Table of Contents

Advertisement

Operator's Manual

®

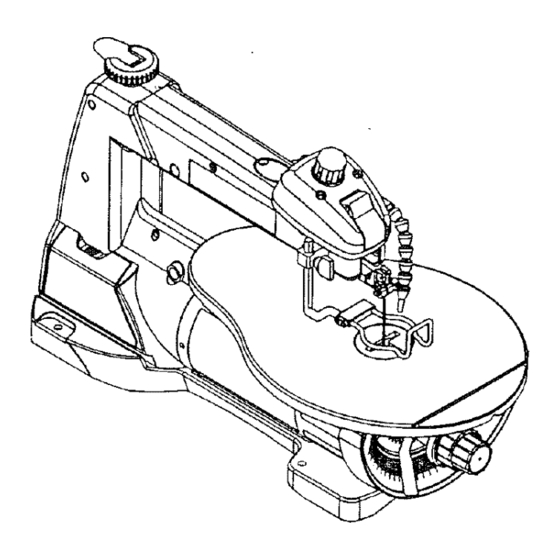

16" SCROLL SAW

Model No.

137.216100

1/9 HP (Max. Developed)

Pin-end

or Plain-end

Blade

400-1600

S.P.M.

CAUTION"

Before

using this Scroll Saw,

read this manual

and follow

all its Safety

Rules and

Operating

Instructions

•

Safety Instructions

•

Installation

Operation

•

Maintenance

•

Parts List

Customer

Help Line

1-800-843-1682

Sears,

Roebuck

and Co., Hoffman

Estates,

IL 60179

U.S.A.

Visit our Craftsman

website:

www.sears.corn/craftsman

10_A20GR

Advertisement

Table of Contents

Summary of Contents for Craftsman 137.216100

- Page 1 Safety Instructions • Installation read this manual and follow all its Safety Rules and Operation • Maintenance Operating Instructions • Parts List Customer Help Line 1-800-843-1682 Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. Visit our Craftsman website: www.sears.corn/craftsman 10_A20GR...

- Page 2 SE(_TION PAGE Product Specifications .............................. Warning ..................................Safety Instructions ..............................Accessories and Attachments ..........................Carton Contents ... _ ............................. Know Your Scroll Saw .............................. Glossary of Terms ..............................Assembly and Adjustments ............................Basic Saw Operation ..............................Maintenance ................................Troubleshooting guide .............................. Parts ....................................

- Page 3 12.ALWAYS WEAR EYE PROTECTION. Any Scroll Saw GENERAL SAFETY INSTRUCTIONS can throw foreign objects into the eyes that could cause permanent eye damage. ALWAYS wear Safety BEFORE USING THE SCROLL Goggles (not glasses) that comply _th ANSi Safety Safety is a combination of common sense, staying alert standard Z87.1 Everyday eyeglasses have only and knowing how to use this Scroll Saw.

- Page 4 influence o fanydrugs, a lcohol or medication that finger positions, where a sudden slip could cause a could affect y ourability tousethetoo!properly. hand to move into the blade when operating the saw. 25.DUST g enerated f romcertain materials c anbe 13.HOLD WORKPIECE FIRMLY against the table top.

- Page 5 Running at a lower voltage wilt damage the mold€. GROUNDING I NSTRUCTIONS This tool is intended for use on a circuit that has a receptacle like the one illustrated in Figure A. IN THE EVENT OF A MALFUNCTION OR Figure A shows a 3-prong electrical plug and receptacle BREAKDOWN, grounding provides a path of least that has a grounding conductor.

- Page 6 AVAILABLE ACCESSORIES UNPACKING AND CHECKING CONTENTS • To avoid injury, do not attempt to modify this tool or • To avoid injury, if any part is missing or damaged, do create accessories not recommended for use with not plug the scroll saw in until the missing or this tool.

- Page 7 Quickrelease Variable speed tension lever control k nob Upper arm Blade guard foot lockknob Bladestorage Blade guard foot Mounting hole Worktable Sawdust b lower Bladelockknob Sawdust collection port Table lockknob Bevel s cale...

