Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Datem Neptune 5000

- Page 1 Neptune 5000 Neptune 5000 Technical Manual © Copyright Datem Limited 2014...

-

Page 2: Revision History

21/07/08 Issued to MS. Multiple 16/03/10 Electronics Update. 22/07/11 Issued to MS 10/12/12 Client Release 19/03/13 Client Release 05/02/14 Client Release 22/10/14 Client Release This document is the property of DATEM and should not be disclosed without prior written consent. -

Page 3: Table Of Contents

Electrical Installation ................13 Topside Power Supply PCB ..............16 Topside Telemetry Board ..............18 LCD Displays..................20 Maintenance ..................21 Frame Assembly ..................22 Description ..................22 Specification ..................22 Assembly ..................22 Maintenance ..................23 © Copyright Datem Limited 2014... - Page 4 Technical Manual Compensator Assembly ................. 25 Description ..................25 Specification ..................26 Assembly ..................26 Operational Information ..............28 Maintenance ..................28 Transformer Pod Assembly ..............31 Description ..................31 Specification ..................33 Assembly ..................33 Electrical Installation ................35 Operational Information ..............

- Page 5 Slip-ring .................... 73 Cone ....................75 Description ..................75 Specification ..................76 Assembly ..................76 Operational Information ..............79 Maintenance ..................80 Cone Rod Assembly ................81 Description ..................81 Specification ..................81 Assembly ..................81 © Copyright Datem Limited 2014...

- Page 6 Technical Manual Operational information ..............82 Cone-rod Removal ................82 Cone-Rod Fitting ................83 Maintenance ..................87 Encoder Assembly ................88 Description ..................88 Specification ..................89 Assembly ..................89 Operational information ..............89 Maintenance ..................91 Cone-Up Sensor Assembly ..............93 Description ..................

- Page 7 Material safety data sheet for wirelock® kit......... 103 Appendix C ..................109 Material safety data sheets for loctite 242 threadlocker......109 Appendix D ..................114 Material safety data sheets for HM10 hydraulic oil........ 114 © Copyright Datem Limited 2014...

-

Page 8: Introduction

Technical Manual This document and the content is ©Copyright Datem Limited 2014. No part of this document may be copied in any way for commercial redistribution, republication, or dissemination without the explicit written permission of Datem Limited. Introduction System Overview... -

Page 9: System Specification

Reference should be made to the following sections of the manual to fulfil detailed maintenance requirements, relevant to each individual sub-system during operation. © Copyright Datem Limited 2014... -

Page 10: Software

PC uses either standard RS232 protocol at 19,200 baud or Ethernet. The data is transmitted to the telemetry system housed in the Topside Control Box. Specification The Neptune 5000 control and acquisition computer software requires a Personal Computer (PC) that meets the following minimum requirements. Processor 2.0 GHz... -

Page 11: Trouble Shooting

Where problems are encountered with software, it is generally related to the installation and un-installation of other software on the PC. The recommended solution to such problems is to re-install the Neptune 5000 software, using the installation CD ROM provided. -

Page 12: Topside Control Box

Technical Manual Topside Control Box Description Figure 2: Topside Control Box The Topside Control Box, illustrated in Error! Reference source not found., is housed in a shock mounted IP65 enclosure. It contains the main system Topside Transformer, Power Supply Board, Telemetry Board, Data Coupling Board and LCD Displays. -

Page 13: Specification

Topside Control Box contain any user serviceable parts, other than fuses. For this reason there are no circuit board diagrams included in the manual. The individual circuit boards are covered in greater detail later in this document. © Copyright Datem Limited 2014... - Page 14 Technical Manual Figure 3: Topside Control Box Wiring Schematic...

- Page 15 Neptune 5000 Figure 4: Topside Control Box Wiring Layout © Copyright Datem Limited 2014...

