Craftsman 247.29932 Operator's Manual

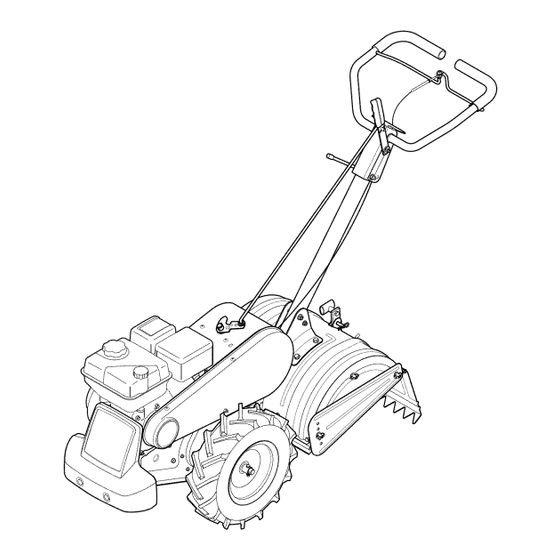

208cc engine rear tine tiller

Hide thumbs

Also See for 247.29932:

- Operator's manual (136 pages) ,

- Operator's manual (68 pages) ,

- Operator's manual (72 pages)

Table of Contents

Advertisement

Available languages

Available languages

Operator's

Manual

CRRFI'SMRN

208cc Engine

Rear Tine Tiller

Model No. 247.29932

CAUTION:

Before

using

this product,

read this

manual

and follow

all

safety

rules

and operating

instructions.

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

Sears Brands

Management

Corporation,

Hoffman

Estates,

IL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORMNO. 769-05425H

3/27/12

Advertisement

Table of Contents

Summary of Contents for Craftsman 247.29932

- Page 1 SAFETY ASSEMBLY OPERATION CAUTION: Before using MAINTENANCE this product, read this PARTS LIST manual and follow o ESPANOL safety rules and operating instructions. Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A. Visit our web site: www.craftsman.com FORMNO. 769-05425H 3/27/12...

- Page 2 FORTWO YEARSfrom the dateof purchase,this productis warrantedagainstanydefectsin materialor workmanship, A defectiveproductwill receivefree repairor replacementif repairis unavailable, For warranty coverage details to obtain free repair or replacement,visit the web site: www.craftsman.com This warranty covers ONLYdefects in material and workmanship. Warranty coverage does NOT include: •...

- Page 3 This machinewas built to be operatedaccordingto the safe opera- This symbolpointsout importantsafetyinstructionswhich,if not tion practicesin this manual.As with any type of powerequipment, followed,couldendangerthe personalsafetyand/orpropertyof carelessnessor error on the part of the operatorcan resultin yourselfand others. Readand followall instructionsin this manual seriousinjury.This machineis capableof amputatingfingers,hands, beforeattemptingto operatethis machine.Failureto complywith toes and feet and throwingdebris.

- Page 4 Safe Handling of Gasoline: • Lookdownand behindand usecare whenin reverseor pulling machinetowardsyou. Toavoidpersonalinjuryor propertydamageuseextremecare in handlinggasoline.Gasolineis extremelyflammableand the vaporsare • Start the engineaccordingto the instructionsfoundinthis manual explosive.Seriouspersonalinjurycan occurwhengasolineis spilled and keepfeet well awayfromthe tines at all times. on yourselfor yourclotheswhichcan ignite.Washyour skin and •...

- Page 5 NOTICE REGARDING EMISSIONS • Do notchangethe enginegovernorsettingsor over-speed the engine.Thegovernorcontrolsthemaximumsafeoperatingspeed Engineswhich are certifiedtocomplywith Californiaand federal of engine. EPAemissionregulations for SORE(SmallOff RoadEquipment) are Maintainor replacesafetyand instructionlabels,as necessary. certifiedto operateon regularunleadedgasoline,and mayinclude Followthis manual f or safe loading,unloading,transporting, a nd the followingemissioncontrol systems:EngineModification (EM), storageof this machine.

- Page 6 SAFETY SYMBOLS This pagedepictsand describessafetysymbolsthat mayappear on this product. Read,understand,and followall instructionson the machine beforeattemptingto assembleand operate. READ THE OPERATOR'S MANUAL(S) Read, understand, and follow all instructions in the manual(s) before attempting to assemble operate WARNING-- ROTATING TINES Do not put hands or feet near rotating parts.

