Craftsman 107.289860 Operator's Manual

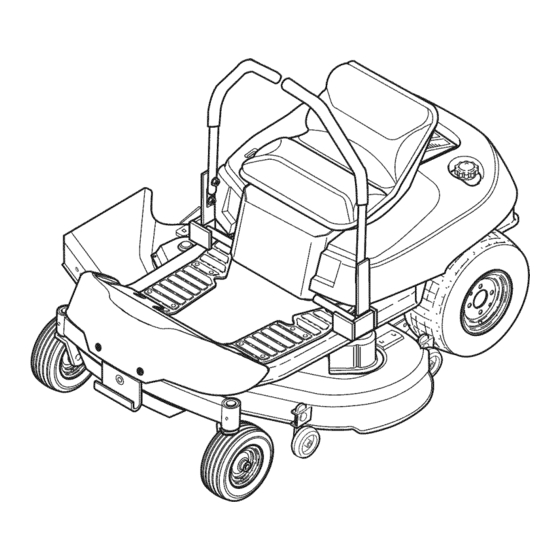

Zero-turn rear engine riders with electric start (21hp briggs & stratton engine with 42" mower)

Hide thumbs

Also See for 107.289860:

- Operator's manual (19 pages) ,

- Quick start manual (2 pages) ,

- Operator's manual (112 pages)

Table of Contents

Advertisement

Available languages

Available languages

Operator's

anual

T

°

ZTS

Zero-Turn Rear Engine Riders with Electric Start

Model No.

107.289860

(21HP Briggs

& Stratton

Engine

with 42" Mower)

CAUTION:

Before using this product,

read

the manual and follow all its Safety Rules

and Operating

Instructions,

For answers to your questions

about this

product,

call:

1-800-659-5917

Sears Craftsman

Help Line

5 am- 5 pm, Mon - Sat

Nota: Una traducci6n

en espaSol

de este Manual

del Operador

puede encontrarse

en la pagina 37.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

U.S.A.

7103147

Revision D

Rev. Date 04/2009

Advertisement

Table of Contents

Summary of Contents for Craftsman 107.289860

- Page 1 Before using this product, the manual and follow all its Safety Rules and Operating Instructions, Sears, Roebuck and Co., Hoffman Estates, IL 60179 Visit our Craftsman website: www.sears.com/craftsman ° & Stratton Engine with 42" Mower) For answers to your questions...

- Page 3 Service & Adjustments NOTE: In this manual, "left" and "right" are CRAFTSMAN FULL WARRANTY When operated and maintained according to all supplied instructions, if any non-expendable ment fails due to a defect in material or workmanship within two years from the date or purchase, call 1-800-659-5917 to arrange for free in-home repair.

-

Page 4: General Operation

Read thesesafetyrulesandfollow themclosely. F ailure t o obeytheserulescouldresult i n lossofcontrol of unit,severe personal injury or deathtoyou,orbystanders, or damage to property or equipment. This mowing deck is capable The triangle _ in text signifies important cautions or warnings which must be followed. GENERAL OPERATION 1. -

Page 5: Slope Operation

SLOPE OPERATION Slopes are a major factor related to loss-of-controland tip- over accidents, which can result in severe injury or death• Operation on all slopes requires extra caution• If you cannot back up the slope or if you feel uneasy on it, do not operate on it. - Page 6 SUGGESTED GUIDE FOR SIGHTING SLOPES FOR SAFE OPERATION ONLY RiDE UP AND DOWN NOT ACROSS HiLL 10 DEGREES MAX. WARNING: To avoid serious injury, operate your unit up and down the face of slopes, never across the face. Do not operate on slopes greater than 10 degrees.

-

Page 7: Service And Maintenance

SERVICE AND MAINTENANCE Safe Handling of Gasoline 1. Extinguish all cigarettes, cigars, pipes, and other sources of ignition. 2. Use only approved gasoline containers. 3. Never remove the gas cap or add fuel with the engine running. Allow the engine to cool before refueling. 4. -

Page 8: Safety & Operation

SAFETY & OPERATION This unit has been designed and manufactured to pro- vide you with the safety and reliability you would expect from an industry leader in outdoor power equipment manufacturing. Although reading this manual and the safety instructions it contains will provide you with the necessary basic knowledge to operate this equipment safely and effec- tively, we have placed several safety labels on the unit to remind you of this important information while you are... - Page 9 Tilt the seat forward to access the ID tag. For answers to your questions about this product, call: 1-800=659=5917 Sears Craftsman Help Line, 5 am - 5 pm, Monday=Saturday. See your local Sears retailer to purchase the following accessories:...

-

Page 10: Installing The Seat

INSTALLING THE SEAT 1. Raise the seat base (see Figure 1). 2. Align the holes in the seat bottom with the holes in the seat base. 3. Secure the seat to the seat base with two 5/16-18 x 3/4 serrated head bolts for the rear seat slots, and two 5/16-18 x 3/4 shoulder bolts for the front slots. - Page 11 INSTALLING THE SEAT SAFETY SWITCH 1. Squeeze the side clips of the safety switch (A, Figure 2), and insert the switch into the slot (B) in the seat bottom. Be sure to slide the switch fully forward. 2. Connect the harness terminal housing (C) to the seat switch.

- Page 12 SETTING UP THE GROUND SPEED CONTROL LEVERS 1. Loosen (do not remove) the hardware securing the ground speed control levers to the lever bases. 2. Raise the levers, aligning the upper hole in each lever with the upper slotted hole in the lever base. 20-23 Nm 15-17 ftqbs 3.

- Page 13 Remove the Packaging Materials Remove the cardboard from the crate. Remove any steel branding securing the unit to the crate. Locate the manual packet. Read the Operator's Locate the operator's manual in the manual packet. You should always read and follow the instructions in the operator's manual.

-

Page 14: Control Functions

Parkin Brake L ever- ENGAGE Positon CONTROL FUNCTIONS The information below briefly describes the function of individual controls. Starting, stop- ping, driving, and mowing require the combined use of several controls applied in specific sequences. To learn what combination and sequence of controls to use for various tasks please read the entire section. -

Page 15: General Operating Safety

Mower Cutting Height Switch To increase the mower cutting height (raise the mower deck), press the top of the yellow cutting height switch. To decrease mower cutting height (lower the mower deck), press the bottom of the switch. Mower cutting height range is approximately 3-3/4"... -

Page 16: Before Starting

CHECKS BEFORE STARTING • Check that the crankcase oil is filled to full mark on dipstick. • Fill the fuel tank with fresh fuel. FUEL RECOMMENDATIONS For daily operation: Use only unleaded gasoline with a pump sticker octane rating of 87 or higher. Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by volume) is approved as a fuel. -

Page 17: Emergency Stopping

EMERGENCY STOPPING In the event of an emergency the engine can be stopped by simply turning the ignition switch to STOP. Use this method only in emergency situations. shut down follow the procedure given in STOPPING THE RIDER AND ENGINE. STOPPING THE RIDER &... - Page 18 DRIVING PRACTICE BASIC DRIVING WARNING: Never operate on slopes greater than 17.6% (10°). See SLOPE OPERATION in the safety section. Zero turn riders operate differently from other four- wheeled vehicles. The drive wheels are also your steer- ing wheels. If you cannot drive the unit on a hill, you will not be able to steer the unit on it.

- Page 19 Practice Turning Around a Corner While traveling forward allow one handle to gradually return back toward neutral (see Figure 10). Practice sev- eral times before mowing. NOTE: To prevent damaging your lawn by pivoting direct- ly on the tire tread, it is best to keep both wheels going at least slightly forward.

-

Page 20: Mower Deck Removal & Installation

MOWER DECK REMOVAL & INSTALLATION NOTE: Perform mower removal and installation on a hard, level surface such as a concrete floor. WARNING After lowering the mower cutting height, engage parking brake, turn off the mower blades, turn the ignition switch to STOP, and remove key before attempting to install or remove the mower. -

Page 21: Maintenance

MAINTENANCE SCHEDULE The following schedules should be followed for normal care of your rider and mower. RIDER MAINTENANCE, All Models Clean Debris from Rider and Engine Compartment * Clean Debris from Engine Cooling Areas & Air Filter * Check Tire Pressure Lubricate Rider &... -

Page 22: Rider Maintenance

Rider Maintenance WARNING Move the ground speed levers to START/PARK positions, engage the parking brake, turn the mower blades OFF, turn the ignition switch OFF, and wait for all moving parts to stop before accessing the engine compartment or performing any maintenance procedures. ACCESSING THE ENGINE COMPARTMENT... - Page 23 LUBRICATION Service Interval: 25 hours. Lubricate the unit at the locations shown in Figures 18 through 22 as well as the following lubrication points. Grease: • front wheel bushings • mower arbors • front wheel grease fittings Use grease fittings when present. Not all greases are compatible.

-

Page 24: Mower Blades

CLEAN DECK & CHECK/REPLACE MOWER BLADES Service Interval: 25 hours or as required. WARNING For your personal safety, do not handle the sharp mower blades with bare hands. Careless or improper handling of blades may result in serious injury. WARNING For your personal safety, blade mounting capscrews must each be installed with two spring washers or a hex washer and spring washer, then... -

Page 25: Cleaning The Battery And Cables

CLEANING THE BATTERY AND CABLES WARNING Corrosion hazard. Batteries contain acid. Always keep the battery upright and do not spill the electrolyte. Avoid contact with skin and eyes. Explosion hazard. Changing the battery produces explosive hydrogen gas. Only charge the battery in a well ventilated area, away from any ignition source such as a water heater, electric motor, or a lit cigarette. -

Page 26: Check / Adjust

CHECK / ADJUST PTO CLUTCH WARNING To avoid serious injury, perform adjustments only with engine stopped, key removed and tractor on level ground. Service Interval: 200 Hours. The Power Take Off (PTO) clutch drives the mower blades. The PTO clutch is engaged and disengaged by the mower blade switch. -

Page 27: Engine Maintenance

Engine Maintenance CHECK ENGINE OIL LEVEL Service Interval: Before each use, and every 8 hours. 1. Turn the engine off, and set the parking brake lever to ENGAGE. 2. Clean the area around the dip stick (C, Figure 30). 3. Remove the dip stick (C) and clean it with a paper towel. -

Page 28: Air Filter Removal & Installation

AIR FILTER & PRE-CLEANER Service Interval: Pre-Cleaner: Every 25 hours or as required. Air Filter: Every 50 hours or as required. Replacement Interval: Pre-Cleaner: As required. Air Filter: Every 200 hours or once per season. Air Filter Removal & Installation 1. -

Page 29: Replace Spark Plug

REPLACE SPARK PLUG Service Interval: Yearly Replacement Spark Plug: 491055S Spark Plug Gap: .030" (.76 mm) 1. Stop the engine and allow it to cool. 2. Clean the area around the spark plug. 3. Remove the spark plug. 4. Check the spark plug gap. It should be .030" (see Figure 34). - Page 30 GROUND SPEED CONTROL ADJUSTMENT The control levers have three adjustments: To Adjust Control Lever Height: Pull the levers in across the operator's lap to their DRIVE positions. Loosen the mount bolts (D, Figure 34) and raise or lower the levers to the desired position. Tighten the mounting bolts.

