Summary of Contents for Hyundai 12EPML

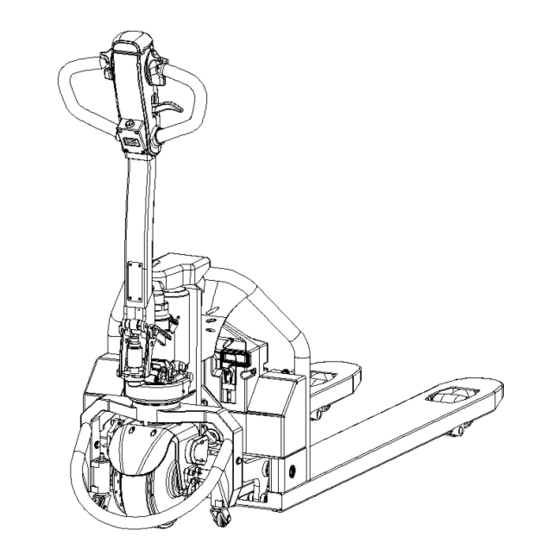

- Page 1 12EPML Electric Pallet Truck (Lithium battery) Operation Manual HYUNDAI CONSTRUCTION EQUIPMENT...

-

Page 2: Table Of Contents

Welcome to use “HYUNDAI” Electric pallet stacker! We hope our Electric pallet truck will provide great convenience for your work! Please read the manual carefully before operation This manual is universal manual. We reserve the right to modify technology of the electric stacker. -

Page 3: Safety Regulations

1. Safety regulations When operating the truck, one should always wear safe shoes. When assembling or disassembling the truck, in order to avoid injury, one should always wear safety goggles. Attention! When the truck is damaged or failure-affecting safety occurs, do not go on operating the truck. - Page 4 Warning! - When turning, high-speed operation should be avoided to prevent the truck from turning upside down. - The goods should not be piled too high to avoid blocking the vision line. - Braking should be conducted slightly and very carefully to prevent the goods from sliding off the tray, which may damage the goods.

-

Page 5: Description

2. Description This truck is suitable to operate on indoor hard and smooth ground. It is not allowed to operate the truck for unsuitable applications. The ambient air temperature does not exceed +40℃ or below -10℃; Hard、flat ground; Forbid to use this truck in the flammable and explosive or acid-base and other corrosive environment;... - Page 6 Model 12EPML Drive type Electric Operation type Walkie Q(kg) 1200 Rated load Load center distance C(mm) Height fork lowered (mm) Thread Y(mm) 1269/1339 Wheel Wheel dimension, front Φ250 Wheel dimension, rear Φ80 Wheel number, front/rear (x = driving 1X-2/4 wheel)...

-

Page 7: Operation

3. Operation Energization Connect the interface of lithium battery. The connectors are connected with each other. Fig.2 Turn on the electric switch. Turn on the electric switch with keys. Fig.3 Lifting and lowering Lifting:press the lifting button on the handle. Lowering:Hold the knob tightly to lower. - Page 8 Travelling Turn the handle to travelling scope; A and C is braking; B is travelling; Fig.5 Rotate the accelerator to start the truck slowly, (For safety, forbid the abrupt acceleration) Reverse Forward Fig.6 Braking Release the accelerator when travelling normally, the truck stop slowly by the regenerative brake of the motor until the brake lock the wheels.

-

Page 9: Operation, Maintenance And Charging Of Battery

Emergency reverse button Parking Release Speed button to stop running. the truck will slow down until the brake suction together in the truck . Lower the fork to the lowered position . Close the electric switch. Disconnect the battery wire off the truck if park for a long time. Disconnect the battery wire off the truck if park for a long time. - Page 10 I) When removing the battery , grasp the plug by hand instead of stay wire J) After the battery is used, if the battery is hot and recharging it, cool it in a ventilated environment K) Do not put the battery in water or seawater L) Do not try to separate, squeeze, hit the battery, the battery will heat or fire.

-

Page 11: Maintenance

Step V:insert the battery connector. 4.3 Precautions of battery charging Must use the special Li-ion charger of our company;working voltage of charger 48V, Max.charging voltage 54.6V,Charging current 6-7A Do not reverse charge the battery Stop charging immediately if found the battery hot during charging, recharge after cooling down naturally must hold the puller when umplug the battery connector, not allow unplug the wire directly... -

Page 12: Common Faults And Trouble Shooting

Routine maintenance: Once everyday and the main content is to keep the surface clean and examine if the power supply cable is damaged. Level 1 maintenance: Once every week. The maintenance contents, besides the contents of routine maintenance, should focus on if the operation of the components is normal, if the fastening items are loose, if there is any oil leakage, if there is any abnormal wearing in mechanical components, if there are abnormal temperature rise or sparks in electric equipment, etc. -

Page 13: Treatment Of Abandoned Material

1. Manual lowering valve 1. Adjust the position of Fork does not lower is not adjusted well; lowering valve screw; 1. Power supply switch 1. Insert key and turn on has not been turned on power supply 2. Battery has completely 2. -

Page 14: Electrical Schematic Diagram

8. Electrical schematic diagram ~ 12 ~... -

Page 15: Packing List

9. Packing list Packing list of 12EPML Electric pallet truck (Lithium battery) Consignee: Ex-work No.: Contract No.: Ex-work Date: Name Q’ty Net weight Dimension Remarks (kg) (L×W×H) 12EPML Electric pallet A complete set truck Technical documents, Accessory box accessories and spare parts.