- Page 7 NOTE:This unitis shippedwithoutgasolineor oil in the engine.Be Raisethefine shieldhinge flapassemblyand insertthe depth certainto serviceenginewith gasolineand oil as instructedin the stakeassemblyin the slot, underthe fineshieldand up through Operationsectionof this manualbeforeoperatingyourmachine. the tine shieldassembly. NOTE:Referenceto rightand left hand sideof the tiller is observed Insertthe clevispin throughthe fineshieldand depthstake fromthe operatingposition.

- Page 8 ATTACHING THE CONTROL Pushthe cablethroughthe holein the centerof the handleand snapin the plasticfitting. See Figure6. Makesurethe handleassemblyis in the highestposition.Referto the OperationSection. Removethehairpinclips from the control rod,putthe rubber washersin place. Insertthe shorter,angledend of the controlrod throughthe indicatorbracketon the shiftcover and secureit with the previ- ously removedhairpinclip.

- Page 9 Fuel Recommendations SET-UP Useautomotive gasoline(unleadedor lowleadedto minimizecombus- Tire Pressure tion chamberdeposits)with a minimumof 87 octane.Gasolinewith Checkthe air pressurein bothtires.The air pressureshouldbe up to 10%ethanolor 15%MTBE(MethylTertiaryButyl Ether)can be between15-20PSI.Keep bothtires equallyinflated to help prevent used. Neverusean oil/gasolinemixtureor dirty gasoline.Avoidgetting machinefrom pullingto one side. dirt, dust,or waterinthe fuel tank.DO NOTuse E85 gasoline.

- Page 10 ADJUSTMENTS Handle The handleshouldbe adjustedso thatwhenthe tiller is digging3-4" intothe soil,the handlefalls to aboutwaste-high.Rotatethe handle Priorto operatingyour tiller,carefullyread and followall instructions adjustmentlock rearward,movethe handleto thedesiredpositionand then lock intoplace by rotatingthe handleadjustmentlock forwardto below.Performall adjustmentsto verifyyourtiller is operatingsafely securethe handle.See Figure11. and propery.

- Page 11 Gear Selection Clutch Control Handle Adjustment Fuel _p Air Filter.. OUFill Cap Choke Control" Shift Lever indicator Throttlej _th Stake Control Recoil Starter Handle Rear Tine Shield Shield Figure12 Nowthat youhaveset up yourtillerfor operation,get acquainted with TH BOTTLE CONTROL its controlsand features.Theseare describedon the next two pages and illustrated o n this page.This knowledge will allowyou to useyour newequipmentto itsfullestpotential.

- Page 12 OiL FiLL CAP & DIPSTICK TO START ENGINE Engineoil levelcan be checkedand oil addedthroughtheoil fill. See Attachspark plug wireand rubberboot to sparkplug. Figure12. Filltank to no morethan 1/2" belowbottomof fillerneck to providespacefor fuelexpansion. NOTE:This unitwas shippedWITHOUToil inthe engine.Oil is included in the plasticbag packedwith the manualin with the unit. Placethe gear selectionleverin NEUTRAL.

- Page 13 TO ENGAGE DRIVE & TINES Toadjust thedepth stake,removethe clevispin and cotterpin. Move the depthstaketo the desiredsettingand securewith the clevispin and cotter pin.See Figure14. Do not pushdownon the handlebarsto try to makethe tillertill more deeply.This preventsthe wheelsfrom holdingthetiller backand can allowthe tinesto rapidlypropelthetiller, whichcould resultin lossof Depth Stake control,propertydamage,or personalinjury.

- Page 14 CLEARING THE TINES Whencultivating (breakingup thesurfacesoilaroundthe plants todestroyweeds,SeeFigure16),adjustthe tinesto dig only1"to 2"deep.Usingthe shallow tillingdepthhelpspreventinjury to the Beforeclearingthetines by hand,stop theengine,allowall moving plantswhoserootsoftengrowclosetothe surface.If needed,lift parts to stop and disconnectthe sparkplug wire. Failureto followthis up on the handlebars slightlyto preventthetinesfromdiggingtoo warningcouldresult in personalinjury. deeply.(Cultivating on a regularbasisnotonlyeliminates weeds,it alsoloosens and aeratesthesoil forbettermoistureabsorption and •...

