Summary of Contents for YONGKANG TG2000i

- Page 1 OWNER'S MANUAL TG2000i DIGITAL GENERATOR YONGKANG ZHONGJIAN TOOLS MANUFACTURE CO.,LTD.

- Page 2 PREFACE Thank you for purchasing a digital generator. This manual covers the operation and maintenance of the model TG2000i generators. All information in this publication is based on the latest product information available at the time of approval for printing.

- Page 3 NOTE: Gives helpful information. If a problem should arise or if you have any questions about the generator, consult an authorized dealer. Our generators are designed to give safe and dependable service if operated according to instructions. Read and understand the Owner's Manual before operating the generator. Failure to do so could result in personal injury or equipment damage.

-

Page 4: Table Of Contents

CONTENTS 1. SAFETY INSTRUCTIONS......................5 2. SAFETY LABEL LOCATIONS ....................7 3. COMPONENT INDENTIFICACTION ..................8 4. PRE-OPERATION CHECK ...................... 10 5. STARTING THE ENGINE......................13 6. GENERATOR USE........................16 7. STOPPING THE ENGINE ......................24 8. MAINTENANCE ........................26 9. -

Page 5: Safety Instructions

1. SAFETY INSTRUCTIONS ■Our generators are designed to give safe and depend-able service if operated according to instructions. Read and understand the Owner's Manual before operating the generator. Failure to do so could result in personal injury or equipment damage. ■Exhaust gas contains poisonous carbon monoxide. - Page 6 To ensure safe operation— ■ Gasoline is extremely flammable and explosive under certain conditions. Refuel in a well ventilated area with the engine stopped. ■Keep away from cigarette, smoke and sparks when re-fueling the generator. Always refuel in a well-ventilated location. ■...

-

Page 7: Safety Label Locations

2. SAFETY LABEL LOCATIONS These labels warn you of potential hazards that can cause serious injury. Read the labels and safety notes and precautions described in this manual carefully. If a label comes off or becomes hard to read, contact your dealer for a replacement. Performance Label Warning Label Brand Label... -

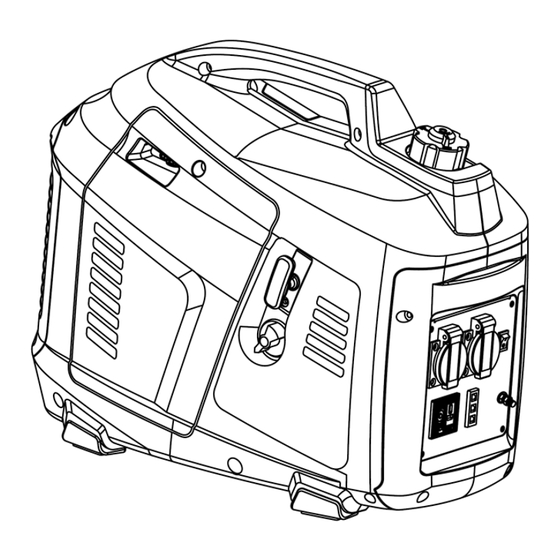

Page 8: Component Indentificaction

3. COMPONENT IDENTIFICATION... - Page 9 Serial number and identification location The engine serial number identifies your particular unit and is important when ordering parts and accessories. Engine serial number:158FYYMMDD0001 The serial number can be found engraved on the crankcase beside the oil filter cap. It is visible when the left maintenance cover is removed.

-

Page 10: Pre-Operation Check

4. PRE-OPERATION CHECK ■ Be sure to check the oil level before each use with the generator on a level surface with the engine stopped. 1. Check the engine oil level. ■ Using non detergent oil or 2-stroke engine oil could shorten the engine's service life. - Page 11 NOTE: The Low Oil Alarm System will automatically stop the engine when the oil level falls below the safe limit. However, to avoid the inconvenience of an unexpected shutdown, it is still advisable to visually inspect the oil level regularly. 2.

- Page 12 ■Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may ignite, if any fuel is spilled, make sure the area is dry before starting the engine. ■Avoid repeated or prolonged contact with skin or breathing of vapor, KEEP OUT OF REACH OF CHILDREN.

-

Page 13: Starting The Engine

5. STARTING THE ENGINE Before starting the engine, disconnect any loads from the AC and DC terminals. 1. Turn the fuel cap vent lever fully clockwise to the “I” position. 2. Turn the engine switch to the ON position. 3. Move the choke lever to the START position. - Page 14 ■ To restart a warm engine, leave the choke in the RUN position. Do not move the choke to the START position when the engine is warm or the air temperature is high. 4. Pull the starter grip lightly until you feel resistance then pull briskly. ■...

- Page 15 High altitude operation At high altitude, the standard carburetor air-fuel mixture will be excessively rich. Performance will decrease, and fuel consumption will increase. A very rich mixture will also foul the spark plug and cause hard starting. Operation at an altitude that differs from that at which this engine was certified, for extended periods of time, may increase emissions.

-

Page 16: Generator Use

6. GENERATOR USE ■To prevent electrical shock from faulty appliances, the generator should be grounded. Connect a length of heavy wire between the generator's ground terminal and an external ground source. ■Connections for standby power to a building's electrical system must be made by a qualified electrician and must comply with all applicable laws and electrical codes. - Page 17 ■The DC receptacle can be used while the AC power is in use. If you use both at the same time, be sure not to exceed the total power for AC and DC. ■Most appliance motors require more than their rated watt-age for start-up.

- Page 18 Output and Overload Indicators The output indicator light (green) will remain ON during normal operating conditions. If the generator is overloaded (in excess of 2.0kVA), or if there is a short in the connected appliance, the output indicator light (green) will go OFF, the overload indicator light (red) will go ON and current to the connected appliance will be shut off.

