Daikin RX09NMVJU Installation Manual

Hide thumbs

Also See for RX09NMVJU:

- Installation manual (39 pages) ,

- Engineering data (176 pages) ,

- Service manual (24 pages)

Table of Contents

Advertisement

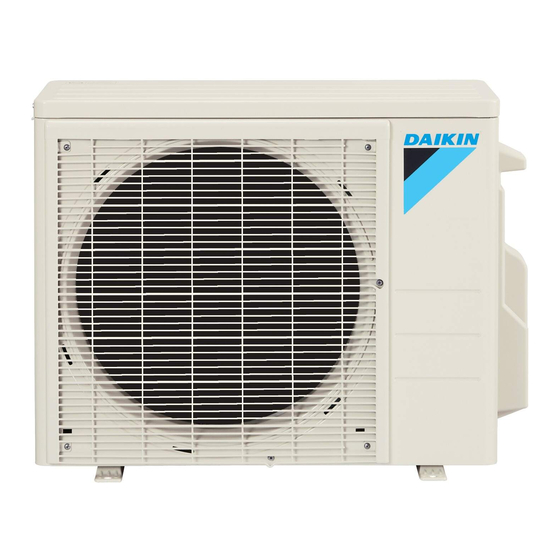

MODELS

RK09NMVJU

RX09NMVJU

RX12NMVJU

RK12NMVJU

RX18NMVJU

RK18NMVJU

RX24NMVJU

RK24NMVJU

RXN09NMVJU

RKN09NMVJU

RKN12NMVJU

RXN12NMVJU

RXN18NMVJU

RKN18NMVJU

RXN24NMVJU

RKN24NMVJU

DAIKIN ROOM AIR CONDITIONER

INSTALLATION MANUAL

R410A Split Series

RXL09QMVJU

RXL12QMVJU

RXL15QMVJU

Installation manual

Manuel dinstallation

Manuel dinstallation

Manual de instalación

Advertisement

Table of Contents

Summary of Contents for Daikin RX09NMVJU

-

Page 1: Installation Manual

DAIKIN ROOM AIR CONDITIONER INSTALLATION MANUAL R410A Split Series Installation manual Manuel dinstallation Manuel dinstallation Manual de instalación MODELS RK09NMVJU RXL09QMVJU RX09NMVJU RX12NMVJU RK12NMVJU RXL12QMVJU RX18NMVJU RK18NMVJU RXL15QMVJU RX24NMVJU RK24NMVJU RXN09NMVJU RKN09NMVJU RKN12NMVJU RXN12NMVJU RXN18NMVJU RKN18NMVJU RXN24NMVJU RKN24NMVJU... -

Page 2: Table Of Contents

Contents Safety Considerations ........1 3. Flaring the pipe end ............. 6 4. Refrigerant piping ............6 Accessories ............. 3 5. Pressure test and evacuating system ......7 6. Refilling refrigerant ............8 Precautions for Selecting a Location ... 3 7. Refrigerant piping work ..........8 Wiring ............... - Page 3 Corroding copper pipes or soldered parts may result in is shorted and operated forcibly, or parts other than those refrigerant leakage. specified by Daikin are used, fire or explosion may occur. (c) Near machinery emitting electromagnetic waves. Electromagnetic waves may disturb the operation of the control system and cause the unit to malfunction.

-

Page 4: Accessories

Accessories Drain socket* Installation manual This is at the bottom of the packaging. Drain cap (1)* Drain cap (2)* 09/12 class 09/12 class 15/18/24 class 15/18/24 class *Only for heat pump models. Warranty Precautions for Selecting a Location 1) Choose a place solid enough to bear the weight and vibration of the unit, where the operating sound will not be amplifi ed. 2) Choose a location where the hot air discharged from the unit or the operating sound will not cause a nuisance to the neighbors of the user. -

Page 5: Precautions On Installation

Precautions on Installation • Check the strength and level of the installation surface so that the unit does not cause any operating vibrations or noise after installation. • Fix the unit in place securely using foundation bolts, as in the figure. (Prepare 4 sets of 5/16 inch (M8) or 3/8 inch (M10) foundation bolts, nuts and washers; all separately available.) • It is best to screw in the foundation bolts until their ends are 3/4 inch (20mm) from the foundation surface. -

Page 6: Installation Space Requirements

Installation Space Requirements • Where a wall or other obstacle is in the path of the outdoor unit’s intake or exhaust airflow, follow the installation space requirements below. • For any of the below installation patterns, the wall height on the outlet side should be 47-1/4 inch (1200mm) or less. 09/12 class Wall facing one side Walls facing two sides More than More than 1-15/16 (50) 3-15/16 (100) -

Page 7: Drain Work (Only For Heat Pump Models, Excluding Rxl Models)

Drain work (only for heat pump 09/12 class 15/18/24 class Drain cap (1) Drain cap (1) models, excluding RXL models) Drain cap (2) Drain cap (2) CAUTION Drain cap (1) In cold areas, do not use a drain socket, drain caps (1,2) Drain Drain and a drain hose with the outdoor unit. -

Page 8: Pressure Test And Evacuating System

Outdoor Unit Installation Pressure test and evacuating system WARNING • Do not mix any substance other than the specified refrigerant (R410A) into the refrigeration cycle. • If refrigerant gas leaks should occur, ventilate the room as soon and as much as possible. • R410A, as well as other refrigerants, should always be recovered and never be released directly into the environment. • Use a vacuum pump for R410A exclusively. -

Page 9: Refilling Refrigerant

Refilling refrigerant Check the type of refrigerant to be used on the machine nameplate. Precautions when adding R410A Fill from the liquid pipe in liquid form. R410A is a mixed refrigerant, so adding it in gas form may cause the refrigerant composition to change, preventing normal operation. -

Page 10: Wiring

Wiring WARNING • Do not use tapped wires, extension cords, or starburst connections, as they may cause overheating, electric shock, or fire. • Do not use locally purchased electrical parts inside the product. (Do not branch the power for the drain pump, etc., from the terminal block.) Doing so may cause electric shock or fire. • Be sure to install a ground fault circuit interrupter. (One that can handle higher harmonics.) (This unit uses an inverter. - Page 11 15/18/24 class [Method of mounting conduit] 1) Dismount the service lid by removing the 2 screws. 2) Pass wires through the conduit and secure them with a lock nut. 3) After completing the work, reattach the service lid to its original position. Power supply Service lid terminal block...

-

Page 12: Facility Setting (Cooling At Low Outdoor Temperature)

Facility Setting* (cooling at low outdoor temperature) This function is limited only for facilities (the target of air conditioning is equipment (such as computer)). Never use it in a residence or offi ce (the space where there is a human). *Only for RX, RK, and RXL models. -

Page 13: Trial Operation And Testing

Trial Operation and Testing Trial operation and testing • Trial operation should be carried out in either COOL or HEAT operation. 1-1. Measure the supply voltage and make sure that it is within the specified range. 1-2. In COOL operation, select the lowest programmable temperature; in HEAT operation, select the highest programmable temperature. 1-3. - Page 14 Two-dimensional bar code is a manufacturing code. 3P379970-6B M15B135 (1511) HT...

Need help?

Do you have a question about the RX09NMVJU and is the answer not in the manual?

Questions and answers