-

Page 16: Topside Power Supply Pcb

Technical Manual Topside Power Supply PCB Overview Figure 5: Topside Power Supply Board The Topside Power Supply PCB provides the power needed by the Topside Telemetry PCB, the High Voltage and Mains Current sensing circuits, and the LCD displays. The Topside Power Supply Board is illustrated in Error! Reference source not found.. - Page 17 Whenever the Topside control box is switched on the Topside Power Supply Board could have both 240vac and 650vac on various exposed components Specification Supply Input 240Vac +/- 10% Supply Input Current 500mA Low Voltage Outputs +/- 15Vdc, +/- 5Vdc Fuse ratings FS1: 1A © Copyright Datem Limited 2014...

-

Page 18: Topside Telemetry Board

Technical Manual Topside Telemetry Board Overview The Topside Telemetry PCB, illustrated in Error! Reference source not found. and the Topside Data Coupling Board, illustrated in Error! Reference source not found., provide the telemetry link with the Subsea Telemetry PCB located in the Subsea Electronics Pod and the Subsea Data Coupler PCB located in the Subsea Transformer Pod. - Page 19 Topside Power Board, while “+5V” is derived from the +15V supply by an on- board voltage regulator. Four yellow LEDs monitor communications activity: “Rx0” is illuminated whenever a character is received from the Topside PC; © Copyright Datem Limited 2014...

-

Page 20: Lcd Displays

Topside Telemetry Board stores its tuning results together with those obtained from the Subsea Telemetry Board. These results are displayed on the Engineering Screen of the Neptune 5000 program. (“Level” is a code related to the receiving circuit threshold voltage; “Quality” is a value corresponding to the number of consecutive valid tuning strings received while ramping up the threshold voltage –... -

Page 21: Maintenance

Any damage to the mains power or umbilical link cable insulation requires replacement of the cables. Damage to the PC communication cable insulation can be repaired with the application of adhesive lined shrink sleeve, providing the inner cores are not damaged. © Copyright Datem Limited 2014... -

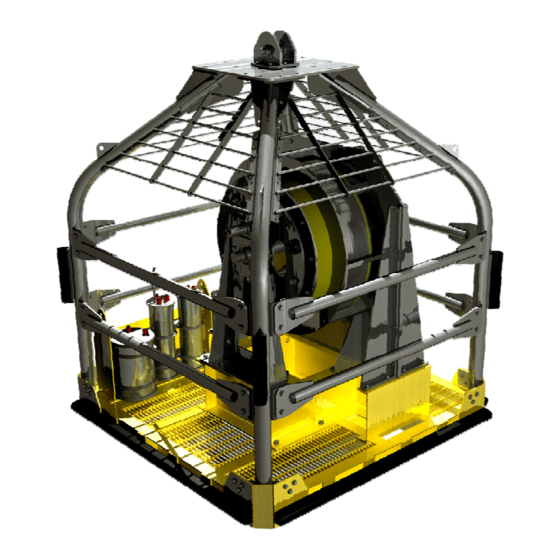

Page 22: Frame Assembly

Technical Manual Frame Assembly Description Datem’s complete frame assembly consists of three main sections: The sub frame, base frame and top frame. Some clients provide alternative frames and in such cases the following information will not be valid. The sub frame provides the mounting point for the thruster. This part of the frame is constructed in mild steel, and painted using a marine grade of high- visibility yellow paint. -

Page 23: Maintenance

In some situations it may be necessary to remake the umbilical termination, due to cable shortening or replacement through damage. Whilst not supplied by Datem, if the termination mounted on the umbilical is an open spelter socket it can normally be re-used. To reuse the termination, cut the cable close to the end of the socket, and drill out the centre. - Page 24 Technical Manual face gap, and the lock-rings should be finger-tight. If the cable is damaged, it should be replaced immediately. It is good working practice to regularly check all fastenings to ensure they are tight, and there is no damage to them or the items they are fitted to. It is also good working practice to regularly check that there are no indications of stress or fractures in any of the frame members, particularly relating to the welds.

