Subscribe to Our Youtube Channel

Summary of Contents for Buchi C-605

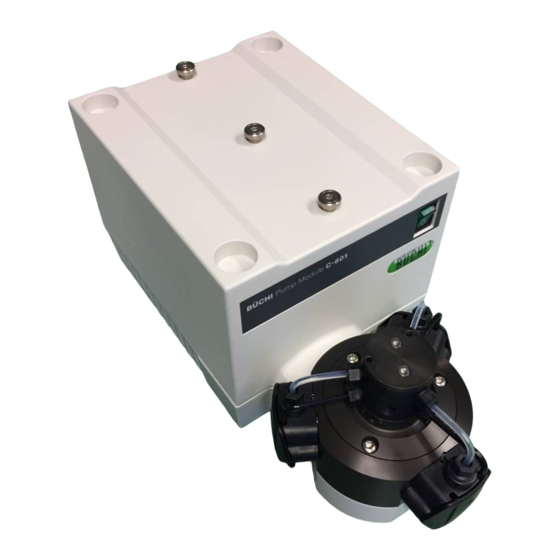

- Page 1 Operation Manual Pump Modules C�601 & C�605 Pump Controller C�610 / Pump Manager C�615 96962...

-

Page 3: Table Of Contents

Pump system 3: Pump Manager C-615 and 2 Pump Modules C-601 or C-605..23 5.3.5 Pump system 4: Control Unit C-620 and 2 - 4 Pump Modules C-601 or C-605 ..25 Read this manual carefully before installing and running your system and note the safety precautions in chapter 2 in particular. - Page 4 Programming ........31 Pump system 4: Control Unit C-620 and 2,3 or 4 C-601 or C-605 ..33 Calibration.

-

Page 5: About This Manual

1 About this manual About this manual This manual describes the Pump Modules C-601 and C-605, the Pump Controller C-610 and the Pump Manager C-615 and provides all information required for its safe operation and to maintain it in good working order. -

Page 6: Safety

2 Safety Safety This chapter highlights the safety concept of the Pump Systems and contains general rules of behavior and warnings from hazards concerning the use of the product. The safety of users and personnel can only be ensured if these safety instructions and the safety- related warnings in the individual chapters are strictly observed and followed, therefore, the manual must always be available to all persons performing the tasks described herein. -

Page 7: Warning Notices Used In This Manual

2 Safety 2 .4 Warning notices used in this manual WARNING Generally, the triangular warning symbol indicates the possibility of personal injury or even loss of life if the instructions are not followed. WARNING Hot surface. WARNING Electrical hazard. WARNING Biohazard. -

Page 8: Other Hazards

Modifications to the instrument are only permitted after prior consultation with and written approval obtained from the manufacturer. Modifications and upgrades should only be carried out by an autho- rized BUCHI technical engineer. The manufacturer reserves the right to decline any claim resulting from unauthorized modifications. -

Page 9: Technical Data

3 .1 Scope of delivery Check the scope of delivery according to the order number. NOTE For detailed information on the listed products, see www.buchi.com or contact your local dealer. 3 .1 .1 Basic instruments Table 3-1: Pump Modules Product... -

Page 10: Standard Accessories

3 Technical data 3 .1 .2 Standard accessories Table 3-2: Standard accessories for Pump Module C-601 and C-605 Product Order number a Connection cable RJ45, 0.3 m 44288 b Solvent filter 44340 Screwdriver Turix wrench (fits fitting and pipe fitting) 44304 Green fittings and ferrules, 1/8’’... -

Page 11: Optional Accessories

3 Technical data Table 3-4: Standard accessories for Pump Manager C-615 Product Order number Mixer (pressure sensor with integrated 51100 mixing chamber) Green fittings and ferrules Torx allen wrench TX6 3 .1 .3 Optional accessories Table 3-5: Optional accessories Product Order number a Injection valve 44850... -

Page 12: Materials Used

3 Technical data Table 3-6: Optional accessories Product Order number h Solvent valve set 44854 i System stand for pump module 44855 j Tubing fitting set 44021 k External pressure sensor without 54040 mixing chamber. Needed only for very pressure sensitive columns, enables to measure direct at the column inlet. -

