Table of Contents

Advertisement

Quick Links

INTRODUCTION

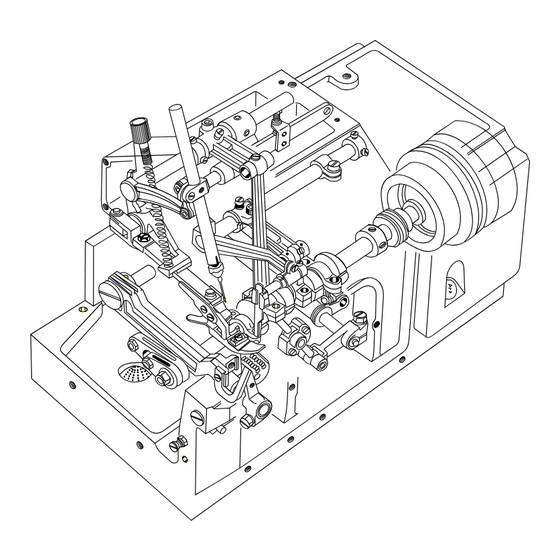

Thank you for your kind patronage to REVO By purchasing REVO DCZ-200-

GS High Speed Self Lubricated Overlock Sewing Machine.

We are sure by installation of this machine in your workshop, you can get

relief from your repeated troubles caused by the out-dated models of

Overlock machines being used by you.

Further more it will make wonderful contribution, certainly to the productivity

when the machine is operated appropriately.

To acquainte the users with proper operation adjustment and maintenance

about this machine we are providing this Instruction-Manual.

Heartily wishing you successful service by REVO DCZ.

Advertisement

Table of Contents

Summary of Contents for Revo DCZ-200-GS

- Page 1 INTRODUCTION Thank you for your kind patronage to REVO By purchasing REVO DCZ-200- GS High Speed Self Lubricated Overlock Sewing Machine. We are sure by installation of this machine in your workshop, you can get relief from your repeated troubles caused by the out-dated models of Overlock machines being used by you.

-

Page 2: Specification

SPECIFICATION Name High Speed Overlocked Stitch Sewing Machine Dimensions 350 x 225 x 285 mm. Weight 21 Kgs Construction Dust-Proof, Oil-tight, Enclosed completely. Stitch type Overedge seaming Sewing Speed upto 6,500 s.p.m. Stitches per inch 6-20 stitches per inch, 7- 23.5 stitches per 30mm Overedge Seaming, Blind Hemming and other uses on general or knitted materials. -

Page 3: Installation

INSTALLATION Fix Supporting Board to the Table by Bolts and Nuts, on which the Rubber Cushion Holder Plate shall be fixed by Wood Screws. $ Rubber Cushions must be put exactly into each horrow on the plate when settiing machine. Machine Table Supporting Board -- Fitting of Belt Cover--... - Page 4 SEWING SPEED AND TURNING DIRECTION OF PULLEY However the available highest sewing speed is 6,500 s.p.m., from the view point of durability of machines, it is preferable to operate at the economical speed of 6,000 s.p.m. after the initial operation at 5,000 s.p.m. in 200 hours approximately -- one month.

- Page 5 Drain Hole Screw for Inner (B) ... for draining Oil inside Frame. Drain Hole Screw for Outer (C) for draining oil collected in the Opening space between between frame and body of the machine. Screw (B) and (C) must be re-tightened after draining. Feeding of new Oil..

-

Page 6: Thread Tension

Position of Needle Thread Eyelet must be changed in case of blind hemming. Refer to "Needle thread Tension" on page 9 please. In case of 1 Needle 2 thread with spreader Needle Thread Lower Looper thread. (for Blind-Hemming Stitch) - - - - (for Wooly Tread) THREAD TENSION Tension of thread should be adjusted as loosely as possible unless the good balance is lost in the seaming. - Page 7 ADJUSTING OF FOOT LIFTER LEVER Adjust Pressure Foot to Start to lift from the top face of stitch Plate turning Adjusting Screw (E) when the Foot Lifter Lever (F) is lowered in 3 mm from the end of Adjusting Screw (E) for Foot Lifter Lever Stopper (D). When Presser Foot is raised to its highest position, adjust the bottom face of it to be 4mm.

-

Page 8: Adjusting Of Stitch Length

ADJUSTING OF STITCH LENGTH By the exchange of Feed Driving Eccentrics, stitch length is adjusted, Each Eccentric has a stamp showing Stitch numbers per inch. (25.4 mm) However, please pay your attention to the fact that there will be difference in some measure owing to kind or thickness of fabrics and ratio of differential feeding. - Page 9 Kind of Feed Driving Eccentrics No. (Stamped) Stitches per inch Stitches per 30 mm. Parts No. 10.5 1010 16.5 23.5 35.5...

-

Page 10: Adjusting Of Differential Feeding

ADJUSTING OF DIFFERENTIAL FEEDING On machines with mark "D" on model plates, adjusting of normal differential feeding (Shrink Sewing) can be made by exchange and combination of eccentrics. At the sewing to increase the effectiveness of differential feeding by exchange of eccentrics turn Pulley manually and confirm that differential Feed Dog will not touch with Main Feeding Dog and Stitch Plate before the operation. -

Page 11: Height Of Needle

When wooly thread is used:- In case such thread which has a plenty elasticity is used, threading of Upper Looper Thread should be changed according to dotted line on the illustration (Right) Note : When it is returned to of ordinary thread after the sewing of wooly thread, donot, forget that the threading must be changed as it was. - Page 12 (6) TIMING BETWEEN UPPER AND LOWER LOOPERS 0.2mm At the rendesvous of Upper and Lower Loopers (A,B) the point Upper Looper passes through the depression just under swelling part on back face of the Lower 0.2mm Looper. It should be adjusted to be less than 0.2mm for allowance of Upper Looper against the backface of Lower Looper, and also against its swelling part.

- Page 13 (9) NEEDLE AND NEEDLE GUARDS 0.05mm Needle and Needle Guard (Rear) : When the Needle which is ascending meets Lower Looper, adjust the allowance with Needle Guard (Rear) (A) to be 0-0.5 mm The Adjusting of Needles Guard (Rear) should be made by Screw (B) for its front-Rear and right-left positioning and by loosening of Screw (C) for High- low positioning.

- Page 14 (12) PARALLELISM OF FEED DOG AND STITCH PLATE When it needs to adjust the Parallelism of Feed Dogs and stitch Plate according to conditions of the sewing, its adjusting shall be made as follows : Remove Rear Cover (A) Remove Cloth Plate Upper (B) Remove Feed Mechanism Cover (C) By the hexagonal Wrench Key (Size - 1/8") loosen Screw (D) and turn Feed Adjusting Pin (F) by the Screw Driver (E) and adjust the parallelism.

- Page 15 (14) EXCHANGE OF LOWER KNIFE Lower Knife can be removed pulling it off downwards after loosening of Screw (B) To fit new Lower Knife or re-sharpened one, insert its blade from the underside and tighten screw (B) (15) SHARPENING OF KNIVES Upper Knife is needles to be re-shapened about one year, because this knife is made of Special Super Steel Alloy.

- Page 16 (16-2) THREADING (Machines for Light Duties) It should be made correctly according to the figure. Needle Thread (Left Needle) Needle Thread (Right Thread) Upper Looper Thread Lower Looper -----(for Wooly Thread) Thread. (Machines for Heavy Duties) Needle Thread (Left Needle) Needle Thread (Right Thread) Upper Looper...

- Page 17 (16-3) EXCHANGE OF NEEDLE CLAMP To Exchange Needle Clamp (... in cases of removal of Needle Bar or Exchange of Needle distance ...) Loosen Screws (B and C) and Pull Needles off, and then turn Needle Clamp (A) anti-clockwise. Tighten Needle Clamp steadily without any looseness to set it.

- Page 18 (16-6) TIMING BETWEEN NEEDLE AND UPPER LOOPER In case of 2 needle machine but the Looper thread is caught by both needle. Insert Upper Looper to Looper Bar (A) at the deepest, and tighten screw (B) temporally, When Needles descending, pass through back side of the Looper, tighten the 5 ~6mm Looper closely to the right Needle by Screw (B) but without touch.

- Page 19 (17) USE OF GUIDE AND OTHER ATTACHMENTS: BLIND HEMMING MACHINE (DCZ - 200) Blind Hemming Guide is assembled on DCZ - 200 machines as the "Standard Equipment". Tightening Screw (B), Guide shall be fitted to Stitch Plate Supporter just underneath of Cloth Plate (Upper) (A) In the blind hemming, depth of seaming line can be adjusted turning Adjusting Screw (D) after loosening of Stopper Screw (C).

-

Page 20: Thread Breakage

(18) How to treat? ... on Sewing Troubles! Trouble and Reasons Countermeasures and Treatment Page A. SKIP - STITCHING a) Incorrect threading Refer to "Threading" 4 - 5, 15 b) Improper fitting of Needle Refer to "Fitting of Needle" and "Height of Needle". 4, 14 (in facing and height) 10, 16... - Page 21 Troubles and Reasons Countermeasures and Treatments Page c) Improper relation between Same as A - d. Needle and Looper d) Improper relation between Refer to "Needle and Needle Guard Needle and Needle Guard D. LOOSENESS ON SEWING FINISH a) Incorrect threading Refer to "Threading".

- Page 22 Troubles and Reasons Countermeasures and Treatments Page e) Blunt cutting of Knives Same as E - e. f) Unfitting of the cutting width with Make both of width fit suitably, Otherwise Stitch Tongue on Stitch Plate. change with new Stitch Plate. g) Improper fitting of Feed Dogs Refer to "Height of Feed Dogs"...

- Page 24 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32617 SIDE COVER 9150 SCREWS FOR 32617 32618 SIDE COVER GASKET 32619 NEEDLE THREAD COVER 32620 NEEDLE THREAD COVER LATCH SPRING 7302 SCREWS FOR 32620...

- Page 26 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32613 TOP COVER (RIGHT) 9150 SCREWS FOR 32613 32597 TOP COVER (RIGHT) GASKET 32970 THREAD LEAD BAR 4435 SCREWS FOR 32970 32974 THREAD LEAD BAR STAY...

- Page 27 18 B 1 8 A...

- Page 28 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32962 TENSION DISC EYELETS FOR LOOPER 6542 LOOPER THREAD TENSION POSTS FELTS FOR 01111 01111 TENSION DISCS 37635 THREAD TENSION SPRING RETAINERS 32952...

- Page 29 18 B 1 8 A...

- Page 30 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 1330 SCREWS FOR 32955, 32358 32358 LOOPER THREAD EYELET (LEFT) 32960 LOWER LOOPER THREAD EYELET DRAIN HOLE SEAL FOR OUTER 9851 DRAIN HOLE SCREW FOR OUTER...

- Page 31 REVO 20 40...

- Page 32 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32774 CRANK SHAFT 32780 FEED DRIVING ECCENTRIC KEY 7609 SCREWS FOR 32773 32820 CRANK SHAFT THRUST COLLAR 7650 SCREWS FOR 32820, 32925 32925...

- Page 33 REVO 20 40...

- Page 34 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32796 LOWER LOOPER DRIVING SHAFT OIL SEAL Notes :...

- Page 35 40-1...

- Page 36 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 90320 NEEDLE BAR CONNECTION LINK PINS OIL WICKS FOR 90320 90321 NEEDLE BAR CONNECTION LINK 32651 NEEDLE BAR CONNECTION BRACKET 4313 SCREW FOR 90320 (32651)

- Page 37 40-1...

- Page 38 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 40-2 32682 THROAT PLATE #3 5401 SCREW FOR THROAT PLATE 32655 NEEDLE GUARD (FRONT) 4404 SCREW FOR 32655 32601 THROAT PLATE SUPPORTER 6662...

- Page 39 TWO LOOPERS SHOULD BE THERE...

- Page 40 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32783 LOOPER DRIVING LEVER CONNECTING RODS 5071 SCREWS FOR 32783 32785 LOPPER DRIVING LEVER LINKS 32784 LOPPER DRIVING LEVER LINKS PINS (SHORT) 9506...

- Page 41 TWO LOOPERS SHOULD BE THERE...

- Page 42 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 9604 SCREWS FOR 30228 32789 LOWER LOOPER HOLDER ARM 32959 LOOPER THREAD PULL-OFF (LEFT) 1326 SCREWS FOR 32959 32790 LOWER LOOPER 3638 SCREW FOR 32790...

- Page 43 11-1...

- Page 44 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32736 PRESSER FOOT 32744 PRESSER FOOT STITCH TONGUE #1 FOR 3 THREAD 32743 PRESSER FOOT STITCH TONGUE #2, #3 FOR 4 THREAD 30619...

- Page 45 11-1...

- Page 46 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32727 PRESSER FOOT RELEASE LEVER 32420 PRESSER FOOT RELEASE LEVER BUSHING 4635 SCREW FOR 32420 32726 PRESSER SPRING 6401 PRESSER SPRING ADJUSTING SCREW...

- Page 47 PENDING 28-1...

- Page 48 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 34134 FEED BAR GUIDE (REAR) 3632 SCREW FOR 34134 3635 SCREW FOR 32866 32858 FEED BAR GUIDE (RIGHT) 9200 SCREW FOR 32858 32857...

- Page 49 PENDING 28-1...

- Page 50 SWARUP MECHANICAL WORKS FEED DRIVING ECCENTRICS TABLE PART No. DESCRIPTION STITCH PER INDH 32821 32822 32835 32823 32824 32825 32836 32826 32827 32828 32837 32838 32829 32839 32830 32840 32841 32842 32832 32843 32844 32845 32833 32846 32847 Notes :...

- Page 52 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 32685 NEEDLE BAR OILING FELT (LEFT) 9853 SCREWS FOR 32685 32812 NEEDLE BAR OILING FELT RETAINER 9604 SCREW FOR 32812 32649 NEEDLE BAR OILING FELT (RIGHT)

- Page 54 SWARUP MECHANICAL WORKS SPARE PARTS LIST OF REVO OVERLOCK MACHINE REF. No. PART No. DESCRIPTION UNITS RATE 7668 OIL TUBE FITTING STUDS 32948 OIL TUBE 47 37668 OIL TUBE FITTING TWO WAY END 32949 OIL TUBE 58 Notes :...

- Page 56 ACCESSORIES...

Need help?

Do you have a question about the DCZ-200-GS and is the answer not in the manual?

Questions and answers