Table of Contents

Advertisement

Quick Links

© 2010 Pella Corporation

INSTALLATION INSTRUCTION - INSTRUCCIONES DE INSTALACIÓN

FOR PELLA

REPLACEMENT AND FIXED WINDOW REPLACEMENT

Lea las instrucciones en español en el reverso.

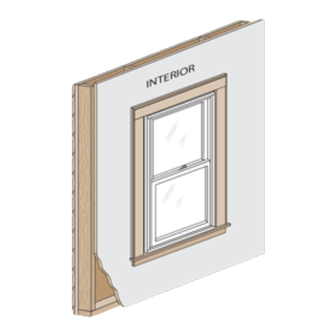

Important! The Pella Precision Fit Casement Replacement Window is designed to replace older style

double-hung windows. The original window frame will remain in place and only the existing sash

will be removed. The Pella Precision Fit Casement Fixed Window is a companion to the Precision Fit

Casement and is designed to replace the fixed center window that shares a common stool and sloped

sill with the adjacent windows and has removable interior stops. This application is typically found

in older homes. The original window frame will remain in place and only the existing sash, glass and

existing stops must be removed. These instructions are not to be used with any other construction

methods. Read these instructions thoroughly before beginning. Failure to install as recommended will

void any warranty, express or implied. For types of installation other than shown, contact your local

Pella representative or visit http://www.pella.com. Building designs, construction methods, building

materials and site conditions unique to your project may require an installation method different

from these instructions and additional care. Determining the appropriate installation method is the

responsibility of you, your architect or construction professional.

YOU WILL NEED TO SUPPLY:

• Cedar or Impervious shims/spacers (12 to 20)

• Wood blocking and bracing

• Closed cell foam backer rod/sealant backer (12 to 30 ft.)

• Pella® SmartFlash™ foil backed butyl window

and door flashing tape or equivalent

• High quality exterior grade polyurethane or silicone sealant

(1 tube per window)

• Great Stuff ™ Window and Door Insulating Foam Sealant

by the Dow Chemical Company or equivalent low pressure

polyurethane window and door foam -

DO NOT use high pressure or latex foams

Installation will require two or more

persons for safety reasons.

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Always read the Pella Limited Warranty before purchasing or installing Pella products.

By installing this product, you are acknowledging that this Limited Warranty is part of the terms of

the sale. Failure to comply with all Pella installation and maintenance instructions may void your Pella

product warranty. See Limited Warranty for complete details at http://warranty.pella.com.

CAUTION: Many windows in older homes are painted with lead-based paint. Removal of old

windows may disturb this paint. Proper precautions must be taken to minimize exposure to dust

and debris. Consult state or local authorities for more information.

PRECISION FIT

®

, CASEMENT, RENOVATION POCKET

®

TOOLS REQUIRED:

• Tape measure

• Level

• Square

• Hammer

• Utility knife

• Sealant gun

• Screwdrivers

(#2 Phillips and Flat blade)

• Rotary cutting tool w/ cut-off wheel (if

existing window has press fit pulleys)

• Drill

• Pliers

• Putty Knife

• Pry bar

• T-25 TORX® Driver

• Chisel

Part Number: 816G0101

Advertisement

Table of Contents

Summary of Contents for Pella 816G0101

- Page 1 The original window frame will remain in place and only the existing sash will be removed. The Pella Precision Fit Casement Fixed Window is a companion to the Precision Fit Casement and is designed to replace the fixed center window that shares a common stool and sloped sill with the adjacent windows and has removable interior stops.

- Page 2 I N T E R I O I N T E R I O R Flashing tape Flashing tape Fixed Window Replacement – Go to Pocket Replacement – Step 6 FIXED SASH REMOVAL on page 7 Go to Step 1 SASH REMOVAL POCKET REPLACEMENT: SASH REMOVAL Note: Verify the opening and window dimensions prior to removing the existing...

-

Page 3: Prepare The Opening

SASH REMOVAL (CONTINUED) B. Cut the balance cords on the bottom sash and lift out the sash. Allow weights to fall to the bottom of the weight pocket. C. Remove the parting stops by prying them out or by pulling them out with a channel lock. - Page 4 PREPARE THE OPENING (CONTINUED) C. Remove plastic wrap and card board packaging from window. DO NOT remove plastic shipping spacers located between the window sash and frame. The shipping spacers will help keep the window square during installation. DO NOT unlock or open window until it is fully fastened in the opening.

- Page 5 SEALING AND FASTENING THE WINDOW (CONTINUED) B. Place a bead of sealant where the existing stool Stool meets the existing frame sill and jambs. Note: Sealant bead placement is critical to ensure contact with replacement window Sill C. Place a bead of sealant where the jamb and sill meet. D.

-

Page 6: Interior Seal

SEALING AND FASTENING THE WINDOW (CONTINUED) G. Finish driving all the installation screws through the wood frame jamb, ensuring the head of the screws is flush with the surface of the wood frame. DO NOT drive screws below flush with the surface of the frame. Improper screw depth, screw Proper screw depth, screw head driven below the surface... - Page 7 EXTERIOR SEAL A. Place a corner bead of sealant at the jambs and head connecting the existing frame and the replacement window frame. Caution: DO NOT seal the bottom exterior to allow for incidental water to weep. B. Optional: Place a bead of sealant where the sill adapter meets the sill.

- Page 8 FIXED SASH REMOVAL (CONTINUED) E. Apply sill flashing tape. Cut a piece of flashing tape 12" longer than the opening width. Apply at the bottom of the opening as shown (2A). Do not allow the flashing Flashing tape to extend past the new window depth. Tape Note: The tape is cut 12"...

- Page 9 PREPARE THE OPENING (CONTINUED) D. Trim the sill adapter to the proper Sealant goes here height by breaking off the grooved leg at the desired dimension (see chart). Once trimmed, apply a bead of sealant to the sill adapter. Attach the sill adapter into the sill by using a board and hammer.

- Page 10 SEALING AND FASTENING THE WINDOW (CONTINUED) E. Finish driving all the installation screws through the wood frame jamb, ensuring the head of the screws is flush with the surface of the wood frame. DO NOT drive screws below flush with the surface of the frame. Improper screw depth, screw Proper screw depth, screw head driven below the surface...

- Page 11 180 grit or finer sandpaper. DO NOT use steel wool. BE CAREFUL NOT TO SCRATCH THE GLASS. Remove sanding dust. Pella products must be finished per the below instructions; failure to follow these instructions voids the Limited Warranty.

-

Page 12: Exterior Finish

The determination of the suitability of all building components, including the use of Pella products, as well as the design and installation of allow for proper management of moisture within the wall systems. The determination of the suitability...