-

Page 25: Compensator Assembly

Observation of the diaphragm pressure indicator in the bottom of the unit can be used to identify the pressure status. A fully pressurised system is signified by approximately 75mm of indicator protruding from the bottom of the compensator © Copyright Datem Limited 2014... -

Page 26: Specification

Technical Manual Specification Dimensions approx. 480mm x 380mm x 300mm Weight in Air approx. 12Kg Weight in Sea Water approx. 10Kg Maximum Operating Pressure 300Bar HM10 Hydraulic Oil Differential Pressure approx. 0.5 Bar Assembly WARNING: The compensator assembly is not generally considered to be a user serviceable item. - Page 27 When pressurising the system, firstly check that all the hydraulic fittings are tight. Fill a pressure pump with the correct oil, and attach it to the hydraulic valve using a suitable hose. Remove the vent plug from the top of the motor © Copyright Datem Limited 2014...

-

Page 28: Operational Information

Technical Manual housing, illustrated in Error! Reference source not found., to allow all the air to escape. Start pumping the oil into the compensator until oil begins to run out the motor top vent plug. At this stage you should refit the vent plug, ensuring it is fitted with a bonded washer. - Page 29 Any damaged fastenings should be replaced immediately. It is recommended to change the oil in the system during each major service, which could be once a year depending upon use. © Copyright Datem Limited 2014...

- Page 30 Technical Manual...

-

Page 31: Transformer Pod Assembly

Electronics Pod. Data is passed between the coupling unit and the Electronics Pod by a coaxial cable fitted to the bulkhead coaxial connector. The general arrangement and connector details for this pod can be in the drawing on the following page. © Copyright Datem Limited 2014... - Page 32 Technical Manual Figure 14: Transformer Pod General Arrangement...

-

Page 33: Specification

Warning: The Power pod is very heavy. Always use appropriate lifting apparatus and follow safe working practices to ensure that all hazards are minimised. © Copyright Datem Limited 2014... - Page 34 Technical Manual Pod Refitting Refitting the pod is simply the reverse process of removal, but special care should be taken with ensuring that the threads on the clamp are in good condition, and that anti-seize grease is applied to the threads of the clamp to avoid galling. Pod Top-Cap Removal To remove the top-cap assembly: 1.

-

Page 35: Electrical Installation

8. The transformer can now be removed from the base cap. Electrical Installation A wiring schematic diagram of the Power Pod is illustrated in Drawing 1677- 03-SCH, which can be found on the following page. © Copyright Datem Limited 2014... - Page 36 Technical Manual Figure 15: Transformer Pod Schematic...

-

Page 37: Operational Information

Any damaged cables or lock-rings should be replaced immediately. Under normal circumstances the oil in the lower section should not require replacement. © Copyright Datem Limited 2014... -

Page 38: Electronics Pod Assembly

A separate low noise power supply is also located on the Power Supply PCB that provides power for the Datem Digital Cone. Data is passed to the Telemetry PCB inside the Electronics Pod via a co-axial connector from the Power Pod. - Page 39 Neptune 5000 Figure 16: Electronics Pod General Arrangement © Copyright Datem Limited 2014...

-

Page 40: Specification

Technical Manual Specification Dimensions approx. 660mm long x 210mm diameter Weight in Air approx. 65 Kg Voltage Supply 240Vac ±10% Maximum Operating Pressure 300 Bar WARNING The electronic boards contained within the Electronics Pod are static- sensitive. It is therefore of great importance to ensure that appropriate action is taken to minimise the potential for such damage. -

Page 41: Subsea Power Supply Pcb

Each output voltage has its own LED status indicator (LED1-8) The telemetry board power supply is output on PL6 +/- 15V The controller board power supply is output on PL7 +12V The cone board power supply is output on PL8 +/- 15V © Copyright Datem Limited 2014... -

