Summary of Contents for Dajiang Innovation Technology XAGD32/9032II

- Page 1 USERS MANUAL 18GA. 2-IN-1 BRAD NAILER & STAPLER MODEL: XAGD32/9032II WARNING Failure to follow warning could result in DEATH OR SERIOUS INJURY. M0821 03/12 V2...

-

Page 2: Table Of Contents

CONTENTS: IMPORTANT INFORMATION EXPLANATION OF THE NAILING ACTION GENERAL SAFETY RULES WORK AREA PERSONAL SAFETY TOOL USE AND CARE SERVICE AIR SOURCE DESCRIPTION AND SPECIFICATION SPECIFICATION FEATURES ASSEMBLY/INSTALLATION OPERATION LUBRICATION ADJUSTING AIR PRESSURE CONNECTING AIR SUPPLY TOOL TESTING NAIL LOADING METHODS OF OPERATION COLD WEATHER OPERATION ADJUSTABLE THE EXHAUST... -

Page 3: Important Information P1

IMPORTANT INFORMATION The employer must enforce the use of safety glasses by the tool operator and others in work area. ALWAYS WEAR EAR AND HEAD PROTECTION. Always WARNING wear ear protection to protect your ears from loud noise, TO AVOID SERIOUS PERSONAL INJURY, ALL USERS AND Always wear head protection to protect your head from EMPLOYERS/OWNERS MUST READ AND UNDERSTAND flying objects. -

Page 4: Air Source

TOOL SERVICE CONDITION THAT MAY AFFECT THE TOOL'S OPERATION. If damaged, have the tool serviced before using. Many USE ONLY ACCESSORIES THAT ARE IDENTIFIED BY THE accidents are caused by poorly maintained tools. MANUFACTURER FOR THE SPECIFIC TOOL MODEL CHECK SAFETY BEFORE USE. Make sure the safety USE OF UNAUTHORIZED PARTS OR FAILURE TO FOLLOW operates properly. -

Page 5: Specification P3

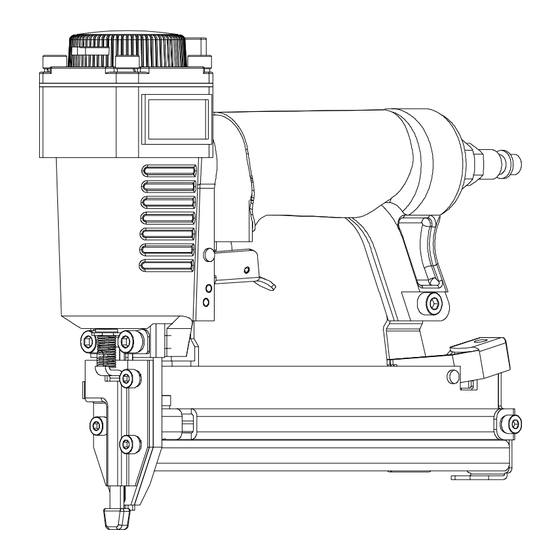

FUNCTIONAL DESCRIPTION AND SPECIFICATIONS WARNING Disconnect the tool from the air source before making any adjustments, changing accessories o storing the tool. Such precautionary safety measures reduce the risk of unintentional tool operation. FIG. 1 Adjustable Exhaust Deflector Trigger Air Cap Hand Grip Air Plug Body... -

Page 6: Features P4

FEATURES If the tool is not used with an in-line lubrication system on the air supply it is necessary to periodically lubricate the 360 adjustable exhaust tool with air tool lubrication. Allows user to direct air away from debris. Comfort-grip handle. Under low use, lubricate once a day. -

Page 7: Tool Testing

against the wood. WARNING THE TOOL MUST NOT OPERATE. Do not exceed maximum recommended air pressure Separate the safety from the wood. Next, point the tool marked on the tool. Verify prior to using the tool that the air downward, pull the trigger and then wait in that position source has been adjusted within the rated air-pressure for 5 seconds or longer. -

Page 8: Methods Of Operation

1).Pull the trigger with the tool off the workpiece. FIG. 6 2).Depress the safety against the workpiece to drive a nail. 3).Move the tool along the workpiece with a bouncing motion. Each depression of the safety will drive a nail. As son as the desired number of nails have been drive, remove finger from the trigger. -

Page 9: Maintenance P7

FIG. 9 FIG. 11 Nose plate (B) Nail Indicator Nose screws (A) Nose (C) USING THE NO-MAR TIP CLEANING WARNING WARNING When cleaning a tool be careful not to disassemble any When attaching or detaching the No-Mar Tip, be sure to portion of the tool since internal components may be remove your finger from the trigger and disconnect the air misplaced or safety components may be improperly... -

Page 10: Recommended Hookup P8

MINIMUM COMPONENTS With ON/OFF switch in OFF position, plug compressor into electrical outlet. REQUIRED FOR HOOKUP Close pressure regulator by turning all the way to the Air compressor: The air compressor must be able to left. Turn compressor ON and let it pump all the way up maintain a minimum of 60PSI when the nailer is being to automatic shut-off pressure.

Need help?

Do you have a question about the XAGD32/9032II and is the answer not in the manual?

Questions and answers