Table of Contents

Advertisement

Service Instructions

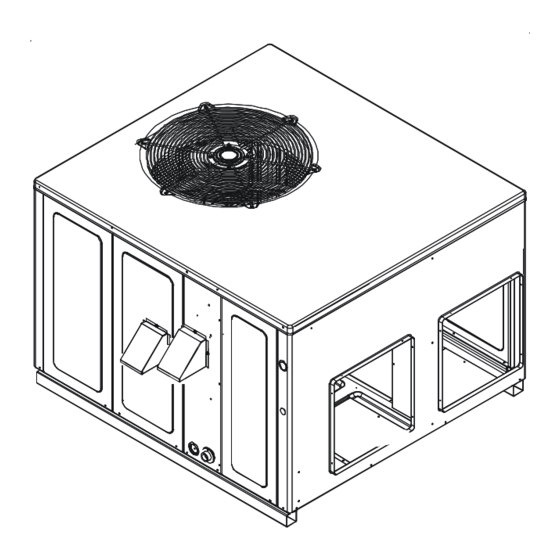

Gas Electric Package Units

This manual is to be used by qualified, professionally trained HVAC technicians

only. Goodman does not assume any responsibility for property damage or

personal injury due to improper service procedures or services performed by

an unqualified person.

Copyright © 2007 - 2010 Goodman Manufacturing

APG/GPG 13 and 15

with R-410A Refrigerant

& Accessories

This Forced Air Central Unit Design Complies With

Requirements Embodied in The American National

Standard / National Standard of Canada Shown Below.

ANSI Z21.47•CSA-2.3 Central Furnaces

Company, L.P.

®

C

US

RS6300007r7

March 2010

Advertisement

Chapters

Table of Contents

Summary of Contents for Goodman APG 13

- Page 1 Service Instructions APG/GPG 13 and 15 Gas Electric Package Units with R-410A Refrigerant & Accessories ® This Forced Air Central Unit Design Complies With Requirements Embodied in The American National Standard / National Standard of Canada Shown Below. ANSI Z21.47•CSA-2.3 Central Furnaces This manual is to be used by qualified, professionally trained HVAC technicians RS6300007r7 only.

-

Page 2: Table Of Contents

TABLE OF CONTENTS SCHEDULED MAINTENANCE ....29 - 31 IMPORTANT INFORMATION ......2 - 3 TROUBLESHOOTING CHARTS ....32 - 33 PRODUCTION IDENTIFICATION ....4 - 5 SERVICING TABLE OF CONTENTS ....34 ACCESSORIES ........... 6 - 14 SERVICING ..........32 - 61 PRODUCT DESIGN ........ -

Page 3: Important Information

IMPORTANT INFORMATION SAFE REFRIGERANT HANDLING While these items will not cover every conceivable situation, they should serve as a useful guide. WARNING WARNING Refrigerants are heavier than air. They can "push out" To avoid possible explosion: the oxygen in your lungs or in any enclosed space.To •... -

Page 4: Production Identification

PRODUCT IDENTIFICATION The model number is used for positive identification of component parts used in manufacturing. Please use this number when requesting service or parts information. G / A BRAND: MINOR ® REVISION: G: Goodman Brand or CONFIGURATION: Distinctions M: Multi-position ®... - Page 5 PRODUCT IDENTIFICATION The model number is used for positive identification of component parts used in manufacturing. Please use this number when requesting service or parts information. G / A BRAND: MINOR ® REVISION: G: Goodman Brand or REFRIGERANT: Distinctions 4: R-410A ®...

-

Page 6: Accessories

ACCESSORIES ACCESSORIES Part Number Description Propane Conversion Kit (*PG13) (LPT-00A may be used on models with AA revisions) LPT-03 LPT-03 can be used with either White-Rodgers or Honeywell gas valve. LPM-05 Propane Conversion Kit (*PG15) HA-02 High Altitude Kit PGC101/102/103 Roof Curb PGED101/102 Downflow Economizer, Small and Medium Chassis... -

Page 7: Lighting Instructions

LIGHTING INSTRUCTIONS *PG13**M*AA FOR YOUR SAFETY READ BEFORE OPERATING WARNING: Improper If you do not follow these instructions exactly, alteration, service or a fire or explosion may result causing property maintenance can damage, personal injury or loss of life. cause injury or property damage. - Page 8 LIGHTING INSTRUCTIONS *PG13**M*AB FOR YOUR SAFETY READ BEFORE OPERATING WARNING : Improper If you do not follow these instructions exactly, alteration, service or a fire or explosion may result causing property maintenance can damage, personal injury or loss of life. cause injury or property damage.