Page 42: Subsea Connector Pcb

Technical Manual Specification Supply Input: 240Vac Supply Input Current: Low Voltage Outputs: +5VDC, +12VDC +/-15VDC Low Voltage Cone Output: +/-15VDC Fuse ratings FS1: 5A(T) FS2: Not fitted FS3: 2A(T) Subsea Connector PCB Overview The Subsea Connector PCB provides the necessary connectors to connect all the sensors within the system to the Subsea Micro controller. - Page 43 The Subsea Microcontroller board simply plugs onto the Connector PCB using plugs PL9, PL10, PL11, and PL12. Specification Supply Input: Controller / Cone +12VDC & +/-15VDC Telemetry +/-15VDC Electrical Installation A wiring schematic diagram of the Electronics pod is shown in Figure 19. © Copyright Datem Limited 2014...

- Page 44 Technical Manual Figure 19: Neptune 5000 Electronics Pod Wiring Schematic...

-

Page 45: Subsea Microcontroller Board

The program code for the Subsea Microcontroller is stored in onboard Flash memory and it is possible to reprogram the memory in-system. Calibration data for the Frame Tilt sensors is stored in the EEPROM memory. © Copyright Datem Limited 2014... - Page 46 PL2 – Inputs / Outputs (Telemetry data, Frame Tilt data, Altimeter data, Penetration, Cone Up, Neptune 3000 Inverter Status) PL3 – Cone Power, Cone Data, Cone Comms, and Pressure Sensor PL4 – Inverter Control via digital (Neptune 5000) or analogue (Neptune 3000) Specification Supply Input:...

-

Page 47: Subsea Telemetry Board

The Subsea Telemetry Board, illustrated in Error! Reference source not found., works with the Topside Telemetry Board and coupling circuitry located on the Subsea Power Supply Board and the Topside Power Supply Board. Figure 22: Sub-Sea Power Board © Copyright Datem Limited 2014... - Page 48 Technical Manual The telemetry system gives a transparent, full duplex serial link between the Subsea Microcontroller Board and the Topside PC capable of transferring data at 19200 baud. LED Indicators Seven LED indicators are fitted to the Subsea Telemetry Board. Three green LEDs show the power supply status: “+15V”...

-

Page 49: Inverter Pod Assembly

Inverter Pod to the Motor Assembly. This cable has a screen braid to minimise electronic interference on the system data. The Inverter Pod contains a specially adapted industrial drive unit, capable of operating a three-phase motor at variable speeds, from a single-phase supply. © Copyright Datem Limited 2014... -

Page 50: Specification

Technical Manual Mounted on the underside of the pod lid is a mains filter unit, to minimise electrical interference on the system data. Mounted above the filter is an Inverter Pod Measurements PCB which measures the motor parameters: Inverter mains input voltage Inverter input current Pod temperature and humidity measurement The general arrangement and connector details for this pod can be seen on... - Page 51 Neptune 5000 Figure 23: Inverter Pod General Arrangement © Copyright Datem Limited 2014...

- Page 52 Technical Manual Figure 24: Inverter Pod Assembly...

-

Page 53: Assembly

Inverter Pod Top-Cap Removal To remove the top-cap assembly: 1. Firstly ensure the power is removed from the system, and appropriate action is taken to prevent accidental energisation, © Copyright Datem Limited 2014... - Page 54 Technical Manual 2. Remove all the cables from the pod’s connectors, and fit dummy connectors or caps to the connectors, 3. Remove the M6 cap bolts from around the top-cap, 4. Fit two of the M6x35 cap bolts to the jacking holes, and systematically turn them, jacking the entire top-cap out of the vessel, 5.

- Page 55 Neptune 5000 Figure 25: Inverter Pod Wiring Schematic © Copyright Datem Limited 2014...

- Page 56 Technical Manual Inverter Set-up Although spare and replacement inverters are generally set up prior to despatch, the settings should be checked after fitting. Where any problems are being experienced with the operation of the inverter, it is again worth checking these settings.

- Page 57 Neptune 5000 Figure 26: Inverter Function Settings © Copyright Datem Limited 2014...

