Table of Contents

Advertisement

Read this entire manual. This

safety alert symbol is used

throughout this manual to call your

attention to messages involving

your personal safety and the safety

of others. Failure to follow these

instructions can result in injury or

death.

WARNING

Si no entiende ingles, se prefiere que

busque a alguien que interprete las

instrucciones para usted.

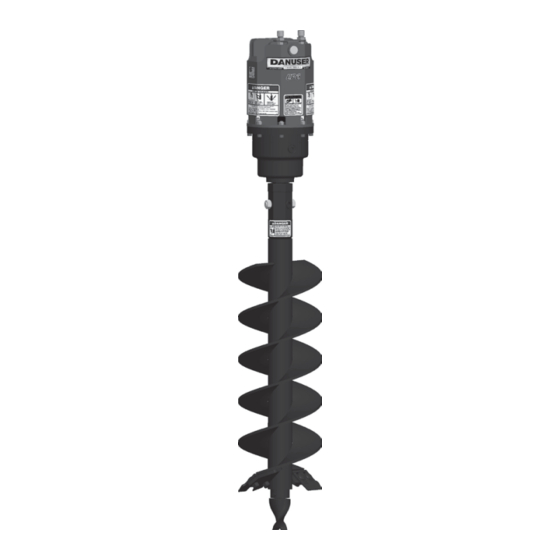

EP

HEAVY DUTY

AUGER SERIES

MODELS

EP6 Hex,

EP10 Hex,

EP15 Hex,

EP20 Hex,

Owner:

Date Purchased:

Model #:

9MEP2457351

Manual #:

Operator's Manual

Danuser LLC

500 E. 3rd St.

P.O. Box 368

Fulton, MO 65251

Tel: (573) 642-2246

E-mail: sales@danuser.com

Website: www.danuser.com

EP6 Round

EP10 Round

EP15 Round

EP20 Round

Serial #:

Fax: (573) 642-2240

Advertisement

Table of Contents

Summary of Contents for Danuser EP6 HEX

- Page 1 HEAVY DUTY AUGER SERIES MODELS EP6 Hex, EP6 Round EP10 Hex, EP10 Round EP15 Hex, EP15 Round EP20 Hex, EP20 Round Owner: Read this entire manual. This safety alert symbol is used Date Purchased: throughout this manual to call your...

- Page 2 Danuser provides this manual "as is" without warranty of any kind, either expressed or implied. Danuser assumes no responsibility for errors or omissions. Danuser assumes no liability for damages resulting from the use of the Danuser is a registered trademark.

-

Page 3: Table Of Contents

WARRANTY REGISTRATION FORM. This form is included in your unit’s paperwork package. If you did not complete a WARRANTY REGISTRATION FORM or did not receive one, please call Danuser LLC. Or, register online at www.Danuser.com. Your satisfaction with our product and your safety as a user of our product are both very important to us. -

Page 4: Safety

If there is anything in this manual you do not understand, contact your dealer or Danuser LLC. The safe use of this machine is strictly up to you, the operator. If this unit is used, loaned,... - Page 5 Safety • Do not allow riders on the equipment at any time. There is no safe place for any riders. • Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating this equipment. Consult your doctor about operating this equipment while taking prescription (continued) or over-the-counter medications.

- Page 6 Always use care when operating the earth auger. Most accidents occur because of neglect or carelessness. Safety is a primary concern in the design, manufacture, sale, and use of earth augers. Danuser confirms to you, our customer, our concern for safety.

