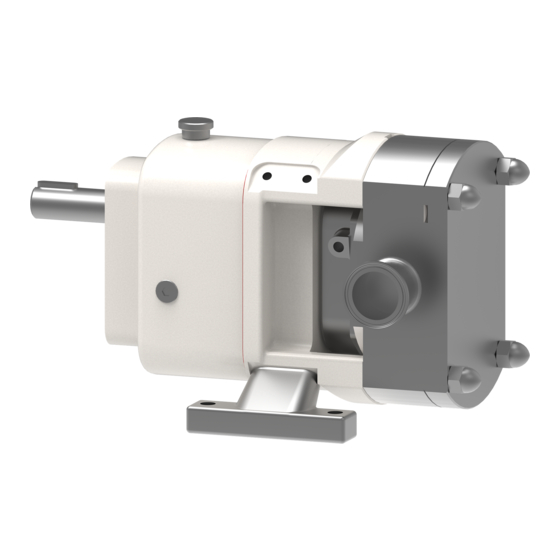

Pump Model and Serial Number. Should you require any information regarding your Classic+ rotary lobe pump contact Wright Flow Technologies Limited or your Wright Flow Technologies Limited distributor, providing the pump model and serial number as stated on the pump nameplate, see Fig 2, which is fixed to the pump gearbox cover. - Page 13 Standard Pump Component Terms. Fig 4 Pump Component Terms Page 13...

-

Page 14: General

General. Classic+ Pumping Principal. The pumping action of the rotary lobe pump principle is generated by the contra rotation of two pumping elements (rotors) within a chamber (rotorcase) - see Fig 5. The rotors are located on shafts, which in turn are mounted within an external gearbox and supported by the bearings;... -

Page 15: Classic+ Range Operating Parameters

Care should be taken when selecting pumps for handling liquids containing abrasive particles as these may cause wear of pump head components. For advice or assistance contact Wright Flow Technologies Limited or your Wright Flow Technologies Limited distributor. Page 15... - Page 16 Nominal Max Diff. Max Diff. Max. Speed @ Pump Range Theoretical Displacement Connection Pressure @ Pressure Speed Max Diff. Size Max Speed Pressure Imp.gal US gal ltr/rev inches rev/min rev/min /100 rev /100 rev CP10/0005/12 0.046 1.01 1.22 1400 1000 CP10/0008/08 0.083 1.83...

-

Page 17: System Design

System Design. 3.3.1 System Design and Installation. When incorporating any pump into a system it is considered good practice to minimize piping runs and the number of pipe fittings (tees, unions, bends etc.) and restrictions. Particular care should be taken in designing the suction line, which should be as short and straight as possible with a minimum of pipe fittings to minimise restricting product flow to the pump. - Page 18 The Net Positive Suction Head available (NPSHa) from the system must WARNING always exceed the Net Positive Suction Head required (NPSHr) by the pump. Observing the following general guidelines should ensure the best possible suction condition is created. − Suction piping is at least the same diameter as the pump connections. −...

-

Page 19: Installations With Cip Systems

When installing a pump complete with base plate, motor and drive, the following guidelines must be observed: a) The preferred drive arrangement for any rotary lobe pump is in-line direct coupled. If an alternative is required please contact Wright Flow Technologies Limited or your Wright Flow Technologies Limited distributor. -

Page 20: Start Up Procedure

Start Up Procedure. Check that all piping and associated equipment are clean and free from WARNING debris and that all pipe connections are secure and leak free. For pumps fitted with flushed product seals check all auxiliary services WARNING are in place and connected and provide sufficient flow and pressure for flushing purposes, refer to section 7.0. -

Page 21: Shutdown Procedure

Fig 8 Rotation against Suction and Discharge Be sure product is available in the suction vessel before starting the pump. This is very important for pumps fitted with un-flushed product WARNING seals, as these sealing arrangements must never be allowed to run dry. Before beginning operation, it is considered good practice to momentarily start/stop the pump to check the direction of rotation and ensure that the pump is free of obstructions. -

Page 22: Routine Maintenance

The pressure rating of the Classic+ series jacketed front cover and rotorcase is 3 Bar (50 psi) and this should not be exceeded without consulting Wright Flow Technologies Limited or your local Wright Flow Technologies Limited distributor. Heating/cooling of the pump head is used to maintain, rather than... - Page 23 Millimetres Inches Model CP10/0005/12 50.0 52.0 1.97 2.05 ¼” CP10/0008/08 50.0 61.0 1.97 2.40 ¼” CP10/0011/05 50.0 61.0 1.97 2.40 ¼” CP20/0020/12 64.0 71.0 2.52 2.80 ½” CP20/0031/07 64.0 81.0 2.52 3.19 ½” CP30/0069/12 92.5 81.0 3.64 3.19 ½” CP30/0113/07 92.5 96.0 3.64...

