Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Moog DS2000

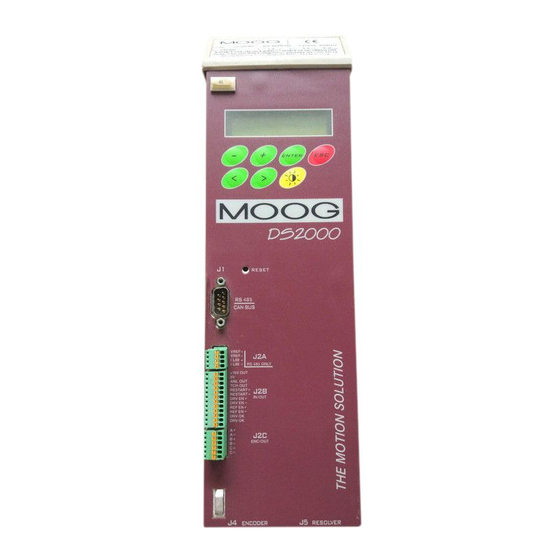

- Page 1 DS2000 USER'S MANUAL (rev.C) GB-4534...

- Page 3 G motor resolver connection, APHAPOS Par. 2.11.2.1, parameter, update figures Size E, update section 2.11.3.2, 3.3.4, 8 – Restart Interlock Function, correct 6.2.1, 6.2.2, 6.3.1, miscellaneous errors 6.7.1.5 Fig. 2.4.1, 2.5, 2.6, 2.8, 2.8.1, 2.14, 3.5.1 Section 8 DS2000 USER’S MANUAL (rev.C)

-

Page 4: Table Of Contents

2.11 Drive starting sequence 2.12 Starting sequence times 2.13 Dynamic braking 2.14 Power off 2.15 Mechanical braking 2.16 Introduction Section 3 European directive (89/336/EEC) Electromagnetic Filters compatibility (EMC) Wiring and grounding Recovery resistor Screening Safety aspects DS2000 USER’S MANUAL (rev.C) - Page 5 Installation and routine test 8.11 RIC identification on the nameplate 8.12 Appendix A - Motors technical data Appendix Appendix B - FC series technical data Appendix C - Active software release Appendix D - Obsolete software release DS2000 USER’S MANUAL (rev.C)

-

Page 6: Introduction

This manual refers to DS 2000 “The Motion Solution” drive, with SW Release 3.20X. The manuals from 0 to 3 release refers to DS2000 drives and SW release below 2.00X. The manuals from 4 to 5 release refers to DS2000 “The Motion Solution” drive, with SW release 3.00X and 3.10X. -

Page 7: Using The Manual

This manual provides the necessary information for a proper installation and use of the DS2000 servodrive. The DS2000 was designed to be easily installed; it is not necessary any specific skill concerning servodrives to start it up. Anyway, the installer should have basics of electronics/electrotechnics, of servodrives, and of safety. -

Page 8: Accident Protection

2 of this manual for the tightening torque of terminal blocks). Tightening torque Screw thread [Nm] [lb in] 1.00 8.85 3.00 26.55 6.00 53.10 8.00 70.80 20.00 177.00 DS2000 USER’S MANUAL (rev.C) -

Page 9: Ec Declaration Of Conformity

INDEX I.4 EC DECLARATION OF CONFORMITY DS2000 USER’S MANUAL (rev.C) -

Page 10: Ec Requirements

EMC standards. Large-Scale Stationary Industrial Tools (WEEE, RoHS). Equipment intended for installation as part of large-scale stationary industrial tools, covered by the exception of Annex IA, No.6, of the European Directives 2002/96/EC (WEEE) and 2002/95/EC (RoHS). DS2000 USER’S MANUAL (rev.C) -

Page 11: Ul Authorization

INDEX I.6 UL AUTHORIZATION (page 1) DS2000 USER’S MANUAL (rev.C) - Page 12 I.10 INDEX UL AUTHORIZATION (page 2) DS2000 USER’S MANUAL (rev.C)

-

Page 13: Ul Requirements

5000 rms Symmetrical Amperes, 460 V +10% maximum” DS2000 60/180, 100/300: “Equipment suitable for use on a circuit capable of delivering not more than 10000 rms Symmetrical Amperes, 460 V +10% maximum”... - Page 14 Littelfuse Inc 1500 85°C (10x1000µs) 550 V S14-K-550 1500 85°C A and B (2ms) AS5046 Epcos Ohg size 550 V S20-K-550 1500 85°C (2ms) S A BC 550 V 2322 595.551 1500 85°C Components NV (10x1000µs) DS2000 USER’S MANUAL (rev.C)

-

Page 15: Icepi Certificate

I.13 INDEX I.8 ICEPI CERTIFICATE DS2000 USER’S MANUAL (rev.C) -

Page 16: Safety Requirements

WARNING: When the Restart Interlock Circuit is activated, the motor can no longer generate a torque. Motors which are not automatically clamped when powered down (e.g. vertical/inclined axes), must be clamped using a mechanical brake DS2000 USER’S MANUAL (rev.C) - Page 17 INDEX I.10 LEGAL ASPECTS This manual can be used only by final Customers/Users of the Moog product it describes and only for proper installation purposes. This manual cannot be reproduced in whole or in part without the prior written consent of Moog.