- Page 9 LIGHTING INSTRUCTIONS *PG15...

-

Page 10: Roof Curbs

ACCESSORIES ROOF CURBS 1 5/8 14 1/2 1 3/8 MODEL RETURN SUPPLY PGC101/102/103 46 1/4 39 3/8 14 1/2 12 1/2 x 23 15 x 22 1/2 DOWNFLOW FILTER RACK (PGFR101/102/103) 1 1/2 26 1/2 Filter Size: 14" x 25" x 2" Measurement in inches. - Page 11 ACCESSORIES PGED103 (DOWNFLOW ECONOMIZER) PGED103 14 X 25 FILTER ATTACHMENT 16 X 20 x 2” FILTER 16 X 20 MIST ELIMINATOR ECONOMIZER (HORIZONTAL APPLICATIONS) 16 1/8 Measurement in inches. MODEL FILTER PGE H101/102 25 1/4 18 1/8 13 3/4 16 1/8 16 x 25 x 1 PGE H103 35 1/4...

- Page 12 ACCESSORIES MOTORIZED/MANUAL FRESH AIR DAMPERS - (HORIZONTAL APPLICATIONS) 7 5/8 5 3/4 11 7/8 MANUAL MODEL PGMDH101 26 1/2 29 3/4 PGMDH102 31 1/2 29 3/4 PGMDH103 29 3/4 MOTORIZED MODEL PGMDMH101 26 1/2 29 3/4 PGMDMH102 31 1/2 29 3/4 PGMDMH103 30 29 3/4 MOTORIZED/MANUAL FRESH AIR DAMPERS...

- Page 13 ACCESSORIES SQUARE TO ROUND CONVERTER (DOWNFLOW APPLICATIONS) 12 1/4 14 3/4 ø ø 22 3/4 22 1/4 12 1/4 14 3/4 22 3/4 22 1/4 ø ø MODEL RETURN SUPPLY SQRPG101/102 22 3/4 12 1/4 22 1/4 14 3/4 SQRPG103 22 3/4 12 1/4 22 1/4...

- Page 14 ACCESSORIES GPGHFR101-103 (EXTERNAL HORIZONTAL FILTER RACK) 16” x 25" x 2" FILTER...

-

Page 15: Product Design

PRODUCT DESIGN Locations and Clearances IMPORTANT NOTE: If using bottom discharge with roof curb, ductwork should be attached to the curb prior to NOTE: To ensure proper condensate drainage, unit must be installing the unit. installed in a level position. Refer to Roof curb Installation Instructions for proper curb In installations where the unit is installed above ground level installation. - Page 16 PRODUCT DESIGN - Compliant scroll compressors perform “quiet” shutdowns A 3/4" - 14 NPT drain connector is provided for removal of that allow the compressor to restart immediately without condensate water from the indoor coil. In order to provide the need for a time delay. This compressor will restart proper condensate flow, do not reduce the drain line size.

- Page 17 PRODUCT DESIGN All line voltage connections must be made through weather proof fittings. All exterior power supply and ground wiring must be in approved weather proof conduit. Low voltage wiring from the unit control panel to the thermostat requires coded cable. See the following figures for ground level and rooftop wiring.

- Page 18 PRODUCT DESIGN The gas pipe supplying the unit must be properly sized based on the cubic feet per hour of gas flow required, specific gravity WARNING of the gas and length of the run. The gas line installation must comply with local codes, or in the absence of local codes, TO AVOID THE RISK OF PROPERTY DAMAGE, with the latest edition of the National Fuel Gas Code ANSI PERSONAL INJURY OR FIRE, USE ONLY COPPER...