Page 13: Technical Data Overview

3 Technical data 3 .3 Technical data overview Table 3-8: Technical data of the Pump Controller C-610 and Pump Manager C-615 Pump Controller C-610 Pump Manager C-615 Dimensions ( W x H x D) 150 x 80 x 120 mm 150 x 80 x 120 mm Weight <... - Page 14 3 Technical data Table 3-9: Technical data of the Pump Module C-601 and C-605 Dimensions ( W x H x D) 160 x 153 x 305 mm Weight 4 kg Connection voltage 100 – 230 VAC ± 15% Power consumption max.

-

Page 15: Description Of Function

Pump system 1: Pump Controller C-610 and 1 Pump Module C-601 Pump system 2: Pump Manager C-615 and 1 Pump Module C-601 or C-605 Pump system 3: Pump Manager C-615 and 2 Pump Modules C-601 or C-605 Pump system 4: Control Unit C-620 and 2-4 Pump Modules C-601 or C-605 4 .1... -

Page 16: Operative Range Of The Pump Systems

Operative range of the pump systems The Pump Module C-601 pumps 2.5 to 250 ml/min of solvent at a maximum pressure of 10 bar. The Pump Module C-605 pumps 2.5 to 250 ml/min of solvent at a maximum of 50 bar. ATTENTION Do not connect the Pump Module C-605 to the Pump Controller C-610, otherwise an error message appears on the display. -

Page 17: Putting Into Operation

5 Putting into operation Putting into operation This chapter describes the installation of the Pump Combination and gives instructions on initial start- NOTE Inspect the instrument for damages during unpacking. If necessary, prepare a status report imme- diately to inform the postal company, railway company or transport company. Keep the original packaging for future transport. -

Page 18: Installation

5 Putting into operation 5 .3 Installation In order to make things clearer, the following descriptions do not contain the complete names of the modular pump systems, but rather the general name. Pump Controller C-610: Pump controller Pump Manager C-615: Pump manager Pump Module C-601/605: Pump module Mixer (pressure sensor with integrated mixing chamber): Pressure sensor Control Unit C-620: Control unit... -

Page 19: Pump System 1: Pump Controller C-610 And 1 Pump Module C-601

5 Putting into operation Pressure tubing 1/8” x 1/16”: Cut the pressure tubing to the desired length. Attach the fitting b and the ferrules to one end of the tubing a as described. Screw the fitting b into the upper output e of the separator head. - Page 20 5 Putting into operation Connect the pump module a to the pump control- ler b via data bus RS-485 by means of the cable RJ45 d. c TTL IN/OUT. Fig. 5.6: Rear connections of pump controller and pump module The overpressure sensor switches off the pump if the pressure exceeds 10 bar. This maximum pres- sure of 10 bar cannot be changed.

-

Page 21: Pump System 2: Pump Manager C-615 And 1 Pump Module C-601 Or C-605

5 Putting into operation 5 .3 .3 Pump system 2: Pump Manager C-615 and 1 Pump Module C-601 or C-605 The “or” between 601 and 605 indicates that operation is either possible with Pump Module C-601 up to 10 bar or with Pump Module C-605 up to 50 bar. - Page 22 5 Putting into operation Installation of the mixer Click the mixer b to the pump module a. Make sure that all fittings are hand-tight. Place the mixer cable c on the left side between pump module and pump manager, and attach it to the PRESSURE input of the pump manager (position f in Fig.

-

Page 23: Pump System 3: Pump Manager C-615 And 2 Pump Modules C-601 Or C-605

Fig. 5.13: Pump head with connected pressure tubing 5 .3 .4 Pump system 3: Pump Manager C-615 and 2 Pump Modules C-601 or C-605 NOTE You can connect two pump modules to the pump manager if both modules are of the same type. - Page 24 5 Putting into operation For the installation of the mixer and the suction tubing, see chapter 5.3.3. Connection tubing between the separator heads of the pumps: The fitting and ferrule are attached to both tubing ends. Attach one end of the connection tubing to the input of the lower separator head a and the other into the output of the upper separator head b.

