Summary of Contents for Teledyne Linea Color GigE LA-GC-02k05B

- Page 1 Linea Color GigE Camera User’s Manual Color CMOS Line Scan sensors | cameras | frame grabbers | processors | software | vision solutions P/N: 03-032-20237-05 www.teledynedalsa.com...

- Page 2 All information provided in this manual is believed to be accurate and reliable. No responsibility is assumed by Teledyne DALSA for its use. Teledyne DALSA reserves the right to make changes to this information without notice. Reproduction of this manual in whole or in part, by any means, is prohibited without prior permission having been obtained from Teledyne DALSA.

-

Page 3: Table Of Contents

Contents LINEA COLOR GIGE SERIES OVERVIEW ............4 ....................4 ESCRIPTION Linea GigE Application Advantages ............5 Linea GigE with TurboDrive..............5 Linea GigE Firmware ................6 ............7 UMBERS AND OFTWARE EQUIREMENTS ............. 8 ISION APERA PPLICATION ESCRIPTION ..............9 AMERA PECIFICATIONS VERVIEW... - Page 4 Camera Configuration Selection Dialog............ 35 ................36 ENSOR ONTROL ATEGORY Sensor Control Feature Descriptions ............36 Gain and Black Level Control Details ............38 Exposure Controls Details ..............39 I/O C ................. 41 ONTROL ATEGORY I/O Control Feature Descriptions ............42 I/O Module Block Diagram ..............

- Page 5 Output Signals Electrical Specifications ..........113 External Output Details ............... 114 ..........114 OMPUTER EQUIREMENTS FOR INEA AMERAS Host PC System ................. 114 Ethernet Switch Requirements ............. 115 Ethernet to Fiber-Optic Interface Requirements........115 DECLARATIONS OF CONFORMITY .............. 116 FCC Statement of Conformance ............116 EU and UKCA Declaration of Conformity ..........

-

Page 6: Linea Color Gige Series Overview

Linea Color GigE combines standard gigabit Ethernet technology (supporting GigE Vision 1.2) with Teledyne DALSA Trigger-to-Image-Reliability, to dependably capture and transfer color images from the camera to the host PC. 4 • Linea Color GigE Series Overview... -

Page 7: Linea Gige Application Advantages

Linea GigE Application Advantages • Optimized, rugged design • GigE Vision 1.2 compliant • Gigabit Ethernet (GigE) interconnection to a computer via standard CAT5e or CAT6 cables • Supports connection to the host computer NIC through a GigE network switch •... -

Page 8: Linea Gige Firmware

Teledyne DALSA website at www.teledynedalsa.com. Firmware updates for Linea GigE are available for download from the Teledyne DALSA web site [http://www.teledynedalsa.com/imaging/support/downloads/firmware/]. Choose Linea GigE Firmware from the available download sections, then choose the zip file download specific to your camera model. -

Page 9: Part Numbers And Software Requirements

Part Numbers and Software Requirements This manual covers the Linea Color GigE models summarized below. New models area added to this manual as they are released by Teledyne DALSA. See Camera Specifications for details of each Linea GigE model. Lens Mount... -

Page 10: Gige Vision Sapera Application Description

GenApi module of the GenICam™ specification. For more information see www.genicam.org. The Teledyne DALSA GigE Vision Module provides a license free development platform for Teledyne DALSA GigE hardware or Sapera vision applications. Additionally supported are Sapera GigE Vision applications for third party hardware with the purchase of a GigE Vision Module license, or the Sapera processing SDK with a valid license. -

Page 11: Camera Specifications Overview

Camera Specifications Overview Camera Controls Synchronization Modes Free running, External triggered, Software trigger through Ethernet Exposure Modes Programmable in increments of 1µs minimum (in µs) is model specific maximum is 3 milliseconds Pulse controlled via Trigger pulse width. Trigger Inputs RS422, and 3.3V to 24V typical (used as Line or Frame triggers) Debounce range from 0 up to 255 µs... -

Page 12: Environmental Specifications

Environmental Specifications Environmental Specifications Performance Storage temperature range -20 °C to +80 °C Humidity (storage and operation) 15% to 85% relative, non-condensing MTBF (mean time between failures) > 100,000 hours, typical field operation Compliance, EMI Certifications Compliance Directives Standards ID Overview EN55032 (2012) Electromagnetic compatibility of multimedia... -

Page 13: Sensor Performance

Sensor Performance The sensor description below provides a specification table and response graphics. The graph describes the sensor response to different wavelengths of light (excluding lens and light source characteristics). Visible light spans wavelengths between about 390 - 780 nanometers. Wavelengths below 390 nm are termed ultra-violet while those above 780 nm are termed infra- red. -

Page 14: Spectral Responsivity

Spatial Correction and Bilinear Sensor Design The bilinear color camera is based on Teledyne DALSA’s bilinear CMOS sensor and designed such that the first line of this two line sensor has red (R) and blue (B) alternating pixels, while the second line has all green (G) pixels. - Page 15 moved for each EXSYNC period is not possible. This scenario may be especially apparent when trying to integrate the camera into an existing system. When it is not possible to generate a square object pixel, color artifacts will occur in the scan direction and is particularly noticeable at sharp edge transitions.

