Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Anets A8

-

Page 2: Table Of Contents

Contents INTRODUCTION ..........................2 A. Security Considerations ....................... 3 B. Product Details ..........................4 1.Specifications .......................... 4 2.Machine parts ......................... 4 3.Extruder drawing ........................5 4.Tool List ..........................6 C. Cura Software ..........................9 1.Installation of Cura14.07 ......................9 1.1 File location in the TF card .................... 9 2. -

Page 3: Introduction

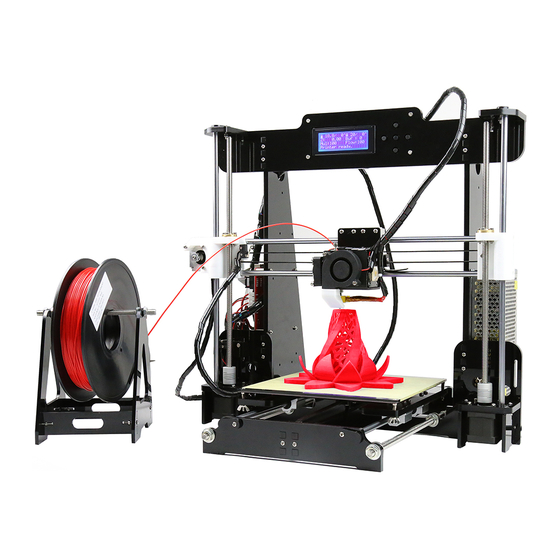

INTRODUCTION A8 FDM 3D printer can print CAD 3D printer model to real . A8 uses Acrylic to build its frame while it uses linear bearings , belts and threaded rods to build X , Y , Z axis . -

Page 4: A. Security Considerations

A. Security Considerations To avoid danger when using 3D printer , please pay attention to precautions below . Danger During Operation , the maximum temeprature of nozzle can be 260 ℃ while hotbed can be 100 ℃ . For your safety , during printing or cooling down , do not touch the nozzle , hotbed and models under printing . -

Page 5: B. Product Details

B. Product Details 1.Specifications Model:A8 Nozzle diameter: 0.4mm Layer thickness:0.1-0.3mm Machine size: 500*400*450mm Printing speed:10-120mm/s Machine weight:7.5KG X Y axis position accuracy:0.05mm Packing size:510*345*215mm Z axis position accuracy:0.015m Gross weight:9.2KG Printing material:ABS,PLA Build size:220*220*240mm Material tendency:PLA LCD screen:Yes Filament diameter :1.75mm Offline printing:SD CARD... -

Page 6: Extruder Drawing

3.Extruder drawing Part Name Quantity Extruder Motor Blower Wind Mouth Nozzle ( 0.4mm) 1 Heating Block Throat Fan Cover Heat Sink Extruder Seat Bend Parts Brass Wheel U-Bearing Briquetting Spring Heating Pipe... -

Page 7: Tool List

4.Tool List... -

Page 10: C. Cura Software

C. Cura Software 1.Installation of Cura14.07 a: Where can I find the software? 1) SD card with shipment; 2) download from Internet; b: Installation process 1) From SD card with shipment Insert SD card and open the file 1.1 File location in the TF card 1)Insert SD card , open the file... - Page 11 2) Download from Internet Official Website:https://ultimaker.com/en/cura-software/list Choose corresponding software to download...

- Page 12 b.Software Installation Process 1. Installation Positioning 2. Click Next Choose 3 options below 4. Click Install...

- Page 13 Please wait for installation 1.Click Next...

- Page 14 1.Installation Success 2.Click to finish Installation complete Click Next...

- Page 15 1.Choose to run Cura 2. Click to finish Click Next...

- Page 16 1.Choose other to customize 2.Choose this option 3.Click Next...

- Page 17 1.Choose to customize 2.Click Next...

- Page 18 This is A8 parameter You can customize name here. We default these data . You can fill in according to actual condition Choose this option DO NOT choose this option !!! 1.Click to finish...

-

Page 19: Cura Setting

Now you have finished the installation. Next , enter Cura . 2. Cura Setting 2.1 Clear platform Delete the dog. Two ways for you : 1.Move mouse to dog ,right click, click “delete object”. - Page 20 2.Left click “File” , choose ”Clear platform”.

- Page 21 Switch to full settings for parameter setting Open file:A8 Cura 14.07.ini...

- Page 22 Position of configuration file: Computer/SD card)/ configuration file for cura-14.07 (suggestion :keep this file copy to your computer) After Loading,the basic and advanced configuration will be changed to the A8 regular printing configuration.

- Page 23 If print once at a time , it will influence the printing quality, even cause damage to priner. So please choose “Printer at once”.

-

Page 24: Layer Height Settings

2.3 Layer height settings Layer height:0.1mm cost long time but have the best printing precision. 0.2mm cost half time compared to 0.1mm , but have general printing precision. 0.3 cost less time with not good precision. It defaults 0.2mm. Left: 0.1mm Right:... - Page 25 The Blue line is the leak filament Enable retraction Enable retraction to avoid filaments leakage when nozzles move in empty area Bottom/Top thickness: 1.2mm Under the same fill density When fill density is less than 20%, it’s easy for 0.6mm thickness to cause hollow on the top.

- Page 26 Bottom/Top thickness setting Fill Density Setting Fill Density: If strength requirement is not so high , set 10% is ok. Please improve fill density when strength requirement gets higher. Printing time will go up as well. Printing Speed setting This is default speed. If other settings aren’t changed, it prints more accurately while the printing process takes more time.

- Page 27 Original Model Support type: None Support type: Touching Support type: Everywhere Support type setting buildplate Attention: Normally we add support to complex model or model with vacant parts. It may have influence on the surface if you choose everywhere. You’d better circle around the model and try to avoid unnecessary support.

- Page 28 None: no support Brim:Touch with the adge Support setting Raft: Totally touch with the bottom Attention: please choose None if the printing platform is ready and the high temperature adhesive tape is good. Please choose Brim when the model is small . Choosing Raft makes it difficult to seperate model from the platform...

- Page 29 Attention: A8 use 1.75mm filament Attention: Flow is proportion of filament , we suggest to use 100 Increasing flow & decrease diameter has the similar effect. Model surface gets many bumps when flow is too big;model frame gets flimsy if flow is too small.

- Page 30 Attention:Normally this option cannot be changed , if changed ,it’s at your peril. Attention:Normally this option cannot be changed , if changed , it’s at your peril. Starting Ending code code...

- Page 31 3.Expert Setting...

- Page 32 1. The minimum length before retraction . Used to avoid frequent retraction. No need to change. 2. Enable Combing: Digital for surface quality , the nozzle will try not to go through surface , that’s why Cura is better than Slic3r. 3.

- Page 33 Skirt is to avoid extruder unfilled before printing , and it appears only when platform attachment type is None. Normally “1” is ok . Change it to “0” when your model reaches the maximum size , or the printing size will be too big. Peripheral line quantity: 1 Peripheral line quantity: 1 Start distance: 3...

- Page 34 1. To ensure the attachment of model to platform , fan won’t start at the beginning. 2-4. Fan speed min & max : If they are not equal , the soft ware will choose a suitable speed during them. 5. Condition to choose cool head lift : When it’s printing with the minimum speed but still cannot reach the minimum time , you need to choose cool head lift .

- Page 35 If no solid infill top , the only qualification is the surface thickness . Please check the detail below. With solid infill top No solid infill top...

- Page 36 With solid infill bottom No solid infill bottom Infill coverlap: 40 Infill coverlap: 20...

- Page 37 Structure types:lines Structure types:lines Structure types:grids Infill covertap: 15 Infill covertap: 30 Infill covertap: 15 Distance X/Y: 0.7 Distance X/Y: 0.7 Distance X/Y: 0.7 These above are examples , you can set these options according to actual requirements. The biggest progress Cura has made is the kinds of support structure types , making it easier to seperate from the model.

- Page 38 30° 45° 60° It’s difficult to seperate if the distance between support and the supported place is too close; The surface will be influenced if the distance is too far. Different angle will generate different support , you can try the examples we provide above which will have different effect.

- Page 39 When choosing “Spiralize When choosing “Only follow the outer contour” : Z axis mesh surface” : The nozzle rises while X,Y axis moves , prints along the surface. and only a hollow bottom and a single layer of surface. Attention: The software defaults not open the option above , you’d better not turn it on .

- Page 40 Brim line amount: 20 Brim line amount: 10 Guidance to use Brim if needed: Expert → Expert Settings → Support → Support Types → Birm. The images above are only for reference , please set the parameter according to actual requirement.

- Page 41 Guidance to use Raft if needed: Expert → Expert Settings → Support → Support Types → Raft. The images above are only for reference , please set the parameter according to actual requirement.

- Page 42 Link to Youmagine Load model Save the Gcode file Model Display Estimated Print Time Estimated Length of Filament Scaling Whirling Mirroring Left click the model and you will see the icon of “whirling, scaling, mirroring. Left click to select model and move → move model. Slide mouse wheel →...

- Page 43 Green: X axis Yellow: Y axis Place platform Reset Red: Z axis Zoom to max size Scaling ratio Modification ratio Reset...

- Page 44 Z axis mirroring Z axis mirroring Z axis mirroring Attention: The model will be converse after mirroring.

- Page 45 Overhang: Used to see the vacant part. Normal: Most used. X-Ray Transparent Layers:Used to simulate the effect of each layer and the path.

- Page 46 Right click model → Left click “Multiply object” → Example: copy 4 model 5 models in total Attention: You can try other functions by yourself.

-

Page 47: D. Printing Operation

D. Printing Operation 1. Introduction of Display Current extrusion rate... -

Page 57: Install Filament

2.Install Filament 2.1 Set Preheat Mode... -

Page 58: Filament Installation

2.2 Filament Installation... -

Page 60: Pull Out Filament

2.3 Pull out filament... -

Page 61: Platform Adjustment

3. Platform Adjustment... -

Page 63: Printing

4.Printing ) SD Card Offline Printing a. Loading mode Cura supports STL file & G-code file. Code Saving Copy file to SD card . Then connect SD card to printer, click reset. Picture below shows the location of print file , there are 2 methods to find print file c. - Page 64 The printer will start printing d. Print model automatically when the extruder & hotbed reaches estimated temp after you choose print model . Attention: If the print bottom fails to stick to platform tight , you can adjust the platform to make it tight during printing. e.

- Page 65 2) USB Online Printing a.Machine settings ( Use USB to connect to PC ) b. Online Pringting...

-

Page 66: E. Faq And Solution

E. FAQ and Solution 1. Z Axis Ajustment During installation, we need to test moving parts: 1. Preparation: Before Z axis moving adjustment, please confirm the height of both Z aixs screw support is the same. ( Keep the same height of two white parts ) - Page 67 2.Ajust concentricity 1. Click to adjust Z axis to move ( Position → Z pos.Fast → +/- ) . If it cannot move smoothly, you need to adjust the unsmooth side’s screw support. Try to keep them at the same height. 2.

-

Page 68: Nozzle Blocking

2. Nozzle blocking Tips: We have removed fan to show obviously. Please cosider movement according to actual requirment. A. Only a little filament left in the nozzle and difficult to take out:... - Page 69 B. Filament full filled in spout...

- Page 70 3. FAQ Symptom Reason Method Print model Synchronous Tighten set screws dislocation wheel/belt loose. or fasten belt Extruder temp is too Glitch with the Too high temp or high and retracting print model slicing problem. speed & distanse is too small Rise extruder temp or check if brass nut Low temp or not...

-

Page 71: F. Maintenance

F. Maintenance Important maintenance tips: 1. maintenance of X,Y,Z axis: Add some lubricants on the rods to reduce friction when the machine works noisy and a little bit shake. 2. Please refer to the USER MANUAL before printing, do preparation of hot bed adjustment first. -

Page 72: G. Maintenance Policy

G. Maintenance policy 1. This product executes regulations of “Product Warranty Card”. 2. Please contact supplier or customer service if the product have any problems . Do not repair it by yourself, otherwise you need to bear all the consequences.

Need help?

Do you have a question about the A8 and is the answer not in the manual?

Questions and answers