-

Page 25: Pump System 4: Control Unit C-620 And 2 - 4 Pump Modules C-601 Or C-605

Fig. 5.16: Pump head with connected pressure tubing 5 .3 .5 Pump system 4: Control Unit C-620 and 2 - 4 Pump Modules C-601 or C-605 For detailed information on this system see the Installation Guide of SepacoreControl. Pump Combinations Operation Manual, Version E... -

Page 26: Operation

6 Operation Operation This chapter explains the operating elements and possible operating modes. It gives instructions on how to operate the Pump Combination properly and safely. ATTENTION Check the glassware for damages prior to each operation and use only glassware in perfect condi- tion. -

Page 27: Pump System 2, 3: Pump Manager C-615 And 1 - 2 Pump Modules C-601/605

Pump system 2, 3: Pump Manager C-615 and 1 - 2 Pump Modules C-601/605 Pump Manager C-615 can be operated with one or two Pump Modules C-601or one or two Pump Modules C-605. Since the pump modules only differ with regard to the maximal pressure, they will be described collectively. -

Page 28: Operation

6 Operation a Pump status d Remaining time of current segment b Current segment 01 e Remaining time of program c Program 01 f Manual mode Fig. 6.3: Overview over the display NOTE When the pump system is pumping, parameters highlighted in a dark color can be changed and selected. -

Page 29: Systematics Of The Menu Mode

6 Operation 6 .2 .4 Systematics of the Menu Mode Main Menu Flowrate %B * Press. act Press. max. Timer ** Solvent *** Program Menu Rest-Vol. A1 **** Rest-Vol. A2 **** Back Rest-Vol. B1 **** Load Rest-Vol. B2 **** Edit Manual control View Show... -

Page 30: Parameters

6 Operation 6 .2 .5 Parameters Table 6-1: Functions of the Main Menu Main Menu Description Flow rate Shows currently set total flow rate of eluent (2.5 – 250 ml). Shows currently set total flow rate of pump B (0 – 100 %). Press. -

Page 31: Programming

6 Operation Table 6-3: Functions of the Edit Menu Edit Menu Description Jumps back to Program Menu. Back Select The programs P01 - P10 or “new” can be selected. Pres. max. Displays the previously set maximum pressure. Flowrate Shows the current eluent flow rate (2.5 – 250 ml) No. - Page 32 Creating a new program, example: Prerequisites: Two pump modules, e.g. C-605, are installed, each with a solvent. No solvent Valve Set is installed. A gradient program P02 is created that initially runs for 25 minutes isocratically with pure Eluent A, then, for 30 minutes, the concentration of Eluent B is continuously increased to 35% and finally this concentration B is maintained for 20 minutes.

-

Page 33: Pump System 4: Control Unit C-620 And 2,3 Or 4 C-601 Or C-605

6 .3 Pump system 4: Control Unit C-620 and 2,3 or 4 C-601 or C-605 When the Pump Module C-601/605 is used, the address switches must be set to 1 and 2. In case further Pump Modules C-601/605 are used, the address switches must be set to 3 and 4. -

Page 34: Calibration

6 Operation 6 .4 Calibration ATTENTION Before carrying out the calibration make sure that the system is free of air. Always calibrate the system under your actual working conditions (flow rate, backpressure, column). After calibration carry out the measurement again to check the current pump flow rate. The pump flow rate can be influenced by the following factors: •... -

Page 35: Calibration Of The Pump Manager C-615

6 Operation 6 .4 .2 Calibration of the Pump Manager C-615 Requirements: To calibrate the Pump Manager C-615 you need a graduated cylinder and a stopwatch. Set the pump flow rate to 100 ml/min and the time to one minute. Place the pressure tubing into the graduated cylinder and start the pump. -

