Advertisement

Quick Links

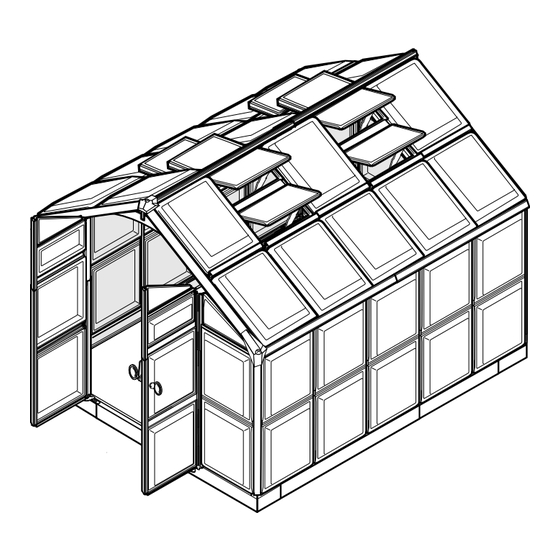

ASSEMBLY INSTRUCTIONS

Overall Dimensions

(Apprimate; Including base)

307 L • 252 W • 215 H cms

120-7/8" L • 99-1/4" W • 84.5/8" H

IMPORTANT!!!

Please read these instructions carefully before you start to assemble this greenhouse. To save time and

ensure proper assembly, follow the step-by-step instructions carefully in order. Assembly is easiest when

at least two people are present. Keep these instructions in a safe place for future reference.

An updated and/or improved version of this assembly guide may be available for download from the

HobbyGrower web site. Also, if you would like to view a brief general assembly video to gain a basic

understanding of how a HobbyGrower brand greenhouse is constructed, visit

http://www.hobbygrower.com, then click on the Assembly tab.

VER 02_11_04

PALRAM AMERICAS

Horticultural Products Division

P

A

L

R

A

M

Formerly SPS International

SAFETY ADVICE

• Do not attempt to assemble the greenhouse in

windy or wet conditions.

• Take special care not to touch overhead power

cables with aluminum profiles.

• Ensure that there are no buried pipes or cable in

the ground before inserting the ground stakes.

• Always wear shoes and saftey goggles during

assembly.

• We strongly recommend the use of work glove

during assembly as aluminum profiles may have

sharp edges.

• Dispose of plastic bags and protective poly film

covers safely - keep them out of reach of small

children.

• The greenhouse must be positioned and

anchored

GENERAL ADVICE

• Before beginning the assembly process,

confirm that all necessary parts have been

included in the package. It is advisable to lay the

parts out in an orderly fashion according to the part

numbers so that parts can be easily identified

during the assembly process. If parts are missing,

contact SPS International at (800) 994-5626.

• This is a multi-part assembly. Allow at least 8 to

10 hours to assemble from start to finish. Do

not begin assembly if heavy winds or rains are

expected within 14 hours.

• Choose a sunny level location for your

greenhouse, away from overhanging trees.

• You can opt to anchor your greenhouse to a

concrete floor, or you can use the supplied anchor

kit to anchor to soil or turf. If you intend to anchor

your greenhouse directly to concrete, you must

CARE & MAINTENANCE

• Use mild soap and water and a soft cloth to wash

greenhouse glazing panels. Rinse with cold water.

• Do not use acetone, abrassive cleaners or

sponges, or other amonia-based cleaners to clean

the clear panels.

• Some chemicals and cleaners can be agressive to

TOOLS & EQUIPMENT REQUIRED

• 100% "Silicone" Sealant

• Crosshead Screwdriver

(compatible w/polycarbonate)

(a.ka. "Philips")

• Tape measure

• Lubricant (mild soap & water

• Work gloves

solution works well)

• Plastic or rubber mallet

• Scissors

on a flat, level surface.

• Do not lean on or push against the greenhouse

during construction.

• Keep children away from assembly area - many

parts may have sharp edges.

• Do not position your greenhouse in an area

exposed to heavy wind.