- Page 19 PRODUCT DESIGN TANKS AND PIPING - PROPANE UNITS NOTE: In "b" and "c", the connector or tubing must be installed so as to be protected against physical and thermal damage. Aluminum-alloy tubing and connectors WARNING must be coated to protect against external corrosion where they are in contact with masonry, plaster, or insulation or PERSONAL INJURY HAZARD are subject to repeated wettings by such liquids as water...

- Page 20 PRODUCT DESIGN TYPICAL PROPANE PIPING PROPANE GAS PIPING CHARTS 5 to 15 PSIG First Stage Sizing Between First and Second Stage Regulator (20 PSIG Max.) Regulator Continuous Maximum Propane Capacities listed are based on 1 PSIG Pressure Drop at 10 11"...

-

Page 21: System Operation

SYSTEM OPERATION The indoor evaporator coil functions to cool and dehumidify HEATING the air conditioned spaces through the evaporative process The heating cycle is accomplished by using a unique tubular taking place within the coil tubes. design heat exchanger which provides efficient gas heating NOTE: The pressures and temperatures shown in the on either natural gas or propane gas fuels. - Page 22 A/GPG15 SYSTEM OPERATION IGNITION CONTROL SEQUENCE OF OPERATION A. Heating Operation: Low stage heat B. Heating Operation: High stage heat Thermostat type is set to two-stage. Thermostat type is set to two-stage. Thermostat “W1” input initiates low stage heating. Thermostat “W1” and “W2” inputs initiate high stage heating.

- Page 23 A/GPG15 SYSTEM OPERATION IGNITION CONTROL SEQUENCE OF OPERATION (CONT.) A. Cooling Operation: Low stage cool Low and high stage compressor outputs are ener- gized. Thermostat type is set to two-stage. Condenser fan motor is energized at high speed. Thermostat “Y1” or thermostat “Y1” and “G” input initiates low stage cooling.

- Page 24 SYSTEM OPERATION PCBAG100 CONTROL BOARD The following tables list the functions for the connectors and terminals, the timings, and the fault codes for the DESCRIPTION PCBAG100 control board. The ignition control is designed for use in gas heating/electric cooling package equipment (rooftop applications) and oper- ates with a two stage heat and two stage cooling system.

- Page 25 SYSTEM OPERATION Voltage Function 24VAC Indoor/Outdoor Thermostat (IDT/ODT) Output 24VAC High Stage Compressor Output 24VAC Pressure Switch/Loss of Charge Switch Input 24VAC Indoor/Outdoor Thermostat (IDT/ODT) Input 24VAC Pressure Switch/Loss of Charge Switch Output 24VAC Low Stage Compressor Output Table 1: Circuit Definitions and Voltage Ratings for the 6-Circuit Connector Circuits Voltage Function...

- Page 26 SYSTEM OPERATION Period Timing Pre-Purge 15 Seconds Inter-Purge 30 Seconds Post Purge 30 Seconds Trial-for-Ignition (TFI) 7 Seconds Flame Stabilization Period 10 Seconds 2 Seconds within Flame Stabilization Period Flame Failure Response Time 2 Seconds or Per ANSI Z21.20 Outside of Flame Stabilization Period Low to High Stage Delay Selectable 5 minutes or 10 minutes (Default = 10 minutes) Heat ON Delay...

- Page 27 SYSTEM OPERATION A/GPG13 PCBAG123 IGNITION CONTROL SEQUENCE OF OPERATION Continous Fan PRE-PURGE - The control energizes the induced draft motor, flashes code “2” on LED, and waits for the 1. When the thermostat calls for continuous fan (G) with pressure switch to close. When the pressure switch out a call for heat or cooling, the indoor the fan has a has closed, the control stops flashing the LED and 7 second delay on make and energizes the “HEAT”...

- Page 28 SYSTEM OPERATION Typical Package Cooling or Package Gas Indoor Outdoor Coil Coil Thermostatic Expansion Valve Restrictor Orifice Assy Either a thermostatic expansion valve or restrictor orifice assembly may be used depending on model, refer to the parts catalog for the model being serviced. Restrictor Orifice Assembly in Cooling Operation In the cooling mode the orifice is pushed into its seat forcing refrigerant to flow through the metered hole in the center of the orifice.

