Weber Automotive MPE 750 Turbo Marine Installation Manual

Hide thumbs

Also See for MPE 750 Turbo Marine:

- Service manual (41 pages) ,

- Service manual (35 pages) ,

- Service manual (41 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Weber Automotive MPE 750 Turbo Marine

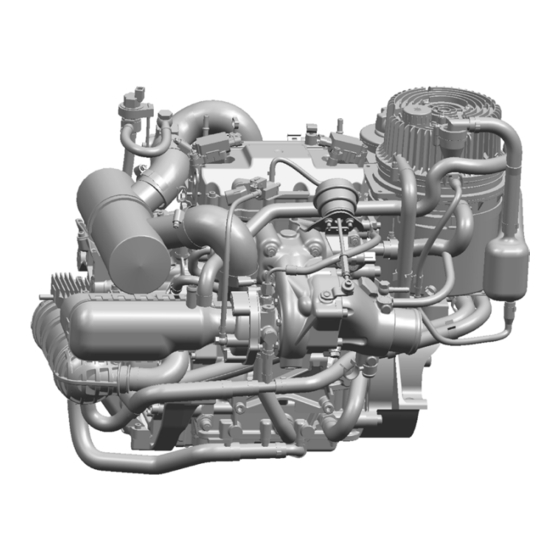

- Page 1 Installation Guide MPE 750 Turbo Marine Closed Loop MPE 750 Turbo Marine - Closed Loop This Installation Guide is valid for the following engine variants: • 103666_I2 749 MAR TC-100 DS V4 2007 3.1 • 103730_I2 749 MAR TC-143 DS V1 2007 3.1 103666_EHB_Rev1.0_080215...

-

Page 2: Table Of Contents

Installation Guide MPE 750 Turbo Marine Closed Loop Table of contents Mechanical Installation 1.1 Engine lift 1.2 Engine fixation and decoupling 1.3 Power Take Off (PTO) 1.4 Throttle cable 2 Alignment engine to drive train Fuel system Cooling water 4.1 Supply sea water 4.2 Flush system 4.3 Boat tow Exhaust system Electric 6.1 Engine monitoring 6.2 Schema engine wire harness 6.3 Schema boat harness 6.4 Required connectors for boat harness... -

Page 3: Mechanical Installation

Installation Guide MPE 750 Turbo Marine Closed Loop Mechanical Installation The following section describes the handling of the engine during installation and the assembly into the boat. In general a clearance of 50 mm between engine and boat hull is required. -

Page 4: Engine Lift

Installation Guide MPE 750 Turbo Marine Closed Loop Engine lift The engine has two lift eyes (1) at the cylinder head. Only use these eyes to raise the engine. 103666_EBH_Rev1.0_080215 Page 2... -

Page 5: Engine Fixation And Decoupling

Installation Guide MPE 750 Turbo Marine Closed Loop Engine fi xation and decoupling The engine mounts are specifi c for marine applications, a decoupling to the boat is necessary. The picture shows the placement and proposed engine bearings (1) of the marine engine. -

Page 6: Power Take Off (Pto)

Installation Guide MPE 750 Turbo Marine Closed Loop Power Take Off (PTO) The connection to the drive train is by a thread M24x2 on the PTO of the engine 103666_EBH_Rev1.0_080215 Page 4... -

Page 7: Throttle Cable

Installation Guide MPE 750 Turbo Marine Closed Loop Throttle cable The engine has a mechanical throttle body which has to be activated by a marine throttle cable. The travel of 70 mm is designed to meet the function throttle levers like the Telefl ex JBS system. -

Page 8: Alignment Engine To Drive Train

To check and adjust the alignment between the engine and the Weber Automotive Jet Propulsion System a Weber Automotive alignment tool was designed. This tool is using a laser to get the engine with drive system set up properly. The use of this tool is described in the installation manual of the Weber Jet Propulsion System. -

Page 9: Fuel System

Installation Guide MPE 750 Turbo Marine Closed Loop Fuel System The fuel pump (1) has to deliver 120 liters per hour at a pressure of 4.5 bar. A possible pump and fi lter confi guration is shown in the following picture. To ensure a safe and adequate fuel delivery a minimum inner diameter of 8 mm is required for fuel hoses and fi... - Page 10 Installation Guide MPE 750 Turbo Marine Closed Loop Fuel System The fuel rails fi ttings ars designed conform to SAE J2044. The use of quick connectors (1) (2) is strictly recommended. (a) Fuel Feed Line from Fuel Pump: Fitting SAE...

- Page 11 Installation Guide MPE 750 Turbo Marine Closed Loop Fuel System The engine and the fuel components including recommended fuel fi lters and stainless steel fuel quick connectors are conform to: • USCG: Boatbilder handbook Subpart J - Fuel Systems: Title 33 CFR Sections 183.501-183.590 •...

-

Page 12: Cooling Water

Installation Guide MPE 750 Turbo Marine Closed Loop Cooling Water The engine itself has no water pump to feed the open loop of the cooling system. In a combination with a jet pump the sea water for cooling is delivered by the jet pump propulsion system. By using different propulsion systems a water pump has to be integrated into the drive train. - Page 13 Installation Guide MPE 750 Turbo Marine Closed Loop Cooling Water 103730_I2 749 MAR TC-143 DS V1 2007 3.1 (2) Fitting at charge air cooler for sea water supply . Inner diameter of tube: 19mm The water / water cooler has a fi tting to drain the water out of the open loop.

-

Page 14: Supply Sea Water

Installation Guide MPE 750 Turbo Marine Closed Loop Supply Sea Water The delivery of sea water of the open loop cooling circuit has to meet the specifi cation listed in the table. Engine: 98 - 105 kW Engine: 49 - 76 kW... -

Page 15: Flush System

Installation Guide MPE 750 Turbo Marine Closed Loop Flush System Especially for the use of the boat in salt water a fl ush system to rinse the open loop cooling circuit is recommended. Therefore a fl ush system has to be implemented by the boat builder. -

Page 16: Boat Tow

Installation Guide MPE 750 Turbo Marine Closed Loop Boat tow In combination with a jet propulsion system there is a risk to fi ll the engine with water by towing the boat. The engine has a wet exhaust system. This means sea water is injected into the exhaust out of the open loop cooling circuit. -

Page 17: Exhaust System

Installation Guide MPE 750 Turbo Marine Closed Loop Exhaust System The exhaust system of the spark ignition marine engine is water cooled. A part of the sea water is injected into the manifold to reduce the exhaust temperature and the noise in the system. This injected water will leave the boat through the exhaust system (1). - Page 18 Installation Guide MPE 750 Turbo Marine Closed Loop Exhaust System Engine exhaust manifold and muffl er can be connected by a rubber tube, e.g. Marine exhaust tube by VETUS. The muffl er should have a volume of approximately 17 Liter and the back pressure of the whole exhaust system has to be: max.

-

Page 19: Electric

Installation Guide MPE 750 Turbo Marine Closed Loop Electric The engine will be delivered including an engine wire harness and Engine ECU. All necessary connectors for the vehicle wire hardness are listed in section 6.4. Also diameters of the wires in the vehicle harness have to match the diameters of the engine harness. -

Page 20: Engine Monitoring

Installation Guide MPE 750 Turbo Marine Closed Loop Electric The engine can give out following output / informations: • MIL (Malfunktion Indicator Light): Will be activated when engine performance is limited • Engine overtemperature lamp: Is activated when engine temperature exceed the limit •... -

Page 21: Schema Engine Wire Harness

Installation Guide MPE 750 Turbo Marine Closed Loop Schema engine wire harness 103666_EBH_Rev1.0_080215 Page 19... -

Page 22: Schema Boat Harness

Installation Guide MPE 750 Turbo Marine Closed Loop Schema boat wire harness 103666_EBH_Rev1.0_080215 Page 20... -

Page 23: Required Connectors For Boat Harness

Installation Guide MPE 750 Turbo Marine Closed Loop Required connectors for boat harness Following table shows the connector parts needed fort he boat wire harness: Connector to the engine wire harness (Engine / Chassis 1): Description Manufacturer Series Part Number... -

Page 24: First Run And Brake In Of Engine

Installation Guide MPE 750 Turbo Marine Closed Loop First engine run and brake in After the engine installation is fi nished a fi rst run with the boat out of the water is recommended. Therefor use the fl ush system to avoid any damage of the engine due to overheat. The use of the fl ush system is described in section 4.2. - Page 25 Installation Guide MPE 750 Turbo Marine Closed Loop First engine run and brake in • Prime the fuel system: Activate the fuel pump by turning on the key switch (not in start position). • Connect the fl ush system as described in section 4.2 •...

-

Page 26: Maintenance

Installation Guide MPE 750 Turbo Marine Closed Loop Maintenance Following table shows the maintenance intervals for the marine engine. mainte- nance Maintenance interval after 25 every 50 every 100 Motor oil and oil ■ ■ ■ Change fi lter ■ every 4 years... -

Page 27: Serial Release

MPE 750 Turbo Marine Closed Loop Engine Serial Release The engine installation and function has to be released by Weber Automotive before warranty will cover the product. Therefore two ways are possible: • Installation check by Weber Automotive, this service will be quoted on a time travel and mateial basis •... -

Page 28: Specification For Fuel, Oil And Coolant

Installation Guide MPE 750 Turbo Marine Closed Loop Specifi cation for fuel, oil and coolant Fuel: Fuel quality Unleaded gasoline according to DIN 51607 („super unleaded“), with an octane rating of at least 95 ROZ [RON] or 85 MOZ [MON]... -

Page 29: Basic Dimensions

Installation Guide MPE 750 Turbo Marine Closed Loop Basic dimensions [mm] Please contact Weber Automotive for detailed drawings or CAD models. 52,5 140° 140° 103666_EBH_Rev1.0_080215 Page 27... -

Page 30: Reference Addresses

Installation Guide MPE 750 Turbo Marine Closed Loop Reference Adresses Throttle cable: RCS: Remote Control Systems GmbH www.r-c-s-online.de Contact Mr. Frank Schneider Frank.Schneider@r-c-s-online.de Helm Throttle Level: Teleflex www.teleflexmorse.com Allpa Marine Equipment www.allpa.nl www.allpa.de www.allpa.eu Exhaust Tube: Vetus Allpa Marine Equipment www.allpa.nl... -

Page 31: Appendix

Installation Guide MPE 750 Turbo Marine Closed Loop 103666_EBH_Rev1.0_080215 Page 29...

Need help?

Do you have a question about the MPE 750 Turbo Marine and is the answer not in the manual?

Questions and answers