• Do not attempt to assemble the greenhouse if

your are tired, have taken drugs or alcohol or if

you are prone to dizzy spells.

• If you use a step ladder, carefully follow the

manufacturer's instructions.

• Hot items such as recently used grills,

blowtorches, etc. must not be stored in the

greenhouse.

purchase separately concrete anchor screws.

• It is advisable to use lubricant to ease the

connection between aluminum profiles and panel

(a mild soap and water solution is useful for this).

• We strongly advise that you keep the special

poly-film protective covers on the side panels and

the first row of roof panels until the greenhouse is

fully assembled. You should however remove the

poly-film prior to installing the very top roof panels.

Also, if the panels will be in the direct sun, the

protective film should be removed. Otherwise the

film may become irreversably bonded to the

polycarbonate panel.

• Keep roof clear of snow and leaves.

the clear panels, which are made of

polycarbonate. For a complete list of chemical

compatibility, visit:

http://www.spscorp.com/compatibility

• To purchase replacement parts, contact customer

service at SPS International at (800) 994-5626.

• Step ladder

• Level

• Large Hammer (for anchor stakes)

• Drill and 5/64" drill bit

See next page for complete list of parts

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Palram MiniPro

- Page 1 • Use mild soap and water and a soft cloth to wash the clear panels, which are made of Overall Dimensions PALRAM AMERICAS greenhouse glazing panels. Rinse with cold water. polycarbonate. For a complete list of chemical (Apprimate; Including base)

- Page 2 CONTENTS CONTENTS ITEM QTY. ITEM QTY. ITEM QTY. ITEM QTY. 325mm 600x600mm 120mm 9 1390mm 1435mm 600mm M10d 600x600mm 1290mm 700mm 600x700mm 1290mm 408mm M601 600x700mm 590mm M606 330x600mm 1200mm 1490mm M602 1495mm M603 600mm M604 12mm 40mm 570mm 590mm 1230mm 1390mm 16 16mm...

- Page 3 Assembling the Base The short profiles M604 are to be used in the continuing assembly for Start assembling the base of the greenhousewith the following preparatory interconnecting all the rest base profiles (c). step: When performing this next connections step , verify that the small Observe the recess cut at the width of profile M601.

- Page 4 Lay the completed base in the position intended to be its correct As shown in drawing 3, assemble the complete greenhouse site, and secure it to the ground using pegs M56 base using all base profiles (M601, M602, M603, M604, M606) as in the drawing.

- Page 5 Door Assembly Select the square panel P2 (with the panel having the door Select profile A16/1290 mm handle hole). slide it unto the profile. Be careful to have the door handle hole on the left side (the opposing side to the IMPORTANT! aluminum profile A16).

- Page 6 We separately assemble now the window assembly (to be Take aluminum profile A38/590, with the flat rectangle side mounted later on). facing you, and slide it between panels P4 and P2, as shown. This is done in two stages, (a) and (b), respectively, where all It is advisable to use a lubricant to ease connection between the items are supplied in the “window kit”.

- Page 7 Take another panel P4 and thread it onto the free edge of Take panel P3 (be sure to position it so that the longer edge is aluminum profile A16/1290. vertical), having the assigned slot (see inset) at the bottom. Ensure that you slide it all the way down. Do not slide it all the way down.

- Page 8 To interlock the two panels, follow the steps below (as shown): Take aluminum profile A13/1390, and slide it all the way down (a) – pull the free edge of panel P3 towards you. along the matching slots on P3 and P4 but leave approximately 50mm (b) –...

- Page 9 Slide a new panel P4, all the way down along aluminum profile Take now one more P3 panel, and interlock it on top of P4, A13/1390. Note that it forms a 90 angle with the preceding P4 employing the same method you used in step 10. panel.

- Page 10 Take now a double sided interlocking aluminum profile Slide two more panels P4 and P3 (P4 first, P3 on it) – continue A11/1390 and slide it all the way down along the free vertical to add such P3 & P4 couples, interconnected by aluminum edges of P3 and P4 but leave approximately 50mm profile A11/1390, until you complete to construct a wall of five protruding at the top.