-

Page 29: Scheduled Maintenance

SCHEDULED MAINTENANCE Package gas units require regularly scheduled maintenance 10. Start the system and run a Heating Performance Test. to preserve high performance standards, prolong the service If the results of the test are not satisfactory, see the life of the equipment, and lessen the chances of costly "Service Problem Analysis"... - Page 30 SCHEDULED MAINTENANCE 1 Thousand 1 Million 100 Thousand 10 Thousand CUBIC Quarter FEET Foot Foot GAS RATE -- CUBIC FEET PER HOUR Size of Test Dial Size of Test Dial Seconds Seconds for One cu/ft cu/ft cu/ft cu/ft cu/ft for One cu/ft cu/ft cu/ft...

- Page 31 SCHEDULED MAINTENANCE Example: To adjust the pressure regulator on the gas valve, turn down (clockwise) to increase pressure and input, and out (counter- It takes forty (40) seconds on the gas meter for the hand on clockwise) to decrease pressure and input. the cubic foot dial to make one complete revolution, with all appliances off, except the unit.

-

Page 32: Troubleshooting Charts

SERVICING COOLING ANALYSIS CHART Sys te m Uns atis factory Com plaint No Cooling Ope rating Cooling Pre s s ure s POSSIBLE CAUSE Test Me thod DOTS IN ANALYSIS Remedy GUIDE INDICATE "POSSIBLE CAUSE" • Pow er Failure Test V oltage •... - Page 33 SERVICING GAS HEATING ANALYSIS CHART Com plaint No He at Uns atis factor y He at POSSIBLE CAUSE Te st Me thod DOTS IN ANALYSIS Re m e dy GUIDE INDICATE "POSSIBLE CAUSE" • Pow er Failure Test V oltage •...

-

Page 34: Servicing Table Of Contents

SERVICING Table of Contents Checking Voltage .......... 35 S-104 Checking Compressor Efficiency ....45 Checking Wiring ..........36 S-105B Thermostatic Expansion Valve ...... 45 Checking Thermostat, Wiring & Anticipator .. 36 S-106 Overfeeding ........... 47 S-3A Thermostat & Wiring ........36 S-107 Underfeeding .......... -

Page 35: Checking Voltage

SERVICING S-1 CHECKING VOLTAGE Max. Voltage Deviation % Voltage = From Average Voltage X 100 Imbalance Average Voltage To find the percentage of imbalance, measure the incoming HIGH VOLTAGE! power supply. Disconnect ALL power before servicing L1 - L2 = 240V or installing this unit. -

Page 36: Checking Wiring

SERVICING 2. With voltmeter, check for 24 volts at wires C and G. S-2 CHECKING WIRING 3. No voltage indicates the trouble is in the thermostat or wiring. 4. Check the continuity of the thermostat and wiring. Repair HIGH VOLTAGE! or replace as necessary. -

Page 37: Checking Transformer & Control Circuit

SERVICING S-4 CHECKING TRANSFORMER AND CON- NOTE: Most single phase contactors break only one side of TROL CIRCUIT the line (L1), leaving 115 volts to ground present at most internal components. 1. Remove the leads from the holding coil. 2. Using an ohmmeter, test across the coil terminals. HIGH VOLTAGE! If the coil does not test continuous, replace the relay or Disconnect ALL power before servicing... -

Page 38: Checking Fan Relay Contact

SERVICING THREE PHASE 4. Start the system and place a piece of cardboard in front of the condenser coil, raising the condensing pressure. Using a voltmeter, test across terminals. 5. Check pressure at which the high pressure control cuts- L1-L2, L1-L3, and L2-L3 - If voltage is present, out. -

Page 39: S-15A Resistance Check

SERVICING Your unit comes with a 180-second anti-short cycle to prevent the compressor from starting and running backwards. MODELS EQUIPPED WITH A HARD START DEVICE A start capacitor is wired in parallel with the run capacitor to increase the starting torque. The start capacitor is of the OHMMETER electrolytic type, rather than metallized polypropylene as used in the run capacitor. -