-

Page 16: Parallax Correction

Example 3. Target running faster than example 1, same EXSYNC (trigger) frequency Line Spatial Correction = 3 Line Spatial Correction = 1.73 Parallax Correction When the camera is not perpendicular to the object surface it will exhibit color. The parallax distortion increases when imaging at steep angles relative to the cameras imaging plain. -

Page 17: Camera Direction

2048 pixels Corrected Image The figure above is the same image corrected using the parallax correction. In this example the value of 3 was used to correct the image. Camera Direction Selectable camera direction accommodates an object direction change on a web and allows you to mount the camera “upside down”. -

Page 18: Connecting The Linea Color Gige Camera

When adding a NIC adapter to a computer, Teledyne DALSA engineering has seen cases where a PCI Express bus Gigabit NIC has better overall performance than the same NIC hardware in PCI bus format. -

Page 19: Connectors

Gigabit NIC. See Ruggedized RJ45 Ethernet Cables for secure cables. • A HD15 connector for camera power, plus trigger, strobe and general I/O signals. Teledyne DALSA provides an optional breakout cable; see Mating GPIO Cable Assembly. See HD15 type Connector Details for connector pin out specifications. -

Page 20: Led Indicators

LED Indicators The Linea GigE has one multicolor LED to provide a simple visible indication of camera state and the RJ45 Ethernet connector has two LEDs for network status conditions. These are described below. Network Status Indicators The Linea GigE RJ45 Ethernet connector has two LEDS which display standardized information, defined as follows: Ethernet Connector LEDs Color... -

Page 21: Linea Gige Ip Configuration Sequence

IP address. The DHCP server then provides the IP address. The Teledyne DALSA Network Configuration tool, installed with the Teledyne DALSA Network Imaging Package, provides a DHCP server which is easily enabled on the NIC used with the Linea GigE (refer to the Teledyne DALSA Network Imaging Package user's manual). -

Page 22: Preventing Operational Faults Due To Esd

Preventing Operational Faults due to ESD Linea GigE camera installations which do not protect against ESD (electrostatic discharge) may exhibit operational faults. Problems such as random packet loss, random camera resets, and random loss of Ethernet connections, may all be solved by proper ESD management. The Linea GigE camera when used with a simple power supply and Ethernet cable, is not properly connected to earth ground and therefore is susceptible to ESD caused problems. -

Page 23: Using Linea Gige With The Sapera Api

DALSA Network Imaging Package user's manual). • Linea GigE also can connect through a Gigabit Ethernet switch. When using VLAN groups, the Linea GigE and controlling computer must be in the same group (refer to the Teledyne DALSA Network Imaging Package user's manual). •... -

Page 24: Installation

Contact Teledyne DALSA concerning the GigE Vision package supporting TurboDrive™ technology. • Optional: If the Teledyne DALSA Sapera LT SDK package is not used, click to install the Linea GigE firmware and user manuals only. Follow the on screen prompts. •... -

Page 25: Gige Server Verification

GigE Server Verification After a successful Sapera GigE Vision package installation, the GigE Server icon is visible in the desktop taskbar tray area (note that in Windows 7 the icon remains hidden until a camera is connected). After connecting a camera (see following section), allow a few seconds for the GigE Server status to update. -

Page 26: Optimizing The Network Adapter Used With Linea Gige

Most Gigabit network interface controllers (NIC) allow user modifications to parameters such as Adapter Buffers and Jumbo Frames. The optimal settings will be system dependent. These should be optimized for use with the Linea GigE during the installation. Refer to the Teledyne DALSA Network Imaging package manual for optimization information. -

Page 27: Quick Startup With Camexpert

GigE Vision Host Control feature “Image Timeout”. • Refer to the Teledyne DALSA Network Imaging package manual if error messages are shown in the Output Messages pane. Try increasing the value of the Linea GigE Interpacket Delay feature available from the GigE Vision Transport Layer Category group in CamExpert. - Page 28 26 • Using Linea GigE with the Sapera API Linea GigE Series Camera...

-

Page 29: About The User Defined Camera Name

When using CamExpert, multiple Linea GigE cameras on the network are seen as different "Linea_C4095-7um_1” devices as an example. Non Teledyne DALSA cameras are labeled as “GigEVision Device”. Click on a device user name to select it for control by CamExpert. -

Page 30: Operational Reference

Operational Reference Using CamExpert with Linea GigE Cameras The Sapera CamExpert tool is the interfacing tool for GigE Vision cameras, and is supported by the Sapera library and hardware. When used with a Linea GigE camera, CamExpert allows a user to test most of the operating modes. - Page 31 Device Selection Drop CamExpert Control Menu Buttons Acquisition Information Acquisition Display Parameter Features • Black can be changed • Grey are Read Only Parameter Category Selection Message Window Features Values shown here • Device Selector pane: View and select from any installed GigE Vision or Sapera acquisition device.

-

Page 32: Creating A Camera Configuration File In The Host

Visibility level from the View ∙ Parameters Options menu. Creating a Camera Configuration File in the Host • When using the Teledyne DALSA Sapera SDK – the CCF is created automatically via a save. • When using a 3 party SDK application, if that SDK supports GenAPI 2.4, then the process is... -

Page 33: Camera Feature Categories

As Linea GigE capabilities evolve the device version will increase, therefore identifying the supported function package. Features listed in the description table that are tagged as Invisible are usually for Teledyne DALSA or third party software usage—not typically needed by end user applications. Also important, features shown by CamExpert may change with different Linea GigE models implementing different sensors, image resolutions, and color versions;... -

Page 34: Camera Information Category

Camera Information Category Camera information can be retrieved via a controlling application. Parameters such as camera model, firmware version, etc. are read to uniquely identify the connected Linea GigE device. These features are typically read-only. GigE Vision applications retrieve this information to identify the camera along with its characteristics. - Page 35 Feature to store a user-programmable identifier of up to 1.00 Device User ID DeviceUserID 15 characters. The default factory setting is the camera Beginner serial number. (RW) Power-up Configuration Selects the camera configuration set to load and make 1.00 UserSetDefault Selector active on camera power-up or reset.

- Page 36 FPGA Board FPGABoard Read FPGA Board temperature 1.00 Device Temperature DeviceTemperature The temperature of the selected source in degrees Celsius Beginner overheatedStatus overheatedStatus Displays the overheated status of the device. (RO) 1.00 DFNC Beginner Device temperature does not exceed upper limit. Overheated Overheated Device temperature exceeds upper limit.

-

Page 37: Camera Configuration Selection Dialog

Camera Configuration Selection Dialog CamExpert provides a dialog box which combines the features to select the camera power up state and for the user to save or load a camera state from Linea GigE memory. Camera Power-up Configuration The first drop list selects the camera configuration state to load on power-up (see feature UserSetDefaultSelector). -

Page 38: Sensor Control Category

Sensor Control Category The Linea GigE sensor controls, as shown by CamExpert, groups sensor specific features. This group includes controls for line rate, exposure time, etc. Sensor Control Feature Descriptions Display Name Feature & Values Description Device Version & View 1.00 Device Scan Type DeviceScanType... - Page 39 Exposure Mode 1.00 ExposureMode Sets the operation mode for the camera’s exposure. Beginner The exposure duration time is set using the Exposure Time Timed Timed feature and the exposure starts with a LineStart event. Uses the width of the trigger signal pulse to control the Trigger Width TriggerWidth exposure duration.

-

Page 40: Gain And Black Level Control Details

Gain and Black Level Control Details The Linea GigE camera provides gain and black level adjustments. The gain and black level controls can make small compensations to the acquisition in situations where lighting varies and the lens iris cannot be easily adjusted. Optimal gain and black level adjustments maximizes the Linea GigE dynamic range for individual imaging situations. -

Page 41: Exposure Controls Details

Exposure Controls Details Exposure Control modes define the method and timing of controlling the sensor integration period. The integration period is the amount of time the sensor is exposed to incoming light before the video line data is transmitted to the controlling computer. •... - Page 42 External Trigger Width Exposure An alternative external trigger mode allows the external signal width to control the exposure duration (feature ExposureMode = TriggerWidth), as illustrated in the following graphic. • Note the exposure delay of 12.7µs from the external exposure control. •...

-

Page 43: I/O Control Category

I/O Control Category The Linea GigE I/O controls, as shown by CamExpert, group features used to configure external inputs and acquisition actions based on those inputs, plus camera output signals to other devices. Linea GigE Series Camera Operational Reference • 41... -

Page 44: I/O Control Feature Descriptions

I/O Control Feature Descriptions Display Name Feature & Values Description Device Version & View 1.00 Selects which type of trigger to configure with the various Trigger Selector TriggerSelector Beginner Trigger features. Single Line Trigger (Start) LineStart Selects a trigger starting the capture of a single line. Selects a trigger starting the capture of a single frame. - Page 45 1.00 Select the activation mode for the selected Input Line Trigger Input Line Activation TriggerActivation Beginner trigger source. This is applicable only for external line input lines. Exposure The trigger is considered valid on the rising edge of the Rising Edge RisingEdge Mode: line source signal (after any processing by the line inverter...

- Page 46 Rotary Encoder Input B Selects which input line to assign to the rotary encoder 1.00 rotaryEncoderInputBSource Source input B (also known as shaft encoder). Note that the Line Expert Mode feature must be set to Input. The list of supported DFNC input line sources is device-specific.

- Page 47 1.00 Controls whether to invert the polarity of the selected Line Inverter LineInverter Beginner input or output line signal. False / True 1.00 Input Line Debouncing Specifies the minimum delay before an input line voltage lineDebouncingPeriod Beginner Period transition is recognizing as a signal transition. DFNC 1.00 Line Electrical Termination...

- Page 48 Output Line Pulse Signal 1.00 Specifies the input line activation mode to trigger the outputLinePulseActivation Beginner Activation OutputLine pulse. DFNC Specifies that the trigger is considered valid on the rising Rising Edge RisingEdge edge of the source signal. Specifies that the trigger is considered valid on the falling Falling Edge FallingEdge edge of the source signal.

-

Page 49: I/O Module Block Diagram

I/O Module Block Diagram Timer and Counter Module TimerEnd Event Timer Input Event Driven Line Line Input Line Selector = Detection Counter Debouncer inverter Line 1 to 6 Level CounterEnd Event Physical Line Trigger Module Line Mode Input Trigger Trigger Signal LineStatus Trigger Line... -

Page 50: Trigger Overview

Trigger Overview Linea GigE line exposures are initiated by a trigger event. A trigger is either the camera's programmable internal clock used in free running mode, an external input used for synchronizing exposures to external triggers, or a programmed function call message by the controlling computer. - Page 51 • If the number of lines within the frame active trigger is greater than the feature “Height”, the frame active trigger will produce more than one frame. • If the number of lines within the frame active trigger is less than the feature “Height”, the frame height is less than the feature “Height”.

- Page 52 Output Line Details The general purpose output line signals either dedicated or shared with inputs. See HD15 type Connector Details for connector pinout and electrical information. • Feature set: LineInverter (RW), outputLineSource (RW), outputLinePulseDelay (RW), outputLinePulseDuration (RW), outputLineValue (RW), outputLineSoftwareCmd (RW), LineSelector (RW), LineFormat (RW), LineMode (RW), LineStatus (RO).

- Page 53 Example of Line Trigger plus Frame Trigger Combined An example setup the Line Trigger mode combined with Frame Trigger using the configurable internal timers is as follows: • Set image "Height" as 80 • Select "TriggerSelector" as "SingleLineTrigger(Start)" • Set "TriggerMode" as "On" •...

-

Page 54: Counter And Timer Control Category

Counter and Timer Control Category The Linea GigE counter and timer controls, as shown by CamExpert, groups parameters used to configure acquisition counters and timers for various input lines and signal edge detection. Block diagrams show the operating sequence of these parameters. Counter and Timer Control Feature Description Display Name Feature &... - Page 55 Select the counter start source. Counter increments from 0 1.10 Counter Start Source counterStartSource to the value of the counterDuration feature. Expert DFNC Counter is stopped. Counter starts on the reception of the Acquisition Start Acquisition Start AcquisitionStart event. Counter starts on the reception of the Acquisition End Acquisition End AcquisitionEnd event.

- Page 56 1.00 Counter Incremental Selects the counter signal activation mode for line inputs. counterIncrementalLineActivation Expert Line Activation The counter increments on the specified signal edge or DFNC level. Increment the counter on the rising edge of the selected I/O Rising Edge RisingEdge Line.

- Page 57 Timer Status 1.00 timerStatus Returns the current state of the timer. (RO) Expert The timer is idle. The CounterStartSource feature is Timer Idle TimerIdle DFNC set to off. Timer Trigger Wait TimerTriggerWait The timer is waiting for a start trigger. Timer Delaying TimerDelaying The timer is counting the requested delay.

-

Page 58: Counter And Timer Group Block Diagram

Counter and Timer Group Block Diagram Timer and Counter Module TimerEnd Event Timer Input Event Driven Line Line Input Line Selector = Detection Counter Debouncer inverter Line 1 to 6 Level CounterEnd Event Physical Line Trigger Module Line Mode Input Trigger Trigger Signal LineStatus... - Page 59 Example: Counter Start Source = CounterEnd (itself) CounterStartSource=CounterEnd (itself) Countermode=Active Countermode=OFF CounterEnd Event Generated Counter is CounterWait Counter is Counter IDLE Trigger Active Completed Counter is incrementing CounterStartSource= CounterEnd (itself) Counter Reset CMD CounterResetSource=CounterEnd • Counter starts when Counter Mode is set to Active. •...

- Page 60 Example: CounterStartSource = Signal (Level Base) Example 1 CounterStartSource= Signal (Level Base ) Example 1 Countermode=Active Countermode=OFF CounterEnd Event Generated CounterResetSource =CounterEnd(Itself) Counter STATUS Counter is CounterWait Counter Active Wait Active Active IDLE Trigger Completed Counter Register CounterStartSource= Signal (Level Base ) CounterTriggerActivation= LevelLow Tick in...

-

Page 61: Advanced Processing Control Category

Advanced Processing Control Category The Linea GigE Advanced Processing controls, as shown by CamExpert, group parameters used to configure Flat Field calibration. Advanced Processing Control Feature Descriptions Display Name Feature & Values Description Device Version & View 1.00 Flat Field Correction flatfieldCorrectionMode Sets the mode for the Flat Field correction. - Page 62 Flat Field Correction 1.00 Specifies the current set of Flat Field coefficients to use. User flatfieldCorrectionCurrentActiveSet Beginner Current Active Set data is uploaded via the file access feature. DFNC Feature used when flatfieldCorrectionMode is Active. In Calibration, changing this feature has no effect unless you save the FFC, where this feature defines where to save the values.

- Page 63 Calibrate PRNU Performs Photo Response Non Uniformity (PRNU) calibration 1.00 flatfieldCalibrationPRNU to a targeted, user-defined value. PRNU calibration eliminates Guru the difference in responsivity between the most and least DFNC sensitive pixel, creating a uniform response to light. No Error NoError No Error Calibration Failed...

- Page 64 White Balance ROI balanceWhiteROIMode When active, the White Balance algorithm limits analysis to Mode the ROI image area to determine the white balance adjustments. 1.00 All of the output image is used in the White Balance Expert algorithm. DFNC Active Active The selected ROI is used in the White Balance algorithm.

-

Page 65: Flat Field Correction Overview

Flat Field Correction Overview The Flat Field correction function (FFC) consists of using two coefficients per pixel which correct the gain and offset of the corresponding pixel. These corrections compensate for Photo-response Non- uniformity (PRNU) and Fix Pattern noise (FPN), unique to each camera sensor. With CMOS sensors, it is imperative to perform FFC calibration under the same conditions the camera is to be used in. - Page 66 Information on the Sapera Flat Field Coefficients File The Flat Field Coefficients File is a standard 16-bit TIFF file. A Sapera application (such as CamExpert) creates a new SapBuffer object of the same width as the sensor but with twice the number of lines. This provides the room to store both offset and gain Flat Field data.

-

Page 67: How To Do A Ffc Setup Via Sapera Camexpert

How to do a FFC Setup via Sapera CamExpert The Sapera LT CamExpert tool provides an easy GUI based method for a user to perform a Flat Field Calibration. The process first requires the user to plan acquisitions in dark and bright conditions, followed by the FFC process itself. - Page 68 Verify a Bright Acquisition Aim the camera at a diffused light source or evenly lit white wall with no shadows falling on it. Using CamExpert, click on the grab button and then the histogram button. Use the lens iris to adjust for a bright gray approximately around a pixel value of 200 (for 8-bit pixels).

- Page 69 CamExpert. For more information, contact your local TCS (technical customer support). Note: Before performing a FFC, Teledyne DALSA recommends evaluating the “bare image” characteristics, which determine the quality of FFC, applied to the image. A bare image has no gains applied.

- Page 70 The camera is now ready to produce bare images. The line profile tool is best used to evaluate a bare image. The following is an example line profile of a bare image of a white uniform object: A good line profile of the bare image of a white and uniform object. Whether a line profile is good or not is mainly determined by three factors: 1.

- Page 71 2) Height: The closer the average output level is to your calibration target the better. It is okay if the level is higher than the target, but it is not desirable to be much lower than the target. Compared to the target, an extremely low output will increase the noise level significantly high after the PRNU is corrected such that the SNR and/or DNR may not meet your application’s requirements.

- Page 72 offset value so to ensure that all pixels’ output are above zero. The black level offset adjustment is located in the Sensor Control category. Histogram of a dark bare image. Step 3. Select Calibration from Flat Field Correction Mode drop-down menu. Step 4.

- Page 73 Histogram of a dark image after FPN has calibrated. PRNU Correction Step 1. Apply illumination and place a white flat target in the spot where the real object will be. Ideally, you would use a professional target. For convenience you can use white paper as the target.

- Page 74 Step 6. Press the Press… command in Calibrate PRNU menu. Step 7. Select Active from Flat Field Correction Mode drop-down menu to apply the calibrated FPN and PRNU parameters to future imaging. You can check the results with the line profile. Line profile of a white uniform target after PRNU is calibrated.

- Page 75 Step 8. You may want to save the FFC results for future use. If you do not save, the FFC result will be lost as soon as the camera loses power. Click Setting… in Camera Information category, Power- up Configuration parameter. In the Power-up Configuration dialog box select one of four UserSets for both Camera Power-up...

-

Page 76: Image Format Control Category

Image Format Control Category The Linea GigE Image Format controls, as shown by CamExpert, group parameters used to configure camera pixel format, image cropping, and the binning function, Additionally a feature control to select and output a camera internal test image simplifies qualifying a camera setup without a lens. - Page 77 1.00 Pixel Color Filter PixelColorFilter Indicates the type of color filter applied to the image. Guru None None No filter applied on the sensor. 1.00 Horizontal Offset OffsetX Horizontal offset from the Sensor Origin to the Area Beginner Of Interest (in pixels). 1.00 Width Width...

- Page 78 1.00 End-of-Line Metadata Selects the content of the End-of-Line Metadata to endOfLineMetadataContentSelector Expert Content Selector control. Each element is part of a QWORD (8 bytes). DFNC Enabling a single element in a QWORD will result on sending the complete QWORD on each line. Control the presence of exposure in the End-of-Line Exposure Time ExposureTime...

- Page 79 Test Image Pattern 1.00 TestPattern Selects the type of test image output by the camera. Beginner Image is from the camera sensor. Image is filled horizontally with an image that goes Grey Horizontal Ramp GreyHorizontalRamp from the darkest possible value to the brightest. Image is filled vertically with an image that goes from Grey Vertical Ramp GreyVerticalRamp...

-

Page 80: Binning

Binning Binning is the process where the charge on two (or more) adjacent pixels is combined. This results in increased light sensitivity since there is twice the sensor area to capture photons. The sensor spatial resolution is reduced but the improved low-light sensitivity plus lower signal-noise ratio may solve a difficult imaging situation. -

Page 81: Metadata Format

Metadata Format The Linea GigE metadata is formatted as follows: QWORD # Bits Feature Name Description 63:48 Gain - Digital All The gain-digital all as an amplification factor applied to the image. 47:40 Line Status All The current status of all available line signals in a single bitfield. -

Page 82: Acquisition And Transfer Control Category

Acquisition and Transfer Control Category The Linea GigE Acquisition and Transfer controls, as shown by CamExpert, groups parameters used to configure the optional acquisition modes of the device. These features provide the mechanism to either have acquisitions coupled to transfers (basic mode) or to decouple acquisitions from both the camera transfer module and the host transfer module. - Page 83 1.00 Number of frames to be acquired in MultiFrame acq uisition Acquisition Frame Count AcquisitionFrameCount Beginner mode. 1.00 Arms the device before an AcquisitionStart command. This Acquisition Arm Cmd AcquisitionArm Guru optional command validates all the current features for consistency and prepares the device for a fast start of the acquisition.

- Page 84 Acquisition Buffering All acquisitions are internally buffered and transferred as fast as possible to the host system. This internal buffer allows uninterrupted acquisitions no matter of any transfer delays that might occur (such as acquisition rates faster that the Gigabit Ethernet link or the IEEE Pause frame).

-

Page 85: Overview Of Transfer Control (Transfercontrolmode)

Overview of Transfer Control (TransferControlMode) Linea GigE acquisition transfers operate either in the basic coupled mode or in an independent decoupled user controlled mode, as described below. TransferControlMode = Basic The Basic Transfer Mode provides maximum compatibility with any control application running on the host computer. -

Page 86: Features That Cannot Be Changed During A Sapera Transfer

Features that cannot be changed during a Sapera transfer The following features cannot be changed during an acquisition or when a Sapera transfer is connected. Feature Group Features Locked During a Sapera Transfer CAMERA INFORMATION UserSetLoad SENSOR CONTROL I/O CONTROL COUNTER AND TIMER CONTROL ADVANCED PROCESSING CONTROL flatfieldCorrectionMode... -

Page 87: Event Control Category

Event Control Category The Linea GigE Event control, as shown by CamExpert, group parameters used to configure Camera Event related features. Event Control Feature Descriptions Display Name Feature & Values Description Device Version & View 1.00 Latch the current timestamp internal counter value in the Timestamp Latch Cmd timestampControlLatch Expert... - Page 88 Event Selector 1.00 EventSelector Select the Event to enable/disable with the Expert EventNotification feature. Start of Acquisition AcquisitionStart Event sent on control channel on acquisition start. End of Acquisition AcquisitionEnd Event sent on control channel on acquisition end. Start of Frame FrameStart Event sent on control channel on an Active Frame.

- Page 89 Event Statistic Selector eventStatisticSelector Selects which Event statistic to display. 1.00 Expert Start of Acquisition AcquisitionStart Event sent on control channel on acquisition start. DFNC End of Acquisition AcquisitionEnd Event sent on control channel on acquisition end. Event sent on control channel on an Active Frame. This Start of Frame FrameStart occurs with the start of the exposure delay.

- Page 90 1.00 Frame End Data EventFrameEndData Data of the frame end event. Guru 1.00 Represents the event ID to identify the EventFrameEnd Frame End Event ID EventFrameEnd Guru software Event. 1.00 Frame End Event EventFrameEndTimestamp Timestamp of the EventFrameEnd event. Guru Timestamp 1.00 Valid Frame Trigger Data...

- Page 91 1.00 Line4Pulse Data EventLine4PulseStartData Data of the line 4 pulse event. Guru 1.00 Represents the event ID to identify the Line 4 pulse Line4Pulse Event ID EventLine4PulseStart Guru generator Event. 1.00 Line4Pulse Event EventLine4PulseStartTimestamp Timestamp of the Line4 Pulse event. Guru Timestamp 1.00...

-

Page 92: Gige Vision Transport Layer Control Category

GigE Vision Transport Layer Control Category The Linea GigE GigE Vision Transport Layer control, as shown by CamExpert, groups parameters used to configure features related to GigE Vision specification and the Ethernet Connection. GigE Vision Transport Layer Feature Descriptions Display Name Feature &... - Page 93 1.00 Reports the current IP configuration status. IP Configuration Status GevIPConfigurationStatus Guru (RO) None None Device IP Configuration is not defined. Device IP Address Configuration is set to PersistentIP PersistentIP Persistent IP (static). Device IP Address Configuration is set to DHCP DHCP DHCP (Dynamic Host Configuration Protocol).

- Page 94 1.00 Current Camera IP Current camera IP configuration of the GevCurrentIPConfiguration Invisible Configuration selected interface. (RO) Link-Local Address Mode Dynamic Host Configuration Protocol Mode. DHCP DHCP Network requires a DHCP server. PersistentIP PersistentIP Persistent IP Mode (static) 1.00 Persistent IP address for the selected interface. Persistent IP Address GevPersistentIPAddress Invisible...

- Page 95 1.00 Indicates if LLA (Auto-IP) is supported by the LLA Supported GevSupportedIPConfigurationLLA Invisible selected interface. The LLA method automatically assigns the camera with a randomly chosen address on the 169.254.xxx.xxx subnet. After an address is chosen, the link-local process sends an ARP query with that IP onto the network to see if it is already in use.

-

Page 96: Defaults For Devicepacketresendbuffersize

1.00 Indicates the Minor version number of the XML XML Minor Version DeviceManifestXMLMinorVersion Invisible file of the selected manifest entry. (RO) 1.00 Indicates the SubMinor version number of the XML SubMinor Version DeviceManifestXMLSubMinorVersion Invisible XML file of the selected manifest entry. (RO) 1.00 Indicates the major version number of the Schema Major Version... - Page 97 • Windows shows a menu to configure options for each network profile available on that computer. • Most systems used with the Linea GigE will have a second NIC for the camera, therefore the Public profile needs to be configured. Expand the options view for Public. •...

- Page 98 The Linea GigE home page presents a short welcome message. Click on the file access button to open an ftp client session, but currently there are no files distributed in the camera. Please go to the Teledyne DALSA support web site to download the latest Sapera LT and Linea GigE firmware.

-

Page 99: Gige Vision Host Control Category

NIC, the data rate of each camera and the trigger modes used. Information on these features is found in the Teledyne DALSA Network Imaging Module User manual. -

Page 100: File Access Control Category

File Access Control Category The File Access control in CamExpert allows the user to quickly upload various data files to the connected Linea GigE. The supported data files are for Linea GigE firmware updates and Flat Field coefficients. File Access Control Feature Descriptions Display Name Feature &... - Page 101 File Open Mode 1.00 FileOpenMode Selects the access mode used to open a file on the device. Guru Read Read Select READ only open mode Write Write Select WRITE only open mode 1.00 Defines the intermediate access buffer that allows the File Access Buffer FileAccessBuffer Guru...

-

Page 102: File Access Via The Camexpert Tool

File Access via the CamExpert Tool • Click on the “Setting…” button to show the file selection menu. • From the file type drop menu, select the file type that will be uploaded to the Linea GigE. This CamExpert tool allows quick firmware changes or updates. •... -

Page 103: Device Streaming Registers

Device Streaming Registers Start – End Command Requirements Important: Every start command must have a corresponding end command. If not, the camera can be in an unpredictable state. This pertains to DeviceRegistersStreamingStart, DeviceRegistersStreamingEnd, DeviceFeaturePersistenceStart, and DeviceFeaturePersistenceEnd. 1.00 Device Registers DeviceRegistersStreamingStart Announces the start of registers streaming without Invisible Streaming Start... -

Page 104: Network Overview & Tools

NIC will get a DHCP assigned IP address for the connected device but connections on the LLA IP address will be lost. The Teledyne DALSA Network Configuration Tool can enable the Teledyne DALSA DHCP server on the NIC used for the GigE Vision network. -

Page 105: Dhcp (Dynamic Host Configuration Protocol)

The DHCP server is part of a managed network. Windows itself does not provide a DHCP server function therefore a dedicated DHCP server is required. The Teledyne DALSA Network Configuration Tool can configure the Teledyne DALSA DHCP server on the NIC used for the GigE Vision network. -

Page 106: Persistent Ip

If the Linea GigE camera is connected to a network with a different subnet, it cannot be accessed. • The Teledyne DALSA Network Configuration Tool is used to set a persistent IP address. Refer to the Teledyne DALSA Network Imaging manual. •... - Page 107 Default LLA mode Persistent IP Mode Attached cameras are automatically assigned NIC and cameras are manually assigned IP IP addresses on the NIC Subnet addresses within the same Subnet 169.254. 169.254. 169.254. xxx.xxx xxx.xxx xxx.xxx xxx.xxx.xxx.xx2 xxx.xxx.xxx.xx3 xxx.xxx.xxx.xx4 Subnet 169.254.xxx.xxx Subnet xxx.xxx.xxx.xxx Subnet mask 255.255.0.0...

-

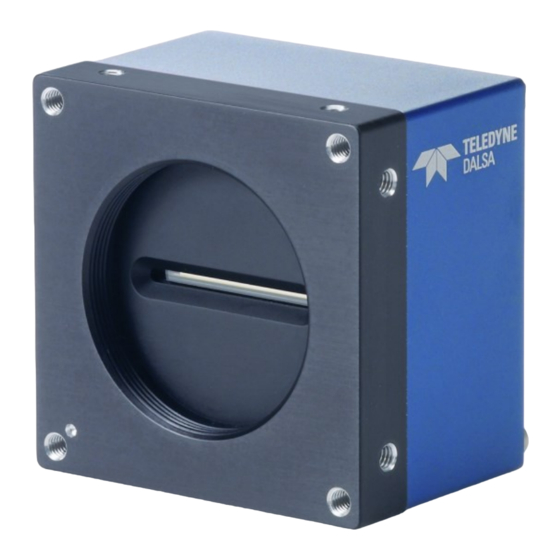

Page 108: Technical Specifications

Technical Specifications Mechanical Specifications Linea Color GigE 2k and 4k Note: Linea GigE 2k/4k with M42x1 Lens Mount 106 • Technical Specifications Linea GigE Series Camera... -

Page 109: Additional Notes On Linea Gige Identification And Mechanical

Additional Notes on Linea GigE Identification and Mechanical Identification Label Linea GigE cameras have an identification label applied to the back side, with the following information: Model Part number Serial number MAC ID 2D Barcode CE logo “Made in Canada” Statement Additional Mechanical Notes Linea GigE supports a screw lock Ethernet cable (see Ruggedized RJ45 Ethernet Cables). -

Page 110: Sensor Alignment Specification

Sensor Alignment Specification The following figure specifies sensor alignment for Linea GigE where all specifications define the absolute maximum tolerance allowed for production cameras. Dimensions "x, y, z", are in microns and referenced to the Linea GigE mechanical body or the optical focal plane (for the z-axis dimension). -

Page 111: Connectors

Camera Power – DC +12 to +24 Volts Mating GPIO Cable Assembly Teledyne DALSA optionally provides for purchase a GPIO breakout cable (HD15 Male to 26-Pos Euro Block) as shown in the following drawing. Use accessory number #AC-CA-00002-00-R when placing your order. - Page 112 110 • Technical Specifications Linea GigE Series Camera...

-

Page 113: Input Signals Electrical Specifications

Input Signals Electrical Specifications External Inputs Block Diagrams Balanced RS422 Receive Mode INPUT (+) External Receive Input Signal INPUT (-) Signal Ground PIN 5 Termination Enable Single-Ended Logic Receive Mode 3.3V, 5V, 12V, 24V INPUT (+) External Receive Input Signal INPUT (-) not connected Signal Ground... -

Page 114: External Input Overview

External Input Overview • Selectable input trigger threshold levels for RS422 (Differential), 3.3V TTL, 5V TTL, 12V, and 24V single-ended signal inputs (see lineDetectionLevel feature). Note that the selected detection level applies to all inputs. • Used as trigger acquisition event, counter or timestamp event, or integration control. •... -

Page 115: Output Signals Electrical Specifications

Output Signals Electrical Specifications External Outputs Block Diagrams Balanced RS422 Drive Mode OUTPUT (+) Output Signal External Output Signal Output Enable OUTPUT (-) PIN 5 Signal Ground Single-Ended Logic Drive Mode 3.3V TTL OUTPUT (+) Output Signal External Output Signal Output Enable OUTPUT (-) not connected... -

Page 116: External Output Details

External Output Details • Programmable output mode such as strobe, event notification, etc. (see outputLineSource feature). • User supplied Pull-up resistor value should be between 1K and 10K depending on supply rail. Resistor Wattage should be calculated accordingly. • Outputs are open on power-up with the default factory settings •... -

Page 117: Ethernet Switch Requirements

Linea GigE cameras support the IEEE 802.3x pause frame flow control protocol automatically so that images from many cameras can be transmitted through the switch to the NIC efficiently, without data loss. As a working example, one such switch tested at Teledyne DALSA is the NETGEAR GS716T. -

Page 118: Declarations Of Conformity

This equipment is intended to be a component of a larger industrial system. EU and UKCA Declaration of Conformity Teledyne DALSA declares that this product complies with applicable standards and regulations. Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment. -

Page 119: Additional Reference Information

This section provides a general overview to selecting a lens for the Linea GigE. Mechanical drawings and Teledyne DALSA part numbers for available lens adapters is provided. The first two lens parameters, Lens Mount and Lens Image Circle, are based on correctly matching the lens to the sensor. - Page 120 M42x1 to Nikon F Bayonet Adapter (AC LA 00115 A1-R ) Nikon F Bayonet to M42x1 Adapter, 12mm BFD, HEAVY DUTY w/clip 118 • Additional Reference Information Linea GigE Series Camera...

- Page 121 M42x1 to C-Mount Adapter (AC-LC-00001-00-R) M42 to C-Mount Adapter, 12mm BFD Linea GigE Series Camera Additional Reference Information • 119...

- Page 122 Lens Image Circle Illustration The graphic below illustrates the Linea GigE 2k/4k active sensor relative to the lens image circle. • The upper graphic compares the Linea GigE 4k relative to a Nikon FDX lens (using the optional F-mount adapter). •...

-

Page 123: Additional Lens Parameters (Application Specific)

Additional Lens Parameters (application specific) There are other lens parameters that are chosen to meet the needs of the vision application. These parameters are independent of the Linea GigE (assuming that the Lens Mount and Lens Sensor Size parameters are correct, as previously covered in this section). A vision system integrator or lens specialist should be consulted when choosing lenses since there is a trade-off between the best lenses and cost. -

Page 124: Optical Considerations

Factors include the nature, speed, and spectral characteristics of objects being imaged, exposure times, light source characteristics, environmental and acquisition system specifics, and more. The Teledyne DALSA Web site, http://mv.dalsa.com/, provides an introduction to this potentially complicated issue. Click on Knowledge Center and then select Application Notes and Technology Primers. -

Page 125: Lens Modeling

Lens Modeling Any lens surrounded by air can be modeled for camera purposes using three primary points: the first and second principal points and the second focal point. The primary points for a lens should be available from the lens data sheet or from the lens manufacturer. Primed quantities denote characteristics of the image side of the lens. -

Page 126: Sensor Handling Instructions

Sensor Handling Instructions This section reviews proper procedures for handling, cleaning, or storing the Linea GigE camera. Specifically the camera sensor needs to be kept clean and away from static discharge to maintain design performance. Electrostatic Discharge and the Sensor Cameras sensors containing integrated electronics are susceptible to damage from electrostatic discharge (ESD). -

Page 127: Cleaning The Sensor Window

Cleaning the Sensor Window Even with careful handling, the sensor window may need cleaning. The following steps describe various cleaning techniques to clean minor dust particles to accidental finger touches. • Use compressed air to blow off loose particles. This step alone is usually sufficient to clean the sensor window. -

Page 128: Ruggedized Rj45 Ethernet Cables

Ruggedized RJ45 Ethernet Cables Components Express Inc. has available an industrial RJ45 CAT6 cable that on one end has a molded shroud assembly with top/bottom thumbscrews, while the other end has a standard RJ45. This cable is recommended when Linea GigE is installed in a high vibration environment. CAT6 certified (tested for near end / far end crosstalk and return All cables made in loss). -

Page 129: Troubleshooting

Using Linea GigE with the Sapera API to verify required installation steps. • Refer to the Teledyne DALSA Network Imaging manual to review networking details. • The Linea GigE camera cannot acquire a DHCP. Linea GigE Series Camera Troubleshooting • 127... - Page 130 In multiple NIC systems where the NIC for the Linea GigE is using LLA mode, ensure that no other NIC is in or switches to LLA mode. It is preferable that the Teledyne DALSA DHCP server is enabled on the NIC used with the camera instead of using LLA mode, which prevents errors associated with multiple NIC ports.

-

Page 131: Verifying Network Parameters

Teledyne DALSA provides the Network Configuration tool to verify and configure network devices and the Linea GigE network parameters. See section Network Configuration Tool of the Teledyne DALSA Network Imaging manual, if there were any problems with the automatic Linea GigE software installation. -

Page 132: Installation Issues And Functional Problems

Device Available with Operational Issues This section considers issues with cabling, Ethernet switches, multiple cameras, and camera exposure. All information concerning the Teledyne DALSA Network Configuration Tool and other networking considerations is available in the Teledyne DALSA Network Imaging manual. - Page 133 Use the Log Viewer tool (see point below) to check on packet resend conditions. • Run the Sapera Log Viewer: Start•Programs•Teledyne DALSA•Sapera LT•Tools•Log Viewer. Start the camera acquisition program, such as CamExpert. There should not be any "packet resend" messages, else this indicates a control or video transmission problem due to poor connections or extremely high EMI environments.

-

Page 134: Acquisition Error Without Timeout Messages

Streaming video problems range from total loss of image data to occasional loss of random video data packets. The following section describes conditions identified by Teledyne DALSA engineering while working with GigE Vision cameras in various computers and setups. See the Teledyne DALSA Network Imaging manual for information on network optimizations. -

Page 135: Other Problems Or Issues

Other Problems or Issues This section describes problems that do not fit any of the categories above. Typically these are issues found in the field under specific or unusual conditions. Buffer Incomplete Error Message This message is generated when the logical acquisition frame buffer takes longer to fill (line rate x frame buffer height) than the time set for the GigE Vision Host Control feature “Image Timeout”. -

Page 136: Contact Information

Sales Information Visit our web site: http://www.teledynedalsa.com/en/products/imaging/ Email: mailto:info@teledynedalsa.com Canadian Sales Teledyne DALSA — Head office Teledyne DALSA — Montreal office 605 McMurray Road 880 Rue McCaffrey Waterloo, Ontario, Canada, N2V 2E9 Saint-Laurent, Quebec, Canada, H4T 2C7 Tel: 519 886 6000...