Advertisement

CONTENTS

1. General information of Outdoor Units ................................................................................................... 3

2. Dimensions .............................................................................................................................................. 4

3. Wiring Diagram ........................................................................................................................................ 5

4. Refrigeration Cycle Diagram .................................................................................................................. 7

5. Indoor units combination ....................................................................................................................... 8

6. Electronic control function..................................................................................................................... 9

7. Troubleshooting .................................................................................................................................... 14

Advertisement

Troubleshooting

Summary of Contents for Pridiom POM273HX

-

Page 1: Table Of Contents

CONTENTS 1. General information of Outdoor Units ....................3 2. Dimensions .............................. 4 3. Wiring Diagram ............................5 4. Refrigeration Cycle Diagram ........................7 5. Indoor units combination ........................8 6. Electronic control function........................9 7. Troubleshooting ............................ 14... -

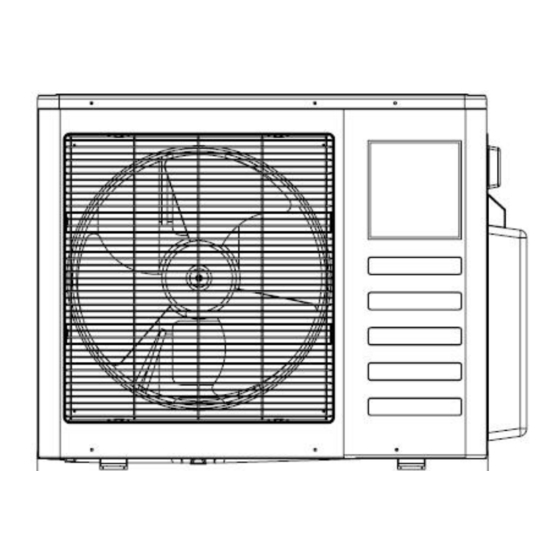

Page 2: General Information Of Outdoor Units

1. General information of Outdoor Units Outdoor unit Power relay control Low noise air flow system Hydrophilic aluminum fin The hydrophilic fin can improve the heating efficiency at operation mode. 4 way valve control It is only operated in the heating operation mode except defrosting operation. Anti-rust cabinet Valve protection cover It protects the valves and prevents water from dripping. -

Page 3: Dimensions

2. Dimensions... -

Page 4: Wiring Diagram

3. Wiring Diagram... -

Page 6: Refrigeration Cycle Diagram

4. Refrigeration Cycle Diagram 4.1 Refrigeration circuit drawing of inverter binary type Axial flow fan EXVA Auxiliary Liquid valve A Filter A Capillary Exhaust Main Capillary A temp. sensor Capillary EXVB Check Liquid valve B Filter B flow fan Condenser Coil temp. -

Page 7: Indoor Units Combination

5. Indoor units combination Indoor unit combination for One unit Two unit 9+9 9+12 Indoor unit combination for One unit Two unit Three unit 9+12 9+9+9 9+9+12 12+12 5.3 Indoor unit combination for One unit Two unit Three unit Four unit 9+12 9+9+9 9+9+12... -

Page 8: Electronic Control Function

Electronic control function 6.1 Abbreviation T1: Indoor ambient temperature T2: Coil temperature of indoor heat exchanger middle. T2B: Coil temperature of indoor heat exchanger outlet. T3: Coil temperature of outdoor heat exchanger T4: Outdoor ambient temperature T5: Compressor discharge temperature Ts: Setting temp. - Page 9 EXV open angle for 2# indoor unit Actual data divide 8 EXV open angle for 3# indoor unit Actual data divide 8 EXV open angle for 4# indoor unit Actual data divide 8 Power supply of outdoor unit AD data Indoor unit number The indoor unit can communicate with outdoor unit well.

- Page 10 6.4.4Number of indoor unit Display Number of indoor unit 6.4.5 Outdoor ambient temp: Corresponding Corresponding Display Corresponding temp. Display Display temp. temp. -7.5 10.5 25.5 -6.5 11.5 26.5 -5.5 11.5 27.5 -4.5 12.5 28.5 -3.5 13.5 29.5 14.5 -1.5 30.5 15.5 -0.5 31.5...

- Page 11 6.4.6 Opening degree of electronic expansion valve: Actual opening degree equals the display data divided 8 6.5 Protection 6.5.1 Three minutes delay at restart for compressor. 6.5.2 Temperature protection of compressor discharge. When the compressor discharge temp. is getting higher, the running frequency will be limited as below rules: ----If 102℃<T5<115 , decrease the freq uency to the lower level every 2 minutes till to F1.

- Page 12 RECOILFRE for 3mins and then resume to former frequency. Model RECOILINFRE POM182HX POM273HX POM365HX During the oil return process, the EXV and indoor units keep the current running mode, the frequency will not be limited by the compressor discharge temp. and the current.

