Table of Contents

Advertisement

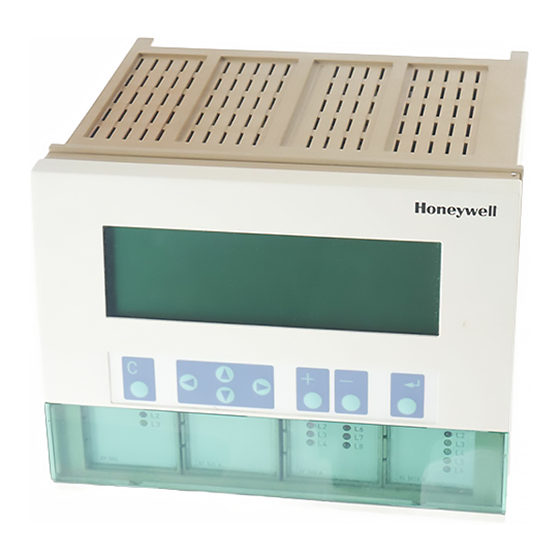

HONEYWELL EXCEL 5000 OPEN SYSTEM

Revision Overview ....................................................................................................................................................................... 3

Safety Instructions ....................................................................................................................................................................... 4

MOUNTING .................................................................................................................................................................................... 5

Electrical Connections ............................................................................................................................................................... 16

® U.S. Registered Trademark

Copyright © 2013 Honeywell Inc. • All Rights Reserved

Control Unit Installation ............................................................................................. 5

Excel 500/600 Housing Layout (not XCL5010) ......................................................... 5

Excel 500/600 Internal Bus Wiring (not XCL5010).................................................... 5

Module Locations (not XCL5010) ............................................................................. 6

Coding the Terminal Block (not XCL5010) ............................................................... 6

Setting the Module Address (not XCL5010) ............................................................. 7

Installation Inside a Control Panel ............................................................................ 7

Excel 500/600 ...................................................................................................... 7

XCL5010 .............................................................................................................. 8

XDL505 Application Module ................................................................................. 9

Installation through a Control Panel Door (not XCL5010) ......................................... 9

External Installation of XI582 .................................................................................. 10

Backlight ................................................................................................................. 11

Distributed I/O Installation ....................................................................................... 11

Dimensions ............................................................................................................. 12

Excel 500/600 .................................................................................................... 12

XCL5010 ............................................................................................................ 13

XI582 .................................................................................................................. 14

Battery Activation during Commissioning (XC6010, only) ....................................... 14

Replacing the Battery ............................................................................................. 15

Dismantling the Control Panel Unit ......................................................................... 15

Dismantling the Control Panel Door Unit ................................................................ 15

Dismantling the Housing Cover .............................................................................. 15

Dismantling the XCL5010 CPU .............................................................................. 16

Dismantling the XI582 Operator Interface ............................................................... 16

Cable Routing ......................................................................................................... 17

Shielding I/O Module, Power Supply Cables .......................................................... 17

Shielding of Data-Transmitting Cables ................................................................... 17

Grounding (XC5010C / XC6010, only) .................................................................... 17

System Ground ....................................................................................................... 17

RFI Suppression ..................................................................................................... 17

XC5010C/XC6010 Cable Lengths and Sizes ......................................................... 17

Lightning Protection ................................................................................................ 17

Summary of Internal Modules ................................................................................. 18

Line Power Supply ............................................................................................. 19

Excel 500/600

CONTROL SYSTEM

INSTALLATION INSTRUCTIONS

CONTENTS

EN1R-1047GE51 R0913

Advertisement

Table of Contents

Summary of Contents for Honeywell Excel 500

-

Page 1: Table Of Contents

Safety Instructions ..................................4 MOUNTING ....................................5 Control Unit Installation ..................... 5 Excel 500/600 Housing Layout (not XCL5010) ............5 Excel 500/600 Internal Bus Wiring (not XCL5010)............ 5 Module Locations (not XCL5010) ................6 ... - Page 2 EXCEL 500/600 - INSTALLATION INSTRUCTIONS XC6010 Computer Module ................. 19 XC5010C CPU Module ..................20 XP502 Power Supply Module ................21 RIN-APU24 Uninterruptable Power Supply ............21 XF521A Analog Input Module ................21 XF526 Analog Input Module................22 ...

-

Page 3: Revision Overview

EXCEL 500/600 - INSTALLATION INSTRUCTIONS REVISION OVERVIEW On the following pages, changes have been made compared to the previous release of this document: Page: Change: Correction of Fig. 70. EN1R-1047GE51 R0913... -

Page 4: Safety Instructions

Risk of electric shock! Disconnect the power supply Installation Instructions are to be observed. before you start to install the Excel 500/600 Controller and do not reconnect the power supply until you have — The Excel 500/600 controller may be installed and completed installation. -

Page 5: Mounting

EXCEL 500/600 - INSTALLATION INSTRUCTIONS MOUNTING Control Unit Installation The Excel 500 and 600 controllers have the same housing and can be installed two different ways: — Installation inside a control panel (see page 7). — Installation through a control panel door (see page 9). -

Page 6: Module Locations (Not Xcl5010)

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Table 1. Internal module locations CAUTION module type module location Incorrectly inserted bus cables can destroy the modules installed. XC5010C / housing, location 4 XC6010 The internal bus begins at the first housing, containing the... -

Page 7: Setting The Module Address (Not Xcl5010)

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Setting the Module Address (not XCL5010) CAUTION In the case of an application prior to CARE 4.0, you can set Unplugging a module before switching OFF the power the module address using the rotary HEX switches located on supply could destroy the module. -

Page 8: Xcl5010

Fig. 13. 5. Plug in the enclosure. Fig. 13. Housing locking screws and latches Fig. 15. Excel 500/600 extended wiring base Using the extended wiring base the I/O terminals are accessible at run-time. 6. Shift latches inwards until the housing is released. -

Page 9: Xdl505 Application Module

EXCEL 500/600 - INSTALLATION INSTRUCTIONS 1, Prepare the door in accordance with the following. dimensions. Fig. 19. Panel door mounting dimensions Fig. 17. Mounting XCL5010 on DIN rail (b) 2. Insert the housing. XDL505 Application Module CAUTION Always plug in the application module before connecting the power supply. -

Page 10: External Installation Of Xi582

EXCEL 500/600 - INSTALLATION INSTRUCTIONS 2. Route cable from the CPU module (XC6010, XC5010C, XCL5010). TxD(CPU) YELLOW BROWN RxD(CPU) GREEN WHITE Fig. 22. Installing the wiring base 7. Complete electrical wiring. 8. Lock the cover. Fig. 25. Routing the cable 3. -

Page 11: Backlight

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Fig. 27. Attaching to wall Fig. 29. Reattaching cover Backlight 5. Make electrical connections (black/gray wire not used). The contrast of the display can be adjusted, using a screw- driver, by rotating the corresponding knob accessible through... -

Page 12: Dimensions

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Dimensions Excel 500/600 Fig. 31. Excel 500/600 outside dimensions EN1R-1047GE51 R0913... -

Page 13: Xcl5010

EXCEL 500/600 - INSTALLATION INSTRUCTIONS XCL5010 Fig. 32. XCL5010 dimensions EN1R-1047GE51 R0913... -

Page 14: Xi582

EXCEL 500/600 - INSTALLATION INSTRUCTIONS XI582 WALL DESK CABLE HOLE Fig. 33. XI582 dimensions Battery Activation during Commissioning (XC6010, only) The controller is delivered from the factory with the battery in the CPU module electrically isolated from the internal circuitry by a safety tag to prevent the battery from discharging in transit. -

Page 15: Replacing The Battery

EXCEL 500/600 - INSTALLATION INSTRUCTIONS NOTE: In the event that your fingers touch the battery contacts, please clean the contacts with cleaning agent. 1. Unscrew the CPU module cover with a screwdriver as shown in the previous section. 2. Release the latch holding the battery in its compartment (See Fig. -

Page 16: Electrical Connections

EXCEL 500/600 - INSTALLATION INSTRUCTIONS 1. Dismantle the controller housing as depicted. 2. Pull the lower part of the housing off the control panel. 3. Lift the housing from DIN rail. Dismantling the XI582 Operator Interface Remove the front cover from the XI582 by inserting tip of an awl (or a similar narrow, pointed object) into the small hole on one side of the operator terminal. -

Page 17: Cable Routing

NOTE: A document providing additional information on system grounding (if required) is available via the To comply with CE requirements, devices with a Honeywell Technical Assistance Center (TAC) or, for voltage in the range of 50...1000 Vac or Honeywell employees, on the Docu Server under: 75...1500 Vdc which are not provided with a supply... -

Page 18: Summary Of Internal Modules

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Summary of Internal Modules Table 4. Summary of Excel 500/600 internal modules module name inputs outputs manual override switches LED display Service LED ORKS C-Bus transmit C-Bus receive Reset button normal CPU module XC5010C service button... -

Page 19: Line Power Supply

A separate CRT 6 or 1450 series (U.S.) transformer must be Do not unplug the CPU module with the power still used for each of the EXCEL 500/600 controller's 24 V connected, since this could destroy the module. First, supplies. -

Page 20: Xc5010C Cpu Module

CPU module printed circuit board. This submodule Fig. 47. Excel 500 CPU module pin-out must be installed when joining several controllers or when The system bus is connected to terminal 16 (C+) and terminal monitoring via a central. -

Page 21: Xp502 Power Supply Module

Further, in the case of the XCL5010, the RIN-APU24 can provide power directly (i.e. without recourse to an XP502). In Fig. 48. Excel 500 CPU module front panel this case, no distinction need be made between controllers The operator interface on the front of the CPU modules... -

Page 22: Xf526 Analog Input Module

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Table 7. Accuracy of analog input sensors measurement error (without sensor tolerance) range PT1000 NTC 20K -58...-4 °F (-50...-20 °C) ≤ 1.2 K ≤ 5.0 K -4...+32 °F (-20...0 °C) ≤ 0.7 K ≤ 1.0 K +32...86 °F (0...30 °C) -

Page 23: Xf523A Digital Input Module

(default), the LED will illuminate when energized (normally- open contacts). In the OFF position, the LED will illuminate when de-energized (normally-closed contacts). Max. signal voltage from non-Honeywell voltage sources: DC Voltage: V = 40 V = 28 V / 50 Hz... -

Page 24: Xf522A And Xf527 Analog Output Modules

EXCEL 500/600 - INSTALLATION INSTRUCTIONS If the inputs are used as totalizers, Table 8 applies. Table 8. Totalizer inputs specifications input frequency pulse duration pulse internal chatter time 1, 2 max. 15 Hz min. 20 ms min. 33 ms max. 5 ms 3 to 12 max. -

Page 25: Xf525A Three-Position Output Module

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Table 9. NO/NC attribute and output characteristic XCL5010 NOTE: The XCL5010 has Pollution Degree 2, making it relay ON/OFF NO/NC attribute logical status suitable for use in residential controls, commercial controls, in a clean environment, or non-safety controls for installation on or in appliances. -

Page 26: Mmi Connection

EXCEL 500/600 - INSTALLATION INSTRUCTIONS max. 170 m Table 10. Signals of serial port min. 0.75 mm 2 signal type controller output controller input Y (0...10 Vdc) signal ground transmit PRIMARY VOLTAGE receive 24 Vac carrier detect TRANSFORMER clear to send... -

Page 27: Screw Terminal Block Installation Procedure

600 mA IMPORTANT -004 240/220 Vac 24 Vac, 50 VA The transformer feeding the Excel 500 Controller must be in the same cabinet. For the selection of the 2 x 24 Vac, 40 VA and 100 VA -005 240/220 Vac transformer, the max. - Page 28 EXCEL 500/600 - INSTALLATION INSTRUCTIONS Fig. 66. Connecting to a screw terminal IMPORTANT Fig. 67. Attaching screw terminal block If there already are additional transformers, for example supplying actuators or active sensors, connect the 24 Vac (-) (secondary side) of the Table 14.

-

Page 29: Pull-Up Resistor Handling

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Pull-Up Resistor Handling Case 1 Case 2 Case 3 10 V 10 V Ω Ω Ω 24.9 k 24.9 k 18.2 k (pull-up) (pull-up) (pull-up) kΩ kΩ kΩ 49.9 kΩ 49.9 kΩ kΩ Fig. 68. Input circuit diagram Table 15. - Page 30 T7560C1006 Combined Room Temp. / Humidity Sensor or H7012B1023 Room Humidity Sensor 20...95% relative humidity 0..10 V = 0...100% Table 17. Room Temperature Sensors suitable for use with Excel 500/600 (external transducer not required) characteristic in controller sensor type range...

-

Page 31: Communications

LC-MV-1xPT1000.0-400°C: converts AGF1 0...10 V = 0…400 °C PT1000 to 0…10 V: order from: www.rinck- electronic.de Table 20. Differential (+ Static Duct) Pressure Sensor suitable for use with Excel 500/600 (no external transducer required) characteristic in controller sensor type range... -

Page 32: Lon Works Bus Termination

Up to 30 controllers can communicate with one another and a The max. communication speed of the XC5010C/XCL5010 is PC central via the system bus. Instead of an Excel 500 / 600 / 76800 baud. The XC5010C/XCL5010 can be mounted 800 controller, other system bus compatible components can also be connected. -

Page 33: System Bus Cable Specification

EXCEL 500/600 - INSTALLATION INSTRUCTIONS C-Bus Termination (XC6010) NOTE: When changing the baud rate of bus devices, proper The XC6010 CPU module may have either the XD505A or communication cannot be ensured until all bus the XD508 submodules mounted on them for C-Bus devices are set to the same baud rate again. -

Page 34: Xc6010 Cable Specifications

EXCEL 500/600 - INSTALLATION INSTRUCTIONS Table 28. DIP switch settings for C-Bus termination (XCL5010) to XC5010C SHIELD XI582 DIP switch communication controller com- setting speed location patibility XD505A, max. 9.6 Kbaud XL20XD middle of XD508, middle max. 76.8 Kbaud XL20XD508... -

Page 35: Xcl5010 Cable Specifications

XC5010C XW585 Fig. 80. Excel 500 and Excel 600 used together with XL-Online PC MMI and XI582 Operator Interfaces NOTE: XI582 units supplied with XW882 cable (for Excel 800 controllers) need an XW884 adapter in order to be connected with the XC5010 and XCL5010 CPU. - Page 36 EXCEL 500/600 - INSTALLATION INSTRUCTIONS Fig. 81. XW584 cable details EN1R-1047GE51 R0913...

-

Page 37: Remote Communications

Modem must support alpha-numeric return codes Modem must follow serial baud rate of the CPU Fig. 82. Serial port locations on Excel 500 Modem must support auto-bauding (baud rate fall-back) When carrier detect (connect) is reported, the carrier must... -

Page 38: Automatic Baudrate Synchronization

Windows™ terminal program. Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative: Automation and Control Solutions Honeywell GmbH Böblinger Strasse 17...