Table of Contents

Advertisement

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

O

'

M

peratOr

s

anual

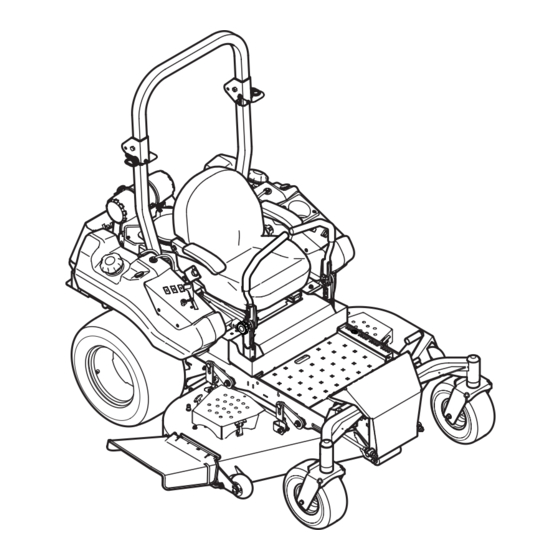

Tank LZ

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-11220

(December 9, 2014)

Advertisement

Table of Contents

Summary of Contents for Cub Cadet Tank LZ

- Page 1 READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE THIS MACHINE. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 Printed In USA Form No. 769-11220...

-

Page 2: Table Of Contents

Thank You If applicable, the power testing information used to establish Thank you for purchasing a Cub Cadet Zero-Turn Tractor. It was the power rating of the engine equipped on this machine can be carefully engineered to provide excellent performance when found at www.opei.org or the engine manufacturer’s web site. -

Page 3: Important Safe Operation Practices

Important Safe Operation Practices WARNING! This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. -

Page 4: General Operation

Training Always wear appropriate clothing and personal protective equipment (e.g. safety glasses, long pants, gloves, hearing protection , safety shoes, hard hat) when operating or Read the Operator’s manual and other training material. If maintaining this machine. Long hair, loose fitting clothing the operator(s) or mechanic(s) cannot read English it is the or jewelry may get entangled in moving parts. - Page 5 Never attempt to operate the machine without the Keep all movements on the slopes slow and gradual. Do mowing deck attached; the machine could tip over. not make sudden changes in speed or direction. Rapid acceleration could cause the front of the machine to lift Keep the machine and especially the engine exhaust and rapidly flip over backwards, which could cause serious system and hydraulic components clean and free of grease,...

-

Page 6: Transporting Machines

Never allow children under 16 years of age to operate this Seat belts shall be used and shall be properly fastened machine. Children 16 and over should read and understand the about the operator’s waist at all times, except when the instructions and safe operation practices in this manual and on ROPS are: the machine and should be trained and supervised by an adult. - Page 7 Hydraulic Devices and Systems Never remove fuel cap or add fuel while the engine is hot or running. Allow engine to cool at least two Hydraulic fluid escaping under pressure may have sufficient minutes before refueling. force to penetrate skin and cause serious injury. If foreign fluid is Never over fill fuel tank.

- Page 8 Do not modify engine Grass catcher components and the discharge cover are subject to wear and damage which could expose moving To avoid serious injury or death, do not modify engine in any parts or allow objects to be thrown. For safety protection, way.

-

Page 9: Safety Symbols

Safety Symbols This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate. Symbol Description READ THE OPERATOR’S MANUAL(S) Read, understand, and follow all instructions in the manual(s) before attempting to assemble and operate WARNING—... - Page 10 2 — S ection peration racticeS...

-

Page 11: Assembly & Set-Up

Assembly & Set-Up Contents of Crate • One Zero-Turn Tractor • One ROPS Assembly • One Deck Wash Hose Coupler • One Zero-Turn Tractor Operator’s • One Engine Operator’s Manual Manual NOTE: This Operator’s Manual covers several models. Tractor The two hydrostatic transmissions are equipped with a features may vary by model. - Page 12 Install Roll Over Protective System (ROPS) Install the upper ROPS section onto the lower ROPS “posts”. Install the bolts and nuts. See Figure 2-4. The Roll Over Protective System (ROPS) has not been installed on your unit for shipping purposes. Using the hardware found in the Roll Over Protective System container, install it on your unit Retaining as follows:...

- Page 13 Move the upper ROPS section to the upright position, and To adjust the height of the drive control levers: insert the locking pins with their retainer hairpin clips. See Remove the flange lock nuts that secure the carriage bolts Figure 2-6. in the drive control levers.

- Page 14 Installing the Seat Insert the wiring harness into the bottom of the seat as shown in Figure 2-11. Remove the two flange lock nuts and shoulder bolts from the manual bag. See Figure 2-9. Figure 2-11 NOTE: When the harness is connected, be sure to push the Figure 2-9 excess wire from the wire harness into the seat box hole Place the seat into position and secure the seat into place with...

