Summary of Contents for Palms 840

- Page 1 USER MANUAL FOREST CRANE PALMS 840 Palmse Mehaanikakoda, Võsupere küla, Vihula vald, Lääne-Virumaa 45202, Estonia. tel. +3723255375 fax +3723255378 e-mail: info@palms.eu http://www.palms.eu...

-

Page 2: Table Of Contents

TABLE OF CONTENTS GENERAL ......................... 1 SAFETY ........................2 TECHNICAL DATA ....................5 ASSEMBLY AND MOUNTING ................. 8 HYDRAULIC SYSTEM ................... 12 OPERATING INSTRUCTIONS ................22 DETACHING FOREST CRANE ................24 STORAGE INSTRUCTIONS ................... 24 MAINTENANCE ...................... 25 10. TROUBLESHOOTING .................... 29 11. -

Page 3: General

FOREST CRANE PALMS 840 GENERAL This manual gives you a detailed overview about forest crane Palms 840. Read the manual carefully before you start using this machine. The manual contains essential directions for efficient and safe use of this equipment. These instructions should always be followed. -

Page 4: Safety

to install a loose crane on equipment other than a Palms trailer such way that the vehicle has the necessary capacity to cope with the lifting and slewing torques that the crane is designed to handle. - Page 5 FOREST CRANE PALMS 840 2.2 Safety distances General safety distance for working with forest crane is 20 metres! Follow special safety distance when working close to live electrical conductors: Rated voltage, kV Safety area, m Up to 0,5 Up to 20 35 –...

- Page 6 FOREST CRANE PALMS 840 2.3 Hydraulic system Hydraulic system must be serviced by qualified and experienced hydraulics mechanic only. Continually inspect the condition of hydraulic system. Repair all safety en-dangering defects immediately. Before hydraulics maintenance work make sure that the system is not under pressure.

-

Page 7: Technical Data

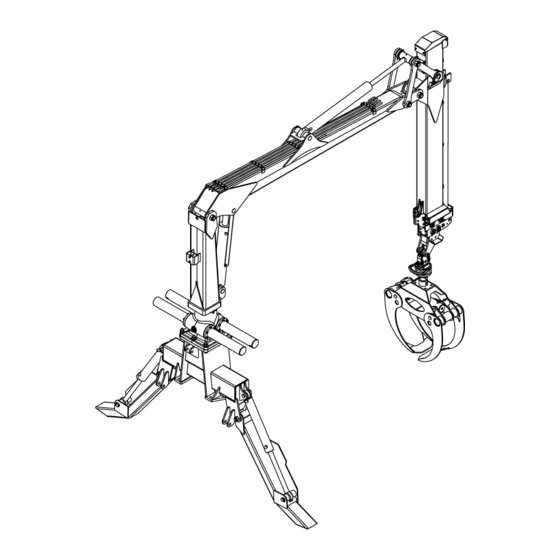

FOREST CRANE PALMS 840 TECHNICAL DATA 3.1 Dimensions of the forest crane Figure 1. Palms 840 dimensions (mm) Figure 2. Grapple 0,215 Pro dimensions (mm) V 1.03 EN 2012 Palmse Mehaanikakoda LLC... - Page 8 FOREST CRANE PALMS 840 3.2 Lifting reach Figure 3. Lifting reach of Palms 840 forest crane V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 9 Table 2. Technical data table of Palms 840 8,4 m PALMS 840 1460kg 1100kg 880kg 470kg Figure 4. Palms 840 lifting power on different distances Manufacturer reserves the right to change specifications without prior notice. V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

-

Page 10: Assembly And Mounting

Retighten bolts after the test run and after first 8 hours of use! Check after 40 working hours, tighten if needed. Visual check is required prior every working session. Figure 5. Connection junctions on Palms 840 support legs V 1.03 EN 2012 Palmse Mehaanikakoda LLC... - Page 11 Use the mounting plate (fig. 6) then mounting the loader to the tractor’s frame or trailer different than Palms. Use mounting plate with thickness not less than 30 mm. Make sure that there will be enough space at mounting point for service access.