- Page 8 SCROLL SAW TERMS BEVEL SCALE - Represents the degree of table angle, from WOODWORKING TERMS 0° to 45 °, when the table is tilted for bevel cutting, BLADE GUARD FOOT - Guards the blade and keeps your KERF -The slot cut by the blade. workpiece from rising.

- Page 9 BLADE STORAGE (FIG, C) " .." ASSEMBLY INSTRUCTIONS The blade storage (1) is located on the left rear s;d e of the scroll saw body. Pull out the blade storage (1) to open. The blade storage can conveniently store your hex To avoidinjury, do not connectthis scrollsaw to'thepower wrenches, and both Pin and Plain end blades.

- Page 10 PLAIN-b.NU _L.AUr-.. r_cl_iuv,,_,.., ir_,o. _-,. p,.,j To remove the blade (1), loosen the blade tension by CAUTION: In order to avoid uncontrollable lifting of the ,- , lifting the quick release tension lever (2). (Fig. E) workpiece, the teeth of the blade should ALWAYS point downward.

- Page 11 CAUTION: In order to avoid uncontrollable lifting of the workpiece, the teeth of the blade should always point To prevent personal injury, always turn the saw OFF and downward. disconnect the plug from source before changing blades Install the blade (1) by inserting one end of it through or making adjustments.

- Page 12 BLADE SELECTION (FIG. Q) BLADE GUARD FOOT ADJUSTMENT (FIG. N, O) When cutting at angles, the table guard foot (1) should be To avoid injuryfrom accidental staring, always turn the adjusted so it's parallel to the table and rests fiat above switch OFF and unplug the scroll saw before moving, the workpiece.

- Page 13 RECOMMENDATIONS FOR Cu]-rlNG When feeding the workpiece into the blade do not VARIABLE SPEED CONTROL ONIOFF SWITCH force the leading edge of the workp_eceinto the blade because the blade will deflect, reducing the accuracy of cut and possibly breaking the blade. Allow the saw For your own safety, always push the control knob OFF to cut material by guiding the workplace into the blade as it cuts.

- Page 14 FREEHAND CUTTING (FIG. T ) ANGLE CU-[qilNL_ _rlu. u] Toavoidinjury fromanaccidental start,makesurethe switch is intheOFFposition andtheplugisnot To avoid injury from an accidental starting, make sure the switch is in the OFF position and the plug is not connected t othepower s ource outlet connected to the power source outlet before moving, replacing the blade or making adjustments 1 Layoutdesired design, o rsecure design tothe...

- Page 15 INTERIOR CUTTING (FIG. W) OR STRAIGHT LINE CUTTING (FIG. V) Lay out the design on the workpiece (1), Drill a 1/4-inch hole in the workpiece. To avoid injury from an accidental starting, make sure the Release the tension knob (1), remove the blade (2). switch is in the OFF position and the plug is not Refer to BLADE REMOVAL AND INSTALLATION.

- Page 16 For your own safety, turn the switch OFF and remove the plug from the power source before maintaining your saw. GENERAL An occasional coat of paste wax on the work table will allow the wood being cut to glide smoothly across the work surface.

- Page 17 Toavoid injuryfrom accidental starting, always turn switch OFF and unplug the scroll saw before moving, replacing the blade or making adjustments. Consult your Sears Service Center if for any reason the motor will not run. PROBLEM PROBLEM CAUSE REMEDY SUGGESTED Adjust blade tension.

- Page 18 SCROLL SAW 137.216100 When servicing use only CRAFTSMAN replacement parts, Use of nay other parts may create a HAZARD or cause product damage. Any attempt to repair or replace electrical parts on this scroll saw may create a HAZARD unless repair is done by a qualified service technician.

- Page 19 16" SCROLL MODEL NO. 137.216100 ir_ tt3...

- Page 20 Your Home For repair-in your home-of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories and Operator's Manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters.