Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KAMA KM376QC

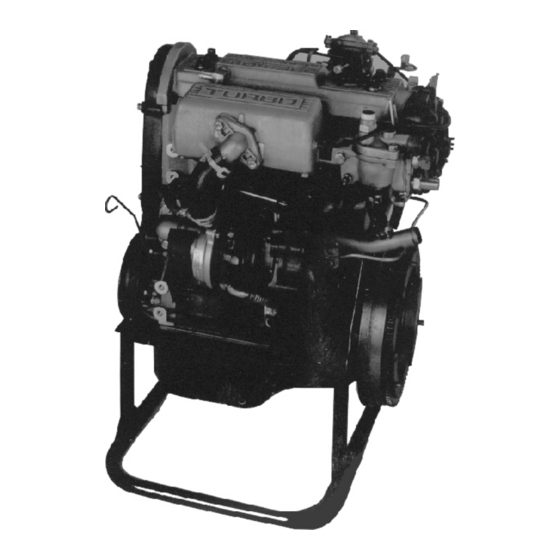

- Page 1 THREE-CYLINDER WATER-COOLED DIESEL KM376 SERIES...

- Page 2 PREFACE Thank you for purchasing KAMA KM376 series three-cylinder water-cooled diesel engine. This manual describes safe information, operation instruction and maintenance of KM376 series diesel engine. Be sure to read this manual carefully before operation, for keeping your engine at the best working condition.

-

Page 4: Table Of Contents

Contents Electric Wiring Diagram 1. Safety Information 1.1 Safety Mark 1.2 Safety Caution 2. Product Instructions 2.1 Main Specifications and Data 2.2 Specifications and Data of Key Parts 2.3 Main Adjusting Data Table 2.4 Tightening Torque of Main Bolts and Nuts 2.5 Operation Control Device 3. - Page 5 11. APPENDIX 9. The Engine Fault and the Elimination Method 9.1 Starting hard or can't start The outline of the tilt-position engine 9.2 The Exhaust Gas is Excessive and Its Color is Abnormal 9.3 Fuel Consumption is Too Large 9.4 The Power is Not Enough 9.5 The Running is Not Stable 9.6 Stopping the Engine Suddenly 9.7 The Engine Can't Stop When the solenoid is Cut Off...

-

Page 6: Safety Information

10. STORAGE 1. SAFETY INFORMATION 10.1 Storage 1.1 Safety Marks Be sure to read and follow the instructions on the manual and safety marks. 10.1.1 The diesel and spare parts and tools leaved from the factory should be Operating the engine without proper training or instruction is not allowed. wrapped in the water-proof plastic cover. - Page 7 9.12 The engine oil level rises DANGER The cause of the fault Elimination method CAUTION: To avoid fire resulted from improper operating. Use the recommended grade diesel oil. Other fuels such as gasoline and 1. There is water leakage at the cylinder 1.

- Page 8 5. The gap between pressure surface 5. Replace the thrust piece, and keep the accident. If necessary, contact your local KAMA agents for replacing the and thrust piece is too large specified gap genuine parts or technical support.

-

Page 9: Product Instructions

2.1 Main Specifications and Data (1) The engine oil in the oil sump is not (1) Refill the engine oil up to the specified enough level Model KM376QC KM376G KM376AG (2) The engine oil becomes thin (2) Choose the specified fuel type Item... -

Page 10: Specifications And Data Of Key Parts

2.2 Specifications and Data of Key Parts 9.8 The engine temperature is over high Specifications and Data The cause of the fault Elimination method Item 1. The water temperature of exhausted is over high Type VE distributor pump Model VE3/9F2500LND (1) The water in the reservoir is not (1) Add water, and eliminate the air Fuel injection... -

Page 11: Main Adjusting Data Table

2.3 Main Adjusting Data Table 9.5 The running is not stable Item 1. Check the air leakage and remedy the 1.There is some air in the fuel Normal adjusting data value Limit value fault then eliminate the air in the fuel system Specification system... -

Page 12: Tightening Torque Of Main Bolts And Nuts

2.4 Tightening Torque of Main Bolts and Nuts 9.3 Fuel consumption is too large The cause of the fault Elimination method Thread Tightening Bolt qty. (1) Fuel leakage (1) replace or tighten securely specification torque (Nm) (2) idle speed is too high (2) regulate idle speed Cylinder head bolt M12 1.25... -

Page 13: Operation Control Device

2.5 Operation Control Device 9.2 The exhaust gas is excessive and its color is abnormal. The operation control device connected to warm-up unit, electric starter and fuel Elimination method The cause of the fault pump solenoid valve respectively. 1. The smoke exhausted is too thick (1) the injecting timing is improper (1) Adjust the injecting timing The electric wiring of the control device is as below figure 2-1. - Page 14 9. THE ENGINE FAULT AND THE ELIMINATION METHOD Elimination method The cause of the fault 1. Starting speed is low. (1) Charge the battery; tighten the connec- (1) Battery electric amount isn't enough tion and repair the terminal if necessary. or the connection is loosened.

-

Page 15: Preparation Before Operation

8.3 The adjustment of the fuel injector 3. PREPARATION BEFORE OPERATION The test and regulation of the injector should be done on the fuel injector test bed. Its purpose is regulating the oil pressure and watching the atomization quality and eliminating the fault. - Page 16 The adjustment engine, even cause the engine to wear rapidly. And the service life of the method of KM376QC/ KM376ZQC ahead angle should be as followed: engine will be also shortened.

-

Page 17: Preparation Before Starting

3.2 Preparation before starting 8. THE ADJUSTMENT OF THE TECHNICAL DATA 3.2.1 Add the lubricating oil (1) The amount of the lubricating oil added should flush with height of the KM376 series engines are different from the general-use diesels in the structure. lubricating oil level in the oil sump. - Page 18 (7) Check the air cleaner The fuel line of the engine fuel system is as shown in figure 3.2.2 followed: If the dust is drawn into the air cleaner and clings to air cleaner parts, it will affect To eliminate the air in the low-pressure fuel line, loosen the connector of the intake the output of the engine sooner or later.

- Page 19 3.2.4 Add the cooling water. (6) Check the battery electrolyte (1) The water in the radiator water tank should be sufficient. Expel the air from the When check the electric circuit, you must close the battery switch, disconnect the water line when adding the water. At the same time, check the water tank and ground terminal.

-

Page 20: Operation Instruction

(4) Check and adjust the valve clearance 4. OPERATION INSTRUCTION Check the valve clearance every 100 running hours method: check valve clearance by removing the cylinder head according to the method described in figure 8-1 of section 8.1. If you want replace the adjusting WARNING shim, use the professional tools for the engine. -

Page 21: Running

(3) Check the injecting pressure and the atomization quality of the fuel OPERATING NOTICE Injector When put the key at the position, 12V DC voltage will open the Check the injecting pressure and the atomization quality of the fuel Injector every solenoid valve in the VE pump. - Page 22 (1) Replace the engine oil, and clean the lubricating oil filter element 4.2.2 When the engine is running normally, inspect the engine oil pressure and Replace the engine oil every 100 hours. temperature, cooling water temperature and the working condition of the charging Clean or replace the lubricating oil filter element.

-

Page 23: Check Engine During The Running

4.3 Check engine during the running Make sure there is no abnormal case during the running referring to following items. 1. Whether the color of the exhaust gas is normal or not. If the engine exhausts black smoke continuously, stop to check it at once. If ignore this symptom, it leads to engine run in a bad condition. -

Page 24: Stop The Engine

In case of missing the necessary item, it will affect the durability of engine parts. As to the parts marked with (*) specially, the owner should have the proper tools and be mechanically proficient. Otherwise, please send your products to your KAMA dealers and consult with them. -

Page 25: Break-In Period And Trial Run

5. BREAK-IN PERIOD AND TRIAL RUN 6. THE STORAGE FOR A LONG TIME A new engine needs a break-in period and a trial-run course. And this course OPERATION NOTICE should not be less than 45 hours or 2800 km. If you don't drain out the cooling reserved in the engine, it will be frozen, During the break-in period, don't let the engine stay at the high-speed state which will damage the parts.

Need help?

Do you have a question about the KM376QC and is the answer not in the manual?

Questions and answers