Table of Contents

Advertisement

Quick Links

These instructions apply only for the destination countries listed on the appliance's data plate.

This is a class 3 built in hob.

We advise you to read this manual carefully, which contains all the instructions for

maintaining the appliance's aesthetic and functional qualities.

For further information on the product: www.smeg.com

Contents

30

30

33

33

33

34

34

34

35

35

36

37

37

37

38

40

40

40

42

42

42

43

45

47

54

29

Advertisement

Table of Contents

Summary of Contents for Smeg PXL664

-

Page 1: Table Of Contents

These instructions apply only for the destination countries listed on the appliance’s data plate. This is a class 3 built in hob. We advise you to read this manual carefully, which contains all the instructions for maintaining the appliance’s aesthetic and functional qualities. For further information on the product: www.smeg.com... -

Page 2: Instructions

Instructions 1 Instructions • Cleaning and maintenance must not be carried out by unsupervised 1.1 General safety instructions children. • Make sure that the flame- Risk of personal injury spreader crowns are correctly • During use the appliance and its positioned in their seats with their accessible parts become very hot. - Page 3 Instructions • Do not use aerosols in the vicinity • Cooking vessels or griddle plates of this appliance whilst it is in use. should be placed inside the perimeter of the hob. • Switch off the appliance after use. • All pans must have smooth, flat •...

- Page 4 Instructions Installation • If required, use a pressure regulator that complies with • This appliance must not be current regulations. installed in a boat or caravan. • After carrying out any operation, • This appliance must not be check that the tightening torque of installed on a pedestal.

-

Page 5: Manufacturer Liability

Instructions Manufacturer liability To dispose of the appliance: The manufacturer declines all liability Power voltage for damage to persons or property Danger of electrocution caused by: • Disconnect the mains power supply. • use of the appliance other than the one envisaged, •... -

Page 6: Identification Plate

Instructions 1.5 Identification plate 1.7 How to read the user manual This user manual uses the following reading The identification plate bears the conventions: technical data, serial number and brand name of the appliance. Do not Instructions remove the identification plate for General information on this user any reason. -

Page 7: Description

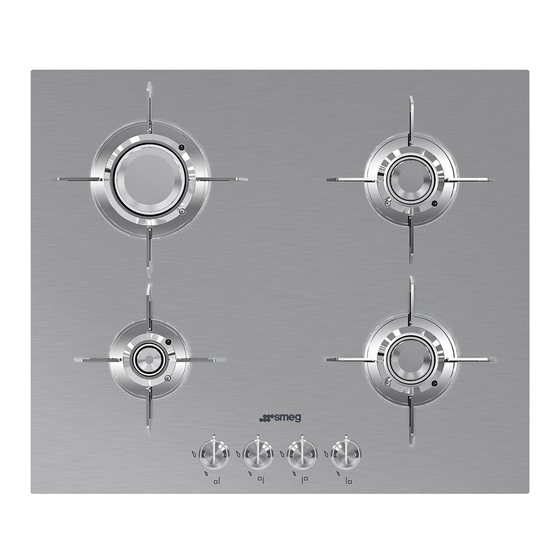

Description 2 Description 2.1 General Description 60 cm 75 cm... -

Page 8: Symbols

Description 100 cm AUX = Auxiliary R = Rapid SR = Semi-rapid UR = Ultra rapid RR = Reduced rapid 2.2 Symbols Cooking zones Burner knobs Front left Centre left Rear left Central Useful for lighting and adjusting the hob Rear right burners. -

Page 9: Use

3 Use Improper use 3.1 Instructions Risk of damage to surfaces Improper use Danger of burns • Do not use aluminium foil to cover the burners or hob body. • Make sure that the flame-spreader • Cooking vessels or griddle plates crowns are correctly positioned in their should be placed inside the perimeter of seats with their respective burner caps. -

Page 10: Using The Hob

3.3 Using the hob Also ensure that the flame-spreader crowns are correctly engaged in the burner holes. All the appliance’s control and monitoring devices are located together on the front panel. The burner controlled by each knob is shown next to the knob. The appliance is equipped with an electronic ignition device. - Page 11 1Practical tips for using the hob Using a griddle For better burner efficiency and to minimise A few precautions are necessary if you wish gas consumption, use pans with lids and of to use a griddle: suitable size for the burner, so that the •...

