Table of Contents

Advertisement

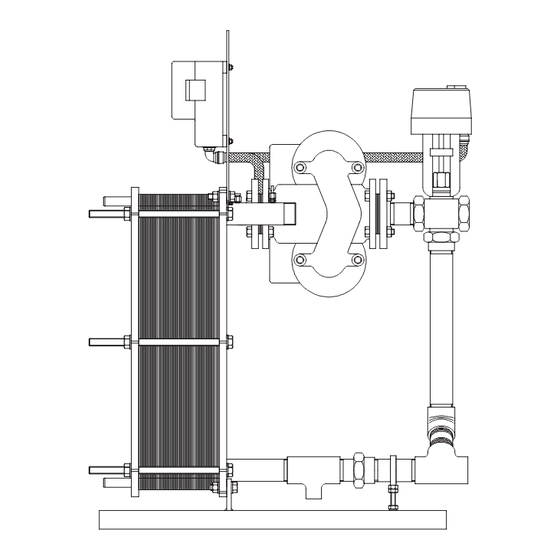

Rycroft HT Breeze

Plate Heat Exchanger

Operation &

Maintenance

Manual

The Ormandy Group: Ormandy O site / Ormandy Rycroft / Ormandy Electric

Ormandy H&S Boilers / Ormandy Newade / Ormandy Dreh / Ormandy Aquatherm

Ormandy Rycroft is a trading name of Ormandy Limited

Registered in England No. 4087023 / VAT Registration No. 875 7906 65

Ormandy Rycroft

Duncombe Road

Bradford

BD8 9TB

England

TEL +44 (0)1274 490911

FAX +44 (0)1274 498580

www.rycroft.com

Advertisement

Table of Contents

Summary of Contents for Rycroft HT Breeze Series

- Page 1 Operation & Maintenance Manual The Ormandy Group: Ormandy O site / Ormandy Rycroft / Ormandy Electric Ormandy H&S Boilers / Ormandy Newade / Ormandy Dreh / Ormandy Aquatherm Ormandy Rycroft is a trading name of Ormandy Limited Registered in England No. 4087023 / VAT Registration No. 875 7906 65...

-

Page 2: Table Of Contents

VERY IMPORTANT – PLEASE READ CAREFULLY Running Safety Points Start Up Working Principles Installing Sizing and Selection Installation Operation and Set Up Health Maintenance Service Spares Information Specification Valve and Actuator detail Pumps Variations... -

Page 3: Running

Take care when lifting, only use the designated lifting point. Use only certified lifting equipment capable of lifting the weight. Water may also be present and spillage occur. Never Lift the Rycroft HT Breeze by it’s pipework, or pipe connections. Take care when handling as some of the edges may be sharp. -

Page 4: Start Up

Start Up Checks Check that the electrical installation is complete. Check that the mechanical installation is complete. Check that the system has been flushed and that there are no leaks. Any air has been eliminated from the system. That valves are opened in required sequence (16) Switch on via switch The front panel will illuminate. -

Page 5: Working Principles

Providing the class of accommodation and details of the number and type of fixtures are known, Rycroft will be pleased to recommend the optimum size of HT Breeze. Or in conjunction with a buffer vessel to form a semi-instantaneous water heater. -

Page 6: Installing

INSTALLING Sizing and Selection To size a stand alone Rycroft HT Breeze, use the following demand factors. Table 1 Private Public Slop Kitchen Washing Dish Facility Hand Hand Shower Bath Sink Sink Sink Machine Sink washer Basin Basin Hospital Hotel & Residential... - Page 7 4.187 kj/kg, ºC Cold Feed Temperature 10ºC Secondary Flow Temperature 60ºC Therefore the required kw rating = 3273 x 4.187 x (60-10) = 190.3 kw 3600 The nearest standard Rycroft HT Breeze is a CP-B100 which is rated at 209 kw...