- Page 24 Millimetres Inches Model CP10/0005/12 70.0 56.0 156.0 2.76 2.20 6.14 0.12 ¼ CP10/0008/08 70.0 56.0 156.0 2.76 2.20 6.14 0.08 ¼ CP10/0011/05 70.0 56.0 156.0 2.76 2.20 6.14 0.30 ¼ CP20/0020/12 80.0 64.0 216.0 3.15 2.52 8.50 0.00 ¼ CP20/0031/07 80.0 64.0 216.0...

-

Page 25: Integral Pressure Relief Valves

Integral Pressure Relief Valves See Fig 11, 12, 13 and 14. The Classic+ models CP10, CP20, CP30 and CP40 can be supplied with integral pressure relief valves. For the CP10, CP20 and CP30 both spring and air loaded versions are available. The function of the valves can be further enhanced with the option of manual or airlift override, offering particular benefits where CIP or SIP procedures are employed. -

Page 26: Setting And Operating Spring Loaded Valves

If the pump on which the valve is fitted is to be installed within either a pressurised system or one incorporating a vessel under vacuum then the application of the valve should be referred to Wright Flow Technologies Limited. The selection, setting and application of integral relief valves is influenced by the viscosity and nature of the pumped media, the pumps operating speed and the required pressure relief setting and mode of operation. -

Page 27: Setting And Operating Air Loaded Integral Pressure Relief Valves

Reinstall cover (108). For integral relief valve with manual lift, see Fig 12; reinstall hand wheel (111) and nut (129). The relief valve is now set. For Integral Relief Valve with Manual Lift - see Fig 12. To operate the manual lift, turn the hand wheel (111) clockwise, which will lift the valve head (102/128). - Page 28 Fig 11 Spring Loaded Integral Pressure Relief Valve CP10, CP20, CP30, CP40. Fig 12 Spring Loaded Integral Pressure Relief Valve with Manual Lift CP10, CP20 and CP30. Page 28...

- Page 29 Fig 13 Spring Loaded Integral Pressure Relief Valve with Air Lift CP10, CP20 and CP30. Fig 14 Air Loaded Integral Pressure Relief Valve with Air Lift CP10, CP20, CP30 and CP40. Page 29...

-

Page 30: Classic+ Disassembly And Assembly

Classic+ Disassembly and Assembly. Before starting any work on the pump the recommended Shutdown Procedure should be followed, refer to section 3.5. While disassembling or assembling the pump it is essential to ensure that the pump and/or components are secured to provide adequate stability. Large pump components or sub-assemblies should be installed using suitable devices. - Page 31 The preferred method of installing bearing cones is that they are heated to approximately 125° C (250° F) prior to installation. During this operation protective gloves should be used. Once bearing cones are installed in the correct position they should be allowed to cool before proceeding with assembly.

-

Page 32: Cp10, Cp20 And Cp30 Pump - Disassembly And Assembly

CP10, CP20 and CP30 Pump - Disassembly and Assembly. 4.1.1 CP10, CP20 and CP30 Front Cover and Rotor Removal Fig 15 CP10 Exploded View of Rotorcase and Rotor Assembly Page 32... - Page 33 Fig 16 CP20 / CP30 Exploded View of Rotorcase and Rotor Assembly Page 33...

- Page 34 Follow recommended shutdown procedure. Refer to section 3.5. For CP10 Pump – refer to Fig 15. For CP20 Pump – refer to Fig 16. Gradually loosen front cover retaining dome nuts (1.03). Care should be taken as there may still be residual product and pressure in the pump head and as the dome nuts are loosened, this will vent to atmosphere.

-

Page 35: Cp10, Cp20 And Cp30 Rotorcase Removal

4.1.2 CP10, CP20 and CP30 Rotorcase Removal Note: Ensure all pipe work is disconnected before commencing rotorcase WARNING removal. 4.1.2.1 CP10, CP20 and CP30 Rotorcase Removal for Pumps fitted with Single Un-Flushed Mechanical Seals and Single O-Ring Seals CP10 Pump Only (After completing section 4.1.1) Slide rotorcase (3.01) from bearing housing (4.01), noting it is located on dowels (4.03), keep arch shims (4.05) in... - Page 36 Single O-Ring Seal as shown in Fig 18 – see section 6.2.1 for removal and replacement. Remove rotor (2.01). Remove O-Ring seal (7.04) from rotorcase (3.01). Fig 18 O-Ring Seal Page 36...