-

Page 12: Cleaning And Maintenance

Cleaning and maintenance 4 Cleaning and maintenance Ordinary daily cleaning Always use only specific products that do 4.1 Instructions not contain abrasives or chlorine-based acids. Improper use Pour the product onto a damp cloth and Risk of damage to surfaces wipe the surface, rinse thoroughly and dry with a soft cloth or a microfibre cloth. - Page 13 Cleaning and maintenance Igniters and thermocouples Refit the flame-spreader crowns making sure that they are correctly positioned in For correct operation the igniters and their housings with their respective burner thermocouples must always be perfectly caps. clean. Check them frequently and clean them with a damp cloth if necessary.

-

Page 14: Installation

Installation 5 Installation 5.2 Section cut from the countertop The following operation requires 5.1 Safety instructions building and/or carpentry work Heat production during appliance and must therefore be carried out operation by a competent tradesman. Risk of fire Installation can be carried out on various materials such as masonry, •... -

Page 15: Mounting

Installation 5.3 Mounting Over empty kitchen unit or drawers If there are other pieces of furniture (lateral Over built-in oven unit walls, drawers, etc.), dishwashers or fridges The clearance between the hob and the under the hob, a double-layer wooden kitchen furniture or other installed base must be installed at least 20 mm from appliances must be enough to ensure... - Page 16 Installation Fixing brackets With steel hob To prevent leakage of liquid between the Screw the fixing brackets (A) into the holes frame of the hob and the work surface, put on the sides of the bottom casing to the insulating seal provided in position properly fasten the hob to the structure.

-

Page 17: Gas Connection

Installation 5.4 Gas connection Connection with a steel hose Make the connection to the gas mains Gas leak using a continuous wall steel hose whose Danger of explosion specifications comply with the applicable standard. • After carrying out any operation, check Carefully screw the connector 3 to the gas that the tightening torque of gas connector 1 of the appliance, placing the... - Page 18 Installation Connection with a steel hose with conical Connection to LPG fitting Use a pressure regulator and make the Make the connection to the gas mains connection on the gas cylinder following using a continuous wall steel hose whose the guidelines set out in the standards in specifications comply with the applicable force.

-

Page 19: Adaptation To Different Types Of Gas

Installation Extraction of the combustion products 1 Extraction using a hood 2 Extraction without a hood The combustion products may be extracted by means of hoods connected to a natural draught chimney whose efficiency is certain A Single natural draught chimney or via forced extraction. - Page 20 Installation Removing the hob top 3. Pull the knobs and the knob bezels upwards to remove them. 1. Remove the grids from the hob. Between knob and the knob bezel there is a spring that is not shown in 2. Remove the flame-spreader crowns and the figure.

- Page 21 Installation 5. Remove the screws that fasten the hob Replacing nozzles top to the burner casing (the figure shows the 60 cm model as an example). 6. Lift the hob top and remove it. 1. Unscrew screw A and push air regulator B as far as it will go.

- Page 22 Installation Adjusting the minimum setting for natural Adjusting the minimum setting for LPG or town gas • Tighten the screw located at the side of 1. Light the burner and turn it to the minimum the tap rod clockwise all the way. position.

- Page 23 Installation Gas types and Countries N° Gas Types GB-IE FR-BE DE 1 Natural Gas G20 20 mbar • • • • • • • • • • G20/25 20/25 mbar • 2 Natural Gas G25 20 mbar • 3 Natural Gas G2.350 G2.350 13 mbar •...

- Page 24 Installation Burner and nozzle characteristics tables 1 Natural Gas G20 Rated heating capacity (kW) Nozzle diameter (1/100 mm) Reduced flow rate (W) 1100 Primary air (mm) Marking on nozzle 2 Natural Gas G25 Rated heating capacity (kW) Nozzle diameter (1/100 mm) Reduced flow rate (W) 1100 Primary air (mm)

- Page 25 Installation 6 LPG G30/31 Rated heating capacity (kW) 1.60 2.50 2.90 3.50 Nozzle diameter (1/100 mm) Reduced flow rate (W) 1300 Primary air (mm) Marking on nozzle Rated flow rate G30 (g/h) Rated flow rate G31 (g/h) 7 Town Gas G110 Rated heating capacity (kW) Nozzle diameter (1/100 mm) Reduced flow rate (W)

-

Page 26: Electrical Connection

Installation 5.6 Electrical connection The appliance can work in the following modes: Power voltage • 220-240 V 1N~ Danger of electrocution 220-240V~ 1 mm • Have the electrical connection performed by authorised technical personnel. 20 mm • Use personal protective equipment. 3 x 1 mm²...