Summary of Contents for Nanni QMS 32T

- Page 1 MARINE GENERATING SET INSTRUCTION MANUAL MU_GE_970315535_ENG QMS 32T QMS 39T QLS 32T QLS 39T QLS 47T...

-

Page 3: Table Of Contents

Contents Safety precautions ........................3 Presentation ..........................6 Fuel supply ............................6 Environmental responsibility......................6 Spare parts ............................6 Identification numbers ........................7 About the generator.........................7 Checks before commissioning ......................7 Principal parts of the generating set .....................8 Instrument panel ...........................10 Technical characteristics ......................11 Operation of the generating set ....................12 Before starting ............................12 Starting the generating set ........................12 During operation ...........................13... -

Page 4: Safety Precautions

Some work requires specific knowledge and equipment. This work should be carried out by Nanni Diesel authorised per- Indicates where to check the coolant sonnel or by a professional. If you have to work on the... - Page 5 Safety precautions I Exhaust gas If you come into contact with any of these fluids, consult a doctor immediately. Exhaust gases contain carbon monoxide. This colour- If the generating set gets too hot, switch it off and dis- less and odourless gas is extremely harmful and could connect it and wait for it to cool down before handling.

- Page 6 The acid in batteries can cause serious injury and even tinues to function optimally. death! These parts can be ordered from all Nanni Diesel deal- When servicing the batteries, wear protective gloves ers throughout the world. and goggles. Batteries contain sulphuric acid which is highly corrosive.

-

Page 7: Presentation

You can order the emergency parts below from any parts. Nanni Diesel authorised dealer. Keep a copy of the list of parts with the set. All the information and specifications in this manual are... -

Page 8: Identification Numbers

Presentation Identification numbers Checks before commissioning Your generating set has 2 identification plates: one for I Caution! : Your generating set must be installed by a the engine and one for the generator. shipyard or authorised representative following the on- board assembly instructions. -

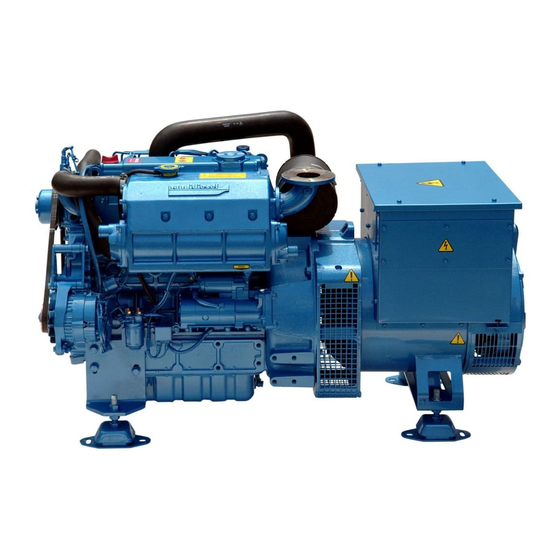

Page 9: Principal Parts Of The Generating Set

Presentation Principal parts of the generating set (QLS32T-QMS32T) Some equipment may not be part of your generating set. The model represented hereafter is a QLS32T. Only the generator is different on the QMS32T. 1. Engine alternator 11. Oil filter 2. Engine alternator belt 12. - Page 10 Presentation Principal parts of the generating set (QLS39T - QMS39T - QLS47T) Certain equipment may not be part of your generating set. The model represented hereafter is a QLS32T. Only the generator is different on the QMS32T and the QLS44T. 1.

-

Page 11: Instrument Panel

The instrument panel allows you to start and stop the generating set, and provides you with important information when the generating set is under operation. Check this informations regularly while operating the generating set. Contact an authorized Nanni Diesel dealer if your generating set is equipped with instruments different than those described in this chapter. -

Page 12: Technical Characteristics

Technical specifications ELECTRICAL CHARACTERISTICS QMS32T QLS32T QMS39T QLS39T QLS47T Continuous / Max power (kW)* 23.2 / 25.5 23.4 / 25.7 28.4 / 31.3 28.5 / 31.2 34.4 / 37.8 Volts / Number of phases 400 / 3 Continuous / maxi current (A) 41.9 / 46 42.2 / 46.4 51.2 / 56.5... -

Page 13: Operation Of The Generating Set

Operation of the generating set Before starting Starting the generating set I Caution! : On a soundproof generating set, the lo- Caution! : Before starting, ensure that the seacock cal/remote selector must be in remote position to start is open as the seawater pump rotor can be damaged if the generating set using the instrument panel. -

Page 14: During Operation

Nanni Diesel authorised dealer. generating set and always close the seacock to prevent the generating set from accidentally filling with seawa-... -

Page 15: Maintenance

Europe (according to the DIN EN 590 standard: a lower quality fuel will result in poor is carried out by a Nanni Diesel authorised dealer. However, some regular checks, particularly those made combustion, which may cause starting problems and each time the engine is used, can only be made by the heavy smoke emissions. -

Page 16: Daily Checks

Maintenance Air filter Daily checks I Attention! Carry out these operations when the Regularly check the condition of the generating set and its compartment before and after it is used: check for generating set is stopped and cold. the presence or not of fuel or oil leaks, the tightness of The air filter essentially reduces the level of noise the different clamps and bolts, the condition of the belts, made by the engine and purifies the air injected into... -

Page 17: Fuel System

Maintenance Fuel system I Warning! : Total cleanliness must be guaranteed • Untighten the drain valve screw to release the air. when working on the fuel circuit. No impurities must en- Open the fuel valve again and drain the circuit. ter the injection pump and the injectors. -

Page 18: Lubrication System

Maintenance Lubrication system Checking the oil level Replacing the oil filter cartridge I Caution! : Carry out these operations with the en- I Caution! : Carry out these operations with the engine gine stopped. Hot oil and hot surfaces can burn. stopped. -

Page 19: Cooling System - Coolant

Maintenance Cooling system - Coolant Coolant filling The cooling system enables the engine to operate at an optimal temperature. Attention! : Do not check the coolant level when In the case of a cooling by closed heat exchanger, the the engine is hot. Pressurised coolant can spurt and coolant is cooled by sea water passing through the ex- cause serious burns. -

Page 20: Cooling System - Seawater

Maintenance Cooling system - Seawater I Caution! : When the craft is in the water, there is a Replacing the seawater pump rotor risk of water penetrating the craft when working on the The seawater pump rotor is an essential component. It seawater circuit. -

Page 21: Engine Electrical System

I Caution! : Some parts of the generating set can be We recommend that you have all these operations extremely hot. carried out by a Nanni Diesel authorised workshop. Check the belt tension by pushing down at midpoint be- If the engine is likely to be subjected to freezing tem- tween the drive pulley and the alternator pulley. -

Page 22: Installation Recommendations

Your generating set is cooled by a coolant passing mendations and guidelines for installing a Nanni Diesel through the different parts of the engine. It may also be generating set. Certain equipment may not be part of fitted with a heat exchanger cooled by seawater which, your order or installation. -

Page 23: Troubleshooting

Some operations must be carried out by a qualified Nanni Diesel authorised engineer. These operations are marked in bold in the tables below. This non-exhaustive list serves as a tool in emergencies and should never be considered a repair procedure. Some of the components listed may not be part of your engine. - Page 24 Troubleshooting Faults and probable causes Engine overheats / Engine coolant temperature too high Faults Solution Seacock is closed Open the Seacock Seawater filter is clogged Close the Seacock and clean the filter Check the position and seal of the seawater filter cover Seawater pump is sucking air and the suction hose Fresh water circuit pump belt is slack or faulty...

- Page 26 NaNNi iNdustries s.a.s. 11, Avenue Mariotte 33260 La Teste France Tel: +33 (0)5 56 22 30 60 Fax: +33 (0)5 56 22 30 79 www.nannidiesel.com...