- Page 18 I.16 INDEX THIS PAGE INTENTIONALLY BLANK DS2000 USER’S MANUAL (rev.C)

- Page 19 SECTION ONE – DESCRIPTION 1. DESCRIPTION 1.1 INTRODUCTION This section describes the DS2000 drive series, providing information about the coding system. Such data allow understanding the DS2000 characteristics and makes clear the necessary concepts to access the following sections. DS2000 USER’S MANUAL (rev.C)

-

Page 20: Product Range

The recovery resistors are placed outside the drive; only the 3, 4, and 6 A models can be equipped with built-in recovery resistor (optional). DS2000 drive is provided together with this manual and the Application Notes in the Appendix of DS2000 user’s manual, for a deep understanding and the best use of the product. 1.3 GENERAL FEATURES... -

Page 21: Technical Data

50 to 1500 Hz Output current Mass Model Size Nominal Peak (kg) 4/12 6/15 10.6 8/22 15.6 14/42 29.7 20/45 31.8 25/70 49.5 30/90 63.6 50/140 99.0 60/180 127.3 100/300 212.7 Tab. 1.0 – Mechanical and electrical characteristics DS2000 USER’S MANUAL (rev.C) - Page 22 1.4.3 OTHER MECHANICAL SPECIFICATIONS 1.4.3.1 IMMUNITY TO MECHANICAL VIBRATION 0.075mm amplitude from 10 Hz to 57 Hz, 1g acceleration from 57 Hz to 150 Hz (according to EN 50178:1997 and to IEC 68-2-6:1995, Fc test). DS2000 USER’S MANUAL (rev.C)

- Page 23 • Recovery resistor overload (software selectable) • Over speed in torque mode control (if speed is 12% above max set value). • IGBT over temperature (software selectable) • Anti-free-wheeling (software selectable) • Safety – Restart interlock function (optional). DS2000 USER’S MANUAL (rev.C)

-

Page 24: Standard Versions Codes

SECTION ONE – DESCRIPTION 1.5 STANDARD VERSIONS CODES DS2000 drives are marked by a code identifying both the current supplied by the Model and the eventual internal recovery resistor. Codes correspond to: • Standard Italian software drives • 6 poles resolver (transformation ratio:0.29), ¼ marker configured, 1024 simulated encoder pulses •... -

Page 25: Special Versions Codes

• Mating connectors provided with the drive The following table summarizes the drive codes: Model Size Code Type CZ1100C0A CZ1101C0A 4/12 CZ1102C0A 6/15 Tab. 1.2 – Special versions codes Additional informations can be found in Section 2 and Section 5. DS2000 USER’S MANUAL (rev.C) - Page 26 SECTION ONE – DESCRIPTION Fig. 1.1 – Table of DS2000 codification DS2000 USER’S MANUAL (rev.C)

-

Page 27: Options

1.8 SERIAL NUMBER – NAMEPLATE Each drive is provided with a serial number identifying the Model, any eventual option and the manufacturing date. This number is a useful tool to verify, through the Moog Database, the original software and firmware revision. - Page 28 1.10 SECTION ONE – DESCRIPTION THIS PAGE INTENTIONALLY BLANK DS2000 USER’S MANUAL (rev.C)

- Page 29 SECTION TWO – WIRING AND INSTALLATION 2. GENERAL INFORMATION 2.1 INTRODUCTION This section describes the installation, wiring and cabling of the Moog DS2000 servo drive series. Such information allows the understanding of DS2000 functionality and makes clear the necessary concepts to access the following sections.

-

Page 30: Dimensions And Drilling Jig

SECTION TWO – WIRING AND INSTALLATION 2.2 DIMENSIONS AND DRILLING JIG Fig. 2.1 – Size A dimensions and drilling jig (mm) DS2000 USER’S MANUAL (rev.C) - Page 31 SECTION TWO – WIRING AND INSTALLATION Fig. 2.2 – Size B dimensions and drilling jig (mm) DS2000 USER’S MANUAL (rev.C)

- Page 32 SECTION TWO – WIRING AND INSTALLATION Fig. 2.3 – Size C dimensions and drilling jig (mm) DS2000 USER’S MANUAL (rev.C)

- Page 33 SECTION TWO – WIRING AND INSTALLATION Fig. 2.4 – Size D dimensions and drilling jig (mm) DS2000 USER’S MANUAL (rev.C)

- Page 34 SECTION TWO – WIRING AND INSTALLATION Fig. 2.4.1 – Size E dimensions and drilling jig (mm) DS2000 USER’S MANUAL (rev.C)

-

Page 35: External Fuses

3A / 250V Delayed fuse DS2000 MODEL Notes E size 100/300 Short Circuit 10000 rms Amps symmetrical Rating Power line fuse 315-FM Semiconductor 24 V auxiliary power supply 3A / 250V Delayed fuse Tab. 2.1 – Recommended fuses DS2000 USER’S MANUAL (rev.C) -