-

Page 31: Brake Adjustment

BRAKE ADJUSTMENT 1. Stop the unit, set the ground speed levers to START/PARK positions, set the parking brake lever to the ENGAGE position, turn the ignition OFF, and wait for all moving parts to stop. Remove the key. 2. Set both transmission release levers to the PUSH position. -

Page 32: Mower Deck Leveling Adjustments

MOWER DECK LEVELING ADJUSTMENTS WARNING Before adjusting the mower, turn the mower blades OFF, turn the ignition switch OFF, remove the key, and allow all moving parts to stop. Disconnect the spark plug wire and fasten it away from the spark plug. Side to Side Leveling If the cut is uneven, the mower may need leveling. -

Page 33: Front To Back Leveling

Figure 40. Orient Blades Front-to-Back Front To Back Leveling If the cut is uneven, the mower may need leveling. Unequal or improper tire pressure may also cause an uneven cut. See CHECK TIRE PRESSURE. 1. Turn the blades front-to-back as shown in Figure 40. Measure the distance from the ground to front tip of center blade, and from ground to rear tips of left hand and right hand blades (see Figure 40). - Page 34 STORAGE Before Storage Before you store your unit for the off-season, read the Maintenance and Storage instructions in the Safety Rules section, then perform the following steps: • Turn the mower blades OFF, set the ground speed control levers to START / PARK, set the parking brake lever to ENGAGE, and remove the key from the igni- tion switch.

-

Page 35: Troubleshooting

Whilenormal c areandregular m aintenance willextend thelifeofyourequipment, prolonged o r constant u se mayeventually r equire thatservice beperformed t oallow ittocontinue operating p roperly. T hetroubleshooting guidebelowliststhe mostcommon problems, theircaus- esandremedies. If youprefer, alloftheseprocedures canbeperformed foryoubya SearsParts& Repair C enter. Seetheback coverforimportant SearsParts&Repair C enter i nforma- tion. - Page 36 Engineruns,but Transmission release levers in PUSH Move levers to DRIVE positions. rider will not 9ositions. drive. Drive belt slips, Belt is broken, Parking brake is not fully released, Rider drive belt Pulleys or belt greasy or oily, slips. Belt stretched or worn. Parking brake Parking brake is incorrectly adjusted, will not hold.

- Page 37 & Stratton Engine con segadora Para obtener sobre este producto, difer- fono-(sin Antes que 1-800-659-5917 Servicio 5 am- 5 pm, Lunes a Sabado de 42") respuestas a cualquier flame al num6ro de tel6- cobro) siguiente: de ayuda Sears Craftsman pregunta...

- Page 39 Declaracibn de Garantia ... Reglas e Informacibn de Seguridad ... 40 Ndmeros de Identificacibn ... Montaje ... Pre-Operacibn ... Operacibn ... Mantenimiento EeServicio y Ajustes ... Almacenamiento ... NOTA: En este manual, "izquierda" y "derecha" se refieren seg#n come se vea desde la posicidn de operacidn. GARANT|A COMPLETA DE FABRICACION Cuando se opera y mantiene de acuerdo con todas las instrucciones que se proporcionan, si alguna pieza no ampliable de este equipo falla debido a un defecto en los materiales o en la fabricaci6n dentro de dos a_os desde la fecha de...

-

Page 40: Transporte Y Almacenamiento

Leaestasreglas deseguridad y sigalas concuidado. Noobedecer e stasreglas puedeocasionar la perdida delcontrol s obrela unidad, l esiones severas a lapersona o la muerte de usted, o espectadores, o daSos a la o alequipo. Esta cubierta objetos. El tri&ngulo_, en el texto denota precauciones o advertencias importantes que deben obedecerse. OPERACION GENERAL 1. -

Page 41: Sistema De Encendido

OPERACION EN CUESTAS Las cuestas son un factor importante relacionado con los acci- dentes por p@dida de control y volcaduras, y pueden propiciar lesiones severas o la muerte. Cualquier operaci6n en cuestas exige precauciones extremas. Si usted no puede dar marcha atras en una cuesta o se siente inquieto en ella, no opere en ella. - Page 42 GUJA SUGERIDA PARA EL AVISTAMIENTO UNA OPERACION SEGURA DEL MONTABLE CON ACCESORIO DOBLAR A LO LARGo DE LA IENTE "D 10 CONDUZCA SOLO HACIA ARRIBAY HACIA ABAJO POR LA PENDIENTE NUNCA DE UN LADO A OTRO 10 GRADOS MAXIMO ADVERTENCIA: Para evitar lesiones graves, opere la unidad hacia arriba y hacia abjo por la pendiente, nunca de un lado a otro.

-

Page 43: Servicio Y Mantenimiento

SERVICIO Y MANTENIMIENTO Manejo Seguro de la Gasolina 1. Apague cigarros, puros, pipas y otras fuentes de ignici6n. 2. Use s61o los contenedores aprobados para gasolina. 3. Nunca quite el tap6n de la gasolina ni cargue combustible con el motor encendido. Permita que el motor se enfrie antes de poner combustible. - Page 44 CALCOMANiAS DE SEGURIDAD Y OPERAClON Esta unidad fue dise_ada y fabricada para ofrecerle la seguridad y confiabilidad que usted esperarfa de un Ifder en la industria de la fabricaci6n de equipos motorizados para el exterior. Aunque leer este manual y las medidas de seguridad que con- tiene le proporcionar_t el conocimiento b_tsico necesario para operar este equipo sin percances y eficazmente, hemos coloca- do varias etiquetas de seguridad en la unidad para recordarle...

- Page 45 Incline la tapa del asiento hacia adelante para ganar acceso a la chapa de identificaci6n. Para obtener respuestas a sus preguntas sobre el pro- ducto, Ilame al: 1=800-659=5917 Servicio Telef6nico de Asistencia de Sears Craftsman, 5 am- 5 pm, Lunes- Sabado. , Recolector de Hierba...

- Page 46 INSTALACION DEL ASIENTO 1. Levante la base del asiento (vea la Figura 1). 2. Alinee los orificios en la parte de abajo del asiento con los orificios en la base del asiento. 3. Sujete el asiento a la base del asiento con dos tuer- cas de cabeza dentada de 5/16-18 x 3_ para los orifi- cios traseros del asiento, y dos tuercas con traba punta de caSonera para las ranuras delanteras.

- Page 47 INSTALACION DEL INTERRUPTER SEGURIDAD DEL ASIENTO 1. Apriete los ganchos laterales del interruptor de seguridad (A, Figura 2), e inserte el interruptor en la ranura (B) en la parte baja del asiento. Asegt3rese de deslizar el interruptor completamente 2. Connecte la caja del terminal de cableado (C) al interruptor del asiento.

- Page 48 MONTAJE DE LAS PALANCAS CONTROL DE VELOCIDAD DESPLAZAMIENTO 1. Aflojo (no retire) los herrajes que sujetan a las palan- cas de control de velocidad de desplazamiento bases (vea la Figura 3). 2. Levante las palancas, alineando el orificio superior en cada palanca con el orificio rasurado superior en la base de palanca.

- Page 49 Retirar los Materiales de Empaque Quite el cart6n del caj6n de embalaje. Quite el encintado de acero que sujeta la unidad al caj6n de embalaje. Ubique el paquete del manual. Leer el Manual Ubique el manual del operador en el paquete del manual.

- Page 50 Palancas deVelocidad Palancas deVelocidad P0_ici6. de DRIVE P0eici6. de PARK FU.C,O. S CO.T.O. La informaci6n abajo describe brevemente la fun- ci6n de los controles individuales. Arrancar, detenerse, conducir y podar el cesped requiere del use combinado de varies controles aplicados en secuencias especfficas.

-

Page 51: Interruptor De Encendido

Ajuste de Altura de Corte de la Sesgadora Para aumentar la altura de corte de la sesgadora (elevar la cubierta de la sesgadora), oprima la parte superior del ajuste de altura de corte amarillo de la sesgadora. Para disminuir la altura de corte de la sesgadora (bajar la cubierta de la sesgadora), optima la parte inferior del ajuste. -

Page 52: Antes De Arrancar

VERIFICACIONES ANTES DE ARRANCAR • Verifique que el aceite del c_trter est_ en la marca de Ileno de la varilla de nivel de aceite. • Llene el tanque de gasolina con combustible fresco. RECOMENDACIONES DE COMBUSTIBLE Para operaci6n diaria: Use s61o gasolina sin plomo donde la calcomanfa de la bomba indique un octanaje de 87 o mayor. -

Page 53: Paro De Emergencia

PARO DE EMERGENCIA En caso de emergencia, el motor puede detenerse simple- mente girando el interruptor de encendido a STOP (paro). Use este m6todo s61o en situaciones de emergencia. Para apagar el motor normalmente, siga el procedimiento DETENER EL MONTABLE Y EL MOTOR. DETENER EL MONTABLE Y EL MOTOR... - Page 54 PRACTICA DE MANEJO - MANEJO BASICO ADVERTENCIA: Nunca opere en cuestas mayoras a 17.6% (10°). Vea OPERACION EN CUESTAS en la secci6n de seguridad. Los tractores de giro cero operan de modo difer- ente a otros vehiculos de cuatro ruedas. Las ruedas de trac- ci6n tambi_n son sus ruedas de direcci6n.

-

Page 55: Manejoa Vanzado

Practica de dar Vuelta en una Esquina Mientras viaja hacia adelante permita que una palanca regrese gradualmente en direcci6n del neutral (vea la Figura 10). Practique varias veces antes de podar el cesped. NOTA: Para evitar girar directamente sobre la banda de rodamiento, es mejor mantener las dos ruedas en mar- cha hacia adelante aunque sea ligeramente. -

Page 56: Retirar La Cubierta

REMOCION E INSTALACION CUBIERTA DE LA SESGADORA NOTA: Ejecute la remocidn e instalacidn de la sesgadora sobre una superficie dura y nivelada como un piso de concreto, ADVERTENCIA Despuds de bajar la altura de corte de la sesgadora, accione el freno de mano, desactive las cuchillas de la sesgadora, gire el interruptor de encendido a STOP y quite la Ilave antes de intentar instalar o retirar la sesgadora. -

Page 57: Mantenimiento

PROGRAMA DE MANTENIMIENTO El siguiente programa debe seguirse para el cuidado normal de su tractor y podadora. MANTENIMIENTO DEL MONTABLE, de toclos los moclelos Limpie el residuo del montable y del compartimiento del motor * Limpie el residuo de las areas de refrigeraci6n del motor y del filtro de aire * Verifique la presi6n de las Ilantas Lubrique el montable y la segadora... - Page 58 Elementos de Mantenimiento del Tractor A ADVERTENCIA Mueva las palancas de velocidad de desplazamiento a las posiciones ARRANCAR/ESTACIONAR, engrane el freno de estacionamiento, APAGUE las cuchillas del cortacdsped, APAGUE el interruptor de ignici6n, y espere que todas las piezas m6viles se detengan antes de acceder al compartimiento realizar cualquier procedimiento mantenimiento.

- Page 59 LUBRICACION Intervalo de Servicio: 25 horas. Lubrique la unidad en los lugares mostrados en las Figuras 18 a 22 asi como en los siguientes puntos de lubricaci6n. Grasa: • engrasadores de la rueda delantera • bujes de la rueda delantera •...

- Page 60 LIMPIAR CUBIERTA Y VERIFICAR/ REEMPLAZAR ASPAS DE PODADORA Intervalo de Servicio: 25 horas o segQn se requiera. ADVERTENCIA Para su seguridad personal, no maneje las aspas afiladas de la podadora con las manos descubiertas. El manejo imprudente o indebido de las aspas puede resultar en lesiones graves. ADVERTENCIA Para su seguridad personal, los tornillos de cabeza hexagonal para montar las aspas deben...

- Page 61 LIMPIAR BATERJA Y CABLES ADVERTENCIA Peligro de corrosi6n. Las baterias contienen dcido. Conserve la bateria siempre de pie y no derrame el electrolito. Evite el contacto con la piel y los ojos. Peligro de explosi6n. Cuando quite o instale los cables de la bateria, desconecte PRIMERO el cable negativo y condctelo al FINAL.

- Page 62 VERIFICAR/AJUSTAR EMBRAGUE DEL PTO ADVERTENCIA Para evitar lesiones graves, s61o haga los ajustes con el motor detenido, la Ilave quitada y el tractor en terreno nivelado. Intervalo de Servicio: 200 horas. El embrague del PTO se embraga y desembraga con el interruptor PTO.

- Page 63 ELEMENTOS DE MANTEN- IMIENTO DEL MOTOR VERIFIQUE EL NIVEL DE ACEITE MOTOR Intervalo de servicio: Antes de cada uso, y cada 8 horas. 1. Apague el motor, y coloque el freno de parada en la posi- ci6n de PARK (parado). Limpie el Area alrededor de la varilla para medici6n del nivel (C, Figura 30).

- Page 64 SERVICIO DEL FILTRO DE AIREY PURIFICADOR Intervalo de servicio: Prepurificador: cada 25 horas o conforme sea necesario. Filtro de aire: cada 50 horas o conforme sea necesario. Intervalo de reemplazo: Prepurificador: conforme sea necesario. Filtro de aire: cada 200 horas o una vez por estaci6n.

- Page 65 REEMPLACE LA BUJJA DE ENCENDIDO Intervalo de servicio: Anualmente Bujia de encendido de reposici6n: 491055S Separaci6n de la bujia de encendido: .76 mm (030"). 1. Pare el motor y espere a que se enfr_e. 2. Limpie el Area alrededor de la bujfa de encendido. 3.

-

Page 66: Ajuste De La Altura De Corte

AJUSTE DE PALANCA DE CONTROL DE VELOCIDAD Las palancas de control tienen tres ajustes: Para Ajustar la Altura de las Palancas de Control: Jale las palancas hacia adentro, encima del regazo del operador a la posici6n de DRIVE. Afloje los pernos de montaje (D, Figura 34) y suba o baje las palancas a la posici6n deseada. - Page 67 AJUSTE DE LOS FRENOS 1. Detenga la unidad, coloque las palancas de veloci- dad de desplazamiento en las posiciones START/PARK (ARRANCAR/ESTACIONAR), la palanca del freno de estacionamiento ci6n ENGAGE (ENGRANAR), apague la ignici6n (OFF), y espere que todas las piezas m6viles se detengan.

- Page 68 AJUSTE DE NIVEL DE LA CUBIERTA DE LA PODADORA ADVERTENCIA Antes de verificar la podadora, apague el PTO y el motor. Permita que se detengan todas las partes en movimiento. Quite la Ilave del encendido, desconecte el cable de la bujia y suj_telo lejos de la bujia.

- Page 69 Figura 40. Orientar las Aspas de Adelante hacia Atr_s Nivelado de Adelante hacia Atras Si el corte es desparejo, es posible que la cortadora de cesped necesite set nivelada. La presiSn de neum&ticos desigual o incorrecto tambien puede causar un corte desparejo.

- Page 70 ALMACENAMIENTO Antes de almacenar su unidad en la temporada baja, lea las instrucciones de Mantenimiento y Almacenamiento ci6n de Reglas de Seguridad, luego realice los siguientes pasos: • Desacople el PTO, ponga el freno de mano y quite la Ilave. •...

- Page 71 ADVERTENCIA Para evitar lesiones graves, realice el mantenimiento podadora solo con el motor apagado y el freno de mano en PARK. Siempre quite la Ilave del encendido, desconecte el cable de la bujia y suj_telo lejos de la bujia antes de empezar con el mantenimiento, para evitar que el motor arranque accidentalmente.

- Page 72 El motoropera Laspalancas d edesembrague dela peroel tractor transmisi6n e nposici6n deEMPUJAR. no avanza. La banda de tracci6n se barre. La banda esta rota. Freno de mano no esta desaccionado. Banda de trac= Poleas o la banda con grasa o aceite. ci6n se barre.

-

Page 73: Repair Parts

RepairParts PTS - 1... -

Page 74: Frame, Body & Seat Group

64 =14 1 38 Torque Ref. No, 11 48 47 to 150 Ft. Lbs, or 204 Nm. PTS - 2 ZTS 6000 - 107.289860 >; To be assembled between Ref. Nos. 33 & 57... - Page 75 SCREEN, Seat Deck 1673320SM RIVET, Pop 1733227ASM FRAME ASSEMBLY 1733965ASM SUPPORT, Seat 7102654YP SEAT DECK, Plastic Sears Craftsman Red ZTS 7301055BMYP PLATE, Control 1960715SM SCREW, Truss Head Torx, 1/4-20 x 3/4 7091591SM SCREW, Hex Whiz Lock Flange, 5/16-18 x 3/4 1728986SM PAD, Footrest R.H.

- Page 76 64 =14 1 38 Torque Ref. No, 11 48 47 to 150 Ft. Lbs, or 204 Nm. PTS - 4 ZTS 6000 - 107.289860 >; To be assembled between Ref. Nos. 33 & 57...

- Page 77 1960534SM WASHER, 3/8 7070814SM TRIM, 8" 1921880SM WASHER, External Tooth, 1/4 1734392ASM GUARD, Debris Footnotes 5/16, 18 x 1-1/2 External Tooth, 3/8 Hex Head, 5/16-18 x 1-1/4, G5 3/8 - 16 x 1-1/4 PTS - 5 ZTS 6000 - 107.289860...

- Page 78 ® 257i Torque screw to 45-55 Ft. Lbs or 61.2-74.8 Nm. PTS - 6 ZTS 6000- 107.289860 Tie to hold both throttle & clutch "_bles to seat support, Tighten Ref, No. 19 external thread into the internal thread,...

- Page 79 .34 LG, Powdered Metal Hex Head, 5/16-18 x 1-1/4, G5 Hex Head, 5/16-18 x 1-1/2, G5 Engine Spring, .438 Hex Head, 7/16-20 x 2-3/4, G5 x .06 THK Hex Head, 5/16-18 x 3/4, G5 PTS - 7 ZTS 6000 - 107.289860...

- Page 80 Transmission Group ZTS 6000 - 107.289860 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. PTS - 8...

- Page 81 Center Hydro Gear EZT L.H. Hydro Gear EZT R.H. Rear 3/8-16 x 2-1/2 Hex Head, GR5 Drive, 54.4 x .12 THK Hex Head, 3/8-16 x 1, G5 Hex Head, 3/8-16 x 2, G5 PTS - 9 ZTS 6000 - 107.289860...

- Page 82 Transmission Group ZTS 6000 - 107.289860 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. PTS - 10...

- Page 83 SPRING, Extension (Used only on Hydro Gear P/N ZC-AHBB-2ADB-1DPX 2ADC-1 DPX) Footnotes Transmission KIT (Includes Ref. Nos. 52 & 53) (Included in Ref. No. 51) (Included in Ref. No. 51) Parking Brake PTS - 11 ZTS 6000 - 107.289860 and ZC-DHBB- and ZC-DHBB-...

- Page 84 Ref: Front Panel * Note: Handlebars out (locked) brake spring to 3" length. 12 Ibs. inward force measured Brake arm to be'--. of foam grips fully nested gear teeth )_12 compress PTS - 12 ZTS 6000 - 107.289860 Parking Brake Switch...

- Page 85 SCREW, 5/16-18 x 1-1/4" Hex Head Cap, GR5, Black 1715025SM BUSHING 1919438SM NUT, 5/16-18 Hex Lock Esna Light 1727603ASM WELDMENT, 1921221SM SCREW, 5/16-18 x 1-1/2" Hex Head Cap, GR5, Black Footnotes Spring 5/16", Black Hex Nyloc BOLT, 5/16-18 Extension Pivot Control PTS - 13 ZTS 6000 - 107.289860...

- Page 86 Ref: Front Panel * Note: Handlebars out (locked) brake spring to 3" length. 12 Ibs. inward force measured Brake arm to be'--. of foam grips fully nested gear teeth )_12 compress PTS - 14 ZTS 6000 - 107.289860 Parking Brake Switch...

- Page 87 Controls Group DESCRIPTION REF NO PART NO. QTY. 1727918SM SHOCK ABSORBER 1703805SM RING, Klipring Extension (for .500 Dia. Shaft) 1725927SM SHAFT, Cross Footnotes PTS - 15 ZTS 6000 - 107.289860...

- Page 88 Tie switchto cable 11 connector body x\\_/ Clip harnessto seatpan. Tie Harness to throttle cable Electric Clutch PTS - 16 ZTS 6000 - 107.289860 To Engine " Block To StarterBolt on Engine _ Tie cables \-._. _ _, loStrop 10 Headligl{t (Optional)

-

Page 89: Electrical Group

Ignition, 5/8-32 6 Pin Indak (Includes Ref. Nos. 20, 21,26, Internal Tooth, 5/8 Thin Hex Head, 1/4-20 x 3/4, G5 Spring, 1/4 External Tooth, 3/8 x .06 THK Hex Head, 5/16-18 x 2, G5 PTS - 17 ZTS 6000 - 107.289860 & 37) -

Page 90: Lift Group

Position for 44" Mower Adjust Ref. No. 12 Add Loctite #271 with thread going to item Ref. No. 21 through Iocknuts _> PTS - 18 ZTS 6000 - 107.289860 _¢.. /" /" Adjust Ref. No. 12 with thread going through Iocknuts... - Page 91 CARRIAGE BOLT, 5/16-18 x 1, G5 1668344SM PIN, Shear 1733533ASM BRACKET, Electric Motor Mount 1916950SM NUT, Hex, 3/8-16 1924940SM WASHER, 3/8 1918213SM NUT, Hex 7/16-14 1930645SM NUT, Hex Flange Two-Way Lock, 3/8-16 Footnotes Powdered Metal Height of Cut PTS - 19 ZTS 6000 - 107.289860...

-

Page 92: Wheel & Tire Group

Wheel & Tire Group NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Torque Ref. No. 8 to 45-50 ft. Ibs. or 61.2-68 Nm. ! t l/k<.<.<. >¢_'J' J .i i PTS - 20 ZTS 6000 - 107.289860... -

Page 93: Wheel & Tire Assembly

TUBE, Caster Wheel Spacer 1734013SM WHEEL & TIRE ASSEMBLY, 7090839SM NUT, Hex Center Lock 2812808SM FITTING, Lube 2172353SM VALVE STEM & CAP 2177725SM NUT, Hex Lug, 7/16-20 Footnotes 18 x 8-1/2-8 Hex Head 11 x 4-5 PTS - 21 ZTS 6000 - 107.289860... -

Page 94: Decals Group

Decals Group ZTS 6000 - 107.289860 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. REAR VIEW ,L..._ PTS - 22... - Page 95 DECAL Height of Cut 1734140SM DECAL Belt & Blade 1734270SM DECAL Handle Control L.H. ZTS 6000 7103067YP DECAL Seat Deck L.H. Craftsman ZTS 7103068YP DECAL Seat Deck R.H. Craftsman ZTS 7102576YP DECAL Handle Control R.H. ZTS 7500 1726631SM DECAL Do Not Remove Foam Around Engine...

- Page 96 42" Mower Deck - Clutch & Support NOTE: Unless noted otherwise, use the standard hardware torque specification chart. BACKSIDE IDLER PULLEY ARBOR DRIVE PULLEY Group Clutch BACKSIDEIDLER PULLEY PTS - 24 ZTS 6000- 107.289860 1"_...

- Page 97 BRACE, Mower Support 1733575ASM SUPPORT, Mower Rear L.H. 1731403ASM SUPPORT, Gauge Wheel L.H. Rear 1732966SM V-BELT, A-Wedge 1734048SM V-BELT, A-Wedge (Used on Export Models) Footnotes Group x 1/4 THK Hex Head, 3/8-16 x 2-1/4, G5 PTS - 25 ZTS 6000 - 107.289860...

- Page 98 42" Mower Deck - Housing NOTE: Unless noted otherwise, use the standard hardware torque specification chart. TORQUE TO 80-90 FT/LBS 108.8 - 122.4 Nm & Arbor Group PTS - 26 ZTS 6000 - 107.289860 TORQUE TO 65-75 FT/LBS or 88.4-102 Nm LUBE FITTING...

-

Page 99: Deflector Assembly

2108202SM BEARING, Spindle 1731372BMYP TUBE & PLATE ASSEMBLY, Spindle 1704314SM LUBE, Fitting, 1/4 7072537SM SHAFT, Spindle 1730100BNYP HOUSING, 42" Sears Craftsman Red 1731917SM WASHER, Spindle Blade, Powdered Metal 1731898ASM BLADE, Mower 42" 7024467SM WASHER, Belleville 7091633SM NUT, Hex, 9/16 721083BMYP... - Page 100 ZTS 6000 - 107.289860 718_ 48 SHORT BLOCK ] 1058 OPERATOR'S [ 1329 REPLACEMENT ] 1330 REPAIR MANUAL Liquid Sealant and Breather Gasket can be used Interchangeably. Engine Briggs Ref. No. Part No. Qty. 794128 399265 391086s 697109 794683 795446...

- Page 101 331877-0144-B1 1022 914 _ 1026 63t_', Assemblies Liquid Sealant and Rocker Cover Gasket can be used interchangeably. Cylinder Engine Briggs & Stratton Ref. No. Part No. Qty. 796005 Head-Cylinder 794114 Gasket-Cylinder Head 793988 Screw (Cylinder Head) 792868 Valve-Exhaust 791935 Valve-Intake 691279 Spring-Valve (Intake)

- Page 102 ZTS 8000- 107.289860 Crankshaft, Piston/Ring Engine Briggs Ref. No. Part No. Qty. 793410 222698s 794124 794125 794126 794127 698469 794143 794571 791118 Valve Gasket Set-Reference Engine Gasket Set-Reference 12/09/2008 1044 Assemblies include all parts shown in frames. and Counterweight & Stratton...

- Page 103 331877-0144-B1 15 _i_ Assemblies Engine Sump, Intake Manifold and Camshaft Engine Briggs & Stratton Ref. No. Part No. Qty. 795993 Sump-Engine 69711O Gasket-Crankcase 690946 Plug-Oil Drain 795387 Seal-Oil (PTO Side) 692125 Screw (Crankcase Cover/Sump) 691968 Governor/Oil Slinger 690564 Tappet-Valve 793880 Camshaft 690193 Manifold-Intake...

- Page 104 zrs8000- lo7.28986o Dipstick/Tube Engine Briggs & Stratton Ref. No. Part No. Qty. 691031 791805 691035 694476 385A 690297 697090 387A 808656 Valve Gasket Set-Reference Engine Gasket Set-Reference 12/09/2008 177 ( Assemblies include all parts shown in frames. and Fuel Pump Assembly Model 331877-0144-B1 Description Ref.

- Page 105 331877"-0144-B1 13o_?)it 95 _ 987 (_) 1266 '4_/" Assemblies Engine Briggs & Stratton Ref. No. Part No. Qty. 692137 Gasket-intake 690227 Stud (Carburetor) 793610 Kit-idle Mixture 690718 Screw (Throttle Valve) 695408 Kit-idle Speed 694918 Pin-Float 696136 Valve-Float 695419 Valve-Choke 791501 Jet-Main (Standard) 843099...

- Page 106 zrs_ooo- lo7.28986o _Jf_ Assemblies Governor, Engine Briggs & Stratton Ref. No. Part No. Qty. 691693 691841 796260 691840 694042 691374 691842 691024 794904 795315 691061 697089 696457 794360 Gasket Set-Reference 1095 Engine Gasket Set-Reference 12/09/2008 334 !_ include all parts shown in frames. Ignition and Alternator Model 331877-0144-B1...

- Page 107 796084 1036 1040 698368 1044 698139 1051 691265 1265 794151 1279 691108 • Carburetor Overhaul Kit-Reference PTS-35 ZTS 6000-107.289860 LABEL 1005 1051 Qty. Description Gear-Pinion Filter-Pre Cleaner Cover-Air Cleaner Fan-Flywheel Label-Emissions (Available from a Briggs & Stratton Authorized Dealer) Panel-Trim...

- Page 108 zrs8000- lo7.28986o Assemblies Engine Briggs & Stratton Ref. No. Part No. Qty. 693551 690323 691532 693699 692024 692034 690372 691224 693713 691283 Valve Gasket Set-Reference Engine Gasket Set-Reference 12/09/2008 801/,:_ 1051 _'/'_ include all parts shown in frames. Starter Motor Assembly Model 331877-0144-B1 Ref.

- Page 109 331 877-01 44-B1 Liquid Sealant is Interchangeable Assemblies Engine Gasket Engine Briggs Ref. No. Part No. Qty. 391086s Seal-Oil (Magneto Side) 794114 Gasket-Cylinder Head 697109 Gasket-Breather 697110 Gasket-Crankcase 791892 Seal-Oil (PTO Side) 692137 Gasket-Intake 691031 SeaI-O Ring (Dipstick) 796187 Gasket Set-Engine 691032 Seal-Dipstick 692138...

- Page 110 zrs8000- lo7.28986o 127 _) Assemblies Carburetor Engine Briggs Ref. No. Part No. Qty. 692137 694918 696136 796184 690727 698781 695410 692138 Valve Gasket Set-Reference Engine Gasket Set-Reference 12/09/2008 121 CARBURETOR OVERHAUL 276 F_bb \c:,/ 987 _:_ include all parts shown in frames. Overhaul &...

-

Page 111: Hardware Identification& Torquespecifications

Hardware identification& TorqueSpecifications Common Hardware Types Hex Head Capscrew Carriage Belt €((((((((((((((((((( _Hex Standard Hardware Sizing When a washer or nut is identified as 1/2", Nominal size, meaning the inside diameter second number is present it represent the threads When bolt or capscrew is identified as 1/2 - 16 x 2", this... - Page 112 PTS-40...

- Page 113 PTS- 41...

- Page 114 PTS- 42...

- Page 115 U.S.A. call 1-800-4-1VlY-HOIVlE® Acuerdo Feficidades por su compra inteligente. Su nuevo producto de Craftsman® fue disefiado y fabricado para afios de operaci6n confiable. Pero como todos los productos, es posible que cada cierto tiempo requiera de reparaciones.

- Page 116 For expert troubleshooting and home solutions advice: For repair - in your home - of all major brand appliances, lawn and garden no matter For the replacement parts, accessories owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters.