Table of Contents

Advertisement

INSTALLATION, OPERATIONS AND MAINTENANCE

C.S.A. Certified

For Natural Gas Or Propane

An ISO 9001-2008 Certified Company

GMGW

Cast Iron

Gas Fired Boilers

For Forced Hot Water

MANUAL

GMGWB045FE

GMGWB070FE

GMGWB096FE

GMGWB195FE

GMGWB295FE

Tested For 100 psi

ASME

Working Pressure

Models

GMGWB120FE

GMGWB145FE

GMGWB170FE

GMGWB245FE

Manufactured by:

ECR International, Inc.

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

P/N# 240011109, Rev. C [07/22/2015]

Advertisement

Table of Contents

Summary of Contents for Green Mountain GMGWB045FE

- Page 1 GMGW Cast Iron Gas Fired Boilers For Forced Hot Water INSTALLATION, OPERATIONS AND MAINTENANCE MANUAL Models GMGWB045FE GMGWB120FE GMGWB070FE GMGWB145FE GMGWB096FE GMGWB170FE GMGWB195FE GMGWB245FE GMGWB295FE Manufactured by: ECR International, Inc. C.S.A. Certified Tested For 100 psi 2201 Dwyer Avenue, Utica NY 13501...

-

Page 2: Ratings & Data - Natural Gas & Propane Gas

Table 1 Heating Net AHRI Water Input AFUE Elect. No. Of Recommended Air Capacity Rating Water Content Model No. Ign. Burners Cushion Tank (Gals.) GMGWB045FE 82.0% GMGWB070FE 82.0% GMGWB096FE 82.0% GMGWB120FE 82.0% GMGWB145FE 82.0% GMGWB170FE 82.0% GMGWB195FE 82.0% GMGWB245FE 82.0% GMGWB295FE 82.0%... -

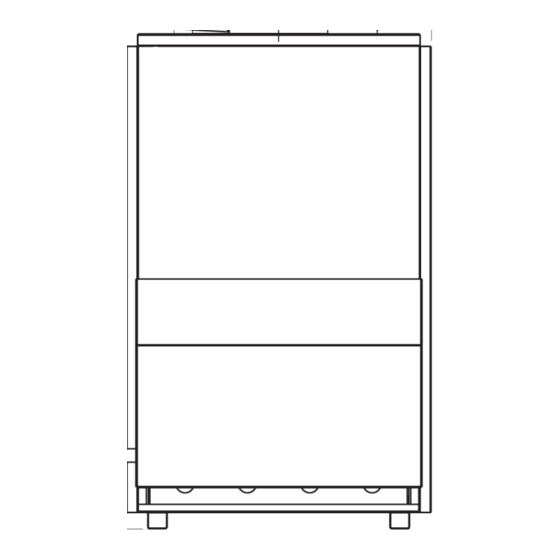

Page 3: Dimensions

2 - DIMENSIONS Dimensions Table 2 - Dimensions Dimensions (Inches) Natural Gas Pump Size Supply & Model No. Inlet* Return Tappings GMGWB045FE ½" 11¼ 5⅝ 27⅛ 20 1¼" GMGWB070FE ½" 15⅛ 28⅛ 20 1¼" GMGWB096FE ½" 15⅛ 28⅛ 20 1¼"... -

Page 4: Table Of Contents

TABLE OF CONTENTS 1 - Ratings & Data - Natural Gas & Propane Gas ............2 2 - Dimensions ......................3 3 - Installation Procedure ....................6 4 - Ventilation & Combustion Air ..................7 5 - Connecting Supply & Return Piping .................8 6 - Vent Installation ....................14 7 - Vent System Modification ..................14 8 - Vent Damper Installation &... - Page 5 SAFETY MESSAGES KEEP THIS MANUAL NEAR BOILER IMPORTANT: Read the following instructions RETAIN FOR FUTURE REFERENCE COMPLETELY before installing!! WARNING Safety Symbols & Warnings The following defined symbols are used throughout this Fire, explosion, asphyxiation and electrical shock manual to notify the reader of potential hazards of varying hazard.

