Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pentair AURORA 1082PF

- Page 1 INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part # A-03-343 | © 2013 Pentair Ltd. | 02/18/13...

-

Page 2: California Proposition 65 Warning

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 IMPORTANT NOTE TO INSTALLER: 1. Be appropriately trained for the task to be performed. This manual contains important information about the 2. Be familiar with the work safety and accident prevention regulations. installation, operation and safe use of this product. -

Page 3: Functional Description

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 Transporting the plate heat exchanger: MANAGER’S OBLIGATIONS: Before transporting the plate heat exchanger, always ensure that the hoisting CAUTION gear is of sufficient dimensions and securely fixed. Never step underneath suspended loads. Danger of injury! Hazardous flow media: Hazardous flow In the case of hazardous media (acids or similar media), high... -

Page 4: Intended Purpose

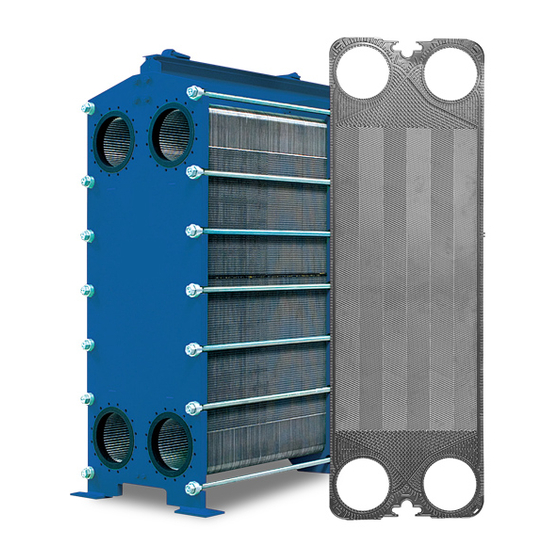

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 Usually single-pass plate heat exchangers are used (shown below). In the case of single-pass plate heat exchangers, all feed and return pipes are connected to the fixed pressure plate. Close temperature differences between the media may demand the use of multipass plate heat exchangers. - Page 5 ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 The pipe connections can be attached to the fixed pressure plate system resulting in “leak ports”. These leak ports divert the or to the loose pressure plate. The pipe connections on the fixed leaking fluid to the outside via gaps in the gasket webs (leak and pressure plate are positioned as follows: grooves), and thus make leakages identifiable immediately.

-

Page 6: Installation

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 the damage in the transport documents and have it receipted by LIFTING AND TRANSPORTING A HEAT EXCHANGER the supplier. Please take a photograph of the damage and report WITH A CY FRAME. Follow the instructions supplied with it to us immediately. -

Page 7: Operation

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 COMMISSIONING, DECOMMISSIONING AND NOTE: If faults occur during commissioning the plate heat OPERATION: exchanger, see the Troubleshooting section. In order to avoid clogging problems during commissioning the plate heat exchanger, Aurora strongly recommends filters or bypasses for CAUTION the first flushing of the piping system. -

Page 8: Long-Term Shutdown

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 LONG-TERM SHUTDOWN. Danger: Danger of Falling Over During Stacking Danger: Premature Component Wear In the case of uncontrolled The components of the heat exchanger can prematurely stacking, the heat exchanger wear due to unfavorable ambient conditions or by flow plates can tumble. - Page 9 ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 1. Release the nuts of the tightening bolts Danger: on the pressure plate. Damage to the a. Release the tightening bolts Heat Exchanger Plates! evenly in small steps on alternate sides (1-2- 3-4) and diagonally If the heat exchanger is tightened to (1-2 and 3-4), in order to prevent an a-dimension that is less than the...

- Page 10 ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 CLEANING THE HEAT EXCHANGER. Danger: Leakage CLEANING THE PLATES OF THE CLOSED PLATE HEAT EXCHANGER. Deposits on the heat exchanger plates impair Hard cleaning tools (e.g. brushes with metal bristles) can the heat transfer between the media, increase the pressure damage the surface of the heat exchanger plates and the loss and can cause or accelerate heat exchanger plate corrosion.

- Page 11 ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 REPLACING THE GASKETS. The gaskets can be either MAINTAINING THE FRAME. attached without adhesive by fitting the studs on the back of the gasket flaps into the corresponding extruded holes, or fixed Danger: with adhesive into the gasket grooves.

- Page 12 ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 INSTALLATION TROUBLESHOOTING GUIDE Fault Possible Cause Remedy Leak between the HE plates. Inadequate or excessive • Compare the actual compression with the compression compression dimension of the dimension on the data plate, and correct as needed. heat exchanger.

-

Page 13: Technical Terms

ITEM A-03-343 DATED NOVEMBER 2012 SUPERCEDES MARCH 2011 TECHNICAL TERMS Term Explanation BY frame. An especially stable frame design, which also allows a high number of heat exchanger plates. Backflushing. A cleaning process in which the direction of flow is reversed. Reversing the direction of flow flushes the particles of contamination from the heat exchanger. - Page 14 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 15 THIS PAGE INTENTIONALLY LEFT BLANK...

-

Page 16: Warranty

WARRANTY Seller warrants equipment (and its component parts) of its own manufacture against defects in materials and workmanship under normal use and service for one (1) year from the date of installation or start-up, or for eighteen (18) months after the date of shipment, whichever occurs first.