-

Page 7: Decals & Safety Signs

The earth auger comes equipped with all safety signs in place. Their locations are shown in Decals & this section. Read and follow their instructions and ensure their care: Safety Signs • Keep safety signs clean and legible at all times. •... -

Page 8: Safety Signs

Decals & Safety Signs (continued) PART NO. DIG7 Locations: Knuckle ear, left side; Knuckle ear, right side TLB & Excavator Knuckle PART NO. DIG6 Locations: Knuckle ear, left side; Knuckle ear, right side Mini-Excavator Knuckle PART NO. DANUSER101 Locations: Quick attach plate, left side; Quick attach plate, right side PART NO. -

Page 9: Drive Unit Specifications

Drive Unit Specifications EP10 EP15 EP20 Minimum Hydraulic Flow 6 GPM 10 GPM 15 GPM 20 GPM Maximum Hydraulic Flow 15 GPM 20 GPM 30 GPM 35 GPM Maximum Continuous Operating PSI 3000 PSI 3000 PSI 3000 PSI 3000 PSI Maximum Auger Diameter 24 inches 30 inches... -

Page 10: Hydraulic Requirements

Pressure and Flow Requirements: • Models EP6, EP10, EP15, and EP20 Danuser Earth Augers are designed to operate within the pressure range of 1500 to 3000 PSI. • Operating flow rate is dependent on model: 6 to 15 GPM for Model EP6, 10 to 20 GPM for Model EP10, 15 to 30 GPM for Model EP15, and 20 to 35 GPM for Model EP20. -

Page 11: Assembly & Installation

Assembly & Drive unit and auger exploded views and part lists Installation are detailed on separate pages in this manual. Skid-Steer Mount = Safety Sign Location REF. NO. PART NO. DESCRIPTION QTY. 10488 Quick Attach Plate Assembly (includes REF. NOS. 1-5 and 9-10) 10965 Cradle Assembly 10975... - Page 12 Assembly & Drive unit and auger exploded views and part lists Installation are detailed on separate pages in this manual. Offset Skid-Steer Mount = Safety Sign Location REF. NO. PART NO. DESCRIPTION QTY. 20652 Offset Quick Attach Plate Assembly (includes REF. NOS. 1-2 and 6-7) 10198 Knuckle Assembly -----...

- Page 13 Assembly & Drive unit and auger exploded views and part lists Installation are detailed on separate pages in this manual. Offset Euro Mount = Safety Sign Location REF. NO. PART NO. DESCRIPTION QTY. 20653 Offset Euro Mount Assembly (includes REF. NOS. 1-2 and 6-7) 10198 Knuckle Assembly -----...

- Page 14 Assembly & Drive unit and auger exploded views and part lists Installation are detailed on separate pages in this manual. John Deere 200/300/400/500 Series Mount = Safety Sign Location REF. NO. PART NO. DESCRIPTION QTY. 20659 John Deere 200/300/400/500 Series Offset Mount Assembly (includes REF.

- Page 15 Assembly & Drive unit and auger exploded views and part lists Installation are detailed on separate pages in this manual. Mini-Excavator Mount REF. NO. PART NO. DESCRIPTION QTY. ----- Drive Unit 10219 Knuckle Sub-Assembly 10193 Pin (1-1/4" x 9-1/2") 20012 Lock Pin ----- Ear Assembly...

- Page 16 Assembly & Installation Drive unit and auger exploded views and part lists are detailed on separate pages TLB & Excavator Mount in this manual. REF. NO. PART NO. DESCRIPTION QTY. ----- Drive Unit 10247 Knuckle Sub-Assembly 10193 Pin (1-1/4" x 9-1/2") 20012 Lock Pin -----...

- Page 17 Assembly & Drive unit and auger exploded views and part lists Installation are detailed on separate pages in this manual. Bolt-on Bucket Mount = Safety Sign Location REF. NO. PART NO. DESCRIPTION QTY. 9591B Bucket Mount Assembly 10976 Knuckle Assembly ----- Drive Unit 10193...

- Page 18 - use genuine Danuser replacement parts only. For hex spindle, use Danuser PN 10038 (3/4" 10 x 4", Gr. 8, 3/4" of thread) special retaining bolt and nut PN 10041. NEVER use a bolt longer than 4". For round (continued) spindle, use Danuser PN 10039 (7/8"...

-

Page 19: Operation

Operation DANGER Contact with underground gas lines or electrical cables may DANGER result in serious injury or death from explosion or electrical shock. Before operating, call 811 or the local number to locate underground utilities. Do not dig near underground This earth auger is utility lines. - Page 20 Shut off the vehicle engine, and remove the vehicle key. ONLY with an authorized Install a new Danuser retaining bolt. This is a special thread length bolt - factory replacement. An use genuine Danuser replacement parts only. For hex spindle, use Danuser auger retaining bolt that PN 10038 (3/4"...

-

Page 21: Removal & Storage

Removal & Before storage, the earth auger should be thoroughly cleaned, washing off all dirt and grime. Make sure the hydraulic system is properly sealed against contaminants entering the unit. Storage Always store the earth auger in a dry, covered location. STEP 1: play. -

Page 22: Troubleshooting

Hose rating too low for hydraulic system Replace with hoses with working pressure pressure rated higher than vehicle hydraulic pressure Hoses pinched Reroute hoses For additional assistance, please call your dealer or contact Danuser direct: Tel: (573) 642-2246 Fax: (573) 642-2240 E-mail: sales@danuser.com... -

Page 23: Maintenance & Lubrication

Proper servicing and maintenance are key to the long life of any attachment. Careful Maintenance & inspection and routine maintenance helps avoid costly downtime and repair. Do not use the Lubrication earth auger with any damaged parts. WARNING DANGER Never check pressurized system for leaks with your bare hand. -

Page 24: Torque Values Chart

Torque Values Chart Torque Values Chart 10.9 Bolt Size Bolt Size Class 8.8 Class 10.9 (inches) Grade 2 Grade 5 Grade 8 (Metric) Class 5.8 ft.-lbs. ft.-lbs. ft.-lbs. mm x pitch ft.-lbs. ft.-lbs. ft.-lbs. in tpi M5 x 0.8 1/4” 20 M6 x 1 1/4”... -

Page 25: Drive Unit Parts

REF. NO. PART NO. DESCRIPTION QTY. MODELS 10180 (H) 20180 (R) Drive Unit EP6 Hex or Rd. 10181 (H) 20181 (R) Drive Unit EP10 Hex or Rd. 10182 (H) 20182 (R) Drive Unit EP15 Hex or Rd. 20001 (H) 20184 (R) Drive Unit EP20 Hex or Rd. -

Page 26: Augers & Accessories

Augers & Accessories AUGER COLLAR DESCRIPTION PART NO. 2 Hex 10328 = Safety Sign 2-9/16 Rd. 10329 Location AUGER ADAPTERS DRIVE AUGER PART UNIT COLLAR 2 Hex 2-9/16 Rd. 10921 2 Hex 10922 2-9/16 Rd. 2 Hex 10923 2-9/16 Rd. 10924 2 Hex 2-9/16 Rd. - Page 27 10631 Bolt 10413 10633 10634 4 diameter auger below 10636 10637 Dirt 10333 Please call Danuser for 3 , 5 , or 6 requests. Hardfaced 10334 Chunky Carbide 10336 10412 "TREE" AUGERS - 4 LENGTH Bolt 10416 NO. OF 2-9/16 DIA.

- Page 28 Operating Load or Rated Operating Capacity of 2250 lbs. or greater, utilizing an auger drive with 2000 ft. lbs. of torque or greater. See patent at danuser.com/patents. HOSE KITS & COUPLERS 10050 FLAT FACE ISO 10051...

- Page 29 This page is intentionally blank.

-

Page 30: Warranty

Any parts or labor required to repair or replace parts not covered under this warranty will be charged to the customer. Parts repaired or replaced by Danuser are then covered by this warranty only for the remainder of the original warranty as if such parts were original parts.

Need help?

Do you have a question about the EP6 HEX and is the answer not in the manual?

Questions and answers