-

Page 8: Installation

The Rycroft HT Breeze should always be installed with a secondary return line coming back from the system and into the cold feed line prior to the Rycroft HT Breeze or Buffer Vessel. This will remove nuisance high limit tripping due to temperature overshoot, which would occur if the unit was intalled on a ‘dead end’... -

Page 9: Operation And Set Up

Before filling the system check that the drain valve is closed and all air vents are open. Flush out the system before installing the Rycroft HT Breeze to remove any foreign matter. Close any manual air vents and run the Rycroft HT Breeze. Crack the vents to release air... - Page 10 The Rycroft HT Breeze can be energised by its own internal time clock function, by a remote switch or Building Management System or by a combination of the two.

- Page 11 Set up The Rycroft HT Breeze control unit is already programmed with temperature and control settings that will suit most applications. All the values are adjustable so that you can customise the unit to exactly match your system.

- Page 12 The system continues to control when the controller is in the set up routine allowing adjustments to be made on the fly System Faults When a fault situation is detected the System Fault (14) indicator will be lit and the internal Fault relay will be energised.

- Page 13 (10) The set up routine is entered by simultaneously pressing and holding the Mode , Step Left and Value Decrease , Pushbuttons for three seconds. Press the Step Right Step Left pushbuttons to move forwards and backwards through the sequence. Press the Value Increase or Value Decrease pushbuttons to alter the value shown in the...

- Page 14 Night set back/Pasteurisation When the DIP switch for Night set-back/Pasteurisation is set to the on position and the unit is put into standby. When the set back/pasteurisation value (S Sb to) is set to above the normal set temperature (S SET To) The controller will assume pasteurisation and will raise the temperature to the set back/pasteurisation value for one hour, before returning to standby.

- Page 15 Factory Default Settings Set Up: Alternative setting record (Date) ………… ………… ……….. Set point = 60 ………… ………… ………… Time clock = Off ………… ………… ………… Day (Set) = 1 = Mon 7 = Sunday Clock (Set) = Time Day 1 ON 1 = 0000 …………...

- Page 16 Primary pump overrun time = 5mins ………... ………… ………… Primary pump overrun temperature = 40°c ………… ………… ………… Secondary pump overrun time = 5mins ………… ………… ………… Secondary pump overrun temperature = 40°c ………… ………… ………… Night Set-back/Pasteurisation temperature = 68°c …………...

-

Page 17: Health

This will provide an insight into future requirements for efficient maintenance. If the Rycroft HT Breeze is cleaned and there is no sign of corrosion, it can be safely assumed an annual inspection will be sufficient for future servicing. All electrical connections should be checked and tightened if necessary. -

Page 18: Service

Service Rycroft offers a full and comprehensive range of service and support. This encompasses the maintenance, commissioning and repair of General water heating equipment. Including Heat exchangers, Boilers, Pressurisation units, Booster sets and Calorifiers. Speak to the customer service and support Department Rycroft Ltd 3.3 Spares... -

Page 19: Information

INFORMATION Specification Power supply requirements Voltage: 230 Volts, 50Hz, Single Phase. Or 400 Volts, 50Hz, Three Phase. Nominal current: Maximum 16Amps (Pump and Duty dependant) for the single phase. The three phase model has no limit. Inputs Temperature probe: Type J thermocouple (Grounded) via a 12 bit A/D ο... - Page 20 4.2 Valve and actuator...

- Page 28 4.3 General Pump Detail Grundfos UPS series The pump is of the canned rotor type, i.e. the pump and motor form an integral unit without a shaft seal and with only two gaskets for sealing. The bearings are lubricated by the pumped liquid.

-

Page 29: Variations

4.4 Variations Single phase & Three phase industrial versions. These versions are generally used in harsher environments and where higher pump duties require electric motors with larger running currents. The units are housed in sheet steel sloping topped enclosures finished in RAL 7032 grey, and fitted with door interlocked isolators.

Need help?

Do you have a question about the HT Breeze Series and is the answer not in the manual?

Questions and answers