-

Page 37: Cp10, Cp20 And Cp30 Rotorcase Removal For Pumps Fitted With Single Flushed Or Double Flushed Mechanical Seals

4.1.2.2 CP10, CP20 and CP30 Rotorcase Removal for Pumps Fitted with Single Flushed or Double Flushed Mechanical Seals. Prior to removal of rotorcase (3.01) for CP10, CP20 and CP30, remove seal housing screws (7.10) and separate housing (7.06) from rotorcase (3.01) noting it is located on dowels (7.09). -

Page 38: Cp10, Cp20 And Cp30 Gearbox Disassembly

Double Flushed Mechanical Seal as shown in Fig 20 and Fig 21. CP10 Pump - see section 5.2.5 for removal and 5.2.6 for replacement. CP20 and CP30 Pumps – see section 5.2.7 for removal and 5.2.8 for replacement. Fig 20 Double Flushed Mechanical Seal –... - Page 39 4.1.3 CP10, CP20 and CP30 Gearbox Disassembly (After completing 4.1.1 or 4.1.2). Fig 22 CP10 Component Parts Page 39...

- Page 40 Fig 23 CP20 and CP30 Component Parts Page 40...

- Page 41 Before starting disassembly of the gearbox remove product seals; refer to section 5.0 for Mechanical Seals, or section 6.0 for O-Ring seals. The following procedure describes complete disassembly of the gearbox. Refer to Fig 22 for CP10; Refer to Fig 33 for CP20 and CP30. Remove guard (5.06).

-

Page 42: Cp10, Cp20 And Cp30 Gearbox Assembly

Remove shafts (5.01 and 5.02) from bearing housing (4.01). Shafts (5.01 and 5.02) will be complete with bearings (5.05) and shims (5.04), keep shims in sets and identify position. Remove oil seals (5.03) from bearing housing (4.01). Remove bearing cups (5.05) and any associated shims (5.04) from bearing housing (4.01), keep bearing cups (5.05) and shims (5.04) in sets and identify position. - Page 43 - Using a depth micrometer or similar device measure any difference (X) in rotor front face alignment, see Fig 25. If a difference is found move shims (5.04) of thickness equal to the difference (X) from beneath the forward rotor's bearing retainer (5.06) and reposition under the front bearing (5.05) cup.

- Page 44 - CP10 Pumps Only Timing marks and gear marks ‘D’ and ‘L’ on gears (5.09) should be visible when viewed on the drive end of the drive shaft. - CP20 and CP30 Pumps Only Timing marks and gear marks ‘D’ and ‘L’ on gears (5.09) should be visible when viewed on the drive end of the shafts (5.01 and 5.02), and the tapered shoulder on the gear (5.09) should face the bearings (5.05).

- Page 45 - Install rotors (2.01) and rotor retainers (2.02) - Check mesh clearance against the Clearance Chart (refer to section 8.1). - To adjust mesh clearance shims (5.08) will need to be inserted between the spacer (5.16) and the gear (5.09). As a guide for a mesh clearance change of one unit (say 0.1mm or 0.004"), shims (5.08) of four units’...

-

Page 46: Cp10, Cp20 And Cp30 Rotorcase, Rotor And Front Cover Assembly

- Install inner retaining rings (6.01), bearing (6.02) outers, outer retaining rings (6.01), lipseal (6.03), blanking cap (6.04), filler plug (6.10), sight glass (6.07) and drain plug (6.09) to cover (6.00). - Install cover (6.00) to bearing housing (4.01) with gasket (6.05), locating on dowels (6.06), and secure with screws (6.11) tightened to correct torque, refer to section 8.2. - Page 47 Install rotorcase (3.01) securing in position with temporary spacers (CP10) or socket cap head screws, washers and nuts (CP20 and CP30) as before. Install rotors (2.01) with o-rings (2.03 and 2.04) and retainers (2.02) tightened to correct torque, refer to section 8.2, using socket tool (not shown).

-

Page 48: Cp40 Pumps - Disassembly And Assembly

CP40 Pumps - Disassembly and Assembly 4.2.1 CP40 Front Cover and Rotor Removal Fig 28 Front Cover and Rotorcase Removal for CP40 Page 48... - Page 49 Follow recommended shutdown procedure - refer to section 3.5. Refer to Fig 28. Gradually loosen front cover retaining dome nuts (1.03). Care should be taken as there may still be residual product and pressure in the pump head and as the dome nuts are loosened, this will vent to atmosphere. Remove dome nuts (1.03).

-

Page 50: Cp40 Rotorcase Removal

4.2.2 CP40 Rotorcase Removal Note: Ensure all pipe work is disconnected before commencing rotorcase WARNING removal. 4.2.2.1 CP40 Rotorcase Removal for Pumps fitted with Single Un-flushed Mechanical Seals and O-Ring Seals (After completing 4.2.1) Remove dome nuts (4.08) fastening rotorcase (3.01) to gearbox (4.01). Single Un-flushed Mechanical Seal for CP40 - see Fig 29 and sections 5.2.1 for removal and section 5.2.2 for replacement. - Page 51 Single O-Ring Seal as shown in Fig 30 – see section 6.2.1 for removal and replacement. Remove O-Ring seal (7.04) from rotorcase (3.01). Fig 30 O-Ring Seal Slide rotorcase (3.01) from gearbox (4.01) noting it is located on dowels (4.03), keep arch shims (4.05) in appropriate sets if they are to be reused. Page 51...