- Page 11 Add one additional P3 – P4 couple (P4 the lower one). We separately assemble now the vent assembly (to be mounted later on). This is done in two stages, (a) and (b), respectively, where all the items are supplied in the “vent kit”. (a) Installing the hinges.

- Page 12 Add one additional P3 – P4 couple (P4 the lower one). We continue now the construction of the Greenhouse’s rear wall. Slide now an aluminum profile A14/1390 along the free edge of the P3 – P4 couple (as shown by the arrows). 1390 1390 1390...

- Page 13 Slide an aluminum profile A11-590 from right to left onto the upper Verify that P3. P4 and P7 are perfectly aligned one above the edge of the panel P3, (a) in the drawing. Now slide the other. Slide aluminum profile A14/1435 all the way down to the vent assembly P7 (also from right to left).

- Page 14 On the two flanks of the vent (see arrows in Continue by adding one more P3 – P4 couple. drawing), slide two different aluminum profiles, namely profile A14/325 on your left and profile A14/600 on your right (as clearly shown in the drawing), until they are positioned at the top of the existing aluminum profiles below them.

- Page 15 At the free edge of the structure (panels P3 & P4) insert Mounting the Second vent. (a) First, slide down P7 unit interconnecting aluminum profile A14/1390, pushing it all the (vent) down the A14/600 profile. Do not push it all the way way down.

- Page 16 Interlock panels P4 and P3 to the right (free edge) of the existing Slide the corner building aluminum profile A13/1390 at the structure, (a) and (b) respectively. Now, (c): on the right (as you free edge, as shown. see) of the second vent, slide panel A14/325. Note that here position it so that the lower top point of the slanted edge should be on the right.

- Page 17 Now, that the rear wall is nearly completed, mount the triangular Repeat the operation (similar steps) with the inner triangles panels P6 (matching the roof support structure). P6, executing the same (a) and (b) operations as in step 27. This is a two stages step. First, slide the outer ones (a) (note directions in the drawing) to interlock with aluminum profiles A14/325, not all the way down.

- Page 18 Continue by forming the other side wall: interlock a P4 – P3 (a) Slide aluminum profile A16/1290 downwards. Pay attention panels couple, followed by sliding an aluminum profile A11/1390, to mount it in the correct direction, so that after interlocking continuing as in step 15 until you complete construction of wall the door panels (P4, P1) on it, the door would open outwards.

- Page 19 By the following four steps, we apply a protection structure to Insert right angle corner M37 (a).into aluminum profile A11/590 the bottom of the left door. (a) Take angle bar M9, slide unto (at the bottom of the door). aluminum profile A16/1290 until it latches into the groove at the Continue by attaching flush with it door stop M48 (b), slide profile bottom of panel A16.

- Page 20 Complete the assembly and strengthening of the other door base Proceed with the operations strengthening the other door's base: (right hand side one) following the same steps as before, namely: insert right angle M9 into the door axis profile A11/590 (a); slide insert right angle M9 into the door axis profile A16/1290 (a);...

- Page 21 An aluminum profile A11/650 is now applied to the left half of Proceed now to form a peripheral strengthening “belt” at the the front base. Half its length will be interlocked with the extreme bottom of the structure (excluding the front side bottom, (explained left panel P4, while the other half remains unconnected under later).

- Page 22 The same process as in step 36 above (but with directions Take metal profile M43 and mount on both its side item M42, reversed) is used to form the right hand half of the bottom base, secure it using screws M29. for right hand side door and adjacent panel P4.

- Page 23 Have two or three persons to carefully lift up the assembled In order to secure the structure unto the base, partially release greenhouse structure and lay it accurately on the fixed down screw M29. base.

- Page 24 Tighten as much as necessary screws M29 (which were partially Connect the greenhouse structure to the base using part M53. loosened - step 40) all along the metal part M43. At Please follow these steps: (a) & (b) Insert part M53 through the both ends of M43 part the screws go through M42 and openings in the metal base and push it into the aluminum profile 11.