Page 36: Power Dissipation

Tab. 2.2 – Power dissipation at nominal current 2.5 SOFT-START The soft-start circuit (current limit at start-up) is included in the drive input stage. Additional data about the soft-start circuit can be found in the Section 5. DS2000 USER’S MANUAL (rev.C) - Page 37 53 ± 2 88 ± 2 88 ± 2 D [mm] 20.5 ± 1 30.5 ± 1 30.5 ± 1 39 ± 2 76 ± 2 76 ± 2 Tab. 2.4 – Mechanical data of recovery resistor DS2000 USER’S MANUAL (rev.C)

- Page 38 SECTION TWO – WIRING AND INSTALLATION 2.7 FANS DS2000 ventilation is provided by one or more fans mounted over the drive and under only for size E. The fans input power is internally supplied except for size E (option “internal 24V”) CAUTION: A free air circulation must be ensured for a proper operation as per the following table..

- Page 39 Shielded Motor resolver 22/20 AWG Shielded Tab. 2.6 – Wiring size CAUTION: To connect more than one drive through the DC BUS (+/-HV), please ask the Service Center. 2.10 AWG/mm CONVERSION Tab. 2.7 – AWG/mm conversion DS2000 USER’S MANUAL (rev.C)

- Page 40 SECTION TWO – WIRING AND INSTALLATION 2.11 WIRING AND CONNECTORS NOTE: Moog DS2000 drives are equipped with all the necessary connectors for a proper operation. It is not necessary to indicate the connectors, or the recovery resistor in the purchase order. All of them are included in the drive code.

- Page 41 Tab. 2.9 – Ground screw, size A and B NOTE: In an especially noisy environment (from an electromagnetic point of view) it can be useful to connect the motor ground (pin 7 of J6 connector) to the ground screw. DS2000 USER’S MANUAL (rev.C)

- Page 42 Phase "L2", three-phase voltage input 230/460V ±10% Phase "L1", three-phase voltage input 230/460V ±10% RR (+ATP) External recovery resistor and +HV of DC BUS External recovery resistor Tab. 2.10 – J6 input power connector, size C DS2000 USER’S MANUAL (rev.C)

- Page 43 Tab. 2.14 – Ground screw, size C NOTE: In an especially noisy environment (from an electromagnetic point of view) it can be useful to connect the motor ground (pin 4 of J7 connector) to the ground screw. DS2000 USER’S MANUAL (rev.C)

- Page 44 The relevant contacts (Molex type 42815-0031) are supplied together with J6, J7, and J9 mating connectors for C size DS2000 drives. These contacts are sized for an 8 AWG (8.4 mm2) cable with a 10 mm wire stripping. It is recommended the use of a Molex crimping tool type 63814-0000, or Molex type 63811-1500, or equivalent.

- Page 45 000 (Moog code AK4967). Pos. Name Function 1 ■ +24V Auxiliary voltage inputs 24 V ±10%, 2A (pin 2 is connected to drive logic 0) 0V (24V) Tab. 2.14D – J8 auxiliary input power supply connector, size D DS2000 USER’S MANUAL (rev.C)

- Page 46 Tab. 2.16D – Ground screw, size D NOTE: In an especially noisy environment (from an electromagnetic point of view) it can be useful to connect the motor ground (terminal 10 of J9 connector) to the ground screw. DS2000 USER’S MANUAL (rev.C)

- Page 47 000 (Moog code AK4967). Pos. Name Function 1 ■ +24V Auxiliary voltage inputs 24 V ±10%, 2A (pin 2 is connected to drive logic 0) 0V (24V) Tab. 2.14E – J8 auxiliary input power supply connector, size E DS2000 USER’S MANUAL (rev.C)

- Page 48 If the value of capacitance of motor and cables, seen from drive output, exceeds 30 nF it is necessary to verify with Moog technicians the need of an adequate choke in series. MOTOR...

- Page 49 The connectors are common to all drives sizes and are all located on the control card. Drive control panel – Frontal view Drive control panel – bottom view Note: Pin 1 is marked with the symbol “■” Fig. 2.10 – Control card connectors DS2000 USER’S MANUAL (rev.C)

- Page 50 As an alternative to the serial interface, the J1 connector can contain the CAN BUS serial interface with the same external connector. For Can Option make reference to the applicative Can Open manual. • Mating connector: female, Sub-D 9 pos. (Moog code AK4751) Pos. Name Function 1 ■...

- Page 51 Analog references (speed and current limit references) are available on the J2A connector. The conductors are fastened by insertion, opening the connector using a screwdriver. • Mating connector: insertion type, 4 poles (Moog code AK4714). Pos. Name Function Differential, non-inverted input of speed or torque reference signal (0÷...

- Page 52 Drive enable, Drive OK signals, Tacho out, Analog out, and Reference enable are available on the J2B connector. The conductors are fastened by insertion, opening the connector using a screwdriver. • Mating connector: insertion type, 12 pin (Moog code AK4722). Pos. Name Function 1 ■...