- Page 19 1. Connect the ground terminal. 2. Start each engine according to "STARTING THE ENGINE". When the output indicator light (green) does not light and the overload indicator light (red) lights instead, set the engine switch to STOP, stop the engine at once and then start the engine again. 3.

- Page 20 4. Switch on the equipment to be used. In case of overload operation or when trouble occurs for the equipment being used, the output indicator light (green) will go out, the overload indicator light (red) will light continuously, and no power will be put out.

- Page 21 The DC receptacle should only be used for charging 12 volt automotive-type batteries, the zero load voltage is 15V-30V. The DC charging output is not regulated. ■ In DC operation, turn the Intelligent Throttle switch to the OFF position. 1. Before connecting charging cables to a battery that is installed in a vehicle, disconnect the vehicles grounded battery cable from the negative (-) battery terminal.

- Page 22 ■The battery gives off explosive gases; Keep sparks flames and cigarettes away. Provide adequate ventilation when charging. ■The battery contains sulfuric acid (electrolyte). Contact with skin or eyes may cause severe burns. Wear protective clothing and a face shield. -If electrolyte gets on your skin, flush with water. -If electrolyte gets in your eyes, flush with water for at Least 15 minutes and call a physician.

- Page 23 Intelligent Throttle System With the switch in the ON position, Engine speed is kept at idle automatically when the electrical load is disconnected and returns to the proper speed to match the power of the electrical load when the load is reconnected. This position is recommended to minimize fuel consumption while in operation.

-

Page 24: Stopping The Engine

7. STOPPING THE ENGINE To stop the engine in an emergency, turn the engine switch to the OFF position. Under normal conditions, use the following procedure. 1. Switch off the connected equipment and pull the inserted plug. 2. Turn the engine switch to the OFF position. The fuel valve will automatically close. - Page 25 3. Allow the engine cool well, turn the cap vent lever fully counterclockwise to the "O" position. ■Be sure the fuel cap vent lever, choke and the engine switch are "OFF" when stopping, transporting and/or storing the generator.

-

Page 26: Maintenance

8. MAINTENANCE Good maintenance is essential for safe, economical and trouble-free operation. It will also help reduce air pollution. The purpose of the maintenance and adjustment schedule is to keep the generator in the best operating condition. ■ Shut off the engine before performing any maintenance. If the engine must be run, make sure the area is well ventilated. -

Page 27: Changing Oil

8.1 CHANGING OIL Drain the oil while the engine is still warm to assure rapid and complete draining. ■Make sure to turn the engine switch and the fuel cap lever OFF before draining. 1. Loosen the cover screw and remove the left side maintenance cover. 2. - Page 28 Wash your hands with soap and water after handing used oil. ■Improper disposal of engine oil can be harmful to the environment. If you change your own oil, please dispose of it properly. Put it in a sealed container, and take it to a recycling center. Do not discard it in a trash bin, dump it on the ground, or pour it down a drain.

- Page 29 8.3 SPARK PLUG SERVICE RECOMMENTED SPARK PLUG: NHSP LD A7RTC To ensure proper engine operation, the spark plug must be properly gapped and free of deposits. 1. Remove the spark plug maintenance cover. 2. Remove the spark plug cap. 3. Clean any dirt from around the spark plug base. 4.

- Page 30 5. Visually inspect the spark plug. Replace it if the electrode is worn, or if the insulator is cracked, chipped or fouled. Clean the spark plug with a wire brush if it is to be reused. 6. Measure the spark plug electrode gap with a wire-type feeler gauge. The gap should be 0.024-0.028in (0.6-0.7mm).

-

Page 31: Transporting/Storage

9. TRANSPORTING/STORAGE To prevent fuel spillage when transporting or during temporary storage, the generator should be secured upright in its normal operating position with the engine switch OFF. Turn the fuel cap vent lever fully counterclockwise to the "O" position. Do not lay the generator on its side when moving, storing or operating it. - Page 32 c. With the drain screw loosened remove the spark plug maintenance cover and the spark plug cap, and pull the starter grip 3 to 4 times to drain the gasoline from the fuel pump. d. Turn the engine switch to the OFF position, and tighten the carburetor drain screw securely. 3.

-

Page 33: Troubleshooting

10. TROUBLESHOOTING When the engine will not start: Is there fuel in the tank? Refill the fuel tank. Is the engine switch on? Turn the engine switch on. Is there enough oil in the enginge? Add the recommended oil. Is there a spark from the spark Replace the spark plug. - Page 34 Appliance does not operate: Is the output indicator light ON? overload Take the generator to indicator light ON? an authorized dealer. Check the electrical Take the generator to appliance or equipment an authorized dealer. for any defects. ■ Replace the electrical appliance or equipment ■...

-

Page 35: Specifications

11. SPECIFICATIONS Generator Model TG2000i 220/230/240 Voltage (V) 7.3/7.0/6.7 Rated current (A) Rated speed (rpm) 4500 Rated output (kVA) Max output (kVA) Frequency (HZ) DC voltage 12V-7.5A Electric circuit breaker Inverter microprocessor controlled Phase Single phase Engine Model Type 158F... -

Page 36: Wiring Diagram

12. WIRING DIAGRAM... - Page 37 ZHONG JIAN TOOLS MANUFACTURE CO LTD. , • No.27 Yongdong East Road, Great wall Industry Area, Yongkang, Zhejiang, China Tel:0086-579-87233668 Fax:0086-579-87232599 E-mail:zjtools@zjtools.cn Http://www.zjtools.cn...

Need help?

Do you have a question about the TG2000i and is the answer not in the manual?

Questions and answers