-

Page 6: Installation Procedure

3 - INSTALLATION PROCEDURE WARNING WARNING Improper installation, adjustment, alteration, service Fire hazard. Do not install boiler on combustible or maintenance could result in death or serious flooring or carpeting. Failure to follow these injury instructions could result in death or serious injury. FOR INSTALLATION ON NON-COMBUSTIBLE Installation must conform to the requirements of the FLOORS ONLY - For installation on combustible... -

Page 7: Ventilation & Combustion Air

4 - VENTILATION & COMBUSTION AIR Provide combustion air and ventilation air in accordance • All Outdoor Air. Provide permanent opening(s) with the section “Air for Combustion and Ventilation,” of the communicating directly or by ducts with outdoors. National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Sections о... -

Page 8: Connecting Supply & Return Piping

5 - CONNECTING SUPPLY & RETURN PIPING WARNING Burn or Scald Hazard. Discharge line shall be installed to relief valve outlet connection to avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation. Discharge line shall: •... - Page 9 5 - CONNECTING SUPPLY & RETURN PIPING Hydronic Piping - General • Do not install shutoff valve between boiler and safety relief valve. • Install piping in accordance with authority having jurisdiction. • Systems with automatic fill valves require back flow prevention device.

-

Page 10: Connecting Supply And Return Piping

5 - CONNECTING SUPPLY AND RETURN PIPING NOTICE Circulators in following illustrations are mounted on system supply side, mounting on system return side is also acceptable practice. Figure 2 - Circulators Mounted on Supply System, Boiler Used In Configuration to Chiller System. See Special Conditions, Page 9 PRESSURE REDUCING... - Page 11 5 - CONNECTING SUPPLY AND RETURN PIPING Figure 3 - Bypass Piping -Automatic Mixing Valve, See Bypass Piping Options, Page 9 TO SYSTEM FROM SYSTEM WATER INLET EXPANSION TANK Note: Bypass connection not showing primary/secondary BOILER ALTERNATE piping CIRCULATOR LOCATION PRESSURE BALL VALVE AIR SEPARATOR...

- Page 12 5 - CONNECTING SUPPLY AND RETURN PIPING Figure 5 - Single Zone System With DHW Priority Figure 6 - Multi-Zone System with Circulators and DHW Priority P/N# 240011109, Rev. C [07/22/2015]...

- Page 13 5 - CONNECTING SUPPLY AND RETURN PIPING Figure 7 - Multi-zone System With Zone Valves And DHW Priority (With Circulator) Figure 8 - Multi-zone System With Zone Valves And DHW Priority (With Zone Valve) P/N# 240011109, Rev. C [07/22/2015]...

-

Page 14: Vent Installation

6 - VENT INSTALLATION Boiler series is classified as a Category I. Vent WARNING installation shall be in accordance with "Venting of Boiler and venting installations shall be performed Equipment," of the National Fuel Gas Code, ANSI by a qualified expert and in accordance with the Z223.1/NFPA 54, or "Venting Systems and Air Supply for Appliances,"... -

Page 15: Vent Damper Installation & Instructions

8 - VENT DAMPER INSTALLATION & INSTRUCTIONS Figure 9 - Damper Installation Figure 10 - Damper Location UN-ACCEPTABLE DAMPER LOCATIONS CHIMNEY REFER TO DAMPER MANUFACTURER'S INSTALLATION INSTRUCTIONS FOR POSITION OF DAMPER CONTROL BOX ACCEPTABLE VENT DAMPER LOCATIONS HOT WATER HEATER BOILER Verify only boiler is serviced by vent damper. -

Page 16: Connecting Gas Service

9 - CONNECTING GAS SERVICE General CAUTION • Use piping materials and joining methods acceptable WHAT TO DO IF YOU SMELL GAS to authority having jurisdiction. In absence of such requirements: • Do not try to light any appliance. • USA - National Fuel gas Code, ANSI Z223.1/NFPA 54 •... -

Page 17: Electrical Section

10 - ELECTRICAL SECTION WARNING Electrical shock hazard. Turn OFF electrical power supply at service panel before making electrical connections. Failure to do so could result in death or serious injury. Electrical Wiring Electrically bond boiler to ground in accordance with requirements of authority having jurisdiction. -

Page 18: Wiring Diagram

11 - WIRING DIAGRAM Figure 12 - Integrated High Limit & Electronic Ignition Control WARNING Modification, substitution or elimination of factory equipped, supplied or specified components may result in personal injury or loss of life. P/N# 240011109, Rev. C [07/22/2015]... - Page 19 11 - WIRING DIAGRAM Figure 13 - Integrated High Limit & Electronic Ignition Control P/N# 240011109, Rev. C [07/22/2015]...

-

Page 20: Lighting Instructions

12 - LIGHTING INSTRUCTIONS OPERATING INSTRUCTIONS FOR INTERMITTENT WARNING PILOT SYSTEM If you do not follow these instructions STOP! Read the safety information to the left. exactly, a fire or explosion may result Set the thermostat to lowest setting. causing property damage, personal injury Turn off all electric power to the appliance. -

Page 21: Normal Sequence Of Operation

13 - NORMAL SEQUENCE OF OPERATION Thermostat actuates on call for heat, completing circuit Figure 15 - Blocked Vent Safety Switch, Roll-out to control. Completed circuit to control will first activate Safety Switch circulator. Control will first monitor water temperature with circulator running to determine if thermostat can be satisfed without firing burner;... - Page 22 14 - GENERAL INSTRUCTIONS • Make visual inspection of main burner and pilot flames Figure 16 - Burner Flame at start of heating season and again in mid-season. Main burner flame should have well defined inner blue mantel with lighter blue outer mantel. Check burner throats and burner orifices for lint or dust obstruction.

-

Page 23: Checking Gas Input Rate To Boiler

15 - CHECKING GAS INPUT RATE TO BOILER Gas input to boiler can be adjusted by removing protective Figure 19 - Boiler Right Side and Front cap on pressure regulator Figure 14, Page 20 and turning screw clockwise to increase input and counterclockwise to decrease input. -

Page 24: Appendix A - Control Module

APPENDIX A - CONTROL MODULE A.1 Installation Environment Considerations A.3 Adjusting Settings To discourage unauthorized changing of settings, procedure WARNING to enter adjustment mode is required. If you do not follow these instructions To enter adjustment mode, press UP, DOWN, and I buttons exactly, a fire or explosion may result simultaneously for three seconds. -

Page 25: Operation

APPENDIX A - CONTROL MODULE A.5 Operation Control determines burner operation is required, module proceeds to start burner (see state codes list) Module continuously monitors boiler water temperature and and heats water in boiler until setpoint temperature is fires or shuts off burner based on this temperature data. achieved or thermostat is satisfied. -

Page 26: Boiler High Limit Temperature Controller

APPENDIX A - CONTROL MODULE A.6 Boiler High Limit Temperature Controller A.7 Troubleshooting • When water temperature reaches setpoint, controller • Following service procedures are provided as general ends heating cycle. guide. • When water temperature drops below setpoint minus •... -

Page 27: Intermittent Pilot Ignition System Verification

APPENDIX A - CONTROL MODULE Table 7 - Troubleshooting Error Codes Error Code Definition Consequence Number Flame current too low. Check for flame. Non critical alarm Flame sensed out of normal sequence (before opening or after closing gas valve). Soft lockout Gas valve relays welded. - Page 28 APPENDIX A - CONTROL MODULE STEP 3: Check spark ignition circuit. • Recheck ignition sequence as follows. Disconnect ignition cable at SPARK terminal on module. — Reconnect main valve wire. WARNING — Adjust thermostat above room temperature. — Verify ignition sequence at burner. Electrical shock hazard.

- Page 29 NOTES P/N# 240011109, Rev. C [07/22/2015]...

- Page 30 NOTES P/N# 240011109, Rev. C [07/22/2015]...

- Page 31 SERVICE RECORD P/N# 240011109, Rev. C [07/22/2015]...

- Page 32 I M P O R T A N T In accordance with Section 325 (f) (3) of the Energy Policy and Conservation Act, this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided primarily to permit the use of an external energy management system that serves the same function.

Need help?

Do you have a question about the GMGWB045FE and is the answer not in the manual?

Questions and answers