Subscribe to Our Youtube Channel

Summary of Contents for biosystems MultiPro

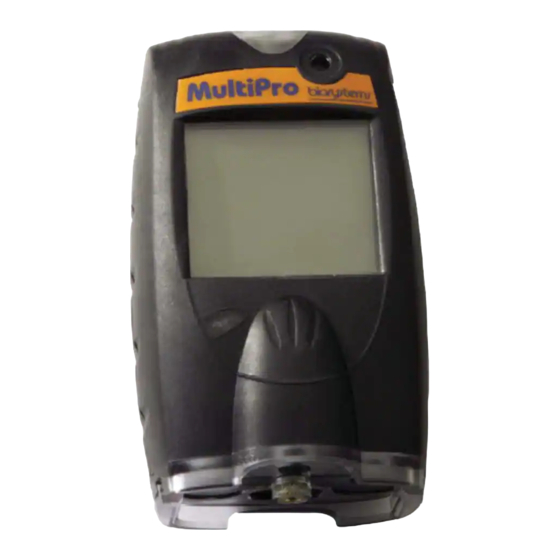

- Page 1 Reference Manual MultiPro Gas Detector 651 South Main Street Middletown, CT 06457 800 711-6776 860 344-1079 Fax 860 344 –1068 11MAY2007 P/N 13-278 Version 1.41 http://www.biosystems.com...

- Page 2 MULTIPRO PERSONAL PORTABLE GAS DETECTORS HAVE BEEN DESIGNED FOR THE DETECTION AND MEASUREMENT OF POTENTIALLY HAZARDOUS ATMOSPHERIC CONDITIONS IN ORDER TO ASSURE THAT THE USER IS PROPERLY WARNED OF POTENTIALLY DANGEROUS ATMOSPHERIC CONDITIONS, IT IS ESSENTIAL THAT THE INSTRUCTIONS IN THIS REFERENCE MANUAL BE READ, FULLY UNDERSTOOD, AND FOLLOWED.

-

Page 3: Table Of Contents

Latching peak alarms 1.4.7 Fault detection Other electronic safeguards 1.5.1 Heartbeat Sensors Optional sample draw pump 1.7.1 Special precautions when using the MultiPro pump Data storage 1.8.1 Black box data recorder 1.8.2 Event logger MultiPro design components 1.10 MultiPro standard accessories 1.10.1 Alkaline MultiPro detectors 1.10.2... - Page 4 Appendix B Calibration Frequency Recommendation Appendix C: Calibration Frequency Appendix C MultiPro Sensor Information Appendix D Toxic Sensor Cross-Sensitivity Appendix E: Basic Parts List MultiPro Remote Sampling Accessories MultiPro Sensors MultiPro Charging & Datalogging Accessories Appendix F Biosystems Standard Warranty Gas Detection Products...

-

Page 5: Certification Information

To reduce the risk of explosion, do not mix old or used batteries with new batteries and do not mix batteries from different manufacturers. Do not charge the MultiPro with any charger other than the appropriate Biosystems MultiPro charger. Standard versions of the MultiPro must... - Page 6 UL/CSA-approved charger, which is Biosystems part number 54-49-103-1. European versions of the MultiPro must be charged with the ATEX- approved charger, which is Biosystems part number 54-49-103-5. The MultiPro must be located in a non-hazardous location during the charging cycle.

-

Page 7: Description

The accuracy of the detector. MultiPro should be checked periodically The MultiPro can also be used to sample with known concentration calibration gas. remote locations with the hand-aspirated Failure to check accuracy can lead to... -

Page 8: Alarm Logic

Sensor over range alarms. course of action is to immediately leave the affected area, and to return only after The MultiPro will go into alarm if a sensor is further testing determines that the area is exposed to a concentration of gas that once again safe for entry. -

Page 9: Latching Peak Alarms

The sensor configuration 1.4.6 Latching peak alarms of the MultiPro may be specified at the time The MultiPro’s alarms are self-resetting of purchase, or changed in the field by unless the alarm latch is enabled. With the appropriately trained personnel. -

Page 10: Special Precautions When Using The Multipro Pump

If the freight charges incurred. MultiPro is being used in an atmosphere that The “black box” data recorder in the MultiPro may contain concentrations of combustible can be upgraded to a fully enabled fuels and solvents that exceed 10% LEL, test datalogger at any time. -

Page 11: 1.10 Multipro Standard Accessories

The MODE button is used to turn the gas, fixed-flow regulator and a hard-shell MultiPro on and off as well as to control carrying case. most other operations, including the automatic calibration adjustment. -

Page 12: Start Up With Pump

If the MultiPro is equipped with a fully enabled datalogger, the following screen will → be shown. The time figure in the upper right corner indicates the sampling interval in minutes and seconds. Instruments without a fully enabled datalogger will show display “not a datalog”... -

Page 13: 2.2 Operating Logic

“beat” every few 2.3 Turning the MultiPro Off seconds to show that the instrument is functioning To turn the MultiPro off, press and hold the normally. MODE button until the display reads “Release Button”. “Please wait” will be If the MultiPro is due for shown briefly and display will go blank. -

Page 14: Alarms

Alarms is 35PPM. The default TWA value for the MultiPro H S sensor is 10PPM. The MultiPro is configured with a series of alarms that are designed to warn the user of 2.4.5 Low battery alarms dangerous conditions. When battery voltage is... -

