Summary of Contents for Jensen 400 Series

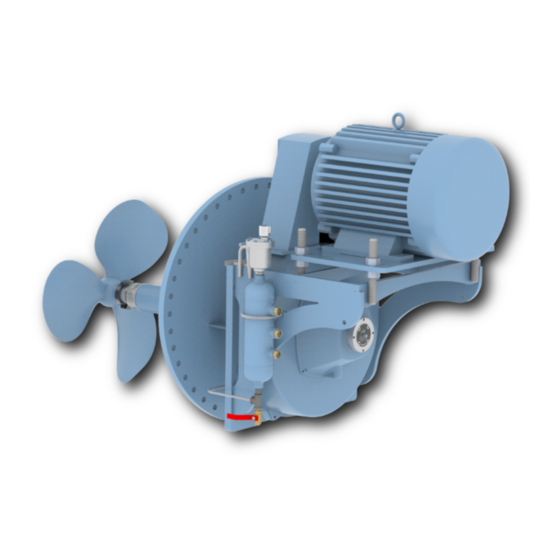

- Page 1 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 400 Series nstallation peration and aintenance anual Jensen Mixers Int. 5354 South Garnett Rd. Tulsa, OK. 74146 S16AC-4 REV 3...

- Page 2 Installation, Operation, Maintenance Installation Series 400 Fixed and Vari-Angle Mixers Remove blank cover plate from tank nozzle and check Jensen supplied mixer cover plate for correct size, hole location and orientation. Clean gasket surface on tank nozzle and mating flange on mixer coverplate.

-

Page 3: Recommended Operation

MONTHLY: With the mixer running, check for noise and vibration. (See Troubleshooting if occurs) MONTHLY or AS NEEDED: Check belt defection and wear. Be sure the pulleys are not worn and are clean. QUARTERLY: Grease hinge zerk if Jensen Actuator is installed. - Page 4 Propeller Clearance & Fluid Levels Almost every vibration problem experienced with Jensen Mixers has proved to be a result of too little clearance between tank walls or floors and the mixer propeller. Operation of mixers with low fluid levels in the tank will cause air to be drawn into the propeller flow stream and will also cause vibration.

- Page 5 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 Motor Belt Alignment V-Belt and Cog Belt Drive Maintenance: Check alignment of pulleys Maintain uniform tension. Avoid heat above 140ºF. (60ºC) Keep drives well ventilated ...

- Page 6 All Jensen Series 400 mixers are equipped with a tungsten carbide reversible shaft wear sleeve. When the tank is out of service for periodic maintenance, the wear sleeve should be inspected. If it is badly worn or scored it should be reversed. To change the sleeve, remove the propeller and shaft lock bushing, reverse the wear sleeve and assemble.

- Page 7 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 400 (Pre 2014 Sentry System) MECHANICAL SEAL CHANGE Jensen Serial Numbers before 480 Mixer DR-101 to DR-1123 450 Mixer DO-101 to DO-781...

- Page 8 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200...

- Page 9 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200...

- Page 10 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 Jensen Serial Numbers AFTER 480 Mixer DR-1106 450 Mixer DO-781 NOTE: Complete seal exchange can be aided by removal of all covers. TAKE NECESSARY STEPS TO CONTAIN PRODUCT 1. If tank product is...

-

Page 11: Retaining Ring

Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 SEAL CHAMBER CLEANING REMOVE BELT HOUSING COVER Partially thread Locate BEARING in 1/4-20 bolts LOCK WASHER and (shown with pry TAB up clearing arrows) to aid in the RETAINING turning RING. - Page 12 For Jensen Mixer Parts - Call 281-350-1200 Jensen Sentry System Recharge/Flush Procedure Jensen's dual purpose Sentry System is designed to provide lubrication to the Seal area and provide a visual notification of a Seal fa ilure. Vent\Breather Assembly Know your system Upper Leak Detection Glass.

-

Page 13: Troubleshooting Guide

Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 TORQUES Fastener Location 420 Bolt Size/Torque 450 Bolt Size/Torque 480 Bolt Size/Torque Belt Cover 75 in-lb ⅜ ⅜ 120 in-lb 120 in-lb Yoke / Hub ½ 30 ft-lb ½ 30 ft-lb ½... - Page 14 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 Material Standards Parts & Materials American British German Cover & Housing Aluminum Casting 356-T6 ASTM B108 CI. SG70A DIN 1725 Aluminum Casting 319F ASTM B108 CI. SC64D DIN 1725 Body Iron Casting ASTM A48 CI.

-

Page 15: Long Term Storage

TERM STORAGE LONG Jensen recommends long term (more than 90 days) storage procedures to protect mixers from atmospheric corrosion, physical damage and other harmful effects. Proper storage is especially important in corrosive or high humidity environments. Store and maintain related equipment (motors, control panels and similar devices) supplied by Jensen according to manufacturers' instruc- tions. -

Page 16: Limited Warranty

Jensen warranty. Jensen will repair or replace, without charge, any part or parts which prove to be defective, under normal and proper use, within twelve months from the date of shipment. - Page 17 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 MIXER SPECIFICATIONS ATEX NOTES: If units are operated in ATEX Zone1 Belts should be checked weekly. Maximum RPM430 @ 60Hrz Maximum RPM360 @ 50Hrz Maximum Torque 680/480 221 Lbs-Ft ...

- Page 18 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200 Placement for Jensen Mixers Locating the mixer(s) approximately 15 degrees to the left of the Fill Line compliments mixer performance and encourages product to be pulled into the mixer propeller and quickly dispersed into the tank.

- Page 19 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200...

- Page 20 Tenney Company www.tenneyco.com For Jensen Mixer Parts - Call 281-350-1200...