-

Page 52: Cp40 Rotorcase Removal For Pumps Fitted With Single Flushed Or Double Flushed Mechanical Seals

4.2.2.2 CP40 Rotorcase Removal for Pumps Fitted with Single Flushed or Double Flushed Mechanical Seals. Prior to removal of rotorcase (3.01) remove seal housing screws (7.10) and separate housing (7.06) from rotorcase (3.01) noting it is located on dowels (7.09). Slide rotorcase from bearing housing (4.01), noting it is located on dowels (4.03), keep arch shims (4.05) in appropriate sets if they are to be re-used Single Flushed Mechanical Seal as shown in Fig 31 and see sections 5.2.3 for... - Page 53 4.2.3 CP40 Gearbox Disassembly (After completing 4.3.1 and 4.3.2) - see Fig 33 Fig 33 CP40 Components Page 53...

- Page 54 Before proceeding with disassembly of the gearbox remove product seals; refer to sections 5.0 for Mechanical Seals or section 6.0 for O-Ring seals. The following procedure describes complete disassembly of the gearbox, refer to Fig 33. Remove drive key (6.12), oil drain (6.09) and breather plugs (6.10), drain oil into suitable container and retain if later inspection is required.

-

Page 55: Cp40 Gearbox Assembly

4.2.4 CP40 Gearbox Assembly Refer to Fig 33. Install bearing cones (5.05) to shafts (5.01 and 5.02) ensuring they locate against the shaft shoulder. The cones are installed as shown in Fig 34. Fig 34 Installation of Bearing cones onto shafts Install spacers (5.17), tab washers (5.20) and lock nuts (5.14) to shafts (5.01 and 5.02) tightening to correct torque, refer to section 8.2. - Page 56 Using a depth micrometer or similar device measure any difference (X) in rotor front face alignment, see Fig 35. If a difference is found move shims (5.04) of thickness equal to the difference (X) from beneath the lower rotors bearing retainer (5.06) and reposition under the front bearing (5.05) cup.

- Page 57 Lubricate retainer (5.16) with oil and mount to timing gear (5.09). Do not tighten. Fig 36 Missing spline alignment. Install rotors (2.01) and rotor retainers (2.02) to shafts (5.01 and 5.02). Check rotor mesh clearance against Clearance Chart - refer to section 8.1.

-

Page 58: Cp40 Rotorcase, Rotor And Front Cover Assembly

4.2.5 CP40 Rotorcase, Rotor and Front Cover Assembly Fit shaft slingers and guard (if fitted, depending upon seal configuration). Install rotorcase (3.01) to gearbox (4.01) locating on dowels (4.03) and secure with nuts (4.08) tightened to correct torque, refer to section 8.2. -

Page 59: Cp50 Pumps - Disassembly And Assembly

CP50 Pumps - Disassembly and Assembly 4.3.1 CP50 Front Cover and Rotor Removal Fig 39 – Front Cover and Rotor Components Page 59... - Page 60 Follow recommended shutdown procedure - refer to section 3.5. Refer to Fig 39. Gradually loosen front cover retaining dome nuts (1.03). Care should be taken as there may still be residual product and pressure in the pump head and as the dome nuts are loosened, this will vent to atmosphere. Remove dome nuts (1.03).

-

Page 61: Cp50 Rotorcase Removal

4.3.2 CP50 Rotorcase Removal Note: Ensure all pipe work is disconnected before commencing rotorcase WARNING removal. 4.3.2.1 CP50 Rotorcase Removal for Pumps fitted with Single Un-flushed Mechanical Seals and O-Ring Seals (After completing 4.3.1) Remove dome nuts (4.08). Slide rotorcase (3.01) from gearbox (4.01), noting it is located on dowels (4.03). - Page 62 Single O-Ring Seal for CP50 see Fig 41 and see section 6.3.1 for removal and replacement. Fig 41 Single O-Ring Seal CP50 Remove O-Ring seal (7.04) from rotorcase (3.01). Slide rotorcase (3.01) from gearbox (4.01) noting it is located on dowels (4.03).

-

Page 63: Cp50 Rotorcase Removal For Pumps Fitted With Single Flushed And Double Flushed Mechanical Seals

4.3.2.2 CP50 Rotorcase Removal for Pumps fitted with Single Flushed and Double Flushed Mechanical Seals Refer to Fig 42 for Single flushed mechanical seal for CP50. Refer to Fig 43 for Double flushed mechanical seal for CP50. Prior to removal of rotorcase (3.01), remove seal housing nuts (7.18) from studs (7.17) and separate housing (7.06) from rotorcase (3.01). -

Page 64: Cp50 Gearbox Disassembly

4.3.3 CP50 Gearbox Disassembly (After completing 4.3.1 and 4.3.2) Fig 44 CP50 Components Page 64... - Page 65 Before proceeding with disassembly of the gearbox remove product seals; refer to section 5.3 for Mechanical Seals and 6.3 for O-Ring Seals. The following procedure describes complete disassembly of the gearbox, refer to Fig 44. Remove guard (4.06) and shaft slingers (7.03) if fitted. Remove drive key (6.12).