- Page 25 Assemble triangle panels P6 into profile A16/408 with the aid Tops of Doors of A11/570. Extend upwards the axis A16/1290 of the two doors (left and right), by first inserting profiles (one each) M10/120 into top of profiles A16/1290 (in both of its two vertical members). Proceed by inserting profile A16/408 into M10/120 concurrently with sliding along top panels of the doors.

- Page 26 Extending the Doors Upwards Using profile A11/590, mount triangle panel P6 on top of panel Take panel P5 and profile A38/590, and install them exactly as done in step 7.

- Page 27 Roof Assembly Insert bridging connector M10/120 into A15/1290. Extend profile Slide two profiles A39/1490 along the two sides (a) of the A15/1290 (with the protruding bridging connector) upwards by greenhouse. Insert a joining bar M10D between each pair to interlocking it with profile A15/700, while threading A15/700 strengthen the join (b).

- Page 28 Slide two corner profiles A13/1390 (one on each side) on triangle Slide two panels P4 onto the profiles A39/1490, one on each panels P6, simultaneously with sliding along panels P4 (just side (this is the beginning of installing the panels on the roof). mounted).

- Page 29 Slide two additional panels P4 (a) into corner profiles A13/1390 (a) Slide apex aluminum profile A40/1495 to fasten apex panels (one on each side), and interconnect each P4’s couple (one on each side) by inserting profile A11/590 between them (b). (b) On each side of the roof, slide from the front backwards, two panels P4 (one on each side) along A39/1490, until it touches the previously mounted roof panels.

- Page 30 (a) Take two assembled vent assemblies P7 and slide them Slide an A11/1390 profile (one on each side) along the two along the just inserted profile A11/1390. slanted P4 panels, interlocking with just added P4 panels. (b) Join the vent with panel P4 under it by driving profile A11/590 between them.

- Page 31 Drive the apex profile A40/1495 forward, but do not pass the (a) Along profiles A11/1390, slide one more vents P7 on top front edges of the windows. of the previous ones. (b) Secure them by introducing profile A38/590. IMPORTANT – ensure that the flat rectangular surface is facing outwards 1495 1495...

- Page 32 Continue the roof assembly operation by repeating the steps Same as step 51 done so far. 1390 1390...

- Page 33 (a) .Insert a joining bar M10d between existing apex profile Same as step 57 A40/1495 and an additional A40/1495 on the outside. 1495 1495 M10d 1390 1495 1495 1390 M10d...

- Page 34 Same as 54 (you continue going around the Greenhouse Install the two upper vents and their fastening by profile structure). A38/590.

- Page 35 Same as step 56. Continue assembling P4 roof panels as in the preceding steps, all the way to the front roof panels. Conclude by pushing A40/1495 all the way to the front. 1390 1390...

- Page 36 Continue assembling P4 roof panels as in the preceding steps, Hold fastening / bridging unit M44 along the front apex of the all the way to the front roof panels. roof (front edges of P4). Conclude by pushing A40/1495 all the way to the front. Slide corner profile A13/1390 so that it connects the right hand front edges of P4’s and the slanted top of M44.

- Page 37 Use pairs of roof brackets “M46/M50” to clamp each wall section Use pairs of roof brackets “M45/M50” to clamp each roof section where shown (in small circles, side walls to roof joints). Fix where shown (along the apex - in small circles). Fix each bracket bracket in place using 12 mm screws M22.

- Page 38 From inside the greenhouse, apply silicone sealant to all the Attach corner caps C55 in all six positions (front and back) using roof joint gaps as shown. screws M22 - 40mm.You will need someone to help you with the step Inject the silicone generously until it oozes from the other side.

- Page 39 Connect parts M49 and M52 to M44 as shown in the drawing. Install door handle M19 in the hole bored the in right hand side These two items constitute the Left Hand door's stopper. door. See inside / outside proper mounting position. INSIDE OUTSIDE DOOR...

Need help?

Do you have a question about the MiniPro and is the answer not in the manual?

Questions and answers