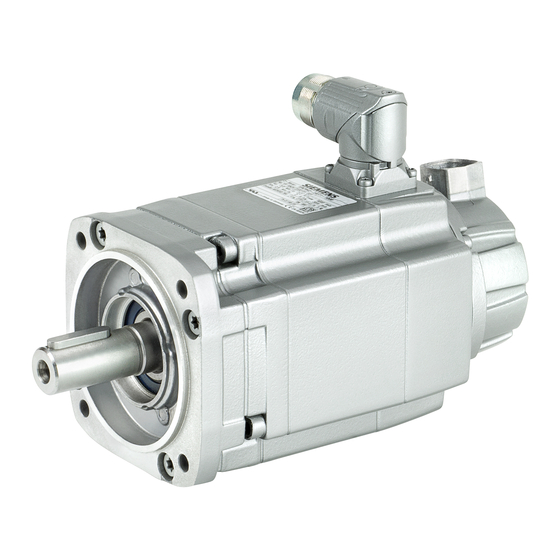

Summary of Contents for Siemens 1FK7 01.

- Page 1 Synchronous motors 1FK7 01. - 1FK7 10. Instructions Edition 10/2007 Synchronmotoren Moteurs synchrones Motores sincrónicos Motori sincroni 610.40 700.21...

-

Page 2: Table Of Contents

Inspection, maintenance, disposal ....... . 23 610.40 700.21 Siemens AG... - Page 3 NOTICE indicates a potential situation which, if not avoided, may result in an undesirable result or state. Siemens AG 610.40 700.21...

- Page 4 This device and its components may only be used for the applications described in the catalog or technical description, and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens. This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

-

Page 5: General Safety Instructions

All safety instructions in the associated product documentation must be observed and given to the end user for his/her information. This declaration contains no condition and durability guarantee to § 443 BGB. The operating manual applies in conjunction with the SIEMENS Configuration Manual, see table. Configuration Manual... -

Page 6: Product Information

Scope of delivery The drive systems are arranged individually. Immediately upon receipt of delivery, check whether the scope of delivery corresponds with the consignment notes. SIEMENS cannot accept any liability for any shortages or deficiencies reported at a later date. -

Page 7: Technical Data

ENGLISH Technical data Rating plate Fig. 1 Rating plate SIEMENS motor type / designation Zero-speed current I IID No., production number Temperature class Zero speed torque M [Nm] Degree of protection Rated torque M [Nm] Encoder version Encoder type Bar code... -

Page 8: Features

- I2048S/R = incremental encoder sin/cos 1 V 2048 S/R - AM2048S/R = absolute value encoder EnDat - AM512S/R = absolute value encoder EnDat - AM32S/R = absolute value encoder EnDat - AM16S/R = absolute value encoder EnDat - resolver 610.40 700.21 Siemens AG... -

Page 9: Transport, Installation And Assembly

Use lifting eyes for transporting the motors where these are provided by the manufacturer. Lifting tackle as per 98/37/EU Directive for Machines, Appendix I. The motor weight is indicated on the rating plate. Fig. 2 Lift and transport with suspension bands Siemens AG 610.40 700.21... -

Page 10: Installation

Nm 1FK701. 4 (d2 = 8) 1FK702. 5 (d2 = 9) 1FK703. 6 (d2 = 11) 1FK704. 6 (d2 = 11) 1FK706. 8 (d2 = 15) 1FK708. 10 (d2 = 18) 1FK710. 12 (d2 = 20) 610.40 700.21 Siemens AG... -

Page 11: Electrical Connections

Only use trained, qualified personnel for assembly work on the converters and plugs. Observe the regulations for working in electrotechnical plants. Do not plug or unplug any connectors unless they are in a de- energized condition. Siemens AG 610.40 700.21... - Page 12 Do not touch the connections with your hands or tools which could be electrostatically charged! Pre-assembled cables from SIEMENS are recommended (not included in scope of delivery). These cables reduce the assembly time and increase operational safety (see project planning instructions).

-

Page 13: Plug Design

P Sense M Sense conn. M Sense clock conn. clock* conn. -1R2 -1R2 +1R1 +1R1 not conn. conn. conn. conn. M-Encoder not connected not connected M-Encoder Fig. 5 Connection configurations and pin assignment of the connectors Siemens AG 610.40 700.21... - Page 14 Maximum permissible twisting moments M Plug Motor Plug size 1FK701. = 5 Nm Power plug 1FK702. - 1FK7100 = 12 Nm 1FK7101 - 1FK7105 = 20 Nm Signal plug 1FK7. = 12 Nm 610.40 700.21 Siemens AG...

-

Page 15: Motors With Drive-Cliq Interface

Fig. 7 Motor with sensor modul (example) The signal link between motor and converter is made by a DRIVE-CLiQ cable MOTION- CONNECT. Only SIEMENS pre-assembled cables may be used. These cables reduce the assembly time and increase operational safety. The plug of the DRIVE-CLiQ cable must be pushed on until the catch springs slot in, pay attention to the plug coding. -

Page 16: Commissioning

The temperatures of motor surfaces can reach more than 100 °C (212 °F). Do not touch hot surfaces! Protection must be provided against accidental contact if necessary. Temperature-sensitive components (electric lines, electronic components) must not touch hot surfaces. 610.40 700.21 Siemens AG... -

Page 17: Checks Before Starting Up

(see type plate for details). The maximum permissible speed is the highest permissible, short-term operating speed. 10. The fitted temperature sensor cannot cater for all possible faults (note the instructions in the Configuration Manual). Siemens AG 610.40 700.21... -

Page 18: Instructions In Case Of Faults

In this connection, please also refer to the relevant section of the operating manual for the components of the entire drive system. Do not disable the protective devices, even in trial operation. Consult the manufacturer or the SIEMENS service center when necessary. For start up, system motor converter: A&D Hotline +49 180 50 50 222... -

Page 19: Inspection, Maintenance, Disposal

Not mixed with solvents, cold cleaning agents of remains of paint Components that are to be recycled should be separated according to: -. Electronics waste (e.g. sensor electronics, sensor modules) -. Iron to be recycled -. Aluminum -. Non-ferrous metal (gearwheels, motor windings) Siemens AG 610.40 700.21... - Page 20 ENGLISH 610.40 700.21 Siemens AG...