- Page 53 2.11.2.4 ENCODER OUTPUT CONNECTOR (J2C) Encoder simulated output are available on the J2C connector. The conductors are fastened by insertion, opening the connector using a screwdriver. • Mating connector: insertion type, 6 pin (Moog code AK4716). Pos. Name Function 1 ■...

- Page 54 J2C connector. The mating encoder connector at drive side is a Sub-D 15 pos., to be soldered (Moog code AK5221). It is recommended to use a low capacitance, multipolar cable with 22 AWG (0,30 mm2) or 20 AWG (0,50 mm2) conductors, shielded (with 85% min.

- Page 55 2.27 SECTION TWO – WIRING AND INSTALLATION MOTOR DS2000 PTC GND GND (PTC) Shield connected to the Shield connected to housing by connector clamp the housing by connector shell Fig. 2.13 – Encoder connections DS2000 USER’S MANUAL (rev.C)

- Page 56 Common Common input for CW LS, CCW LS and Tc/Vc to be connected to 0L N.C. Not Connected N.C. Not Connected N.C. Not Connected N.C. Not Connected N.C. Not Connected Tab. 2.20A – J4 Limit Switches connector DS2000 USER’S MANUAL (rev.C)

- Page 57 The mating resolver connector is a male Sub-D 9 pos., to be soldered, provided together with the drive (Moog code AK5220). It is recommended to use low capacitance, multipolar cable with 22 AWG (0,30 mm2) or 20 AWG (0,50 mm2) conductors, each pair twisted and shielded, with an independent overall shield (with 85% min.

- Page 58 2.30 SECTION TWO – WIRING AND INSTALLATION Fig. 2.14 – Resolver connections DS2000 USER’S MANUAL (rev.C)

- Page 59 2.11.3.1 FAS T/FAS K/FAS N/FAS Y/FAE CONNECTION MOTOR RESOLVER CONNECTOR SIGNAL TYPE COS- COS+ SHIELD SEN- SEN+ PTC_MOTOR 10kHz- PTC_MOTOR 10kHz+ Tab. 2.22 – Resolver connectors MOTOR ENCODER CONNECTOR SIGNAL TYPE B and V PTC_MOTOR Tab. 2.23 – Encoder connector DS2000 USER’S MANUAL (rev.C)

- Page 60 2.32 SECTION TWO – WIRING AND INSTALLATION MOTOR POWER CONNECTOR SIGNAL TYPE MOTOR POWER CONNECTOR SIGNAL TYPE Tab. 2.24 – Power connectors DS2000 USER’S MANUAL (rev.C)

- Page 61 Drive resolver connector Name Pin Name on Motor resolver connector Pin No. G motor Pin No. 1 ■ COS+ COS- SHIELD SEN+ SEN- PTC_MOTOR THERM 1 10kHz- PTC_MOTOR THERM 2 10kHz+ Tab.2.25B – Old resolver connection scheme DS2000 USER’S MANUAL (rev.C)

- Page 62 The ground (pin 3, drive side) has to be connected to the motor connector housing. Several motor G have as standard a NTC for thermal feedback, the DS2000 can manage PTC sensor or NTC sensor without any hardware change (see Section 6 for additional data).

-

Page 63: Soft-Start

SECTION TWO – WIRING AND INSTALLATION 2.12 DRIVE STARTING SEQUENCE In order to properly power and enable DS2000 “The Motion Solution” series drives, it is necessary to follow a start-up sequence, in which the minimum times to fall within are indicated in order to allow the internal circuits to reach the operating voltage levels and to make the internal devices ready for enabling. - Page 64 • RESET is necessary only after the first drive start-up or, in case of FAULT, to restore the proper operation of drive. • DRIVE OK signal depends upon the three-phase voltage presence, in order to allow a quick and immediate enabling of motor torque. DS2000 USER’S MANUAL (rev.C)

- Page 65 • t after 100 ms (this time can be increased in case load inertia is much bigger than motor inertia) the DRIVE ENABLE can be removed = 100 ms Fig. 2.16 – Dynamic braking sequence times DS2000 USER’S MANUAL (rev.C)

- Page 66 Three-phase input voltage release delayed time in order to avoid the undervoltage FAULT. • t DC BUS discharge time = 100 ms, t = 15 ms, t = 6 min. (to access the drive). REFERENCE ENABLE DRIVE ENABLE 230/460 Three-phase Fig. 2.17 – Power-off sequence times DS2000 USER’S MANUAL (rev.C)

- Page 67 Note 2: For FASTACT motors, size 3 and size 4, t ≥ 1000 ms DRIVE ENABLE 24V BRAKE POWER SUPPLY BRAKE RELEASE CLAMP REFERENCE ENABLE MOTOR 0 rpm SPEED Fig. 2.18 – Mechanical braking sequence times DS2000 USER’S MANUAL (rev.C)

- Page 68 2.40 SECTION TWO – WIRING AND INSTALLATION THIS PAGE INTENTIONALLY BLANK DS2000 USER’S MANUAL (rev.C)

-

Page 69: European Directive (89/336/Eec)

