Table of Contents

Advertisement

Quick Links

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Series PMH

Indoor unit

[Model names]

PMH-P1BA

PMH-P1.6BA

PMH-P2BA

INDOOR UNIT

FILTER

CHECK MODE

TEST RUN

PMH- P1,1.6,2BA

REMOTE CONTROLLER

Ceiling Cassettes

[Service Ref.]

PMH-P1BA

PMH-P1BA

PMH-P1.6BA

PMH-P1.6BA

PMH-P2BA

PMH-P2BA

1Hr.

CENTRALLY CONTROLLED

ON OFF

CLOCK

CHECK

FILTER

CHECK MODE

˚C

TEST RUN

STAND BY

ERROR CODE

NOT AVAILABLE

FUNCTION

DEFROST

TEMP.

ON/OFF

PMH- P1,1.6,2BA

R407C

1

1

1

CONTENTS

1. TECHNICAL CANGES ········································2

2.

3. SAFETY PRECAUTION ······································3

4. PART NAMES AND FUNCTIONS·······················5

5. SPECIFICATIONS ·············································10

6. DATA··································································16

7. OUTLINES AND DIMENSIONS ························29

8. WIRING DIAGRAM···············································30

9. REFRIGERANT SYSTEM DIAGRAM ·····················31

10. TROUBLE SHOOTING ·····································32

11. DISASSEMBLY PROCEDURE··························35

12. PARTS LIST ······················································38

13. OPTIONAL PARTS············································41

1

2001

No. OC238

REVISED EDITION-B

• PMH-P1BA

,PMH-P1.6BA

,PMH-P2BA

1

1

are added in REVISED EDITION-B.

• Please void OC238.REVISED EDI-

TION-A.

• Refer to the OCT03 REVISED EDI-

TION-C as regarding control

relation.This manual does not cover

outdoor units. When servicing them,

please refer to the service manual

No.OC180 REVISED EDITION-A,

OC261 and this manual in a set.

[Service Ref.]

<OC180 REVISED EDITION-A>

PUH-P1.6VGA

PUH-P1.6YGA

PUH-P2VGA

PUH-P2YGA

<OC261>

PUH-P1VGAA.UK

PUH-P1.6VGAA.UK

PUH-P1.6YGAA.UK

PUH-P2VGAA.UK

PUH-P2YGAA.UK

1

···3

Advertisement

Table of Contents

Summary of Contents for Mitsubishi PMH-P1BA

-

Page 1: Table Of Contents

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS No. OC238 REVISED EDITION-B TECHNICAL & SERVICE MANUAL Series PMH Ceiling Cassettes R407C • PMH-P1BA ,PMH-P1.6BA ,PMH-P2BA are added in REVISED EDITION-B. • Please void OC238.REVISED EDI- Indoor unit TION-A. • Refer to the OCT03 REVISED EDI- [Model names] [Service Ref.]... -

Page 2: Technical Canges

TECHNICAL CHANGES PMH-P1BA PMH-P1BA PMH-P1.6BA PMH-P1.6BA PMH-P2BA PMH-P2BA Outdoor units which are connected to PMH-P•BA and PMH-P•BA have been added. The parts No. of REMOTE CONTROLLER has changed. (The following parts numbers are interchangeable.) FILTER CENTRALLY CONTROLLED 1Hr. CHECK MODE... -

Page 3: Combination Of Indoor And Outdoor Units

COMBINATION OF INDOOR AND OUTDOOR UNITS Outdoor unit Indoor unit PUH-P 1.6VGA 1.6YGA 2VGA 2YGA 1VGAA.UK 1.6VGAA.UK 1.6YGAA.UK 2VGAA.UK 2YGAA.UK PMH-P1BA — — — — — — — — PMH-P1.6BA — — — — — PMH-P2BA — — — —... - Page 4 [1] Service tools Use the below service tools as exclusive tools for R407C refrigerant. Tool name Specifications Gauge manifold ·Only for R407C. ·Use the existing fitting SPECIFICATIONS. (UNF7/16) ·Use high-tension side pressure of 3.43MPa·G or over. Charge hose ·Only for R407C. ·Use pressure performance of 5.10MPa·G or over.

-

Page 5: Part Names And Functions

PART NAMES AND FUNCTIONS Indoor (Main) Unit PMH-P1BA, PMH-P1BA PMH-P1.6BA, PMH-P1.6BA PMH-P2BA, PMH-P2BA Auto Air Swing Vane Guide vane Disperses airflow up and down and adjusts the angle Air flow can be changed to horinzontally of airflow direction. by moving the Guide vane to the left or right. - Page 6 PMH-P1BA PMH-P1.6BA PMH-P2BA Remote controller Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button. Operation buttons TIME SETTING button AIR SPEED button This sets of switches the TIMER button current time. start time and This sets the fan speed.