- Page 15 Connecting the Battery Cables The mechanical suspension mechanism incorporates weight/ride adjustment controls for operators in the 100 to 280 lb. weight range CALIFORNIA PROPOSITION 65 WARNING (turn the knob on the front of the seat clockwise to increase the Battery posts, terminals, and related accessories weight capacity and counter-clockwise to decrease.

-

Page 16: Controls & Features

Controls & Features Deck Lift Pedal RH & LH Drive Control Levers Deck Height Index Deck Lift Release Lever Parking Brake Lever Transmission Bypass Lever Tool Box Digital Tachometer & Hour Meter Throttle Control Ignition Switch Choke Knob Transmission Bypass Lever PTO Knob Cup Holder Accessory Switch Receptacles... - Page 17 Power Take-Off (PTO) Knob Parking Brake Lever The parking brake lever is located on the LH console to The PTO knob is located on the LH console to the left of the the left of the operator’s seat. When pulled up it engages operator’s seat next to the ignition switch.

- Page 18 Deck Height Index Fuel Valve RIGHT FUEL The fuel valve is located behind the TANK seat on the right side of the frame. The valve switches the fuel flow The deck height index consists of several holes located on the from the right and left tank and also left of the foot platform.

-

Page 19: Operation

It has been prepared to help you ever malfunction, do not operate the machine. Contact your operate and maintain your machine efficiently. authorized Cub Cadet Dealer. Fill the fuel tank with only clean, fresh, unleaded gasoline •... -

Page 20: Driving The Tractor

Practice Operation (Initial Use) Turn the ignition key clockwise to the START position and release it as soon as the engine starts; however, do not Operating a zero-turn tractor is not like operating a conventional crank the engine continuously for more than 10 seconds type riding tractor. - Page 21 Turning the Tractor While Driving Forward Move the throttle control lever forward to the full throttle (FAST) position. WARNING! When reversing the direction of travel, NOTE: Although the tractor’s engine is designed to run at we recommend performing gradual ‘U’ turns where full throttle, when performing a practice session the tractor possible.

- Page 22 Turning While Driving Rearward The greater the fore-to-aft distance between the two levers, the sharper the tractor will turn. To turn the tractor while driving rearward, move the control To execute a “pivot turn,” move the turn side drive control levers as necessary so that one lever is forward of the other.

- Page 23 Executing a Zero Turn Stopping the Tractor WARNING! Move both drive control levers to the neutral position to When executing a zero turn, the stop the motion of the machine. tractor MUST BE STOPPED. Executing a zero turn while the tractor is moving can significantly reduce Push the PTO down to the disengaged position.

- Page 24 Using the Mower Deck To prevent rutting or grooving of the turf, if possible, change the direction that the strips are mowed by approximately 45° WARNING! Make certain the area to be mowed is for the next and each subsequent mowing. free of debris, sticks, stones, wire or other objects WARNING! Be careful when crossing gravel paths...

- Page 25 Mower Cutting Blades Low-lift — These blades require less horsepower than hi-lift and medium-lift blades, and they generally work best with wide The blades normally “factory installed” on a mower afford the best leaf grasses, sparse grass growth, and sandy soil conditions. grass cutting performance on the majority of grasses and mowing They generally produce the lowest noise levels.

-

Page 26: Maintenance & Adjustment

Maintenance & Adjustments Maintenance Schedule Before Every 25 Hours Every 50 Hours Every 500 Hours After Mowing Each use Check gasoline level Check tires & tire pressure Check deck, mower and hydro drive belts Check blades and blade bolt tightness Check safety switches for proper operation Check fluid level in transmission oil expansion reservoir Check engine intake screen/cover... - Page 27 OIL CHART Number of Oil Points Description DAILY Apply a few drops of SAE engine oil, grease, or use a spray lubricant. Apply Deck Suspension Pivots the oil to both sides of pivot points. Wipe Height Adjustment Turnbuckle Clevis Pin off any excess.

- Page 28 Periodically check the safety interlock circuits to ensure they are working properly. If a safety circuit is not working as designed, contact you Cub Cadet dealer to have the tractor inspected. DO NOT operate the machine if any safety circuit is not functioning properly.

- Page 29 Changing the Engine Oil Battery WARNING ! If the engine has been recently run, CALIFORNIA PROPOSITION 65 WARNING the engine, muffler and surrounding metal surfaces Battery posts, terminals, and related accessories will be hot and can cause burns to the skin. Exercise contain lead and lead compounds, chemicals known caution to avoid burns.

- Page 30 Put blocks on each side of the opposite traction wheel and jack up the tire that leaks about an inch Remove the spark plugs and pour approximately one off the ground. ounce of oil into each cylinder. Crank the engine one or Loosen and remove the lug nuts and remove the wheel.