Compliance with the European Directive 89/336/EEC is required for all electric and electronic products brought onto the European market after December 31st, 1995. DS2000 drives meet the following EMC product standard related to the Directive: EN 61800-3:1996 and EN 61800-3/A11:2000: "Adjustable speed electrical power drive systems. -

Page 70: Filters

* = the FN2070-3-06 filter have faston at both sides * = the FN250-6/07 filter have wiring leads (length=300mm) at both sides * = the FN250-12/07 filter have wiring leads (length=300mm) at both sides Tab. 3.2 – Filter dimensions DS2000 USER’S MANUAL (rev.C) - Page 71 Tab. 3.3 – Maximum torque of mounting screws at terminal block WARNING: the filter can produce high leakage currents (see Filter Data Sheets) WARNING: the filter must be connected to ground before connecting the supply WARNING: High Voltage - Discharge time approx. 10 seconds DS2000 USER’S MANUAL (rev.C)

-

Page 72: Wiring And Grounding

The shield of the cable must be uncovered from insulation coating and RF connected to the stand-off through the metallic hose clamp, as in Fig.3.2. Fig. 3.2 – Grounding of shield without metallic connector DS2000 USER’S MANUAL (rev.C) -

Page 73: Recovery Resistor

Cable 1 = J2A, J2B, J2C Cable 2 = Motor power Cable 3 = Recovery resistor and –AT Cable 4 = Safety - Restart Interlock (optional) NOTE:Unshielded (three-phase power supply) and Sub-D cables are not shown in the figure. DS2000 USER’S MANUAL (rev.C) - Page 74 Cable 1 = J2A, J2B, J2C Cable 2 = Motor power Cable 3 = Recovery resistor and +/-AT Cable 4 = Safety - Restart Interlock (optional) NOTE:Unshielded (three-phase power supply) and Sub-D cables are not shown in the figure. DS2000 USER’S MANUAL (rev.C)

- Page 75 Cable 1 = J2A, J2B, J2C Cable 2 = Motor power and +/-AT Cable 3 = Recovery resistor Cable 4 = Safety - Restart Interlock (optional) NOTE:Unshielded (three-phase power supply) and Sub-D cables are not shown in the figure. DS2000 USER’S MANUAL (rev.C)

- Page 76 Cable 1 = J2A, J2B, J2C Cable 2 = Motor power and +/-AT Cable 3 = Recovery resistor Cable 4 = Safety - Restart Interlock (optional) NOTE:Unshielded (three-phase power supply) and Sub-D cables are not shown in the figure. DS2000 USER’S MANUAL (rev.C)

- Page 77 The crossing of the cabinet should be accomplished with a low impedance (RF) connection between cable shield and enclosure. If a connector is not involved, the shortest practical lengths of connecting strap should be used (see Fig.3.7). Fig. 3.7 – Partition penetration DS2000 USER’S MANUAL (rev.C)

-

Page 78: Screening

EN 50178:1997, product family standard, has been carried out in factory as a routine test. The DC Insulation Resistance Tests of EN 60204-1:1997, par.19.3, may be carried out without disconnecting the drive and the EMC filters. DS2000 USER’S MANUAL (rev.C) -

Page 79: Introduction

The purpose of this section is to provide a series of suggestions to make the first start-up of a DS2000 drive, connected to a Moog motor, easier. All the information hereinafter are easy and descriptive, in order to be clearly understood even by personnel not skilled in servosystems installation. -

Page 80: Drive Setting Up Information

SECTION FOUR – STARTING 4.2 DRIVE SETTING UP INFORMATION To set a drive it is necessary to search for some information, unless Moog already set them upon customer’s request. It is necessary to know: a) Motor settings Number of motor poles... -

Page 81: First Start-Up

Inadequate connections (i.e.: unshielded cables) cause feedback and motor control errors. 4.3.2 “TEMPORARY” OR TEST POWER WIRING In order to carry out a drive test, it is possible to supply the DS2000 with power in two ways: • By a 24 VOLT, 1.5 A source •... -

Page 82: Configuration For Installation In Electrical Cabinet

Additional settings for installation in the electrical cabinet concern the torque remote enable setting in order to allow the CNC to control torque supply, when requested, giving the DRIVE ENABLE hardware signal. Remember to eliminate the settings used on test bench that eventually limit performances. DS2000 USER’S MANUAL (rev.C) -

Page 83: Introduction

SECTION FIVE – COMPONENT DESCRIPTION 5. COMPONENT DESCRIPTION 5.1 INTRODUCTION This section provides descriptions for the DS2000 Series Drives. DS2000 USER’S MANUAL (rev.C) -

Page 84: Recovery Circuit

WARNING: do not touch recovery resistor during operation to avoid scalds. 5.2.1 CIRCUIT DESCRIPTION The high power supply consists of four functional blocks: • High voltage rectification and filtering • Soft-start of AC mains power-on • Low voltage control power supply • Recovery circuit DS2000 USER’S MANUAL (rev.C) -