- Page 12 FOREST CRANE PALMS 840 4.3 Mounting forest crane to the tractor with 3-point linkage system Before mounting crane to the 3-point linkage (pos.1, fig. 6.1) make sure that: tractor is heavy enough and will not keel over tractor is placed firmly on even ground ...

- Page 13 FOREST CRANE PALMS 840 4.4 Mounting control valve The valve must be installed in the way that levers cannot be used inadvertently! Install the valve to desired location using the included bracket. Leave enough space for hoses to avoid risk of abrasion or clamping while working with forest crane.

-

Page 14: Hydraulic System

FOREST CRANE PALMS 840 HYDRAULIC SYSTEM 5.1 Connection Before connecting forest crane to the tractor’s hydraulic system, make sure, that hydraulic oils are compatible. Forest crane has been tested and should use Addinol HVLP 32 hydraulic oil or other compatible oil that meets DIN 51524-3 requirements. - Page 15 FOREST CRANE PALMS 840 Do not connect pilot operated color TP line in to the main return line! If crane is not used, leave pilot operated TP return line open. Do not close TP return line with regular plug fitting. Pressure can build up and damage valves.

- Page 16 FOREST CRANE PALMS 840 5.2 Parker hydraulic diagrams and control functions Figure 8. Hydraulic diagram for Parker L90LS (A23 and A24) full electric control valve V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 17 FOREST CRANE PALMS 840 Figure 9. Electrical scheme for full electric control valve (A21 and A23) V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 18 FOREST CRANE PALMS 840 Figure 10. Electrical scheme for full electric control valve (A22 and A24) V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 19 FOREST CRANE PALMS 840 Figure 11. Error codes and messages for full electric control valve (A21 and A23) V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 20 FOREST CRANE PALMS 840 Figure 12. Error codes, messages and actions for IQAN – LC5 module V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 21 FOREST CRANE PALMS 840 Figure 13. Hydraulic diagram for Parker F130 CF (A13) pilot operated control valve V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 22 FOREST CRANE PALMS 840 Figure 14. Hydraulic diagram for Nordhydraulic NH 4/8 XYZ (A7) control valve V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 23 FOREST CRANE PALMS 840 Figure 15. Hydraulic diagram for Nordhydraulic NH 6/8 XY (A3) control valve V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

-

Page 24: Operating Instructions

FOREST CRANE PALMS 840 OPERATING INSTRUCTIONS 6.1 Testing Ensure that the control valve levers are in the middle position. Swich on the pump and let oil flow through the valve for a while. Lower the support legs. Ensure that there are no people or obstacles in the operating area. The... - Page 25 FOREST CRANE PALMS 840 Working on inclined surface, do not operate with the full lifting torque and be extremely careful. Loading uphill note, that turning crane with too much load might cause the oil pressure in slewing device cylinders to reach critical point, where shock valve has to intervene.

-

Page 26: Detaching Forest Crane

FOREST CRANE PALMS 840 DETACHING FOREST CRANE Choose sufficiently hard and even level ground for detaching forest crane. Ensure, that no unauthorized persons are around crane during detaching and storing process. When storing control valve, make sure it is out of the reach of children. -

Page 27: Maintenance

FOREST CRANE PALMS 840 MAINTENANCE 9.1 Maintenance table ACTION OBJECT Maintenance interval, working hours 8 h or after working shift 40 h or after working week 320 h Check cylinders and Check pins and lockings, 1. Crane Check the condition of primary structures... - Page 28 FOREST CRANE PALMS 840 9.3 Changing oil in slewing device There is Addinol SAE 80W90, API GL4, GL5 oil in slewing device by manufacturer. 1. Change oil after 960 working hours or once a year. 2. Ensure that the slewing device is in horizontal position, as shown on fig. 17.