Page 40: S-16A Checking Fan & Blower Motor

SERVICING 4. Using an ohmmeter, check the motor windings for conti- WARNING nuity to ground (pins to motor shell). If the ohmmeter indicates continuity to ground, the motor is defective and Discharge capacitor through a 20 to 30 OHM must be replaced. resistor before handling. -

Page 41: Checking Compressor Windings

SERVICING Ignition of the discharge can also occur at the venting terminal High Voltage or inside the compressor, if there is sufficient contaminant air present in the system and an electrical arc occurs as the Connections terminal vents. 3/16" Ignition cannot occur at the venting terminal without the presence of contaminant air, and cannot occur externally C L G N from the venting terminal without the presence of an external... -

Page 42: S-17B Ground Test

SERVICING If either winding does not test continuous, replace the WARNING compressor. NOTE: If an open compressor is indicated, allow ample Damage can occur to the glass embedded terminals if time for the internal overload to reset before replacing the leads are not properly removed. This can result in compressor. -

Page 43: S-17D Operation Test

SERVICING 4. Next check the molded plug. S-18 TESTING CRANKCASE HEATER Voltage check: Apply control voltage to the plug (OPTIONAL ITEM) wires (18 to 28 volt ac). The measured dc voltage at the female connectors in the plug should be The crankcase heater must be energized a minimum of four around 15 to 27 vdc. -

Page 44: Leak Testing

SERVICING S-101 LEAK TESTING 1. Connect the vacuum pump, vacuum tight manifold set with high vacuum hoses, thermocouple vacuum gauge and charging cylinder as shown. (NITROGEN OR NITROGEN-TRACED) 2. Start the vacuum pump and open the shut off valve to the high vacuum gauge manifold only. -

Page 45: Charging

SERVICING NOTE: Even though the compressor section of a Scroll S-103 CHARGING compressor is more tolerant of liquid refrigerant, continued floodback or flooded start conditions may wash oil from the WARNING bearing surfaces causing premature bearing failure. REFRIGERANT UNDER PRESSURE! S-104 CHECKING COMPRESSOR EFFICIENCY * Do not overcharge system with refrigerant. - Page 46 SERVICING Pressure vs. Temperature Chart R-410A °F °F °F °F °F °F PSIG PSIG PSIG PSIG PSIG PSIG -37.7 114.0 37.8 216.0 74.3 318.0 100.2 420.0 120.7 522.0 137.6 -34.7 38.7 74.9 100.7 121.0 137.9 116.0 218.0 320.0 422.0 524.0 -32.0 118.0 39.5...

-

Page 47: Overfeeding

SERVICING S-106 OVERFEEDING 3. Refer to the superheat table provided for proper system superheat. Add charge to lower superheat or recover Overfeeding by the expansion valve results in high suction charge to raise superheat. pressure, cold suction line, and possible liquid slugging of Superheat Formula = Suct. - Page 48 SERVICING REQUIRED LIQUID LINE TEMPERATURE LIQUID PRESSURE REQUIRED SUBCOOLING TEMPERATURE (°F) AT SERVICE VALVE (PSIG)

-

Page 49: Checking Subcooling

SERVICING 4. If a temperature or pressure change is noticed, the S-109 CHECKING SUBCOOLING expansion valve is operating. If no change is noticed, the Refrigerant liquid is considered subcooled when its tempera- valve is restricted, the power element is faulty, or the ture is lower than the saturation temperature corresponding equalizer tube is plugged. -

Page 50: Checking Restricted Liquid Line

SERVICING S-112 CHECKING RESTRICTED LIQUID LINE S-115 COMPRESSOR BURNOUT When the system is operating, the liquid line is warm to the When a compressor burns out, high temperature develops touch. If the liquid line is restricted, a definite temperature causing the refrigerant, oil and motor insulation to decom- drop will be noticed at the point of restriction. -

Page 51: Checking Extedrnal Static Pressure

SERVICING 6. Start up the unit and record the pressure drop across the NOTE: Both readings may be taken simultaneously and read drier. directly on the manometer if so desired. 7. Continue to run the system for a minimum of twelve (12) 4. -