Page 15: Sensor Over Range Alarms

2.4.6 Sensor over range alarms PC connection via infrared port The MultiPro will go into alarm if a sensor is exposed to a concentration of gas that MultiPro instruments that exceeds its established range. In the case of are equipped with a fully... -

Page 16: Sampling

The MultiPro can also be used to sample minimum of 55 seconds or until remote locations with either the hand- readings stabilize. -

Page 17: Starting The Motorized Sample Pump

→ allows the MultiPro to continuously monitor remote locations. The pump is powered by the MultiPro battery. When the pump is attached to the instrument, “PUMP” will be shown on the display in the current gas Block the sampling inlet by placing a finger readings screen. -

Page 18: Sample Draw Probe

To perform a functional (bump) test, do the standard probe assembly from Biosystems. following: The sample probe handle contains moisture 1. Turn the MultiPro on and wait at least barrier and particulate filters designed to three minutes to allow the readings to remove contaminants that might otherwise fully stabilize. -

Page 19: Fresh Air/Zero Calibration

4. Attach the calibration adapter and MultiPro will briefly display AUTO CAL connect the calibration cylinder to the and then begin a 5-second countdown. MultiPro as shown in figure 4.1. Flow gas to the sensors. 5. Wait for the readings to stabilize. (Forty- →... -

Page 20: Manual Fresh Air / Zero Calibration

0 without pressing the MODE button. 1. The atmosphere in which the instrument If the MultiPro still fails to calibrate after is located is contaminated (or was attempting the manual fresh air / zero contaminated at the time the instrument calibration, contact Biosystems. -

Page 21: Span Calibration Failure: Toxic And Lel Sensors

Too Low followed by the O2 CAL Error in the gas readings screen. screen immediately after the failed calibration The MultiPro will also display a “Needs Cal” attempt. message for any sensors that are currently Press MODE to acknowledge the warning due for calibration during instrument start-up. -

Page 22: Maintenance

2. instrument, then gently pry the two clasps at 4. Return the battery pack to the MultiPro the top of the instrument open while and re-tighten the top center screw. The... -

Page 23: Storage Guidelines For The Li-Ion Battery

UL/CSA-approved any further. charger, which is Biosystems part 2. If the MultiPro fails to turn on, then the number 54-49-103-1. European versions battery may be severely discharged and of the MultiPro must be charged with the should be returned to the charger. -

Page 24: Duo-Tox Sensor Replacement

Duo-Tox replacement procedure see Oxygen (O 1 hour section 5.4.2 below. none The sensors in the MultiPro are located in a 15 minutes vented compartment at the bottom of the 15 minutes instrument. Note: Steps 9 and 10 assume that the To install a sensor: sensor stabilization period has passed. -

Page 25: Sample Probe Assembly

7. Reassemble the MultiPro and allow the new sensor to stabilize as described in steps 6-8 in section 5.4.1. 8. When the instrument restarts for the first time, the CF screen will be shown. 9. Press the MODE button to advance the CF value until the correct value is shown. -

Page 26: Multipro Pump Maintenance

1/4” OD appropriate software is not available, the tubing, or probe tubes made of other MultiPro can be programmed directly with the materials (such as stainless steel). MODE button. Probe tubes are exchanged by loosening the... -

Page 27: Set Options

Selecting “Cal Due Use On” will Once the “Set Alarms” submenu has been reached, the MultiPro will display the Default allow the MultiPro to be used when it is due Alarms screen and then begin scrolling for calibration. Selecting “Cal Due Use Off”... -

Page 28: Set Cal Gas

To disable the bump due warning, set the Once the set cal gas submenu has been interval to OFF. reached, the MultiPro will scroll through the Once the bump due interval various calibration gas values screens and has been set correctly, click the the set default cal gas option. -

Page 29: Appendices

The default Warning and alarms Danger alarm levels in the MultiPro are less than or Many toxic substances are commonly encountered equal to the OSHA-assigned ceiling levels for both in industry. -

Page 30: Appendix B Calibration Frequency Recommendation

One of the most common questions is being performed, should question! One of the professional that we are asked at Biosystems is: trigger a resumption of organizations to which Biosystems “How often should I calibrate my daily checking. -

Page 31: Appendix C Multipro Sensor Information

Appendix D Toxic Sensor Cross-Sensitivity The table below provides the cross-sensitivity response of the MultiPro toxic gas sensors to common interference gases. The values are expressed as a percentage of the primary sensitivity, or the reading of the sensor when exposed to 100ppm of the interfering gas at 20ºC. -

Page 32: Appendix F Biosystems Standard Warranty Gas Detection Products

General Biosystems, LLC (hereafter Biosystems) warrants gas detectors, sensors and accessories manufactured and sold by Biosystems, to be free from defects in materials and workmanship for the periods listed in the tables below. Damages to any Biosystems products that result from abuse, alteration, power fluctuations including surges and lightning strikes, incorrect voltage settings, incorrect batteries, or repair procedures not made in accordance with the Instrument’s Reference Manual are not covered by the Biosystems standard...

Need help?

Do you have a question about the MultiPro and is the answer not in the manual?

Questions and answers