Table of Contents

Advertisement

Quick Links

Installation – Parts List

ALUMINUM AND STAINLESS STEEL

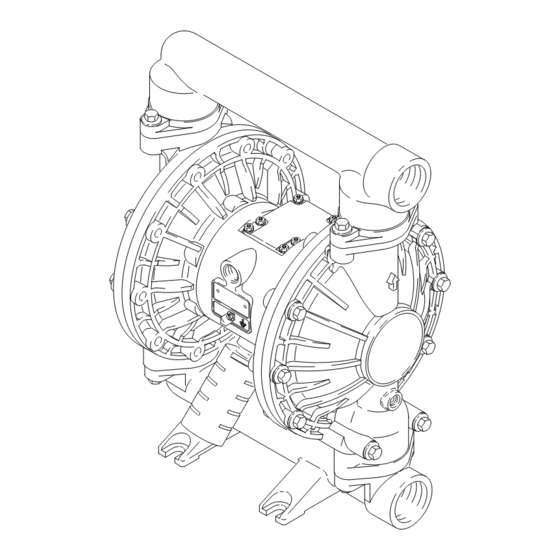

Husky

Diaphragm Pumps

1.5-inch AODD pump for fluid transfer applications.

For professional use only.

See Models on page 2 for a list of pump models and descriptions.

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

1590 Air-Operated

Model No. DB3777 shown

308441ZAH

EN

03263B

II 2 GD c IIC T4

Advertisement

Table of Contents

Summary of Contents for Graco Husky 1590 DB3 Series

- Page 1 Installation – Parts List ALUMINUM AND STAINLESS STEEL Husky 1590 Air-Operated 308441ZAH Diaphragm Pumps 1.5-inch AODD pump for fluid transfer applications. For professional use only. See Models on page 2 for a list of pump models and descriptions. 120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure 120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure Important Safety Instructions Read all warnings and instructions in this...

-

Page 2: Table Of Contents

Diaphragm Repair ..... . . 18 Graco Information ......36 Bearing and Air Gasket Removal . -

Page 3: Symbols

Read all instruction manuals, tags, and labels before operating the equipment. • Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. • Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 4 WARNING TOXIC FLUID HAZARD Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed. • Know the specific hazards of the fluid you are using. • Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state and national guidelines.

-

Page 5: Installation

1. Read TOXIC FLUID HAZARD on page 4. tion. 2. Use fluids and solvents which are compatible with Graco recommends taking all the above factors into the equipment wetted parts. Refer to the account in system design. To maintain pump efficiency,... - Page 6 Installation • Pump: Connect a ground wire and clamp as shown in 2. For all mountings, be sure the pump is bolted directly . 1. Loosen the grounding screw (W). Insert one to the mounting surface. end of a 12 ga (1.5 mm ) minimum ground wire (Y) 3.

- Page 7 3. Connect remaining ends of tubes to external air A fluid drain valve (J) is required to relieve pressure in signal, such as Graco’s Cycleflo (P/N 195264) or the hose if it is plugged. The drain valve reduces the Cycleflo II (P/N195265) controllers.

- Page 8 TYPICAL FLOOR-MOUNT INSTALLATION Air supply hose Bleed-type master air valve (required for pump) Air regulator Air line quick disconnect Master air valve (for accessories) Air line filter Fluid suction hose Fluid supply Fluid drain valve (required) Fluid shutoff valve Fluid hose Fluid inlet port Fluid outlet port Ground wire (required;...

- Page 9 Installation Changing the Orientation of the Fluid Inlet Fluid Pressure Relief Valve and Outlet Ports CAUTION NOTE: Remove and rotate the center manifold(s) to change the orientation of inlet or outlet port(s). Follow the Torque Instructions, page 29. Some systems may require installation of a pressure relief valve at the pump outlet to prevent overpressurization and rupture of the pump or hose.

- Page 10 Installation Air Exhaust Ventilation The air exhaust port is 3/4 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can cause erratic pump operation. WARNING If the muffler (P) is installed directly to the air exhaust FIRE AND EXPLOSION HAZARD port, apply PTFE thread tape or anti-seize thread Be sure to read and follow the warnings lubricant to the muffler threads before assembly.

-

Page 11: Operation

Operation Pressure Relief Procedure NOTE: If the fluid inlet pressure to the pump is more than 25% of the outlet working pressure, the ball check valves will not close fast enough, resulting in inefficient pump WARNING operation. PRESSURIZED EQUIPMENT HAZARD 4. -

Page 12: Maintenance

Maintenance Lubrication Flushing and Storage The air valve is designed to operate unlubricated, WARNING however if lubrication is desired, every 500 hours of operation (or monthly) remove the hose from the pump To reduce the risk of serious injury whenever you air inlet and add two drops of machine oil to the air inlet. -

Page 13: Troubleshooting

Troubleshooting • Relieve the pressure before checking or servicing the WARNING equipment. To reduce the risk of serious injury whenever you • Check all possible problems and causes before are instructed to relieve pressure, always follow the Pressure Relief Procedure on page 11. disassembling the pump. - Page 14 Troubleshooting PROBLEM CAUSE SOLUTION Fluid in exhaust air. Diaphragm ruptured. Replace. See pages 18-20. Loose diaphragm shaft bolt (107). Tighten or replace. See pages 18-20. Damaged o-ring (108). Replace. See pages 18-20. Pump exhausts excessive air at stall. Worn air valve block (7), o-ring (6), Repair or replace.

-

Page 15: Service

Service Repairing the Air Valve Tools Required • Torque wrench • Torx (T20) screwdriver or 7 mm (9/32 in.) socket wrench • Needle-nose pliers • O-ring pick • Lithium base grease NOTE: Air Valve Repair Kits 236273 (aluminum center housing models) and 255061 (sst center housing models) are available. - Page 16 Service Reassembly Insert narrow end first. 1. If you removed the bearings (12, 15), install new Grease. ones as explained on page 21. Reassemble the fluid section. Install with lips facing narrow end of piston (11). 2. On aluminum center housing models, install the Insert wide end first.

-

Page 17: Ball Check Valve Repair

Service Ball Check Valve Repair Apply medium-strength (blue) thread locker to the threads. Torque to 120-150 in-lb (14-17 Nm). See Torque Instructions, page 29. Tools Required Arrow (A) must point toward outlet manifold (103). • Torque wrench Not used on some models. •... -

Page 18: Diaphragm Repair

Service Diaphragm Repair WARNING Tools Required • Torque wrench To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the • 13 mm socket wrench Pressure Relief Procedure on page 11. • 15 mm socket wrench (aluminum models) or 1. - Page 19 Service 4. Loosen but do not remove the diaphragm shaft bolts a. Install the o-ring (108*) on the shaft bolt (107). (107), using a 15 mm socket wrench (1 in. on stainless steel models) on both bolts. NOTE: This b. Install the fluid side diaphragm plate (105) on the step does not apply to pumps with overmolded bolt so the rounded side faces in, toward the diaphragms.

- Page 20 Service 402* 403* 401* 03274A 03275A Cutaway View, with Diaphragms in Place Cutaway View, with Diaphragms Removed 401* 403* 108* Lips face out of housing (1). Rounded side faces diaphragm (401). Air Side must face center housing (1). Grease. Apply medium-strength (blue) thread locker. Torque to 20 to 25 ft-lb (27 to 34 N-m) at 100 rpm maximum.

-

Page 21: Bearing And Air Gasket Removal

Service Bearing and Air Gasket Removal out of the housing. Inspect the packings. See F . 12. Tools Required Reassembly • Torque wrench 1. If removed, install the shaft u-cup packings (402*) so the lips face out of the housing (1). •... - Page 22 Service Insert bearings tapered end first. Press-fit bearings flush with surface of center housing (1). Apply medium-strength (blue) thread locker. Torque to 130-150 in-lb (15-17 N Muffler not included on Model No. 253485. 03277 Detail of Air Valve Bearings 03278B ____________________________________________________________ .

-

Page 23: Pump Matrix

Pump Matrix Husky 1590 Aluminum and Stainless Steel Pumps, Series A Your Model No. is marked on the pump’s serial plate. To determine the Model No. of your pump from the following matrix, select the six digits which describe your pump, working from left to right. The first digit is always D, designating Husky diaphragm pumps. -

Page 24: Repair Kit Matrix

Repair Kit Matrix For Husky 1590 Aluminum and Stainless Steel Pumps, Series A Repair Kits may be ordered separately. To repair the air valve, order Part No. 236273 for aluminum center housing models or Part No. 255061 for stainless steel center housing models (see page 27). Parts included in the Air Valve Repair Kit are marked with a symbol in the parts list, for example (3). -

Page 25: Parts Drawing

Parts Drawing 301* 402* 201* 202* Aluminum Model Shown Not used on some models. Used on PTFE models only. 401* Used on stainless steel models only. ‡ These parts are unique to remote piloted air motor, DC----, DT---- 108* 403* These parts are included in the Pump Repair Kit, which may be purchased separately. -

Page 26: Parts

Parts Air Motor Parts List (Matrix Column 2) Ref. Ref. Digit Part No. Description Digit Part No. Description Same as B with the following exceptions 188838 HOUSING, center; aluminum 195921 HOUSING, center; remote, aluminum 1 188854 COVER, air valve; aluminum 195918 COVER, air;... - Page 27 Parts Fluid Section Parts List (Matrix Column 3) Digi Ref. Digi Ref. Part No. Description Part No. Description 15A615 COVER, fluid; aluminum 15A615 COVER, fluid; aluminum 192078 MANIFOLD, inlet; aluminum; 189402 MANIFOLD, inlet; aluminum BSPT 15A616 MANIFOLD, outlet; aluminum 15A658 MANIFOLD, outlet;...

- Page 28 Parts Seat Parts List (Matrix Column 4) Ball Parts List (Matrix Column 5) Ref. Ref. Digit Part No. Description Qty. Digit Part No. Description Qty. 301* 112419 BALL; PTFE 201* 189318 SEAT; 316 stainless steel 301* 112423 BALL; acetal 202* 112418 O-RING;...

-

Page 29: Torque Instructions

Torque Instructions Always follow torque sequence when instructed to torque fasteners. 1. Left/Right Fluid Covers Torque bolts to 190-220 in-lb (22-25 N SIDE VIEW 2. Inlet Manifold Torque bolts to 120-150 in-lb (14-17 N BOTTOM VIEW 3. Outlet Manifold ... -

Page 30: Dimensions

Dimensions FRONT VIEW PUMP MOUNTING HOLE PATTERN 1/2 npt(f) Air inlet 3/4 npt(f) Air Exhaust Muffler not included on Model No. 253485. Dimensions B, C, F, G, H and M can vary by up to 1/4 in. (6.3 mm) depending on the seat and diaphragm material fitted in the pump. - Page 31 Pump with Stainless Steel Flanged Manifold Ports SIDE VIEW FRONT VIEW Dimensions B, C, F, G, H and M can vary by up to 1/4 in. (6.3 mm) depending on the seat and diaphragm material fitted in the pump. 308441ZAH...

- Page 32 Dimensions Aluminum OR SST Center SST Cover Aluminum Aluminum Flanged Manifold Ports Center Center SST SST Center SST Center Aluminum Cover Cover Aluminum Cover SST Cover Dimension 10.8 10.8 13.5 10.8 10.8 15.9 15.9 15.9 15.9 15.9 16.8 16.3 16.3 16.8 16.3 18.3...

-

Page 33: Technical Data

Technical Data Maximum fluid working pressure ............. .120 psi (0.8 MPa, 8 bar) Air pressure operating range . -

Page 34: Performance Chart

Performance Chart Example of Finding Pump Air Consumption and Air Pressure at a Specific Fluid Delivery and Discharge Head: To supply 60 gpm (227 liters) fluid flow (horizontal scale) at 40 psi (0.28 MPa, 2.8 bar) discharge head pressure (vertical scale) requires approximately 50 scfm (1.40 m?/min) air consumption at 70 psi (0.49 MPa, 4.9 bar) inlet air pressure. - Page 35 308441ZAH...

-

Page 36: Graco Standard Husky Pump Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.