- Page 58 Technical Manual Maintenance NOTE: Appropriate safe working practices should be followed to ensure that all hazards are minimised. When the system is in operation, the inverter pod should be washed down with clean, salt-free water whenever it is returned to the deck of the ship. This will reduce corrosion, and enable thorough inspection of all the main housing, connectors, and connecting cables.

-

Page 59: Motor / Gearbox Assembly

3 Phase, induction Motor Rating (Nom.). 240Vac/50Hz 3kW HM10 Hydraulic Oil, Weight 90Kg Maximum Operating Pressure 300 Bar Assembly There is no exploded view of the motor/gearbox, as there are no user serviceable parts used. © Copyright Datem Limited 2014... -

Page 60: Maintenance

Technical Manual It is very important not to attempt disassembly of this sub-system, as the removal of certain fastenings without correct support can cause irreversible and costly damage to the internal construction. Maintenance NOTE: Appropriate safe working practices should be followed to ensure that all hazards are minimised. -

Page 61: Thruster Assembly

When ordering any replacement parts, please quote the assembly drawing number, revision, and title, followed by the item number and description of the part you wish to order. © Copyright Datem Limited 2014... - Page 62 Technical Manual Figure 27: Thruster General Assembly...

- Page 63 Neptune 5000 Figure 28: Thruster Backplate and Driver Assembly © Copyright Datem Limited 2014...

- Page 64 Technical Manual Figure 29: Thruster Drum and Cassette Assembly...

-

Page 65: Maintenance

Mechanism Description The mechanism consists primarily of a drum and cassette assembly, which combine as a storage media for unused cone-rod, and a means of pushing the cone-rod through the straightener. © Copyright Datem Limited 2014... - Page 66 Technical Manual The mechanism also consists of the front and rear drive plates, and five drive pegs. In addition to the rotary drive parts are the five lead screw assemblies that pull the cassette out of the drum as the unit rotates. All the above assemblies are mounted on a central shaft that fits between the chassis back-plate and pedestal.

-

Page 67: Bearing Housing

Check for any oil leaks before and after system use. Any excess air in the assembly can be bled from the top drain plug whilst maintaining oil pressure from the main compensator assembly. Refer to Compensator section for instruction on system oil pressurisation. © Copyright Datem Limited 2014... - Page 68 Technical Manual...

-

Page 69: Straightener

When ordering any replacement parts, please quote the assembly drawing number, revision, and title, followed by the item number and description of the part you wish to order. © Copyright Datem Limited 2014... - Page 70 Technical Manual Figure 30: Thruster Straightener Assembly...

- Page 71 The procedure below should be followed for setting the straightener. 1. Tighten the adjustable roller by hand, until it is in contact with the cone-rod. © Copyright Datem Limited 2014...

- Page 72 Technical Manual 2. Using the main system controls, or the manual inverter, push the rod out, observing the travel of the end of the rod to ensure it does not come in contact with anything. At the same time slowly tighten the roller a further ¼...

-

Page 73: Slip-Ring

There are no user serviceable parts in the slip ring assembly. Please return the unit to Datem for service/repair. Operational Information The slip ring must not be placed in water without the intended cables fitted, and the lock-rings tightened. - Page 74 Technical Manual Maintenance When mobilising the system or fitting a new slip ring that has not been in use for an extended period of time, it may be necessary to rotate the unit for 1 to 2 minutes to ensure that any residue on the rings is removed.

-

Page 75: Cone

Neptune 5000 Cone Description The Neptune 5000 system can use either a Datem 5cm or 10 cm Digital Cone. The Cone is the main sensor of the system that a pushed into the ground to obtain the geotechnical soil data. The cones are manufactured to high physical dimensional tolerances in order to meet strict miniature cone penetrometer testing guidelines. -

Page 76: Specification

Although some degree of more extensive servicing is possible on cones sustaining field damage, it’s recommended to return the cone to the Datem Cone servicing facilities. When ordering any replacement parts, please quote the item... - Page 77 Neptune 5000 Figure 34: 5cm Digital Cone Assembly © Copyright Datem Limited 2014...