- Page 7 Display In this display example on the bot- CENTRALLY CLOCK display tom left, a condition where all dis- CONTROLLED display play lamps light is shown for expla- The current time , start time and stop time can be displayed in ten second nation purposes although this differs This indicates when the unit is con- intervals by pressing the time switch...

- Page 8 PMH-P1BA PMH-P1.6BA PMH-P2BA Remote controller Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button. Operation buttons TEMP. ADJUSTMENT button TIME SETTING button AIR SPEED button This sets the room temperature. The This sets the current time, start time This sets the ventilation fan speed.

- Page 9 Display In this display example on the bot- CENTRALLY CLOCK display tom left, a condition where all dis- CONTROLLED display play lamps light is shown for expla- The current time , start time and stop time can be displayed in ten second nation purposes although this differs This indicates when the unit is con- intervals by pressing the time switch...

-

Page 10: Specifications

SPECIFICATIONS 5-1. SPECIFICATIONS Service Ref. PMH-P1.6BA Item Cooling Heating Function Btu/h 15,000 17,100 Capacity 4,400 5,000 Total input 1.65 1.70 Service Ref. PMH-P1.6BA Power supply(phase, cycle, voltage) Single Phase, 50Hz, 220-230-240V Input 0.06 0.06 Running current 0.29 0.29 Starting current 0.32 0.32 External finish... - Page 11 Service Ref. PMH-P2BA Item Cooling Heating Function Btu/h 18,400 21,300 Capacity 5,400 6,250 Total input 2.35 2.42 Service Ref. PMH-P2BA Power supply(phase, cycle, voltage) Single Phase, 50Hz, 220-230-240V Input 0.06 0.06 Running current 0.29 0.29 Starting current 0.32 0.32 External finish Unit : Galvanized sheets with gray heat insulation, Grille munsell 0.98Y 8.99/0.63 Heat exchanger Plate fin coil...

- Page 12 Service Ref. PMH-P1BA / PMH-P1BA Item Cooling Heating Function Btu/h 10,700 11,600 Capacity 3,150 3,400 Total input 1.15 1.06 Service Ref. PMH-P1BA / PMH-P1BA Power supply(phase, cycle, voltage) Single Phase, 50Hz, 220-230-240V Input 0.04 0.04 Running current 0.19 0.19 Starting current 0.21...

- Page 13 Service Ref. PMH-P1.6BA / PMH-P1.6BA Item Cooling Heating Function Btu/h 15,000 17,100 Capacity 4,400 5,000 Total input 1.65 1.70 Service Ref. PMH-P1.6BA / PMH-P1.6BA Power supply(phase, cycle, voltage) Single Phase, 50Hz, 220-230-240V Input 0.06 0.06 Running current 0.29 0.29 Starting current 0.32 0.32 External finish...

- Page 14 Service Ref. PMH-P2BA / PMH-P2BA Item Cooling Heating Function Btu/h 18,400 21,450 Capacity 5,400 6,250 Total input 2.35 2.42 Service Ref. PMH-P2BA / PMH-P2BA Power supply(phase, cycle, voltage) SinglePhase, 50Hz, 220-230-240V Input 0.06 0.06 Running current 0.29 0.29 Starting current 0.32 0.32 External finish...

- Page 15 The air capacity should be 20% or less of the air flow SPEC(Hi). 288.5 4-{2.8 Flesh air intake hole Flesh air intake hole (Knock out) (Knock out) Air flow Air capacity taken outside (Hi) PMH-P1BA, PMH-P1BA 8.4m /min 1.6m /min PMH-P1.6BA, PMH-P1.6BA 10.0m /min 2.0m...

-

Page 16: Data

DATA 6-1. PERFORMANCE DATA 1) COOLING CAPACITY(1) PMH-P1BA, PMH-P1BA Outdoor intake air D.B.(°C) Indoor Indoor Intake air Intake air D.B.(°C) W.B.(°C) SHC(W) P.C. SHC(W) P.C. SHC(W) P.C. 3,119 2,089 0.67 0.92 3,024 2,026 0.67 0.97 2,930 1,963 0.67 1.03 3,339 1,836 0.55... - Page 17 COOLING CAPACITY(2) PMH-P1BA, PMH-P1BA Outdoor intake air D.B.(°C) Indoor Indoor Intake air Intake air D.B.(°C) W.B.(°C) SHC(W) P.C. SHC(W) P.C. SHC(W) P.C. 2,804 1,878 0.67 1.10 2,678 1,794 0.67 1.18 2,552 1,710 0.67 1.28 3,024 1,663 0.55 1.13 2,930 1,611 0.55...

- Page 18 COOLING CAPACITY(3) PMH-P1.6BA, PMH-P1.6BA Outdoor intake air D.B.(°C) Indoor Indoor Intake air Intake air D.B.(°C) W.B.(°C) SHC(W) P.C. SHC(W) P.C. SHC(W) P.C. 4,356 2,614 0.60 1.32 4,224 2,534 0.60 1.39 4,092 2,455 0.60 1.48 4,664 2,239 0.48 1.34 4,532 2,175 0.48 1.42 4,378...

- Page 19 COOLING CAPACITY(4) PMH-P1.6BA, PMH-P1.6BA Outdoor intake air D.B.(°C) Indoor Indoor Intake air Intake air D.B.(°C) W.B.(°C) SHC(W) P.C. SHC(W) P.C. SHC(W) P.C. 3,916 2,350 0.60 1.58 3,740 2,244 0.60 1.70 3,564 2,138 0.60 1.84 4,224 2,028 0.48 1.63 4,092 1,964 0.48 1.75 3,828...

- Page 20 COOLING CAPACITY(5) PMH-P2BA, PMH-P2BA Outdoor intake air D.B.(°C) Indoor Indoor Intake air Intake air D.B.(°C) W.B.(°C) SHC(W) P.C. SHC(W) P.C. SHC(W) P.C. 5,346 3,047 0.57 1.88 5,184 2,955 0.57 1.99 5,022 2,863 0.57 2.10 5,724 2,576 0.45 1.92 5,562 2,503 0.45 2.02 5,373...

- Page 21 COOLING CAPACITY(6) PMH-P2BA, PMH-P2BA Outdoor intake air D.B.(°C) Indoor Indoor Intake air Intake air D.B.(°C) W.B.(°C) SHC(W) P.C. SHC(W) P.C. SHC(W) P.C. 4,806 2,739 0.57 2.26 4,590 2,616 0.57 2.42 4,374 2,493 0.57 2.62 5,184 2,333 0.45 2.31 5,022 2,260 0.45 2.49 4,698...

- Page 22 Service Ref. D.B.(°C) P.C. P.C. P.C. P.C. P.C. P.C. 2,159 0.63 2,346 0.69 2,618 0.80 3,434 0.95 3,876 1.06 4,318 1.14 PMH-P1BA 2,074 0.68 2,244 0.74 2,482 0.86 3,315 1.03 3,740 1.14 4,165 1.23 PMH-P1BA 2,006 0.72 2,176 0.81 2,380 0.93 3,128 1.09...

- Page 23 6-2. PERFORMANCE CURVE Cooling performance curve(50Hz) Heating performance curve(50Hz) Correcting the capacity line influenced by frosting Not correcting the capactiy line influenced by frosting INDOOR D.B.(°C) INDOOR W.B.(°C) INDOOR INDOOR W.B.(°C) D.B.(°C) -12 -10 OUTDOOR W.B.(°C) OUTDOOR D.B.(°C)

- Page 24 6-3. ELECTRICAL DATA Indoor unit … 220V 50Hz Single phase Outdoor unit … 220V 50Hz Single phase / 380V 50Hz 3phase Indoor unit PMH-P1.6BA PMH-P2BA Service Ref. PUH-P1.6VGA PUH-P1.6YGA PUH-P2VGA PUH-P2YGA Outdoor unit Mode Cool Heat Cool Heat Cool Heat Cool Heat Capacity (W)

- Page 25 Indoor unit ··· 220V 50Hz Single phase Outdoor unit ··· 220V 50Hz Single phase / 380V 50Hz 3phase PMH-P1BA PMH-P1.6BA PMH-P2BA Indoor unit PMH-P1BA PMH-P1.6BA PMH-P2BA Service Ref. PUH-P1VGAA.UK PUH-P1.6VGAA.UK PUH-P1.6YGAA.UK PUH-P2VGAA.UK PUH-P2YGAA.UK Outdoor unit Mode Cool Heat Cool Heat...