-

Page 13: Troubleshooting

7. Troubleshooting Indoor unit error code explanation: Vertu series: Display LED STATUS EEPROM error Communication error between indoor and outdoor unit Zero-crossing examination error Fan speed beyond control Outdoor units temp. sensor or connector of temp. sensor is defective Indoor units temp. sensor or connector of temp. sensor is defective Inverter module protection Outdoor voltage too low protection Compressor discharge temp. -

Page 14: Trouble Shooting

7.3Trouble shooting 7.3.1 Indoor unit trouble shooting Indoor unit display LED STATUS EEPROM error Replace indoor PCB Circuit or software error on indoor PCB Indoor unit display LED STATUS outdoor communication error Disconnect the power supply, after 1 minute, connect the power supply, turn on the unit with remote controller Does unit... - Page 15 power supply Be sure the power supply is good connection of connectors and correct the connection good? Indoor PCB is defective. Replace the indoor PCB. Indoor unit display LED STATUS Fan speed beyond control Is the indoor fan motor Repair the connector and connector and connection reconnect good?

- Page 16 Is the indoor temperature evaporator sensor Repair the connector and connector and connection reconnect good? Replace the sensor and Replace the.indoor PCB check if E6 display again? Indoor unit display LED STATUS Inverter module protection Revise the power and retest. Is voltage normal? Is all connection good? Revise the power and retest.

- Page 17 Indoor unit display LED STATUS Compressor top protection against temperature Is the connection Does compressor Reconnect and retest. good? operate? refrigerant protector Replace the protector. circulation normal? volume normal? Check the outdoor Charge refrigerant main PCB. Is there some problem? Replace the outdoor PCB.

- Page 18 Is connection to connector of pipe temp. sensor good? Repair connector Check the resistance of the temp. sensor according to Annex 1 Replace the sensor LED STATUS Outdoor unit display No 2 Indoor units pipe temp. sensor or connector of pipe temp. sensor is defective Is connection to connector of pipe temp.

- Page 19 defective Is connection to connector of pipe temp. sensor good? Repair connector Check the resistance of the temp. sensor according to Annex 1 Replace the sensor LED STATUS Outdoor unit display Outdoor units temp. sensor or connector of temp. sensor is defective Is connection to connector of pipe temp.

- Page 20 Check the voltage of power supply, if the voltage is about 220V, turn off the power supply to indoor unit and turn it on again after 1 minute Does the trouble occur again? Check the voltage of secondary of T3 transformer in outdoor power board , is this voltage 12-14V(AC) Replace the outdoor power board...

- Page 21 LED STATUS Outdoor unit display outdoor units communication protection Is the LED in outdoor main PCB light? Check the signal wires between outdoor PCBs, is it connected good. 1.Is the +5 voltage in outdoor main board? Power Board: CN4, Red wire and yellow (GND) Outdoor main PCB: CZ1 2.Is the +3.3v...

- Page 22 Off: 105c; On: 90c The trouble shooting is same with the one of indoor unit P2 protection. LED STATUS Outdoor unit display Compressor current protection Check the resistance of compressor, normally U and V is 1 ohm U and W is 1 ohm V and W is 1ohm...

- Page 23 Are the U,V,W connected to compressor and inverter module right? Repair connector Replace the outdoor power board If the problem comes to again, check wingding resistance of inverter compressor, is it ohm? Replace inverter compressor LED STATUS Outdoor unit display P4(LED flashes for nine times) Compressor drive malfunction(module protection arose)...

- Page 24 Condenser high-temperature protection When outdoor pipe temp. is more than 65°C, the unit will stop, and unit runs again when outdoor pipe temp. less than 52°C. Is the outdoor pipe temp. more than 65°C ? Is the outdoor pipe temp sensor right according to the annex 1 Replace the outdoor main board Replace the outdoor pipe temp sensor Annex 1...

- Page 25 29.9058 7.9708 2.6368 28.3459 7.6241 2.5397 26.8778 7.2946 2.4468 25.4954 6.9814 2.3577 24.1932 6.6835 2.2725 22.5662 6.4002 2.1907 21.8094 6.1306 2.1124 20.7184 5.8736 2.0373 19.6891 5.6296 1.9653 18.7177 5.3969 1.8963 17.8005 5.1752 1.830 16.9341 4.9639 1.7665 16.1156 4.7625 1.7055 15.3418 4.5705 1.6469...

- Page 26 Annex 2 1. Reference voltage data: Rectifier : Input :220-230V(AC), output :310V(DC) Inverter module: U,V, W 3ph. Result 60-150V(AC) 60-150V(AC) 60-150V(AC) Photo-couple PC817, PC851: Control side <+5V, AC side :< 24V(AC) S terminal and N: changeable from 0-24V 2. Check the Diode Bridge component ( In wiring diagram, rectifier) Remark: If this part is abnormal, the LED will not light.

Need help?

Do you have a question about the POM273HX and is the answer not in the manual?

Questions and answers