Yard Machines Series 580 Operator's Manual

Mtd

Hide thumbs

Also See for Series 580:

- Operator's manual (29 pages) ,

- Operator's manual (20 pages) ,

- Operator's manual (20 pages)

Advertisement

Table of Contents

YARD

OPERATOR'S

MANUAL

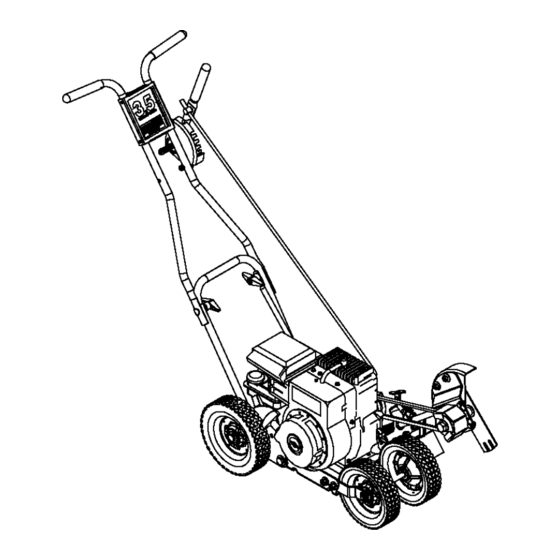

Edger

Model Series 580

IMPORTANT:

READ SAFETY

RULES AND INSTRUCTIONS

CAREFULLY

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered,

brush-covered

or grass*covered

land unless the engine's exhaust system is equipped with a spark attester meeting applicable

local or

state laws (if any). If a spark attester is used, it should be maintained in effective working order by the operator. In the State of California

the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws

apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the

service department,

P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS

INC. P.O. BOX 368022 CLEVELAND,

OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO. 770-10397A

(10/00)

Advertisement

Table of Contents

Summary of Contents for Yard Machines Series 580

- Page 1 YARD OPERATOR'S MANUAL Edger Model Series 580 IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered or grass*covered land unless the engine's exhaust system is equipped with a spark attester meeting applicable local or state laws (if any).

-

Page 2: Table Of Contents

Maintaining and Servicing The Edger ..............Off-season Storage .................... Troubleshooting ....................Model Series 580 Parts List ................Warranty Information ..................Back Cover FINDINGMODEL NUMBER This Operator's Manual is an important part of your new edger. It will help you assemble, prepare and maintain the unit for best performance. -

Page 3: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFEOPERATION P RACTICES WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE THIS MACHINE. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. - Page 4 4. Never o perate withdamaged s afety devices. 18.Onlyusepartsandaccessories made forthis Failure todoso,canresult i n personal injury. machine bythemanufacturer. Failure todoso,can 5. Never r unanengine indoors orina poorly result i npersonal injury. 19.If situations o ccurwhich arenotcovered inthis ventilated a rea.Engine exhaust contains carbon monoxide, anodorless a nddeadly gas.

-

Page 5: Assembling The Edger

SECTION 2: ASSEMBLING YOUR EDGER IMPORTANT: This unit is shipped WITHOUT styles vary by model. GASOLINE or OIL. After setting up the unit, service engine with gasoline and oil as instructed in the separate engine manual packed with your unit. Upper Handle NOTE: Reference to right or left hand side of the edger is observed from the operating position. -

Page 6: Know The Edger

Secure withtheflatwasher a ndhairpin clip ClutchRodAdjustment removed e arlier. S eeFigure 5. Before operating the edger, check the adjustment of the clutch rod as follows: Hairpin Clip \\ C,u,chRoO Disconnect the spark plug wire and ground it as instructed earlier in this section. Refer to Figure 2. With the blade clutch/depth control lever in the _'_J Flat Washer_! -

Page 7: Operating The Edger

Blade Clutch / Depth Control Lever Throttle Control & Choke Control Blade Angle Adjustment Lever Curb Height Adjustment Lever Pull Rope / Recoil Starter NOTE: Handle, wheel and blade styles vary by model. Yours may differ slightly. Figure 6 SECTION 4: OPERATING T HEEDGER The operation of any edger can result To start the edger's engine, proceed as follows: in foreign objects being thrown into... -

Page 8: Making Adjustments

Movethethrottle control leverontheengine into To disengage the blade, proceed as follows: the STOP or OFF position. Move the blade clutch!depth control lever to the left and place it in the top notch in the depth adjustment IMPORTANT: Make certain that the engine's spark plug bracket. - Page 9 Edging EdgerBladeAngleAdjustment Placing the blade angle adjustment lever in the second WARNING: Rotating cutting blade may throw notch from the right will put the spindle assembly at a objects causing personal injury. Keep area 90 ° angle for vertical edging as illustrated in Figure 11. clear of bystanders do not operate...

-

Page 10: Maintaining And Servicing The Edger

To adjust the height of the curb wheel, proceed as Trimming follows: Placing the blade angle adjustment lever in the notch furthest to the left will put the spindle assembly at a Perform the FrontWheelAdjustment for curb wheel proper angle for trimming with the edger as illustrated in operation as instructed earlier in this section. -

Page 11: Replacing The Edger Blade

Remove the blade spindle belt guard by removing the hex screws, two lock washers and two hex nuts which secure it to the blade spindle plate. See Figure 17. Blade Spindle Plate Shoulder Spacer Compression Spring (Lubricate welll) Hex Screws Blade Spindle Figure 15 Belt Guard... -

Page 12: Off-Season Storage

SECTION 7: OFF-SEASON S TORAGE Observe the following when preparing the edger for Store the edger in a dry, clean area. Do not store long-term storage: next to any corrosive matedals, such as lawn fertilizer. Clean and lubricate unit thoroughly as instructed on Coat the edger, especially any springs and page 10 of this manual. -

Page 13: Model Series 580 Parts List

SECTION 9: MODEL SERIES 580 PARTS LIST V-BELTS are specially designed to engage and disengage safely. A substitute (non-OEM) V-Belt can be dangerous by not disengaging completely. Ref. Ref. Part Number Part Number Description Description 781-0086 712-0413 Hex Jam Nut, 5/8-18... - Page 14 ModelSeries580 > Spindle assembly shown forreference only. See page 13 for parts breakdown)

- Page 15 ModelSeries580 Ref. Ref. Part Number Description Part Number Description 712-0267 Hex Nut, 5/16-18 738-0898 Front Axle, .50 x 7.98 736-0119 710-0654A Lock Washer, 5/16 Self-tapping Screw, 3/8-16 x 1.0 712-0287 Hex Nut, 1/4-20 714-0104 Internal Cotter Pin, .072 x 1.0 736-0329 Lock Washer, 1/4 736-0264...

- Page 16 MANUFACTURER'S LIMITED WARRANTY FOR: YARD c. Routine maintenance items such as lubricants, filters, The limited warranty set forth below is given by MTD blade sharpening and tune-ups, or adjustments such PRODUCTS INC ("MTD") with respect to new merchandise as brake adjustments, clutch adjustments or deck purchased and used in the United States, its possessions...