- Page 29 Using the appropriate lubricants like HP 2 Longlife Grease, Beacon EP2, Multipurpose GR Moly, Mobilux EP2, Mobil Grease MP Special, Energrease LS-EP2 or similar. Right lubricants guarantee troublefree operation of the machine. Figure 18. Greasing points of Palms 840 V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 30 9. Cylinder eyelet, B Greasing 2% molybdensulfide Table 5. Oil and lubricant grade table of Palms 840 9.5 Changing the hydraulic oil Change hydraulic oil at least once in two years. Forest crane hydraulic system has been filled with Addinol HVLP ISO VG. 32 (DIN 51524/3) hydraulic oil at the factory. Oil temperature should not exceed 75°C in summer, winter oil can be used all year round...

-

Page 31: Troubleshooting

FOREST CRANE PALMS 840 10. TROUBLESHOOTING TROUBLE POSSIBLE CAUSE REMEDY CRANE’S WORKING PUMP RUNNING TOO SLOWLY CHECK PUMP ROTATING SPEED MOVEMENTS ARE SLOW NOT ENOUGH OIL ADD OIL (AIR-BLEEDING) FAULTY PUMP CHANGE OR GET THE PUMP FIXED LEAKS OR OBSTRUCTIONS IN OIL LINES... -

Page 32: Spare Parts

FOREST CRANE PALMS 840 11. SPARE PARTS 11.1 Main parts Figure 19. Spare part positions of Palms 840 forest crane V 1.03 EN 2012 Palmse Mehaanikakoda LLC... - Page 33 FOREST CRANE PALMS 840 Pos Code Part name 840100001 Housing of FD-legs 840100002 FD-leg outrigger left 840100003 FD-leg outrigger right 840100004 Column 840100005 Main boom 840100006 Ext.boom 840100007 Puller 1 840100008 Puller 2 840100009 Puller 3 840100010 Puller 4 840100011 Cylinder cover...

- Page 34 FOREST CRANE PALMS 840 Pos Code Part name 840100038 Grapple shaft 25x93 840100039 Shaft of support leg cylinder, lower 840100040 Shaft of support leg cylinder, upper 840100041 Shaft of support leg joint 840100042 Hanger 840100043 Rotator 840100044 Grapple 22 840100045 Nut M100x2...

- Page 35 840100074 Washer M12 DIN 125 840100075 Washer M24 DIN 125 840100076 Spring washer M8 DIN 127 B 840100077 Spring washer M12 DIN 127 B Table 7. Spare part list of Palms 840 forest crane V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 36 FOREST CRANE PALMS 840 11.2 Extension boom spare parts Figure 20. Spare part positions of Palms 840 forest crane extension boom V 1.03 EN 2012 Palmse Mehaanikakoda LLC...

- Page 37 FOREST CRANE PALMS 840 Pos Code Part name 840100101 Extension boom 840100102 A-telescope 840100103 B-telescope 840100104 Cover A 840100105 Cover B 840100106 Cylinder of telescope 840100107 Chain roller A 840100108 Chain roller B 840100109 Fitting block 840100110 Ext.boom slide lower 840100111 A-telesc.

- Page 38 FOREST CRANE PALMS 840 Pos Code Part name 840100137 Bearing 62208 2RS 840100138 Bronze slide bearing 50-45x50 WB800 840100139 Bronze slide bearing 50-36x40 WB800 840100140 Chain A 840100141 Chain B 840100142 LH10-44 Clevis pin 840100143 Circlip ø80x2.5 DIN 472 840100144...

-

Page 39: Warranty

FOREST CRANE PALMS 840 12. WARRANTY The machine shall not be taken into use before the operating manual is thoroughly read and understood. Duration of warranty: Parts manufactured by Palmse Mehaanikakoda LLC, warranty is three years. Hydraulic components, sliding bearings, cylinders, rotators, pumps, valve blocks and all other parts and equipment not manufactured by Palmse Mehaanikakoda LLC, manufacturer warranty applies.

Need help?

Do you have a question about the 840 and is the answer not in the manual?

Questions and answers