- Page 26 6-4. STANDARD OPERATION DATA Service Ref. PMH-P1.6BA PMH-P2BA Mode Cooling Heating Cooling Heating Capacity 4,400 5,000 5,400 6,250 Input 1.65 1.70 2.35 2.42 Indoor unit Service Ref. PMH-P1.6BA PMH-P2BA Phase, Hz 1, 50 1, 50 Volts Amperes 0.29 0.29 0.29 0.29 PUH-P •...

- Page 27 PMH-P1BA PMH-P1.6BA PMH-P2BA Service Ref. PMH-P1BA PMH-P1.6BA PMH-P2BA Mode Cooling Heating Cooling Heating Cooling Heating Capacity 3,150 3,400 4,400 5,000 5,400 6,250 Input 1.15 1.06 1.65 1.70 2.35 2.42 PMH-P1BA PMH-P1.6BA PMH-P2BA Indoor unit Service Ref. PMH-P1BA PMH-P1.6BA PMH-P2BA Phase, Hz...

- Page 28 6-6. NOISE CRITERION CURVES PMH-P1.6BA PMH-P1BA SPL(dB) LINE SPL(dB) LINE NOTCH NOTCH PMH-P1BA PMH-P1.6BA NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE THRESHOLD OF APPROXIMATE THRESHOLD OF HEARING FOR NC-20 NC-20 HEARING FOR CONTINUOUS CONTINUOUS NOISE NOISE...

-

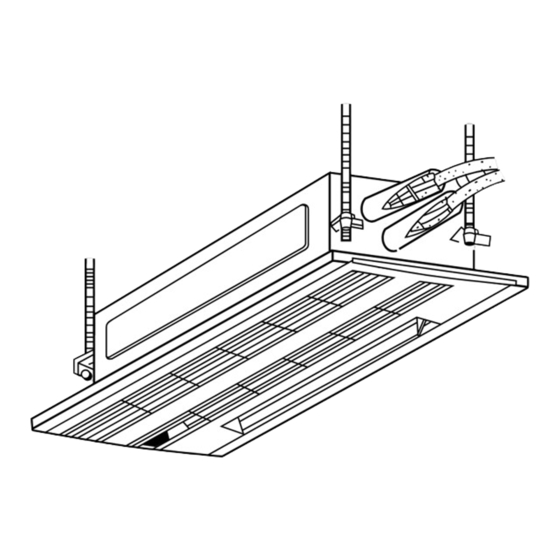

Page 29: Outlines And Dimensions

OUTLINES AND DIMENSIONS PMH-P1BA, PMH-P1BA Unit : mm PMH-P1.6BA, PMH-P1.6BA PMH-P2BA, PMH-P2BA... -

Page 30: Wiring Diagram

WIRING DIAGRAM PMH-P1BA, PMH-P1.6BA, PMH-P2BA PMH-P1BA , PMH-P1.6BA , PMH-P2BA [LEGEND] NOTES: 1.Since the outdoor side electric wiring may change be sure to check NAME SYMBOL the outdoor unit electric wiring for servicing. INDOOR CONTROLLER BOARD 2.Indoor and outdoor connecting wires are made with polarities, make... -

Page 31: Refrigerant System Diagram

REFRIGERANT SYSTEM DIAGRAM PMH-P1BA, PMH-P1BA / PUH-P1VGAA.UK PMH-P1.6BA / PUH-P1.6VGA , PUH-P1.6VGAA.UK , PUH-P1.6YGA , PUH-P1.6YGAA.UK PMH-P1.6BA / PUH-P1.6VGAA.UK , PUH-P1.6YGAA.UK PMH-P2BA / PUH-P2VGA , PUH-P2VGAA.UK , PUH-P2YGA , PUH-P2YGAA.UK PMH-P2BA / PUH-P2VGAA.UK , PUH-P2YGAA.UK Unit : mm Refrigerant flow in cooling <4-way valve solenoid coil>... -

Page 32: Trouble Shooting

TROUBLE SHOOTING How to check the parts PMH-P1BA, PMH-P1.6BA, PMH-P2BA PMH-P1BA , PMH-P1.6BA , PMH-P2BA Parts name Check points Room temperature Disconnect the connector then measure the resistance using a tester. thermistor (TH1) (Surrounding temperature 10:~30:) Pipe temperature thermistor (TH2) - Page 33 Check method of indoor fan motor (fan motor / control p.c.board) Notes · High voltage is applied to the connecter (FAN) for the fan motor. Give attention to the service. · Do not pull out the connector (Fan) for the motor with the power supply on. p.c.board) (It causes trouble of the control Self check...

- Page 34 <Thermistor Characteristic graph> Room temperature thermistor(TH1) Thermistor for < Thermistor for lower temperature > Pipe temperature thermistor(TH2) lower temperature Condenser/evaporator temperature thermistor(TH5) Thermistor R =15kΩ ± 3% Fixed number of B=3480kΩ ± 2% Rt=15exp { 3480( 273+t 15kΩ 9.6kΩ 6.3kΩ 5.4kΩ...

-

Page 35: Disassembly Procedure

DISASSEMBLY PROCEDURE PMH-P1BA, PMH-P1BA Be careful on removing heavy parts. PMH-P1.6BA, PMH-P1.6BA , PMH-P2BA, PMH-P2BA OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS Photo 1 1. Removing the intake grille Opening the air intake grille (1) Press the of the air intake grille.(See figure 1) - Page 36 OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS Photo 2 2. Removing the electrical parts box Claw in middle Stabilizer Electrical parts of stabilizer (1) Remove the panel. (2) Remove the cover. (3) Remove the electrical parts cover. (4) Disconnect the connectors of fan motor, vane motor, drain pump, room temperature thermistor, pipe temperature thermistor, condenser/evaporator temperature thermistor and drain sensor on the electrical controller board.

- Page 37 OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS Photo 6 Drain sensor Drain pump 5. Removing the drain pump (1) Remove the panel. (2) Unhook the claw in the middle of stabilizer and remove the drain pan. (3) Remove the cover. (4) Remove the electrical parts cover. (5) Disconnect the connector of drain pump.

-

Page 38: Parts List

PARTS LIST PANEL PARTS PMH-P1BA PMH-P1BA PMH-P1.6BA , PMH-P1.6BA PMH-P2BA , PMH-P2BA CENTRALLY CONTROLLED 1Hr. ON OFF CHECK CLOCK FILTER CHECK MODE ˚C TEST RUN STAND BY ERROR CODE DEFROST NOT AVAILABLE FUNCTION TEMP. ON/OFF Q'ty/set Price Wiring Recom- Remarks PMH-P1/1.6/2... - Page 39 FUNCTIONAL PARTS PMH-P1BA PMH-P1BA PMH-P1.6BA , PMH-P1.6BA PMH-P2BA , PMH-P2BA SLEEVE BEARING VANE MOTOR VANE SLEEVE CONDENSER / EVAPORATOR TEMPERATURE THERMISTOR PIPE TEMPERATURE THERMISTOR / LIQUID ROOM TEMPERATURE THERMISTOR Part number that is circled is not shown in the figure.

- Page 40 ELECTRICAL PARTS PMH-P1BA PMH-P1BA PMH-P1.6BA , PMH-P1.6BA PMH-P2BA , PMH-P2BA Q'ty/set Price Wiring Recom- Remarks Diagram mended Part No. Part Name Specification PMH-P1/1.6/2 (Drawing No.) Unit Amount Symbol Q'ty CONTROL BOX (RG02B337G10) — TERMINAL BLOCK T7W E13 716 3P (S1, S2, S3)

-

Page 41: Optional Parts

OPTIONAL PARTS 13-1. TIMER Part No. PAC-SC32PTA (with set back function) Model Name Program timer 13-1-1. Program timer specifications Part name Program timer Parts No. PAC-SC32PTA Exterior dimensions (inch) 5-4/32 4-23/32 23/32 (130 120 18mm) Installation Wall mount Type of clock Quartz Clock accuracy 50 second / month at 25:... - Page 42 13-1-3. How to connect program timer (1) Install the program timer next to the remote controller the same way as the remote controller is installed. (2) Connect the program timer and the remote controller with a 5-wire cable as shown in the figure below Connect to indoor unit NOTE:While the program timer is connected to the remote controller, the with 2-wire cable.

- Page 43 13-2. Remote Sensor Part No. PAC-SE41TS-E Applied Service Ref. PMH-P1 / 1.6 / 2BA, PMH-P1 / 1.6 / 2BA 13-3. Remote Operation Adapter Part No. PAC-SF40RM-E Applied Service Ref. PMH-P1 / 1.6 / 2BA, PMH-P1 / 1.6 / 2BA 13-4. Remote ON/OFF Adapter Part No.

- Page 44 HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN cCopyright 2000 MITSUBISHI ELECTRIC ENGINEERING CO., LTD. Distributed in Sep. 2001 No. OC238 REVISED EDITION-B 250 New publication, effective Sep. 2001 Distributed in May. 2001 No. OC238 REVISED EDITION-A 225 Specifications subject to change without notice Issued in Dec.