Page 36: Maintenance

7 Maintenance Maintenance This chapter provides instructions on all required maintenance to keep the instrument in good working condition. WARNING All maintenance and repair work requiring the opening or removal of instrument covers and lids must be carried out by trained personnel and only with the tools provided for this purpose. WARNING Electrical hazard: •... -

Page 37: Cleaning The Seals

7 Maintenance 7 .5 .1 Cleaning the seals To prolong the lifetime of the seals and in case of unwanted sample contamination (foaming or boiling retardation) rinse the seals with water or ethanol. Dry the cleaned seals with a soft cloth. 7 .5 .2 Changing the seals Visually examine the seals regularly, if seals become cracked and brittle replace them with new ones. -

Page 38: Piston Backrinsing

7 Maintenance 7 .6 Piston backrinsing ATTENTION When working with aqueous saline solutions, residues might collect behind the piston seal. These residues must be removed since they can contribute to a faster wearing of the seals. The system can be rinsed with a spraying device filled with water. -

Page 39: Changing The Suction And Pressure Tubing

7 Maintenance • Remove the valve screw fittings and tubing. • Remove the valves and insert the new valves. The inlet valve is marked by one ring a at the head end, and is attached with that ring facing the pump head in the direction of the arrow. The outlet valve is marked by two rings b at the head end and is inserted into the pump with the unmarked side first. -

Page 40: Troubleshooting

The appropriate course of action is listed in the column “Corrective measure”. The elimination of more complicated malfunctions or errors is usually performed by a BUCHI technical engineer who has access to the official service manuals. In this case, please refer to your local BUCHI customer service agent. - Page 41 EEPROM C-605. Contact the BUCHI customer service Transfer error to RS485. Contact the BUCHI customer service The wrong pump is connected (C-605 instead Replace C-601 with C-605. of C-601). Table 8-2: Error messages of the Pump Manager C-615 Error number...

-

Page 42: Pulsation Of A Pump Module

Refill solvent bottle B. Check level sensor position. Check level sensor adjustment. No pressure sensor connected. Check connection; otherwise, contact the BUCHI customer service 8 .2 Pulsation of a pump module A repeated strong pulsation of the pumps suggests that the opening or closing times of the inlet or outlet valves are not correct. -

Page 43: Customer Service

Contacts for official BUCHI customer service offices are given on the BUCHI website at: www.buchi. com. If malfunctions occur on your instrument or you have technical questions or application prob- lems, please contact one of these offices. -

Page 44: Shutdown, Storage, Transport And Disposal

9 Shutdown, storage, transport and disposal Shutdown, storage, transport and disposal This chapter instructs on how to shut down the instrument, how to pack it for storage or transport and specifies the storage and shipping conditions. 9 .1 Storage and transport WARNING Biohazard: •... -

Page 45: Spare Parts

BUCHI. Always state the product designation and part number when ordering any spare parts. Use only genuine BUCHI consumables and spare parts for maintenance and repair to ensure optimum system performance and reliability. Prior written permission of the manufacturer should be obtained before any modifications are made to the spare parts used. - Page 46 10 Spare parts Table 10-1: Spare parts (cont.) Product Order number e Mixer (pressure sensor with inte- 51100 grated mixing chamber) Overpressure sensor 51110 FEP pressure tubing 1/8’’ x 1/16’’, 44354 length 5 m FEP suction tubing 4mm x 2.5 mm, 54059 lenght 5 m Pump Combinations Operation Manual, Version E...

-

Page 47: Declarations And Requirements

11 Declarations and requirements Declarations and requirements 11 .1 FCC requirements (for USA and Canada) English: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to both Part 15 of the FCC Rules and the radio interference regulations of the Canadian Department of Communications. -

Page 48: Declaration Of Conformity

11 Declarations and requirements 11 .2 Declaration of conformity Pump Combinations Operation Manual, Version E... - Page 50 BÜCHI Labortechnik AG CH-9230 Flawil 1 / Switzerland T +41 71 394 63 63 F +41 71 394 65 65 www .buchi .com Quality in your hands...

Need help?

Do you have a question about the C-605 and is the answer not in the manual?

Questions and answers