Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Danfoss Aeroquip FT1380P

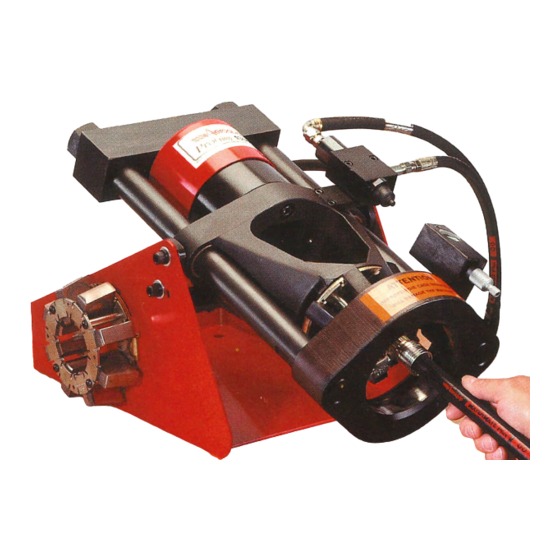

- Page 1 Operator’s Manual Aeroquip® by Danfoss Procrimp FT1380P Crimp Machine...

-

Page 2: Table Of Contents

Crimping Procedures Calibration Maintenance Maintenance lntervals Machine Maintenance Procedures Die Cage Maintenance Procedures Crimp Machine Components Die Cage Components Hydraulic Schematic FT1380P Target Settings for MatchMate Plus Hoses AQ435955684211en-000101 2 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. -

Page 3: Safety Lnstructions

This setting avoid any sharp impact. Nev- is preset at the factory and er strike a die with a hardened should not require adjust- instru ment. ment. 3 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 4: Specifications

For easy positioning of Match Mate fittings into FT1380 “M” series die cages. Part Number FT1330-XL Die Cages FT1380-275-MO7O FT1380-200-M180 FT1380-200-M320 FT1380-275-M090 FT1380-200-M210 FT1380-275-M370 FT1380-275-M120 FT1380-200-M240 FT1380-275-M420 FT1380-200-M150 FT1380-200-M280 FT1380-275-M465 4 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 5: Setup And Assembly Lnstructions

7. Remove the SAE 37° cap on the 2021-4-6S adapter on top of the valve. 8. Install a -6 return hose to pump return port and valve top port. This hose must be capable of containing 200 psi. 5 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 6: Operating Instructions

438, and the crimp diameter is .025 too large, the micrometer should be increased by 050 ( 2 x .025 ) to 488 in order to produce the correct crimp diameter. 6 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 7: Crimping Procedures

Further pump- ing will not result in additional crimp stroke. 6. Release the hydraulic pressure on the power source to retract crimp cage. 7. Verify correct crimp diameter. 7 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 8: Calibration

NOTE: If your Crimp Diameter falls between the numbers shown in Table A, simply determine or interpolate the Bracket to Ring Gap, since the relationship between the numbers is linear. 8 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 9: Maintenance Lntervals

Reassemble components and liberally apply High Efficiency PTFE Grease (Danfoss part number T-400-G) to the die surface which slides along the spring plate. Torque the die cage bolts to 50 in. -lbs. Ensure that all dies slide in and out freely. -

Page 10: Crimp Machine Components

Adapter (not included with FT1380P-1-3 Kit) 22003-6-12S 3/8-16 X 0.75 SHCS FT1380P-3-12 Pressure Plata FT1380-3-25 1/2-13 X 1.00 8HC8 1C0190BEEE0160A Hose Assemblv 210104-2-6S 3/8” Lock Washer FF9230-0501S 5/16” Flat Washer FT1380P-3-5 Frame 10 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 11: Die Cage Components

*The FT1380-200-NO. (FT1380-2-9) requires 16 springs and the FT1380-201-NO. (FT1380-2-9A) requires 8 springs. Hydraulic Schematic Sequence 1. Pump on - Cylinder advances. 2. Valve energized - Cylinder holds position. 3. Pump and Valve de-energized -Cylinder retracts. 11 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... -

Page 12: Ft1380P Target Settings For Matchmate Plus Hoses

0.827 -M280 0.691 -M240 0.790 -M280 0.887 -M320 0.714 -M280 0.845 -M320 0.960 -M370 0.323 -M320 0.877 -M370 0.675 -M465 0.440 -M370 0.493 -M465 0.781 -M465 0.544 12 | Aeroquip by Danfoss FT1380P Crimp Machine Operator’s Manual | 2023.06. AQ435955684211en-000101... - Page 13 Phone: +86 21 3418 5200w Danfoss can accept no responsibility for possible errors in catalogs, brochures, and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.