- Page 31 Leveling the Mower Deck Front-to-Back Leveling Park the mower on a flat paved surface, engage the parking When correctly adjusted the mower deck should be level side to brake, shut off the engine, remove the key from the ignition side, and the front of the deck should be approximately 1⁄4” lower than the rear of deck.

- Page 32 The brake shoes can be adjusted as the shoes wear. To adjust the Flange Lock Nut brake shoes proceed as follows: NOTE: If the brakes need replaced, please see your Cub Cadet Service Dealer. There is an access hole on the lower inside of the backing plate inside the rear tires.

- Page 33 Rotate the drum back and forth to make sure the brake shoes are not rubbing excessively, if they are rotate the adjusting star back slightly until there is just a slight rub. NOTE: A slight rub is acceptable since a used brake will seat. To contract the brake shoes, rotate the star adjustment outward away from the axle until there is a slight rub between the shoes and the drum.

-

Page 34: Service

(marked POS). If you have a recurring problem with blown fuses, have the tractor’s electrical system checked by your Cub Cadet Service Dealer. Carefully lift the battery out of the tractor. Safety Switch Operation Checks Install the battery by repeating the above steps in the reverse order. -

Page 35: Deck Removal

Electric PTO Clutch Remove the four lynch pins that secure the deck to the deck lift assembly. See Figure 6-3. This clutch operates when the engine is running, the operator is in the operator’s seat and the PTO is engaged. This electric clutch is a normally trouble free device. -

Page 36: Replacing The Blades

Replacing the PTO Belt The speed nut should hold the carriage screw and tab bolt in place, if not re-install as shown in Figure 6-6. Remove the PTO belt from the deck as instructed in the Using a 1⁄2” drive insert the male end into the 1⁄2” square Deck Removal section then remove it from around the PTO opening in the deck idler assembly and rotate the idler clutch. - Page 37 Wrap a rag around one end of the blade and grasp it to To replace the blade reverse the above process and tighten nut to 100-120 lb ft. prevent it from turning, or secure the blade by placing a block of wood between the blade and the deck housing. NOTE: Add a small amount of multi-purpose grease to the See Figure 6-8.

- Page 38 Several components must be removed and special tools used in order to change the tractor’s transmission drive belt. See your Cub Cadet dealer to have the transmission drive belt replaced. Tractor Creeping Creeping is the slight forward or backward movement of the mower when the throttle is on and the speed control levers are in the neutral position.

-

Page 39: Troubleshooting

Troubleshooting Problem Cause Remedy Excessive vibration 1. Cutting blade loose or unbalanced. 1. Tighten blade and spindle. 2. Damaged or bent cutting blade. 2. Replace blade. Uneven cut 1. Deck not leveled properly. 1. Perform side-to-side deck adjustment. 2. Dull blade. 2. -

Page 40: Replacement Parts

Replacement Parts Component Part Number and Description 954-04327 Deck Belt (LZ-54) 954-04319 Deck Belt (LZ-60) 954-04328 PTO Belt (LZ-54) 954-04296 PTO Belt (LZ-60) 954-04320 Drive Belt 942-04416 Hi-Lift Blade, 19.0 (LZ-54) 942-04415 Hi-Lift Blade, 21.0 (LZ-60) 918-05132 Deck Spindle 634-3159 Deck Wheel 731-10336 Deck Skid Guard... - Page 41 Component Part Number and Description 946-04812 Choke Control 946-05103 Park Brake Cable 625-05000 Ignition Key 631-05176A Discharge Chute Assembly 634-05088 Wheel Assembly (LZ-54 & LZ-60), 24 x 12-12 634-04750 Wheel Assembly, 13 x 6.50-6 KM-49065-7010 Oil Filter KM-BPR4ES Spark Plug KM-11013-7044 Air Filter Element (Outer) KM-11013-7045 Air Filter Element (Inner) KM-49019-0014 Fuel Filter...

-

Page 42: Attachments & Accessories

Attachments & Accessories The following attachments and accessories are compatible with your Cub Cadet Tank tractor. See your Cub Cadet dealer or the retailer from which you purchased your tractor for information regarding price and availability. WARNING: 59A30037150 Model front weight kit is required when operating any lap bar steering Tank model equipped with a compatible grass collector. - Page 43 Notes...

-

Page 44: Warranty

Warranty Conditions — Australia (Not applicable to other Regions) The benefits given to you under this warranty are in addition to other rights and remedies that you have under Australian law in relation to the goods. MTD Products Australia Pty Ltd warrants that this machine is free from defects in material and workmanship. This warranty is limited to repairing or replacing any part which appears upon inspection by MTD Products Australia Pty Ltd or its agent to be defective in material or workmanship.