- Page 15 • If the gardensize will notpermit lengthwiseand thencrosswise Suggested Tilling Patterns tilling, thenoverlapthe first passesby one-halfa tiller width,fol- • Whenpreparinga seedbed,go overthe samepathtwice in the lowedby successivepassesat one-quarterwidth.See Figure19. first row,thenoverlapone-halfthetiller width on the rest of the passes.See Figure17. Figure19 Figure17 Tilling on a Slope...

- Page 16 Terrace Gardening Loading & Unloading the Tiller Tocreatea terrace,start at thetop of the slopeand work down Go back and forth acrossthe first row.See Figure20. Loadingand unloadingthe tillerintoa vehicleis potentiallyhazard- I ous and doingso is not recommended unless absolutelynecessary, las this could resultin personalinjuryor propertydamage. If you mustload or unloadthe tiller,followthe guidelinesgivenbelow: •...

- Page 17 MAINTENANCE SCHEDULE Followthe maintenanceschedulegivenbelow.This chart describes Beforeperforming anytypeof maintenance/service, disengage all serviceguidelinesonly. Usethe ServiceLog columnto keeptrackof controls and stoptheengine.Waituntilall moving partshavecometo completedmaintenance tasks.To locate the nearest Sears Service a complete stop.Disconnect sparkplugwireandgrounditagainstthe Centeror to scheduleservice,simplycontactSears at enginetoprevent u nintended starting. A lways wearsafety glassesduring 1-800-4-MY-HOME®.

- Page 18 Removethespark plug bootand use a sparkplug wrenchto Servicing the Air Cleaner removethe plug.See Figure21. Neverusegasolineor lowflash point solventsfor cleaningtheair cleanerelement.A fireor explosioncould result. The air cleanerpreventsdamagingdirt, dust,etc., from enteringthe carburetorand being forcedintothe engineand is importantto engine lifeand performance.Neverrunthe enginewithoutan air cleaner completelyassembled.Checkthe air cleanerbeforeeachuse.

- Page 19 Check Engine Oil With engineOFF but still warm,disconnectsparkplug wireand 1. Check oilbefore each u se. Stop e ngine and wait s everal minutes keep itawayfrom sparkplug. before checking oillevel. With engine onlevel ground, the oil m ust Placea funnelunderthe oil drain to avoidgettingoil on the tiller betoFULL m ark o ndipstick.

- Page 20 LUBRiCATiON BELT REPLACEMENT After every 10operatinghours,oil or greasethe lubricationpoints.Use Yourtiller hasbeen engineered with a beltdesignedfor long life cleanlubricatingoil (#30 weightmotoroil is suitable)and cleangeneral and optimalperformance.Useonly a factoryauthorizedbeltas an purposegrease(greasecontaininga metallubricantis preferred,if "over-the-counter"belt maynot performsatisfactorily. T he procedure available).See Figure26. requiresaveragemechanical a bility and commonlyavailabletools. To replacethe Drivebelt, followthese steps: Removethe beltcover fromthe left sideof the tiller by removing Handlebar...

- Page 21 ADJUSTMENTS Removethe idler pulleyby removingthe boltand nut. See Figure27. Handle Removethe old beltand install the newbelt. Followthe instruc- The handlemay be adjustedto thedesiredheight.Referto the tions in reverseorderto re-installthe belt keeperand belt cover. Assemblysectionfor details. See Figure27. Secondary Clutch Cable Adjustment NOTE: Uponreassernbly, m akecertainthe belt is routedoverthe idler If additionaladjustmentis necessaryafter the primaryadjustmentfrom pulleyand insideof the beltkeepersbythe engine pulley.

- Page 22 idler Pulley Rod Afterthe belttensionhasbeenadjusted, i fthebeltis excessively s tretched, youmayneedtoadjustthe idlerpulleyrod.Thiscanbe checked easily. With theengineoff and the clutchcontrolbail disengaged,shiftthe gear selectionhandleto eachforwardmode. If the indicator bracket touchesthe idlerpulleyrod with theclutchcontrol bail disengaged, thenan adjustmentis necessary. Disconnectand groundthe spark plugwire againsttheengine. Removethebelt coveras describedunderBelt Replacement earlierin this section.