-

Page 66: Cp50 Gearbox Assembly

4.3.4 CP50 Gearbox Assembly The following procedure describes the assembly of the gearbox, refer to Fig - Install bearings (5.05) complete with spacers (5.05) to shafts (5.01 and 5.02) ensuring correct positioning of all components as either removed in 4.3.3. Above or supplied as new replacement set, see Fig 45. - Page 67 - Install tab washers (5.07) and lock nuts (5.19) tightening to correct torque, refer to section 8.2. Secure tab washers. Note: Ensure that the cups of the rear most bearings (5.05) are in position on inner races before proceeding. - Install bearings (6.02) complete with spacers (6.02) to shafts (5.01 and 5.02) ensuring correct positioning of all components as either removed in 4.3.3 above or as supplied as new replacement set, see Fig 46.

- Page 68 - Rotate shafts (5.01 and 5.02) such that keyways for rotor keys are vertically upwards. - Lubricate retainer (5.16) with oil and install to timing gear (5.09). Do not tighten. Note: Pins (5.23) should not be installed at this stage. - Clamp gear (5.09) to shaft (5.02) using tool (supplied) and associated stud and nut, ensuring that two screws in retainer (5.16) are visible through holes in tool.

-

Page 69: Cp50 Rotorcase, Rotor And Front Cover Assembly

4.3.5 CP50 Rotorcase, Rotor and Front Cover Assembly Referring to Fig 33 and Fig 44. Install spacers’ (5.24) and product seal sleeves (7.15) to shafts (5.01 and 5.02). Note: Pins (5.23) should not be installed at this stage. Install rotorcase (3.01) to gearbox (4.01) locating on dowels (4.03) and secure with dome nuts (4.08) tightened to correct torque, refer to section 8.2. - Page 70 Note: If it is found that the measured front clearance is greater than that shown in the Clearance Chart, refer to section 8.1, then new spacers (5.24) will need to be obtained and machined to the correct lengths to achieve correct front clearance. Be sure faces of spacers’...

-

Page 71: Classic+ Mechanical Seal Removal & Replacement

Classic+ Mechanical Seal Removal & Replacement. General Procedures for Installing Mechanical Seals. "Quick summary" of mechanical seal installation Mechanical seals are precision-engineered assemblies incorporating finely lapped seal faces and seats. They must be handled with care and will not give optimum performance unless installed carefully and according to instructions. -

Page 72: Cp10, Cp20, Cp30 And Cp40 Mechanical Seals

CP10, CP20, CP30 and CP40 Mechanical Seals 5.2.1 CP10, CP20, CP30 and CP40 Single Mechanical Seal Removal Fig 49 Single Un-flushed Mechanical Seal Remove front cover (1.01), rotor retainers (2.02), o-rings (2.04) and rotorcase (3.01), refer to section 4.1.2.1 (CP10, CP20 and CP30) or section 4.2.2.1 (CP40). -

Page 73: Cp10, Cp20, Cp30 And Cp40 Single Mechanical Seal Replacement

5.2.2 CP10, CP20, CP30 and CP40 Single Mechanical Seal Replacement Refer to Fig 50 for CP10, CP20, CP30 and CP40 Install o-rings (7.01) to stationary seal seat (7.04). Install stationary seal seats (7.04) to rotorcase (3.01) ensuring correct location of o-rings (7.01). Note: On CP10 models the stationary seal seat (7.04) has a location recess which fits over the anti-rotation washer (7.13). -

Page 74: Cp10, Cp20, Cp30 And Cp40 Single Flushed Mechanical Seal Removal

5.2.3 CP10, CP20, CP30 and CP40 Single Flushed Mechanical Seal Removal Refer to Fig 51 for CP10, CP20, CP30 and CP40 Fig 51 Single Flushed Mechanical Seal Remove front cover (1.01), rotor retainers’ (2.02), o-rings (2.03), rotors (2.01), o-rings (2.04) and rotorcase (3.01), refer to sections 4.1.2.1 and 4.1.2 (CP10, CP20 or CP30) or 4.2.2.1 (CP40). -

Page 75: Cp10, Cp20, Cp30 And Cp40 Single Flushed Mechanical Seal Replacement

5.2.4 CP10, CP20, CP30 and CP40 Single Flushed Mechanical Seal Replacement Refer to Fig 51 for CP10, CP20, CP30 and CP40 Install o-rings (7.01) to stationary seal seats (7.04). Install stationary seal seats (7.04) to rotorcase (3.01) ensuring correct location of o-rings (7.01). Note: On CP10 models the stationary seal seat (7.04) has a location recess which fits over the anti-rotation washer (7.13). -

Page 76: Cp10 Double Flushed Mechanical Seal Removal

5.2.5 CP10 Double Flushed Mechanical Seal Removal Refer to Fig 52. Fig 52 Double Flushed Mechanical Seal Remove front cover (1.01), rotor retainers’ (2.02), o-rings (2.03), rotors (2.01), o-rings (2.04) and rotorcase (3.01), refer to sections 4.1.1 and 4.1.2. Loosen but do not remove screws (7.11), which secure rotary seal cartridge assemblies (7.11) to shafts (5.01 and 5.02). -

Page 77: Cp10 Double Flushed Mechanical Seal Replacement

5.2.6 CP10 Double Flushed Mechanical Seal Replacement Refer to Fig 52 Install o-rings (7.01) to stationary seal seats (7.04 and 7.12). Install stationary seal seats (7.04) to rotorcase (3.01) ensuring correct location of o-rings (7.01). Note: The stationary seal seat (7.04) has a location recess which fits over the WARNING anti-rotation washer (7.13). -

Page 78: Cp20, Cp30 And Cp40 Double Flushed Mechanical Seal Removal

5.2.7 CP20, CP30 and CP40 Double Flushed Mechanical Seal Removal Fig 53 Double Flushed Mechanical Seal Remove front cover (1.01), rotor retainers’ (2.02), o-rings (2.03), rotors (2.01), o-rings (2.04) and rotorcase (3.01), refer to sections 4.1.1 and 4.1.2 (CP20/CP30) or sections 4.2.1 and 4.2.2 (CP40). Loosen but do not remove screws in rotary seal cartridge assemblies (7.11), which secure rotary seal cartridge assemblies (7.11) to shafts (5.01 and 5.02). -

Page 79: Cp20, Cp30 And Cp40 Double Flushed Mechanical Seal Replacement

5.2.8 CP20, CP30 and CP40 Double Flushed Mechanical Seal Replacement Refer to Fig 53. Install o-rings (7.01) to stationary seal seats (7.04). Install stationary seal seats (7.04) to rotorcase (3.01) ensuring correct location of o-rings (7.01). Note: The stationary seal seats (7.04) have a triangular shape which must WARNING locate fully into the rotorcase (3.01) bore. -

Page 80: Cp50 Mechanical Seals

CP50 Mechanical Seals 5.3.1 CP50 Single Mechanical Seal Removal Fig 54 Single Un-Flushed Mechanical Seal CP50 Remove front cover (1.01), rotor caps (2.02), o-rings (2.03), retainers’ (2.05), rotors (41), o-rings (2.04) and rotorcase (3.01), refer to sections 4.3.1 and 4.3.2. Remove rotary seal cartridge assemblies (7.11) with o-ring (7.01) from shafts (5.01 and 5.02) by simply sliding off. -

Page 81: Cp50 Single Flushed Mechanical Seal Removal

5.3.3 CP50 Single Flushed Mechanical Seal Removal Refer to Fig 55. Fig 55 Single Flushed Mechanical Seal CP50 Remove front cover (1.01), rotor caps (2.02), o-rings (2.03), retainers (2.05), rotors (2.01), o-rings (2.04) and rotorcase (3.01) refer to sections 4.3.1 and 4.3.2. Remove rotary seal cartridge assemblies (7.05) with o-ring (7.01) from shafts (5.01 and 5.02) by simply sliding off. -

Page 82: Cp50 Double Flushed Mechanical Seal Removal

Install lipseals (7.08) and o-rings (7.07) to housings (7.06). Install housings (7.06) to shafts (5.01 and 5.02). Install rotary seal cartridge assemblies (7.05) with o-ring (7.01) to shafts (5.01 and 5.02) ensuring engagement of drive slots with pins (5.23) in shafts (5.01 and 5.02). -

Page 83: Cp50 Double Flushed Mechanical Seal Replacement

5.3.6 CP50 Double Flushed Mechanical Seal Replacement Refer to Fig 56. Install o-rings (7.02) to stationary seal seats (7.04). Install stationary seal seats (7.04) to rotorcase (3.01) ensuring correct location of o-rings (7.02). Note: The stationary seal seat (7.04) has a triangular shape, which must WARNING locate fully into the rotorcase (3.01), bore. -

Page 84: Classic+ Single O-Ring Seals

Classic+ Single O-Ring Seals General Procedures for Fitting Single O-Ring Seals "Quick Summary" of O-Ring seal installation. O-Ring seals are a simple but effective means of shaft sealing. They will provide optimum performance only if installed carefully in accordance to the following instructions below and sections 6.2 and 6.3. -