Page 52: Testing Primary Limit

SERVICING S-301 TESTING AUXILIARY LIMIT S-300 TESTING PRIMARY LIMIT CONTROL The auxiliary limit control is a preset nonadjustable control APG/GPG units use a snap-disk type primary limit device. mounted in the blower compartment area. Sometimes referred to as "stat on a stick". The limit setting is fixed and must not be readjusted in the field. -

Page 53: Checking Flame Rollout Switch

SERVICING If a limit switch opens, the indoor blower is energized on heat speed and the induced draft blower is energized. The LED on the control flashes "4" to indicate an open limit switch. The blower and inducer remain on while the limit switch is V O L T / O H M open. -

Page 54: Testing Inducer Motor

SERVICING S-303 TESTING INDUCER MOTOR Gas Valve On/Off Switch Inlet Pressure HIGH VOLTAGE! Disconnect ALL power before servicing Outlet Inlet or installing this unit. Multiple power sources may be present. Failure to do so may cause property damage, personal injury or death. -

Page 55: Checking Main Burners

SERVICING S-305 CHECKING MAIN BURNERS The main burners are used to provide complete combustion of various fuels in a limited space, and transfer this heat of the burning process to the heat exchanger. Proper ignition, combustion, and extinction are primarily due to burner design, orifice sizing, gas pressure, primary and STREAM B secondary air, vent and proper seating of burners. - Page 56 SERVICING Pressure Regulator WARNING (under cap screw) Open to Open to Atmosphere Atmosphere Disconnect gas and electrical power supply. 1. Connect a water manometer or adequate gauge to the inlet pressure fitting of the gas valve. Outlet Inlet Pressure 2. Remove the pressure tap fitting at the manifold if provided Pressure or check at the gas valve outlet fitting and connect another Gas Valve On/Off...

-

Page 57: Checking For Delayed Ignition

SERVICING If the pressure switch opens before the ignition period, the If operating pressures differ from above, make necessary induced draft blower will remain on and the control will stay pressure regulator adjustments, check piping size, etc., and/ in pre-purge until the pressure switch is closed for an entire or consult with local utility. -

Page 58: High Altitude Application

SERVICING 8. If not as listed, replace control. S-313 TESTING IGNITION CONTROL MODULE Note: the pressure switch must be mounted with the dia- NOTE: Failure to earth ground the unit, or a high resistance phragm in a vertical position. connection in the ground may cause the control to lockout due to failure to flame sense. - Page 59 SERVICING 2. Check for 24 volts at "R" to "C" thermostat terminals. Voltage present - check pressure switch circuit. If pressure switch circuit checks closed, proceed to No voltage - check 3 amp automotive type fuse on step 4. control board. A blown fuse could indicate a short in the 24 volt circuit (thermostat or limit circuit).

- Page 60 SERVICING Blower Off Delay Settings Syste m Condition Fla she s/Sta tus speed up Internal Control Fault, Micro Controller COOL HEAT UNUSED Detected Hardware Failure, or Gas Valve Detected Energized W hen it Should be De-energized Lockout Due to Excessive Retries Pressure Switch Stuck Closed Pressure Switch Stuck Open Open High Temperature Lim it...

-

Page 61: Checking Flame Sensor

SERVICING B1809918 Ignition Board Fault Codes Flame Equipment Status Status Light Check Sensor Normal Operation Check Input Power, No Power or Check Fuse on Control, Internal Control Fault Replace Control Check Gas Flow, Ignition Failure, Check Gas Pressure, Open Rollout Switch, Check Gas Valve, 1 Blink or Open Aux. -

Page 62: Accessories Wiring Diagrams

ACCESSORIES WIRING DIAGRAMS ECONOMIZER HIGH VOLTAGE! DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. - Page 63 ACCESSORIES WIRING DIAGRAMS ECONOMIZER HIGH VOLTAGE! DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. GPC13MED102 & 103 FOR *PG13 & 15**M4* (WIRING DIAGRAM FOR USE WITH ECONOMIZERS BUILT SINCE MARCH 2008) Wiring is subject to change.