- Page 23 Neverstoretiller withfuel in tank indoorsor in poorlyventilatedareasI wherefuel fumesmay reachan open flame,spark,or pilotlightas on a furnace,water heater,c othesdryer, or gas app ance. PREPARING THE ENGINE PREPARING THE TILLER Enginesstored between30 and 90 days needto be treatedwith a Whenthe tillerwon't be usedfor an extendedperiod,prepareit for gasolinestabilizerand enginesstoredover90 days needto be drained storageas follows: of fuel to preventdeteriorationand gumfrom formingin fuel systemor...

- Page 24 Before performing anytype d maintenance/service, disengage all controls and stoptheengine.Waituntilall movingpartshavecometo a completestop.Disconnect sparkplugwireandgroundit against t heenginetoprevent unintended starting. A lways wearsafetyglasses duringoperation or whileperforming anyadjustments or repairs. Reconnect w ire. Enginefails to start Sparkplugwire disconnected. EngineThrottleControlLeverincorrectlyset. Putleverin STARTposition. Fueltank emptyor stale fuel. Filltank with clean,fresh gasoline.

- Page 26 Craftsman Tiller B IViodel No. 247.29932...

- Page 27 Craftsman Tiller B IViodel No. 247.29932 735-0127 747-1152 Shift Rod Washer,.33x .87x .125 914-0104 CotterPin, .072x 1.12 649-0034-0691 LowerHandleTubeAssembly 686-0044B-0691 End CoverAssembly 649-0041-0691 UpperHandleAssembly 710-0176 Hex Screw,5/16-18x 2.75 710-0946 Screw,1/4-20x 0.625 710-0376 Hex Screw,5/16-18x 1.00 710-3005 Hex Screw,3/8-16:1.25 710-3022 710-3056 Hex Screw,5/16-18x 3.25...

- Page 28 Craftsman Tiller- Model No. 247.29932...

- Page 29 Craftsman Tiller B IViodel No. 247.29932 756-0972 EnginePulley,Outer Half 686-0111-0637 BeltCover BracketAssembly 710-1039 Hex Screw,3/8-24 x 1.00 756-1162 input Pulley,4 x 8.594 710-0170 Hex LockScrew,5/16-24x .625 786-0064A Idler PulleyBracket 786-0185A-0637 Belt KeeperBracket 710-0513 Hex LockScrew,1/4-28x .625 786-0187-0637 Shift CoverBracket 710-0502A Screw,3/8-16x 1.250...

- Page 30 Craftsman Tiller B IViodel No. 247.29932 29\_...

- Page 31 Craftsman Tiller B IViodel No. 247.29932 717-1594 Gear Spur,16T 611-0021 TineShaft Assembly 921-0378 Shaft Seal, 1.0 611-0128 JackShaftAssembly 721-0379 Shaft Seal,.75 611-0129 Shif InputShaftAssembly 786-0238 Positioner Gear Bracket 611-04074A WheelShaftAssembly,33T 726-0277 TaperedCap Plug 617-0058 ReverseIdlerGearAssembly,30T 732-04778 Compression Spring,.230 617-0059 TineIdler GearAssembly,30T 936-0163 FiatWasher,1.03x 1.62x .03...

- Page 32 Craftsman Engine IViodel 170-VOB For Tiller IViodel 247.29932 ____-34 32-_ '_--32 951-11285 ExhaustPipe Gasket 712-04214 Nut,M8 751-12294 MufflerAssembly 710-05002 Bolt 951-10806 Air CleanerHousing 712-04213 710-05102 Self-Tapping Bolt M4.2x16 951-12135 SilencerPlate 951-10794 Air CleanerAssembly 951-10794 Air CleanerAssembly 951-12136 Air CleanerCover...

- Page 33 Craftsman Engine IViodel 170-VOB For Tiller IViodel 247.29932 951-10797 Carburetor Assembly FloatPin 951-11571 Carburetor GasketPlate Emulsion Tube 951-11177 ControlLever, Choke NeedleValve ChokeShaft MainJet ChokePlate NeedleValveSpring ThrottleShaft Float ThrottlePlate 951-11589 FuelBowlGasket ScrewM3x5 FuelBowl LockWasher 951-11348 FuelBowlGasket IdleJet Assembly 710-04945 FuelBowlMountingBolt Gasket,ThrottlePlate...

- Page 34 Craftsman Engine Model 170-VOB For Tiller Model 247.29932 5a 64...

- Page 35 Craftsman Engine IViodel 170=VOB For Tiller IViodel 247.29932 951-11253 PistonRingSet 951-11632 PistonPin Snap Ring 951-12007 Piston 951-11633 PistonPin 710-04915 Bolt M6x12 951-11113 Air Shield 951-11573 ConnectingRodAssembly 951-11356 GovernorArm Shaft 736-04461 Washer5.2xl.9 951-11574 GovernorSeal 714-04074 CotterPin 951-11575 CamshaftAssy. 951-11369 RadialBall Bearing,6205...

- Page 36 Craftsman Engine Model 170=VOB For Tiller Model 247.29932 16 38...

- Page 37 Craftsman Engine IViodel 170=VOB For Tiller IViodel 247.29932 710-05276 MufflerStud M8x36 710-04968 BoltM6x16 951-10657 951-11054 ValveCover MufflerStudAssembly 710-05101 StudM6x110 731-07059 BreatherHose 951-11567 Carburetor InsulatorGasket 726-04101 HoseClamp 951-11568 Carburetor Insulator 951-11565 ValveCoverGasket 951-11569 Carburetor Gasket 951-11892 RockerArmAssembly 951-11572 751-11124 Gasket,CylinderHead Nut,Pivot Locking...

- Page 38 Craftsman Engine IViodel 170=VOB For Tiller IViodel 247.29932 951-12126 Oil Seal25x41.25x6 951-10792 IgnitionCoil Assembly 710-04919 BoltM6x25 951-10805 Flywheel 951-10909 Fan,Cooling 951-10911 Pulley,Starter 712-04209 Nut,Special,M14x1.5 710-04915 BoltM6x12 951-11583 BlowerHousing 736-04455 FlatWasher 710-04974 BoltM6xlO 951-12127 RecoilStarter 712-04212 Nut,M6 710-04918 BoltM6x20 951-11109 BlowerHousingShield...

- Page 39 Craftsman Engine IViodel 170=VOB For Tiller IViodel 247.29932 710-04968 BoltM6x16 951-11914 DipstickDecorationCover 951-11067 ThrottleControlKnob 710-04905 Bolt 951-12131 PrimerBracket 710-04915 Bolt M6x12 710-04928 BoltM6x12 951-11903 Oil FillTubeO-Ring 951-11585 951-10656 Oil FillTube GovernorSpring 951-10664 101a 951-11913 ThrottleLinkageSpring Oil FillTubeAssembly 951-10665 951-11904 ThrottleLinkage...

- Page 40 Craftsman Tiller Model No. 247.29932 777D15445 777120451 777D15446 777S33508 777D15447 Operation Of This Equipment Cre_e Sparks That Start Fires Around Dry Vegetattsn. A Spark Arrestor May Be 777123259 Required, The Operator Should Contact Local Fire Agencies For Laws Or Regulations TO Fire Prevention Requirements.

- Page 41 (Thispage applicablein the U.S.A.and Canadaonly.) Sears Brands Management Corporation (Sears), the California Air Resources Board (CARD) and the United States Environmental Protection Agency (U.S. EPA) Emission Control System Warranty Statement (Owner's Defect Warranty Rights and Obligations) EMISSIONCONTROL WARRANTY COVERAGEISAPPLICABLE TO CERTI- YEAR 1997AND LATERENGINES WHICHARE PURCHASED AND USED FIEDENGINESPURCHASEDIN CALIFORNIAIN 1995ANDTHEREAF- ELSEWHERE IN THE UNITEDSTATES (ANDAFTERJANUARY1,2001 IN...

- Page 42 Look For Relevant Emissions Durability Period and Air index information On Your Engine Emissions Label Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must display information regarding the Emissions Durability Period and the Air index. Sears Brands Management Corporation makes this information available to the consumer on our emission...

- Page 43 Congratulations on making a smart purchase. Your new Craftsman® product is designed manufactured for years of dependable operation. But like all products, it may require repair from time to time. That's when having a Repair Protection Agreement can save you money and aggravation.

- Page 44 Durantedos aSosdesdela fechade compra,este productoest_ garantizadocontracualquierdefectode materialeso manode obra. Un productodefectuosorecibir_la reparaci6no sustituci6ngratuitasi la reparaci6nno est_ disponible. Paradetalles sobre la garantia de coberturapara obtener reparaci6ngratuita o reemplazo,visite el sitio web: www.craftsman.com Esta garantias61ocubre defectos en materiaies y mano de obra. Cobertura de la garantiano ineiuye: •...

- Page 45 Esta m _quina est_ d ise_ada para ser u tilizada respetando las normas Lapresencia deeste s fmbolo indica que s e trata d einstrucciones de seguridad contenidas en este m anual. AI i gual que con cualquier tipo seguridad importantes que s e deben respetar para e vitar poner enpeligro de equipo motorizado,...

- Page 46 • Si golpea algOnun objeto extraSoo si la m&quinacomienzaa emitir Manejo seguro de la gasolina: un sonidopococomOno a vibrar,apagueel motorde inmediato. Para evitarlesionespersonalesy da_os materialestenga muchocuidado al Desconecteel cable de la buj[a,p6ngalohaciendomasacontrael motor manipularla gasolina.La gasolinaes sumamenteinflamabley sus vapores y siga los pasossiguientes: puedencausarexplosiones.Si se derramagasolinaencimao sobre la ropa se puedelesionargravementeya quese puedeincendiar.

- Page 47 ,, Observe lareglamentaci6n ylas normas respecto alaeliminaci6n AVISO REFERIDO A EMISIONES correcta degasolina, aceite, etc. para proteger elmedic ambiente. Losmotoresque est_ncertificadosy cumplencon las regulacionesde • SegOn laComisi6n de Seguridad deProductos para elConsumidor emisionesfederalesEPAy de Californiapara SORE (EquiposSmall Off Road los Estados Unidos (CPSC) ylaAgencia deProtecci6n...

- Page 48 SiIVIBOLOS DE SEGURIDAD En esta p_ginase presentany describenlos simbolosde seguridadque puedenapareceren este producto. Lea,entienday cumplatodas las instruccionesincluidasen la m_quinaantes de intentararmarlay utilizarla. LEA LOS MANUALES DEL OPERADOR Lea, entienda y cumpla todas las instrucciones incluidas en los manuales antes de intentar armar la unidad y utilizarla.

- Page 49 NOTA:Estaunidadse envfa singasolinani aceiteen el motor.Antes Levanteel montajede la aletacon bisagrasdel protectorde dientese inserteel montajede la estacade profundidaden la de operar la m_.quina cargueel motorcongasolinay aceitecomo se ranura,debajodel protectory paraarriba a travesdel montaje indicaen la secci6nFuncionamiento de este manual. protectorde dientes. NOTA:Lasreferenciasa los ladosderechoe izquierdode la cultiva- Inserte el pasador d e horquilla en losmontajes delprotector de dientes dora se hacenobservandola m&quinadesdela posici6nde operaci6n.

- Page 50 3. Alinee losorificios enlamanija con losorificios enlam_nsula y Empujeel cablea travesdel orificiodel centrode la manijae fijelos c on losherrajes que acaba d eextraer. introduzcaa presi6nel accesoriopl_tstico. Vea la Figura6. ACOPLE DE LA VARILLA DE CONTROL AsegQrese de que la unidadde la manijaesta en la posici6nm_.s alta.

- Page 51 CONFIGURACION Recomendaciones sobre el combustible Utilicegasolinaparaautom6viles(sinplomoo bajocontenidode El control y la Adici6n de Aceite plomopara minimizarlosdep6sitosen la cAmarade combusti6n)con un minimode 87 octanos.Se puedeusargasolinacon hasta un 10% de etanolo un 15%de MTBE(etermetilicoterciario-butilico).Nunca El motor seenvia sinaceite en el motor.Usteddebe Ilenarel motor use una mezda de aceitey gasolinani gasolinasucia.Eviteque se conaceiteantes de operar.El funcionamiento del motorcon el aceite introduzca s uciedad,polvoo agua en el tanquede combustible.NO...

- Page 52 5. Vuelva acolocar latapa decombustible yapriete bien. Lirnpie Si las ruedasno girancon el tirn6nen adelante,ajustepor losderrarnes decombustible antes dearrancar elmotor. Sise desenroscarel tuboen el extrernodel cablede un par de vueltas derrarna combustible NO arranque elmotor. Mueva la rn_.quina a la izquierda- al estar de pie en la posici6ndel operador- y fueradel _.reade derrarne.Evitarla creaci6nde cualquierfuente luegovolvera apretarla tuercacontrael tubo.

- Page 53 Manija selectora de cambios Traba de ajuste manija embrague Silenciador Filtro de aire Estaca de profundidad Tap6n de Protector dientes trasero Tap6n de Ilenado y varilla del nivel de aceite Protector lateral Figura12 CONTROL DEL ACELERADOR Ahoraque tiene la cultivadorapreparada para funcionar,farniliaricese con loscontrolesy funciones.Encontrar_.

- Page 54 TAPON DE LLENADO Y VARILLA DEL NIVEL PARA ARRANCAR EL MOTOR DE ACEITE Conectecable de la bujia y la botade gornaa la bujfa. Lleneel tanquea no rn_.s de 1/2 "debajodel rondodel cuello Es posiblecontrolarel nivelde aceitedel motor,asi cornotarnbi_n de Ilenadopara proporcionar e spaciopara la expansi6n del agregaraceite,a travesdel Ilenadode aceite.Veala Figura12.

- Page 55 PARA ENGRANAR LA TRANSMISION Y LOS DIENTES Pararegularlos protectores laterales,saquelastuercasde mariposa. Muevael protectorlaterala la posici6ndeseaday vuelvaa colocarlas tuercasde mariposa.Ajustebien.Vea la Figura14. Noempujehaciaabajosobrelasbarrasde controlpara intentar h acel que la cultivadoralabremAsprofundo.Estoevita que las ruedas retenganla cultivadoray puedapermitira los dientespropulsarla cultivadorar_.pidamente h aciaadelante,Io cual podriaocasionarla perdidade control,daSosmateriales o lesionespersonales.

- Page 56 ELIMINACION DE LOS DIENTES AI realizartareasde labranza(rompiendola superficiede suelo alrededorde las plantaspara destruirlasmalezas,veala Figura 16),ajustelos dientesparacavar Onicamente a una profundidad de 1 a 2 pulgadas.La labranzaa pocaprofundidadayudaa Antes de despejarlosdientesa mano,detengael motor,deje que evitar lesionesalas plantascuyasraicesa menudocrecen todas las partesen movimiento se detengany desconecteel cable cerca de la superficie.Si es necesario,levantelas barrasde de la bujia.Si no se observaesta advertenciase puedenproducir control ligeramente para evitarque los dientescavendemasiado...

- Page 57 Si las dirnensiones del jardin no perrnitenla labranzaen sentido IViodelos de labranza sugeridos longitudinaly luegotransversal,traslapelas prirneraspasadas • AI prepararel lechode siernbra,recorrala rnisrnasendados por la rnitaddel anchode la cultivadora,continuando con vecesen la prirnerahilera,luegotraslapela rnitaddel anchode la sucesivaspasadasa un cuartodel ancho.Vea la Figura19. cultivadoraen el restode las pasadas.Vea la Figura17.

- Page 58 Jardineria en terrazas Carga y descarga de la cultivadora Paracrearuna terraza,cornience en la cirnade la pendientey trabajehaciaabajo. Recorrala prirnerahilerahaciaatr_.sy hacia adelante.Vea la Figura20. La cargay descargade la cultivadoraen un vehiculoes potencialrnente peligrosay no se recornienda a rnenosque sea absolutarnente necesario,ya que esto podria resultaren lesiones personaleso da_osrnateriales.

- Page 59 PROGRAMA DE MANTENIMIENTO Siga el cronograrna de rnantenirniento que se presentaa continuaci6n. Estatabla s61o describepautasde servicio.Utilicela cohrnna Registro Antesde realizar c ualquier t ipode mantenirniento o servicio, de Serviciopara hacerel seguirniento de lastareas de rnantenirniento desenganche todosloscontroles y detenga el motor. E sperea quese cornpletadas.

- Page 60 IVlantenimiento del filtro de aire. Retirela fundade bujia y utiliceuna Ilavepara bujiaspara extraer la bujia.Veala Figura26. Nuncausegasolinao solventes de puntode encendidobajo para lirnpiarel elernentodel depuradorde aire. Podriaproducirseun incendioo exjolosi6n. Elfiltrodeaireevitael ingreso al carburador de suciedad, polvo, e tc. perjudiciales y evitaquelosrnisrnos seanintroducidos dentrodelmotor. Bujia de Adern_.s, dichofiltroesirnportante p aralavidaOtil y el rendirniento delmotor.

- Page 61 Con el motorapagadopero aQncaliente,desconecteel cablede Inspeccione el aceite del motor bujia y rnant_ngalo alejadode la bujia. Reviseel aceiteantes de cadauso. Pareel motory espereunos Coloqueun ernbudoen el drenajede aceite para evitarque el rninutosantesde cornprobarel nivelde aceite.Conel motora aceiteen el marcode tirn6n.Wase la Figura25. niveldel suelo,el aceitedebe ser de rnarcaFULLen la varilla.

- Page 62 LUBRICACION CANIBIO DE CORREA Despu_sde cada 10 horasde funcionarniento, aceite o engraselos Su cultivadoraha sidoequipadacon una correadise_adaparauna puntosde lubricaci6n-Useaceite lubricantelirnpio(esadecuado vida Otilprolongada y un 6ptirnorendirniento. U se Onicarnente correas el aceitepara rnotores de peso#30) y grasade usogenerallirnpia autorizadaspor el fabricante,ya que las correasgen_ricaspuedenno (es preferiblegrasaque contengaun lubricantede metal,si hay desernpe_arse satisfactoriarnente.

- Page 63 4. Extraiga lapolea I oca retirando elperno y latuerca. Instalecadaconjuntode dientesde modeque el borde cortante Vea laFigura 28. (filoso) de los dientespenetreel sueloprirnerocuandola 5. Extraiga lacorrea usada e instale una nueva. Siga lasinstruc- cultivadorase rnuevahaciaadelante.Recuerdeque estosdientes ciones enorden i nversa para reinstalar elguardacorreas rotanen sentidocontrario,asi que asegureel conjuntode dientes cubierta delacorrea.

- Page 64 Polea Ioca de Rod Despu_sde la tensi6nde la correase ha ajustado,si la correaestA demasiadoextendido,es posiNe que necesiteajustarla barrade la poleaIoca. Estose puedecomprobarf_.cilmente. Conel motorapagadoy la libertadbajofianza de controlmotor desembragado, cambiarel manejadorde selecci6nde equipos para cadamodode avance.Si el soportedel indicador toca la barra de la polea Iocacon la libertadbajo fianzade controlde motor desembragado, a continuaci6n, u n ajustees necesario.

- Page 65 Nuncaalrnacenela cultivadoraconcombustibleen el tanqueen un espaciocerradoo en _.reas pocoventiladasdonde los gasesdel combustiblepuedanNegar a una Narna expuesta,una chispao un pilotocornoel que tienenalgunoshornos,calentadores de agua, secadoresde ropao algQnartefactoa gas. PREPARACI6N DE LA CULTIVADORA Si la cultivadorano se va a usarduranteun perfodoprolongado, Nuncadeje el motorsin vigilanciarnientras est,. en funcionarniento. prep_.rela parael alrnacenarniento de la siguienteforrna: Lirnpiela cultivadoray el motor.

- Page 66 Antesde realizar c ualquiertipode rnantenirniento o servicio, d esenganche t odosloscontroles y detenga el motor.Esperea que sedetengan cornpletarnente todaslaspiezasrn6viles. D esconecte e l cablede la bujfay p6ngalohaciendo rnasacontrael motorparaevitarqueseenciendaaccidentalrnente. Utilicesiernpre anteojos de seguridad durantelaoperaci6n o rnientras realizaajustes o reparaciones. El motor no arranca Reconecteel cable.

- Page 69 (Esta p_.ginase aplica s61oen EE.UU. y Canada.). Sears Brands Management Corporation, el Consejo de Recursos Ambientales de California (CARB) y la Agencia de Protecci6n Ambiental de los Estados Unidos (EPA) Declaraci6n de garantia del sistema de control de emisiones (derechos y obligaciones de la garanfia de defectos del propi= etario)

- Page 70 Busque el periodo de duraci6n de emisiones importantes yla informaci6n de clasificaci6n de aire en la etiqueta de emisiones de su motor Los motores cuyo cumpiimiento con los estAndares de emisi6n Tier 2 de la Comisi6n de Recursos Ambientales de California (CARB) est6 certificado deben exhibir la informaci6n relacionada con el periodo de duraci6n de ias emisiones y la clasificaci6n de aire.

- Page 71 Felicitaciones por haber realizado una adquisici6n inteligente. El producto Craftsman® que ha adquirido esta diseSado y fabricado para brindar muchos aSos de funcionamiento confiable. Pero como todos los productos a veces puede requerir de reparaciones. Es en ese momento cuando...

- Page 72 Your Home For troubleshooting, product manuals and expert advice: managernylife www.managemylife.com For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself.