Graco Viscount I Plus Instructions-Parts List Manual

Hydraulic motor

Hide thumbs

Also See for Viscount I Plus:

- Instructions-parts list manual (30 pages) ,

- Instructions-parts list manual (24 pages)

Table of Contents

Advertisement

Quick Links

INSTRUCTIONS-PARTS LIST

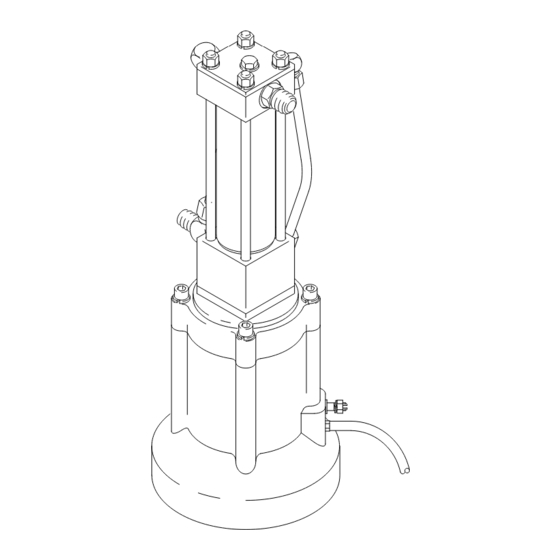

Viscount I Hydraulic Motor

1500 psi (105 bar) Maximum Hydraulic Input Pressure

Part No. 236-417, Series A

US and Foreign Patents Pending

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

Plus

COPYRIGHT 1994, GRACO INC.

2-4

5

6

7

7-13

15-17

18

18

19

19

20

20

308-330

Rev. A

Advertisement

Table of Contents

Summary of Contents for Graco Viscount I Plus

-

Page 1: Table Of Contents

Graco Phone Numbers ......GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 COPYRIGHT 1994, GRACO INC. -

Page 2: Warnings

WARNINGS High Pressure Spray Can Cause Serious Injury. For Professional Use Only. Observe All Warnings. Read and understand all instruction manuals before operating equipment. FLUID INJECTION HAZARD General Safety Diffuser (only on spray guns) The hydraulic motor and pump can generate high fluid pres- The spray gun diffuser breaks up spray and reduces the risk sure. - Page 3 Any pails used when flushing: Use only metal, grounded pails when flushing. Make firm metal-to-metal contact Always use Graco-approved Hydraulic Oil or equivalent (see Accessories). Do not substitute a lower grade oil or one with between a metal part of the gun/valve and the pail. Use the lowest possible pressure.

- Page 4 Do not use, the high pressure spray emitted from it can cause a fluid expose Graco hose to temperatures above 180 F (82 C) or injection injury or other serious bodily injury or property dam- below –40 F (–40 C).

-

Page 5: Installation

A motor mounting plate (P) is available; see Accesso- ries on page 18 to order. For detailed installation in- formation, contact your Graco distributor or Graco Technical Assistance (see back cover). Be sure that your power supply is equipped with a suc- tion filter to the hydraulic pump and a system return line filter of 10 micron size. -

Page 6: Operation

Clean or repair as dispensing. needed. 1. Engage the spray gun/dispensing valve safety Always use Graco-approved Hydraulic Oil or equiv- latch. alent (see Accessories). Do not substitute a lower 2. Close the supply line shutoff valve(s) first, then grade oil or one with a lower flash point. -

Page 7: Troubleshooting

Troubleshooting Problem Cause Solution Reciprocator stops running. Worn valve or valve balls (3); Repair valve. See page 10. broken valve spring (18). Broken trip rod (17), spring (12) or Replace parts. See page 10. retainers (11). Poor performance or reduced effi- Worn piston seals (5, 6, 7). -

Page 8: Service

Service Motor Disassembly Motor Reassembly 1. Grease the o-ring (107) and install it on the motor 1. Stand the motor upright. Remove the four screws cap (102). Install the motor cap, washers (105) (104) and washers (105) holding the motor cap and nuts (106) on the reciprocator tie rods (37). - Page 9 Service Grease. Apply thread lubricant. Beveled side faces up. 03058 Fig. 5...

- Page 10 Service Reciprocator Service 7. Inspect the valve sleeve (19), valve stop (25), and spool (S) for damage. If any of these parts re- Disassembly quires replacement, unscrew the two screws (26) NOTE: Repair Kit 236–698 is available. For the best holding the stop (25) to the spool (S).

- Page 11 Service 32 (Ref) 39(Ref) 03063 Fig. 6...

- Page 12 Service Reassembly 10. To assemble the valve mechanism, use Repair 1. Install the block packing (14*) and wiper (15*) in Tool 189–305 as follows: the housing retainer (36). The spring of the block a. Slide the yoke (4) into the repair tool, as packing and the lips of the wiper must face up .

- Page 13 Service Spring faces up. Apply primer to threads and let dry 3 to 4 minutes. Lips face up. Apply 1–2 drops of thread sealant to female threads. Apply thread sealant to female threads. Torque to 42–45 in–lb (4.7–5.1 N.m). Torque to 54–56 in–lb (6.1–6.3 N.m). Torque to 30–40 ft–lb (41–54 N.m).

- Page 14 Notes...

-

Page 15: Parts

Parts 236–417 Viscount I Motor, Series A Part No. Description 236–418 RECIPROCATOR, hydraulic See pages 16 and 17 for parts 189–079 CAP, motor 189–068 BASE, motor 112–339 SCREW, cap, socket hd; 3/8–24 unf–3a; 2.25 in. (57.2 mm) 100–133 WASHER, lock; 3/8 in. size 106–292 NUT, hex;... - Page 16 Parts 236–418 Viscount I Reciprocator, Series A 32 (Ref) 39(Ref) 03063...

- Page 17 Parts 236–418 Viscount I Reciprocator, Series A Part No. Description Part No. Description 236–594 TOP CAP ASSEMBLY 106–292 NUT, hex; 3/8–24 unf–2b 106–274 O-RING; buna-N 100–133 WASHER, lock; 3/8 in. size 100–069 BALL; carbon steel 178–181 PLATE, cap 189–077 YOKE, valve 106–470 ELBOW, 90 ;...

-

Page 18: Accessories

Accessories Use Only Genuine Graco Parts and Accessories Graco Approved Hydraulic Fluid Motor Mounting Plate Kit 236–714 Consists of: Premium, ISO grade 46 petroleum-based hydraulic oil Adapter Plate 189–206, containing rust and oxidation exhibitors and anti-wear four Screws 100–001, agents. 210 F (99 C) Flash Point. -

Page 19: Technical Data

Technical Data Maximum hydraulic fluid input pressure ..........1500 psi (105 bar) Maximum hydraulic fluid input volume . -

Page 20: Warranty

Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defec- tive. - Page 21 3X8–330 Rev. B Supersedes Rev. A Parts Change Notice Some parts in Rev. A of manual 308–330 have changed but have not yet been changed in the instruction manual. Please note the changes below and mark them in your manual or keep this sheet with your manual.