Page 85: Fans

AC mains power. This is intended to prevent blowing of line fuses on power-up. The switch is a relay on DS2000 Series up to size B. It is an SCR on the other sizes. The soft start switch will close when the monitoring circuit and associated control software determines that the high-voltage DC BUS has charged up and the DC BUS is at steady state. - Page 86 CAUTION: In applications where the working cycle implies decelerations with high inertial loads, from high velocity in very short deceleration time, it is necessary to properly size the recovery resistor. In these cases, please contact Moog Service Centers. DS2000 USER’S MANUAL (rev.C)

- Page 87 6.8 (ext.) 30/90 62.5 6.8 (ext.) 50/140 75.0 5.6 (ext.) 60/180 75.0 5.6 (ext.) 100/300 192.3 2.2 (ext.) 1000 47 (int.) 4/12 47 (int.) 6/15 13.4 33 (int.) Tab. 5.2 – Setting protection coefficient of recovery resistor DS2000 USER’S MANUAL (rev.C)

-

Page 88: High Power Output Section

SECTION FIVE – COMPONENT DESCRIPTION In applications where high or continuous recovery energy is anticipated, consult your Moog sales representative, requesting an application review. In case of different resistors, different parameters must be set. 5.3 HIGH POWER OUTPUT SECTION The high power supply section has the following features: •... -

Page 89: Control Section

The position feedback can be both the resolver and the encoder; inside the drive the two signals are managed by two separate circuits in order to obtain the same final information for the speed loop. DS2000 USER’S MANUAL (rev.C) - Page 90 All the motors produced by Moog, are provided with this feature and give high performances at high rotation speed.

- Page 91 Note: If the output current at high speed (max working speed) is too high, it is possible trying to reduce it, reducing the motor inductance value (-20 %) and reducing the motor BEMF value; the reason is linked to the motor reluctance, that change in the motor revolution DS2000 USER’S MANUAL (rev.C)

- Page 92 Integral and Proportional Gain, as well as properly adjusting the filters, if necessary. It is possible to minimize the error acting on VKI and VKP gains during the device operation thus obtaining the required response. DS2000 USER’S MANUAL (rev.C)

- Page 93 Fig. 6.1 – DS2000 front panel NOTES: • First screen at drive start-up show you the DS2000 size. The DRIVE ENABLE and REFERENCE ENABLE signals are shown in the start-up screen on the display by two stylized letters: “D” and “R” respectively.

-

Page 94: Reset

• The main menu is not “circular”; when the bottom is reached, press ESC or < to go back. The Enter button can be used to go forward the menu. 6.2 MOTOR PARAMETERS MENU Fig. 6.2 – Motor parameters menu DS2000 USER’S MANUAL (rev.C) - Page 95 If this value is not available, it is possible to obtain it using a multi-meter (set as an inductance- meter). Attention: for G motors use the L value instead of L DS2000 USER’S MANUAL (rev.C)

- Page 96 Allowed values: • data 0 (for PTC thermal feedback) • 1 (for NTC thermal feedback) Description: it indicates the type of motor feedback ENCODER<>RESOLVER Allowed values: Note: • ENCODER (for ENCODER feedback) • RESOLVER (for RESOLVER feedback) DS2000 USER’S MANUAL (rev.C)

- Page 97 Note: set the values indicated on the nameplate of Allowed values: from 1024 to 8192 in 512 unit steps the motor or refer to the data indicated on the motor catalogue. Attention: available only with encoder feedback mode DS2000 USER’S MANUAL (rev.C)

-

Page 98: Drive Parameters Menu

SECTION SIX – COMMANDS 6.3 DRIVE PARAMETERS MENU Fig. 6.3 – Drive parameters menu DS2000 USER’S MANUAL (rev.C) - Page 99 Description: it indicates NTC/PTC threshold value PTCNTC THRESHOLD= used to protect motor from overtemperature Note: set following value for Moog motor: Allowed values: from 100 Ω to 10000 Ω in 1 unit steps •...

- Page 100 Description: set a time for I2T trigger TIME I2T IGBT= Note: default value is 500 ms for all DS2000 drives Allowed values: from 100 ms to 1000 ms in 10 ms unit steps Description: enable the fault reaction on I2T IGBT...

- Page 101 Note: Input analog reference remains diminished at Allowed values: from 0 A to max current in 100 mA unit steps this set value; setting 10 V input analog reference, the max set revolutions are obtained DS2000 USER’S MANUAL (rev.C)

- Page 102 Note: set the selected value on the numeric control to Allowed values: from 3.2 V to 10.0 V in 0.1 V unit steps obtain a direct correspondence Attention: function available only with analog I limit enabled DS2000 USER’S MANUAL (rev.C)

-

Page 103: Control Loops Parameters Menu

Description: it allows to correct and cancel any ANAL.REF.OFFSET= eventual analog offset at speed reference input Allowed values: Note: from -50 to +50 DS2000 USER’S MANUAL (rev.C) -

Page 104: Drive Enable Menu

DRIVE ENABLE MENU DESCRIPTION 6.5.1 Description: it allows to control the drive if in the DRIVE ENABLE DRIVE PARAMETER menu the DRIVE ENABLE is set in LOCAL mode Allowed values: Note: • DRIVE OFF • DRIVE ON DS2000 USER’S MANUAL (rev.C) -

Page 105: Display Variables Menu

• In digital limit mode the max current is indicate • In analog limit mode the analog limit is indicate Description: it indicates the effective phase shift according to the motor load and PHASE SHIFT velocity DS2000 USER’S MANUAL (rev.C) -

Page 106: Utility Menu

Description: it indicates the checksum calculated by the drive resident software Attention: in case of mismatch between calculated value and mapped value the program resident on memory may be damaged. It is necessary to reload the program 6.7 UTILITY MENU Fig. 6.7 – Utility menu DS2000 USER’S MANUAL (rev.C) - Page 107 Description: Analog Out is configured as the instant value of the V V PHASE VOLTAGE phase voltage (as a sum of B.E.M.F. and resistive drop). The analysis of the sinusoidal wave correct shape allows to point out any eventual control problem DS2000 USER’S MANUAL (rev.C)

- Page 108 The motors manufactured by Moog are already phased in the factory to be used with DS2000 Drives. CAUTION: in this phase the motor can rotate for a revolution fraction, it is recommended to make sure it is free to rotate to avoid risk of friction, which could compromise phasing accuracy.

- Page 109 +/- 255 internal units (255 are related to 180° electrical angle). NOTE: The Autophasing doesn’t go automatically at the end; each step must be controlled by the user with the keyboard. NOTE: Through the APHAPOS parameter it is possible to manually correct the motor phasing. DS2000 USER’S MANUAL (rev.C)

-

Page 110: Keyboard Lock Menu

After calibration, save the acquired value. NOTE: It is possible to disable this functionality and modify manually the offset values through a Moog VARIABLES menu parameter. 6.7.1.8 UTILITY MENU - MOOG VARIABLES CAUTION: Please contact Service Center before using this feature. -

Page 111: Fault Detection Menu

6.19 SECTION SIX – COMMANDS 6.9 FAULT DETECTION MENU Fig. 6.9 – Fault detection menu DS2000 USER’S MANUAL (rev.C) - Page 112 Description: it indicates an anomaly inside the voltage reading SYSTEM ERROR ON VBUS DETECT. system on DC BUS. Try to switch the drive off and cut off the line. In case the FAULT persists, the drive is broken DS2000 USER’S MANUAL (rev.C)

- Page 113 IGBT FAULT I2T PROTECTION for excessive phase current at looked rotor or very low speed condition Description: it indicates an excessive estimated temperature FAULT RR PROTECTION of the recovery resistor Press ENTER for exit END OF SCANNING DS2000 USER’S MANUAL (rev.C)

- Page 114 6.22 SECTION SIX – COMMANDS THIS PAGE INTENTIONALLY BLANK DS2000 USER’S MANUAL (rev.C)

- Page 115 The drive should be returned to Moog Service Centers if after the check/correct action the troubleshooting condition persists. See also Chapter 6, par. 6.9 (Fault Detection Menu).

-

Page 116: Faults On Drive Output Section

7.4 FAULTS ON FEEDBACK SECTION Condition Encoder Pulses Detection Error. Check/Correct Check, if possible, that the problem is not present with another motor. Condition Fault Resolver Check/Correct Check, if possible, that the problem is not present with another motor. DS2000 USER’S MANUAL (rev.C) -

Page 117: Control Loops Troubles

- Remove signal cables, set PTC type, short-circuit pin 6 and pin 8 of J5 connector and check that the fault disappears - Check the software release (see Appendix) WARNING: Power-off the drive before checking the motor temperature DS2000 USER’S MANUAL (rev.C) -

Page 118: Recovery Resistor Troubles

WARNING: Power-off the drive before checking the recovery resistor temperature Condition RR Protection Fault (cold resistor). Check/Correct - Check “Recovery Resist. Resrec”, “Recovery Resist. Power” and “Recovery Resist. Coeff.” parameters. WARNING: Power-off the drive before checking the recovery resistor temperature DS2000 USER’S MANUAL (rev.C) -

Page 119: Intended Application

(RIC) and can be requested as an option for size E, followed by all the other sizes. The RIC optional card can be installed only on Moog drives DS2000 and DS2100 series. The installation of the card on other drives, or the use not according to this Manual is regarded as inappropriate use. -

Page 120: Restart Interlock Function

SECTION EIGHT – Safety function RESTART INTERLOCK (Optional) 8.2 RESTART INTERLOCK FUNCTION The restart interlock safety function by Moog has been validated compliant with the provisions of category 3 as defined in the harmonized standard EN-954-1:1996 by demonstrating that: • a single fault does not lead to the loss of the safety function •... - Page 121 The associated drive must be electrically isolated from the supply if the restart interlock relay function is not plausible (input and output not compatible). Only after the fault has been removed, the restart interlock and the associated operating mode may be used again. DS2000 USER’S MANUAL (rev.C)

-

Page 122: Safety Requirements

WARNING: When the Restart Interlock Circuit is activated, the motor can no longer generate a torque. Motors which are not automatically clamped when powered down (e.g. vertical/inclined axes), must be clamped using a mechanical brake DS2000 USER’S MANUAL (rev.C) -