Page 85: Oring Seals For Cp10, Cp20, Cp30 And Cp40 Pumps

Oring Seals for CP10, CP20, CP30 and CP40 Pumps 6.2.1 CP10, CP20, CP30 and CP40 Oring Seal Assembly and Removal Fig 57 O-Ring Seal for an CP10, CP20, CP30 and CP40. - Before assembly or disassembly of the seals, ensure pump is fully shutdown, refer to section 3.5. -

Page 86: O-Ring Seal For Cp50 Pump

O-Ring Seal for CP50 Pump 6.3.1 CP50 O-Ring Seal Assembly and Removal Fig 58 CP50 O-Ring Seal. - Before assembly or disassembly of the seals, ensure pump is fully shutdown, refer to section 3.5. - Install o-ring (7.04) into the rotorcase (3.01). - Install rotary seal sleeves (7.15) onto shafts (5.01 and 5.02), ensuring engagement of slots in rotary seal sleeves (7.15) and drives pins (5.230 - Install o-ring (2.04 onto shaft (5.01 and 5.02). -

Page 87: Classic+ Packed Gland Seals

Classic+ Packed Gland Seals 6.4.1 General Procedures For Fitting Packed Gland Seals "Quick Summary" of packed gland seal installation. Packed gland seals are a simple but effective means of shaft sealing. They will provide optimum performance only if installed carefully and according to instructions. -

Page 88: Packed Gland Seals - Cp10, Cp20, Cp30 And Cp40 Series Pumps

Packed Gland Seals - CP10, CP20, CP30 and CP40 Series Pumps 6.5.1 Packed Gland Seal Removal See Fig 71 Fig 71 Remove front cover (38), rotor retainers (35), o-rings (34), rotors (41), o- rings (25), dome nuts (87) and rotorcase (40) refer to sections 4.1.1 and 4.1.2 (CP10/CP20/CP30) or 4.2.1 and 4.2.2 (CP40). -

Page 89: Packed Gland Seal Replacement

6.5.2 Packed Gland Seal Replacement See Fig 71 Install slingers (62) and sleeves (66) to shafts (9 and 10). Install spacers (63), if previously removed. Note: If gland tubes (64) have been removed from rotorcase (40) they should be installed at this point. Apply liquid retainer (Loctite 640 or similar) to one end of tubes (64) on outside diameters to a width of approximately 5mm (3/16"), and similarly apply to inside diameters of rotorcase (40) bores. -

Page 90: Flushed Packed Gland Seal Replacement

Remove front cover (38), rotor retainers (35), o-rings (34), rotors (41), o- rings (25), dome nuts (87) and rotorcase (40), (which is located on dowels (57)), refer to sections 4.1.1 and 4.1.2, (CP10/CP20/CP30) or 4.2.1 and 4.2.2, (CP40). Remove nuts (81), which secure followers (67) to rotorcase (40). Remove followers (67). -

Page 91: Packed Gland Seals - Cp50 Series Pumps

Packed Gland Seals - CP50 Series Pumps. 6.6.1 Packed Gland Seal Removal See Fig 73. Fig 73 Remove front cover (38), rotor caps (35), o-rings (34), retainers (53), rotors (41), o-rings (25), dome nuts (87) and rotorcase (40), refer to sections 4.3.1 and 4.3.2. -

Page 92: Flushed Packed Gland Seal Removal

6.6.3 Flushed Packed Gland Seal Removal See Fig 74. Fig 74 Remove front cover (38), rotor caps (35), o-rings (34), rotors (41), o-rings (25), dome nuts (87) and rotorcase (40) (which is located on dowels (57)) - refer to sections 4.3.1 and 4.3.2. Remove nuts (81), which secure followers (67) to rotorcase (40). -

Page 93: Flushed Packed Gland Seal Replacement

6.6.4 Flushed Packed Gland Seal Replacement See Fig 74 Install slingers (62) and sleeves (66) to shafts (9 and 10) ensuring engagement of drive slots over pins (76) in shafts (9 and 10). Install packing rings (65) and lantern rings (88) to gland tube (94) bores, ensuring correct location of lantern rings such that they align with the liquid supply connection holes in tubes (94). -

Page 94: Seal Conversion To Flushed Packed Gland (With Shaft Sleeve)

- Follow instructions for packed gland replacement, refer to section 6.3.2. 6.6.6 Seal Conversion to Flushed Packed Gland (With Shaft Sleeve) See Fig 75 Remove front cover (38), rotor caps (35), o-rings (34), retainers (53), rotors (41), o-rings (25), dome nuts (87) and rotorcase (40) (which is located on dowels (57)), refer to sections 4.3.1 and 4.3.2. -

