Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Daikin FXDQ-M

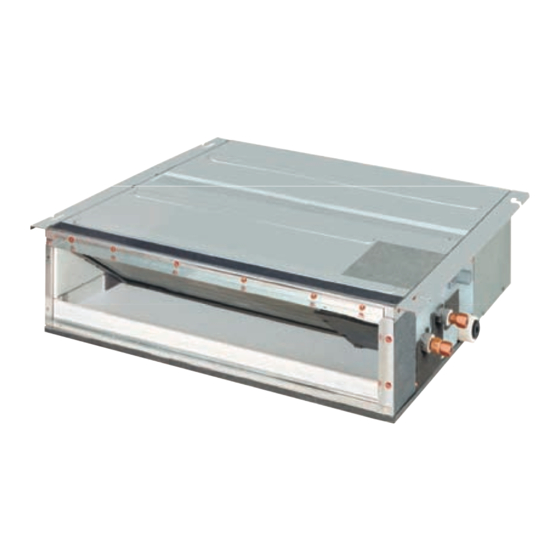

- Page 1 EDUS 39 - 600 - F2_a FXDQ-M Slim Ceiling Mounted Duct Type AMERICAS...

-

Page 2: Table Of Contents

EDUS39-600-F2_a FXDQ-M Slim Ceiling Mounted Duct Type 1. Features ......................2 2. Specifications ....................3 3. Dimensions ....................5 4. Piping Diagrams..................8 5. Wiring Diagrams..................9 6. Electric Characteristics................10 7. Capacity Tables ..................11 7.1 Cooling Capacity ..................11 7.2 Heating Capacity ..................12 8. Fan Performances..................13 9. -

Page 3: Features

The values of operation sound level represent those for rear-suction operation. Sound level values for bottom-suction operation can be obtained by adding 5 dB. Values are based on the following conditions: Ceiling FXDQ07~12M: external static pressure in. Wg 0.12; FXDQ18~24M: external static pressure in. Wg 0.16 FXDQ-M... -

Page 4: Specifications

Refer to the fan curves for actual fan performance. 5. Anechoic chamber conversion value, measured under JISB8616 conditions. During actual operation, these values are normally somewhat higher as a result of installation conditions. 6. Refer to page 10 for Power Input. FXDQ-M... - Page 5 Refer to the fan curves for actual fan performance. 5. Anechoic chamber conversion value, measured under JISB8616 conditions. During actual operation, these values are normally somewhat higher as a result of installation conditions. 6. Refer to page 10 for Power Input. FXDQ-M...

-

Page 6: Dimensions

EDUS39-600-F2_a Dimensions 3. Dimensions FXDQ07/09/12MVJU FXDQ-M... - Page 7 Dimensions EDUS39-600-F2_a FXDQ18MVJU FXDQ-M...

- Page 8 EDUS39-600-F2_a Dimensions FXDQ24MVJU FXDQ-M...

-

Page 9: Piping Diagrams

R1T : Thermistor for suction air temperature R2T : Thermistor for liquid line temperature R3T : Thermistor for gas line temperature Capacity Liquid φ1/2” / 12.7 mm φ1/4” / 6.4 mm 07/09/12/18M φ5/8” / 15.8 mm φ3/8” / 9.5 mm FXDQ-M... -

Page 10: Wiring Diagrams

EDUS39-600-F2_a Wiring Diagrams 5. Wiring Diagrams FXDQ07M/09M/12M/18M/24MVJU FXDQ-M... -

Page 11: Electric Characteristics

Electric Characteristics EDUS39-600-F2_a 6. Electric Characteristics 4D051757 FXDQ-M... -

Page 12: Capacity Tables

EDUS39-600-F2_a Capacity Tables 7. Capacity Tables Cooling Capacity FXDQ-M Cooling capacity Indoor Air Temp. °FWB Outdoor air temp. Unit size °FDB 10.5 11.1 11.3 10.5 10.9 11.1 10.5 10.7 10.9 10.4 10.6 10.9 10.3 10.4 10.6 10.1 10.2 10.4 10.0 10.2... -

Page 13: Heating Capacity

Capacity Tables EDUS39-600-F2_a Heating Capacity FXDQ-M Heating Capacity Indoor Air Temp. °FDB Outdoor Air Temp. Indoor unit °FDB °FWB 22.0 20.0 26.0 24.0 30.0 28.0 35.0 32.0 39.0 36.0 44.0 40.0 47.0 43.0 51.0 47.0 54.0 50.0 57.0 53.0 60.0 56.0... -

Page 14: Fan Performances

Note: 1. The remote controller can be used to switch between HIGH and LOW. 2. The air flow is set to STANDARD before leaving the factory. You can switch between STANDARD ESP and HIGH ESP with the remote controller. FXDQ-M... -

Page 15: Sound Levels

The operating condition is external static pressure 0.04” Wg. Operation noise differs with operation and ambient conditions. Model 208~230V, 60Hz FXDQ07MVJU FXDQ09MVJU FXDQ12MVJU FXDQ18MVJU FXDQ24MVJU Octave Band Level 208V~230V FXDQ07MVJU FXDQ09MVJU FXDQ12MVJU 4D052846 4D052847 4D052848 FXDQ18MVJU FXDQ24MVJU 4D052850 4D052849 FXDQ-M... -

Page 16: Installation

EDUS39-600-F2_a Installation 10. Installation : inches Center of Gravity FXDQ07 / 09 / 12MVJU 4D051766 FXDQ18MVJU 4D051767 FXDQ24MVJU 4D051768 FXDQ-M... -

Page 17: Safety Considerations

Refrigerant gas may produce toxic gas if it comes in contact can be securely fastened. with fire such as from a fan, heater, stove, or cooking FXDQ-M... -

Page 18: Before Installation

Avoid drainage and insulate piping in order to prevent con- putting any pressure on other parts, especially the refrig- densation. erant piping. FXDQ-M... - Page 19 Air filter (13) Quantity 2 pcs. 1 pc. • Operation manual • Installation manual Shape OPTIONAL ACCESSORIES • This indoor unit requires one of the operation remote con- trols listed below. Remote controller Wired type BRC1D71 Wireless type BRC4C82 FXDQ-M...

-

Page 20: Selecting Installation Site

• If you think the humidity inside the ceiling might exceed 86°F present due to the risk explosion resulting in serious injury and RH80%, reinforce the insulation on the unit body. or death. Use glass wool or polyethylene foam as insulation so that the FXDQ-M... -

Page 21: Preparations Before Installation

24 type 43-5/16 44-7/8 (2) Make sure the range of the unit’s external static pres- sure is not exceeded. See the Engineering Data for the range of the external static pressure setting. (3) Open the installation hole. (Pre-set ceilings) FXDQ-M... - Page 22 (3) Attach the air filter (accessory) in the manner shown Filter Force in the diagram. The four holes which cannot be covered by the air fil- ter should be covered with commercially available tape. In case of bottom side In case of back side FXDQ-M...

-

Page 23: Indoor Unit Installation

Flare shape (in.) (in.) torque (ft.lbf) (in.) φ1/4 10.4–12.7 0.342–0.358 φ3/8 24.1–29.4 0.504–0.520 R0.016-0.031 φ1/2 36.5–44.5 0.638–0.654 φ5/8 45.6–55.6 0.760–0.776 CAUTION Overtightening may damage the flare and cause leaks. Ensure that oil does not to adhere to any portions other FXDQ-M... - Page 24 (Refer to Fig. 9) CAUTION • When brazing a pipe while feeding nitrogen inside the pipe, make sure to set the nitrogen pressure to 29 psi or less using the pressure reducing valve. FXDQ-M...

-

Page 25: Drain Piping Work

• Drain piping passing indoors • Drain pipe connection hole Referring the figure below, insulate the metal clamp (1) and drain hose (2) using the included large sealing pad (5). (Refer to Fig. 12) FXDQ-M... -

Page 26: Installing The Duct

REMOTE CONTROLLER INSTALLATION MANUAL. • All wiring must be performed by an authorized electrician. • This system consists of multiple indoor units. Mark each indoor unit as unit A, unit B , and so forth, and be sure the FXDQ-M... -

Page 27: Wiring Example

Min. 187 18 type 0.13 Max. 253 heating, and in worse cases, electric shock or fire. 24 type 0.13 MCA: Minimum Circuit Amps (A) MFA: Max. Fuse Amps (A) KW: Fan motor output (kW) FLA: Full Load Amps (A) FXDQ-M... - Page 28 W I R I N G O F F (accessory) Power supply wiring Wiring through Terminal block (6P) Ground wire hole Remote controller wiring Transmission wiring REMOTE TRANSMISSION FORCED CONTRL WIRING Fig. 15 • Power supply wiring and Ground wire FXDQ-M...

- Page 29 • If the terminal screws are tightened too hard, screws might be damaged. • Refer to the following below for the tightening torque of the terminal screws. FXDQ-M...

-

Page 30: Field Setting And Test Run

FIELD SETTINGS manual that came with CONTRL WIRING the remote controller. Remote controller wiring • The settings can select Mode No., No., FIRST CODE terminal block NO. and SECOND CODE NO. Remote Remote controller 2 controller 1 (SUB) (MAIN) FXDQ-M... - Page 31 Closing the normally open cir- cuit between terminals T1 and Unit stopped by changing input A T2 stops operation of the unit. When T1-T2 is opened, the unit from “on” to “off” must be restarted with the remote controller. FXDQ-M...

- Page 32 • The remote controller wiring is cut. CAUTION • Always stop the test run using the remote controller to stop operation. WARNING • After finishing the test run, make sure to check drainage in the drain pump according to “7. DRAIN PIPING WORK”. NOTE FXDQ-M...

-

Page 33: Accessories

Sealing material (12) Air filter (13) ing plate mounting plate Quantity 1 pc. 2 pcs. 1 pc. 2 pcs. 1 pc. (Other) • Operation manual • Installation man- Shape C:3PN06240-4E Refer to Controller manual for optional accessories for controllers. FXDQ-M... - Page 34 AMERICAS 1645 Wallace Drive, Suite 110 Carrollton, TX75006 info@daikinac.com www.daikinac.com July 2009 EDUS39-600-F2_a Printed in U.S.A. 07/2009...