Page 123: Restart Interlock Circuit

The check of condition 2 allows to find the short circuit on the wiring of the NC contact of the safety relay. When this check is not available it is necessary to follow the wiring procedures following listed. DS2000 USER’S MANUAL (rev.C) - Page 124 In case of fault the motor must be stopped via the hardware channel(s) and via the line contactor. The motor must not restart until the fault has been fixed. WARNING: In case of malfunction the whole safety circuit need to be checked by qualified personnel taking into account the necessary safety procedures DS2000 USER’S MANUAL (rev.C)

- Page 125 SECTION EIGHT – Safety function RESTART INTERLOCK (Optional) Fig.8.1 – RESTART INTERLOCK CIRCUIT DS2000 USER’S MANUAL (rev.C)

-

Page 126: Restart Interlock Connections

Series of NO contacts of RL1A and RL2A relays. User available. Wiring practice The external cable to RESTART INTERLOCK connector must be protected against mechanical damages according to the safety requirements of EN ISO 13849-2:2003, tab. D.4 (prEN 954-2) in order to prevent short circuits. DS2000 USER’S MANUAL (rev.C) - Page 127 Pick-up voltage = 14.4 Vdc Drop-out Voltage = 2.4 Vdc Resistance = 1.152 Ω Vmax = 28.8 Vdc Contact Rmax = 30 mΩ @ 6 Vdc, 1 A Imax = 3 Adc Vmax = 30 Vdc DS2000 USER’S MANUAL (rev.C)

-

Page 128: Application Example

PLC, which, after the t1 delay, disables the axis according to the sequence of par.8.4.2, by removing the DRIVE ENABLE signal (input DRV EN) • The correct operation of the SW channel cannot be verified (but see also par.8.4.2.1). DS2000 USER’S MANUAL (rev.C) - Page 129 • The door control module must be compliant with at least category 3 of EN 954-1. • See par.8.6 for the technical data DS2000 USER’S MANUAL (rev.C)

-

Page 130: Sequence And Procedure Using The Restart

CAUTION: must be taken into account DS2000 USER’S MANUAL (rev.C) - Page 131 (condition 2) when this cannot be excluded. For alI of the simulated fault situations, the line contactor must disconnect alI of the machine or plant drives from the line supply. DS2000 USER’S MANUAL (rev.C)

-

Page 132: External Plausibility Tests

NC contact of the line contactor • Protection of program - The program shall be monitored by e.g. a watchdog - The program shall be in permanent memory protected against electrical interference and shall be equipped with a start-up test procedure DS2000 USER’S MANUAL (rev.C) -

Page 133: Installation And Routine Test

SECTION EIGHT – Safety function RESTART INTERLOCK (Optional) 8.11 INSTALLATION AND ROUTINE TEST The restart interlock circuit (RIC) is installed and tested in Moog. 8.12 RIC IDENTIFICATION ON THE NAMEPLATE The restart interlock circuit is identified by the words “Restart Interlock” on the nameplate Fig.8.4 –... - Page 134 8.16 SECTION EIGHT – Safety function RESTART INTERLOCK (Optional) THIS PAGE INTENTIONALLY BLANK DS2000 USER’S MANUAL (rev.C)

- Page 135 APPENDIX APPENDIX A: Motor technical data For motors technical data refer to motor Moog catalogues or contact the Moog Service Centers. DS2000 USER’S MANUAL (rev.C)

- Page 136 APPENDIX APPENDIX B: FC series technical data The DS2000 drive can directly command FC series low rpm special motors. Note: To increase the effective system resolution at very low speed, it is possible to scale some system parameters as in the following table:...

- Page 137 Note: P1 and P2 are normally closed switches Opening P1 disable CW rotation Opening P2 disable CCW rotation Note: If P3 connected to 0L the drive is in speed control If P3 connected to +24V the drive is in torque control DS2000 USER’S MANUAL (rev.C)

- Page 138 Special software used in CAN Open options (speed mode). Option card needed. Make reference to the CAN Open DS2000 manual (GB-4540). 4.100 Special software used in CAN Open options (speed mode). Option card needed. NTC motor sensor version. Make reference to the CAN Open DS2000 manual (GB-4540). DS2000 USER’S MANUAL (rev.C)

- Page 139 Included in release 3.201 3.000 A, B, C Replace by release 3.100 3.000AFW A, B, C Replace by release 3.100AFW 3.000LSW A, B, C Replace by release 3.100LSW 3.001 A, B, C Replace by release 3.101 DS2000 USER’S MANUAL (rev.C)

- Page 140 APPENDIX THIS PAGE INTENTIONALLY BLANK DS2000 USER’S MANUAL (rev.C)

- Page 142 Luxembourg Norway Russia Singapore South Africa Spain Sweden United Kingdom Moog Italiana S.r.l. Casella Site Via Avosso, 94-16015 Casella (Genova) - Italy Telephone: (+39) 010 96711 Fax:(+39) 010 9671280 For the location nearest to you, contact www.moog.com/worldwide GB-4534 PRINTED IN ITALY...

Need help?

Do you have a question about the DS2000 and is the answer not in the manual?

Questions and answers