Page 95: Flushed Product Seals Auxiliary Services

Flushed Product Seals Auxiliary Services Terminology. a) "Quench" To provide a liquid barrier that is not induced to flow through the seal area by any external means. b) "Flush" - To provide a liquid barrier that is induced to flow through the seal area by an external means. -

Page 96: Double Mechanical Seal (For High Pressure Flush)

Double Mechanical Seal (for High Pressure Flush) - See Fig 18 (CP10) and Fig 28 (CP20, CP30, CP40) and Fig 51 (CP50) Refer to section 4.3.4. This seal arrangement requires a supply of media to be circulated between the inboard and outboard mechanical seals. The flush media must be supplied at a flow rate of 4.5 Litres per minute per shaft seal assembly. -

Page 97: Specifications

Specifications Clearance Chart Page 97... - Page 98 Millimetres x 0.01 Inches x 0.001 Page 98...

-

Page 99: Fasteners & Torque Settings

Fasteners & Torque Settings. Page 99... -

Page 100: Lubricants

Lubricants. Gearbox oil recommended for use with Classic+ is an ‘EP (Extreme Pressure) grade gear lube’ for the following temperature ranges. EP150 -2 – 0° C (0 – 32° F) EP220 0 – 30° C (32 - 85° F) EP320 30°... -

Page 101: Foundation Dimensions And Weights

Foundation Dimensions and Weights. Page 101... - Page 102 Millimetres MODEL Weight (mm) (mm) (Kg) CP10/0005 18 j6 47.5 116.4 162.5 CP10/0008 18 j6 54.5 116.4 162.5 CP10/0011 18 j6 65.5 116.4 162.5 CP20/0020 24 j6 88.75 160.5 207.5 235.5 CP20/0031 24 j6 88.75 160.5 207.5 235.5 CP30/0069 133.5 38 k6 69.5 111.3 60.6...

-

Page 103: Rectangular Inlet

Rectangular Inlet Millimeters Inlet Area Equivalent Bore Model (mm²) Diameter (mm) CP10/0005/12 CP10/0008/08 CP10/0011/05 36.0 40.0 85.0 60.0 18.0 20.0 51.0 63.5 1860 48.7 CP20/0020/12 25.0 28.0 105.0 80.0 12.5 14.0 60.0 36.0 2209 53.0 CP20/0031/07 45.0 48.0 105.0 80.0 22.5 24.0 60.0... -

Page 104: Trouble Shooting

Trouble Shooting. CAUSES ACTION INCORRECT DIRECTION OF ROTATION REVERSE MOTOR PUMP NOT PRIMED EXPEL GAS FROM SUCTION LINE/PUMP CHAMBER & PRIME INSUFFICIENT NPSH AVAILABLE INCREASE LINE DIA. & STATIC SUCTION HEAD. SIMPLIFY SUCTION LINE & REDUCE LENGTH. REDUCE PUMP SPEED AND PRODUCT TEMPERATURE. PRODUCT VAPOURIZING IN SUCTION LINE AIR ENTERING SUCTION LINE REMAKE PIPING JOINT... -

Page 105: Typical Noise Emission Data - Cp10, Cp20 And Cp30 Pumps

Typical Noise Emission Data - CP10, CP20 and CP30 Pumps. Page 105... -

Page 106: Typical Noise Emission Data - Cp40 And Cp50 Pumps

Typical Noise Emission Data – CP40 and CP50 Pumps. Page 106... -

Page 107: Service History

8.10 Service History. Pump Model: Pump Serial No: Date Comments Page 107... -

Page 108: Tool List

8.11 Tool List. Listed below are tools required for the maintenance for the Classic+. TYPE SIZE OR RANGE CP10 CP20 CP30 CP40 CP50 Combination Spanner 8 mm ● Combination Spanner 10 mm ● Combination Spanner 13 mm ● ● ● Combination Spanner 17 mm ●... - Page 109 TYPE SIZE OR RANGE CP10 CP20 CP30 CP40 CP50 Adjustable to Min. 39 NM Torque Wrench ● (28.76 ft-lb.) Adjustable to Min. 107 NM Torque Wrench ● (78.91 ft-lb.) Adjustable to Min. 135 NM Torque Wrench ● (99.56 ft-lb.) Adjustable to Min. 130 NM Torque Wrench ●...

-

Page 110: Notes

Notes. The information contained in this document is correct at time of print, but may be subject to change without prior notice. Page 110... - Page 111 Wright Flow Technologies Ltd. Edison Road, Eastbourne, East Sussex, BN23 6PT United Kingdom Phone: +44 1323 509211 Fax: +44 1323 507306 E-mail: wright.eu@idexcorp.com Wright Flow Technologies, Inc. 406 State Street Cedar Falls, Iowa 50613 U.S.A. Phone: (319) 268-8013 Fax: (803) 216-7686 E-mail: wright.usa@idexcorp.com...

Need help?

Do you have a question about the Classic+ and is the answer not in the manual?

Questions and answers