- Page 78 Technical Manual Figure 35: 10cm Digital Cone Assembly...

-

Page 79: Operational Information

It is recommended to use a small amount of silicone grease on all o- rings during assembly. It is of utmost importance to ensure that the tip o ring behind the filter holder is fitted and that the tip is tight. © Copyright Datem Limited 2014... -

Page 80: Maintenance

Technical Manual Maintenance NOTE: Appropriate safe working practices should be followed to ensure that all hazards are minimised, particularly if access is gained to the cone by supporting the base above the deck and pushing. During normal operation, the cone should be checked every time the CPT returns to the ship, to ensure it is still tightly screwed to the cone-rod. -

Page 81: Cone Rod Assembly

21.5m nominal for 20 m push. Weight approx. 30kg. Maximum Operating 300 Bar Pressure Assembly There is no exploded view of the cone-rod, as there are no user serviceable parts used. Any damage to the cone-rod requires complete replacement. © Copyright Datem Limited 2014... -

Page 82: Operational Information

Cone-rod Removal The following procedure describes the tasks required to remove a rod from the Neptune 5000 CPT unit. The rod will leave the cassette in a circular anti clockwise motion and not through the hole in the base plate. -

Page 83: Cone-Rod Fitting

The following procedure describes the tasks required to fit a coiled rod to the Neptune 5000 CPT unit. The rod will be wound onto the cassette in a circular clockwise motion and not through the hole in the base plate. This is a 2 man procedure. - Page 84 Technical Manual Two or three coils under the Coiled Rod Support Bar. Remainder on top. Figure 37: Coils underneath the coiled rod support bar 4. Hook approx half a coil of rod onto the Cassette making sure the Upper Connector lines up with the connector recess in the Cassette. 5.

- Page 85 If the wrong plate is fitted or the Cassette has already been rotated one full turn too many and a coil of rod is trapped before fitting the plate then the rod will not be loaded properly. © Copyright Datem Limited 2014...

- Page 86 Technical Manual First coil passing behind second loading plate Figure 41: First coil passing behind second loading plate 12.If both plates fit okay and the first coil is tight behind then continue to retract until all the coils are inside the Drum and the Coiled Rod Lower Coupling is in-line with the cone up sensor and stop.

-

Page 87: Maintenance

The connectors on both ends of the cable should be tightly fitted with no face gap, and the lock-rings should be finger-tight. Any damaged cables should be replaced immediately. © Copyright Datem Limited 2014... -

Page 88: Encoder Assembly

Technical Manual Encoder Assembly Description The Encoder Assembly, illustrated below, provides the measurement of the penetration distance and speed. It mounts on the back of the thruster unit, and consists of a sealed pressure vessel containing a high accuracy optical encoder, and a sprocket assembly. -

Page 89: Specification

Topside. When assembling an encoder the sprocket must rotate freely, and be able to move in the vertical axis of the slotted guide plate without horizontal movement. © Copyright Datem Limited 2014... - Page 90 Technical Manual...

- Page 91 Neptune 5000 Figure 45: Encoder Parts Drawing © Copyright Datem Limited 2014...

-

Page 92: Maintenance

Technical Manual Maintenance NOTE: Appropriate safe working practices should be followed to ensure that all hazards are minimised. When the system is in operation, the encoder should be washed down with clean, salt-free water whenever it is returned to the deck of the ship. This will reduce corrosion, and enable thorough inspection of all the main housing, gears, connector, and connecting cable. -

Page 93: Cone-Up Sensor Assembly

Figure 46: Cone Up Sensor Specification Maximum Operating Pressure. 300Bar Operating Distance. 30mm Contact Rating. 15Vdc / 0.2A Contact Status (Cone up). Open Contact Status (Cone out). Closed © Copyright Datem Limited 2014... -

Page 94: Assembly

There are no user serviceable parts in the cone up sensor unit. Please return unit to Datem for service/repair. When ordering any replacement parts, please quote the assembly drawing number, revision, and title, followed by the item number and description of... - Page 95 Neptune 5000 © Copyright Datem Limited 2014...

-

Page 96: Operational Information

Technical Manual Operational Information There are two very important criteria that must be observed when working with the cone-up sensor. 1. The magnetic flux unit and the sensor must be correctly orientated to ensure correct operation. The two large spots on the magnetic flux unit must be orientated vertically (in line with the cone-rod). -

Page 97: Altimeter Assembly

10m – 500kHz/6°. Assembly There is no exploded view of the altimeters, as there are no user serviceable parts used. Any damage to these units requires return to Datem for assessment. Operational information It is important to ensure that the correct o-rings have been fitted to the connectors on the end of the altimeter housing, and that the securing screws ©... -

Page 98: Maintenance

Technical Manual are tight. Either altimeter can be fitted on either end of the y-cable, as the altimeters are addressed serially. The mounting arm should only be tightened to the point where it holds the position it is set to, but will move out the way if it is pushed. The sensors must be fitted in a vertical orientation. -

Page 99: Fault Finding

Any problems encountered that are not covered in this version of the technical manual should be referred directly to Datem. Our technical staff should be able to provide additional fault finding advice in such situations. When seeking advice, it is necessary to provide the following information: 1. -

Page 100: Tools And Equipment

Technical Manual Tools and Equipment Recommended Mechanical Tool Kit Spanners (metric): 10mm, 12mm, 13mm, 17mm, 19mm, 24mm Socket set (metric): 10mm, 12mm, 13mm, 17mm, 19mm, 24mm, 30mm Electricians Screwdriver set (VDE approved) Allen Keys (metric): 1.5mm, 3mm, 4mm, 5mm, 6mm, 8mm Long nose pliers (VDE approved) Cutters (VDE approved) Hammer... -

Page 101: Sample Instructions For The Wirelock® Kit

Neptune 5000 Appendix A Sample instructions for the wirelock® kit. © Copyright Datem Limited 2014... - Page 102 Technical Manual...

-

Page 103: Material Safety Data Sheet For Wirelock® Kit

Neptune 5000 Appendix B Material safety data sheet for wirelock® kit. This information covers all the requirements of the Health and Safety at Work Act 1974, Section 6, C.O.S.H.H and C.H.I.P. regulations. © Copyright Datem Limited 2014... - Page 104 Technical Manual...

- Page 105 Neptune 5000 © Copyright Datem Limited 2014...

- Page 106 Technical Manual...

- Page 107 Neptune 5000 © Copyright Datem Limited 2014...

- Page 108 Technical Manual...

-

Page 109: Material Safety Data Sheets For Loctite 242 Threadlocker

Neptune 5000 Appendix C Material safety data sheets for loctite 242 threadlocker. This information covers all the requirements of the Health and Safety at Work Act 1974, Section 6, C.O.S.H.H and C.H.I.P. regulations. © Copyright Datem Limited 2014... - Page 110 Technical Manual...

- Page 111 Neptune 5000 © Copyright Datem Limited 2014...

- Page 112 Technical Manual...

- Page 113 Neptune 5000 © Copyright Datem Limited 2014...

-

Page 114: Material Safety Data Sheets For Hm10 Hydraulic Oil

Technical Manual Appendix D Material safety data sheets for HM10 hydraulic oil. This information covers all the requirements of the Health and Safety at Work Act 1974, Section 6, C.O.S.H.H and C.H.I.P. regulations. - Page 115 Neptune 5000 © Copyright Datem Limited 2014...

- Page 116 Technical Manual...

- Page 117 Neptune 5000 © Copyright Datem Limited 2014...

- Page 118 CPT market. With more than 30 Control & Acquisition Systems seabed systems worldwide Datem is one of the major manufacturers of CPT equipment. Subsea Electric Motors Our personnel are highly motivated, professionally...

Need help?

Do you have a question about the Neptune 5000 and is the answer not in the manual?

Questions and answers