Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Denso RC8

- Page 1 DENSO ROBOT RC8 CONTROLLER ELECTRIC GRIPPER CONTROL BOARD USER'S MANUAL...

- Page 2 Copyright © DENSO WAVE INCORPORATED, 2013-2016 All rights reserved. No part of this publication may be reproduced in any form or by any means without permission in writing from the publisher. Specifications are subject to change without prior notice. All products and company names mentioned are trademarks or registered trademarks of...

-

Page 3: Table Of Contents

Preface ........................... 1 FOR SAFE USE........................2 2.1. CAUTION ........................3 2.1.1. General ........................3 2.1.2. Design ........................3 2.1.3. Operating Environment ................... 4 2.1.4. Installation ....................... 4 2.1.5. Operation ........................ 4 2.1.6. Maintenance and Inspection ................... 5 2.2. WARNING ........................5 2.2.1. - Page 4 4.1.5. Installation ......................15 4.1.6. Electric Gripper and Wiring to Control Board ............16 4.1.7. Connecting to Power Supply ................20 4.1.8. Grounding Work ....................21 4.1.9. Emergency Stop wiring Connection ..............21 4.1.10. Prevention of Malfunction by Noise ..............22 4.1.11.

-

Page 5: Preface

Preface Thank you for purchasing our DRH-ESG1 Series Electric Gripper. This operation manual contains information necessary to use the DRH-ESG1 Series. Be sure to read the respective operation/instruction manuals for the electric gripper, electric gripper control board, and electric gripper command to gain a firm understanding of their content before use. -

Page 6: For Safe Use

FOR SAFE USE Cautionary descriptions given here are for correct use of the products and for prevention of hazard on you and other people in vicinity and damage with equipment. These descriptions are divided into three items of “DANGER”, “WARNING” and “CAUTION” depending on the severity of hazard or damage and level of imminence. -

Page 7: Caution

Mishandling of the product poses a risk. Please read the respective operation/instruction manuals for the electric gripper, electric gripper control board, and electric gripper command. • It is the user’s responsibility to verify and determine the compatibility of this product with the user’s system, and to use them properly. -

Page 8: Operating Environment

We can provide a specially designed gripper which mechanism maintains gripping force in the event of power-loss, as a special specification. Please contact our sales representatives if you would like to order a such gripper. 2.1.3. Operating Environment • Do not use this product in a place exposed to ignitable, inflammable or explosive substances. -

Page 9: Maintenance And Inspection

2.1.6. Maintenance and Inspection • If the electric gripper is used integrated into a system (machine, robot, etc.), ensure that regulations and standards for safety measures are strictly observed, and use the product properly and safely. • Do not disassemble and reassemble the components relating to the basic structure of the product or its performance and function. -

Page 10: Installation

2.2.2. Installation • Provide an emergency-stop device in a readily accessible position so the device can be actuated immediately upon occurrence of a dangerous situation during operation. Lack of such device in an appropriate position may result in injury. • When installing the product including fingers, be sure to securely support and mount them. -

Page 11: Maintenance And Inspection

Always use the cable supplied with the product for connection between the electric gripper and electric gripper control board. • Use DENSO WAVE genuine products for main components such as electric gripper, electric gripper control board. 2.3.2. Working Environment •... -

Page 12: Fixing The Product

• Do not bring a floppy disk or other magnetic media within one meter of the product. The magnetic field generated by the magnet may destroy the data in the floppy disk, etc. 2.3.3. Fixing the Product • When handling the product, wear protective gloves, protective goggles, safety shoes, or other necessary gear to ensure safety •... -

Page 13: Storage Environment

2.3.6. Storage Environment The environment in which the gripper is stored must be: • Not exposed to direct sunlight and moisture • Be dark cool and 30 cm higher or more than the floor surface to prevent occurrence of dew condensation •... -

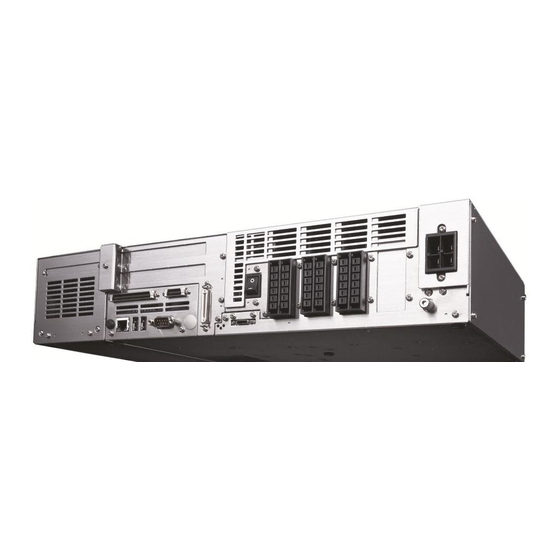

Page 14: Overview

3.2. Features • Robot controller (RC8) integration Surplus wiring between the gripper controller and robot controller has been eliminated by integrating the electric gripper control board into the robot controller (RC8). -

Page 15: System Configuration

3.3. System Configuration Electric gripper connection cable Note 1 Note 2 C connection (0.2 m) B connection (1 m) A connection (4 m, 6 m) B, C connection (4 m, 6 m) Electric gripper Electric gripper control board Robot controller (Ver.1.1.2 or later) Notes: 1. -

Page 16: Names And Functions Of Connectors And Leds

3.4. Names and Functions of Connectors and LEDs ③ ① ② ④ ⑤ ⑥ ⑦ Name Connector/LED Function Lights up (green) when the electric gripper power is ON. Lights up (yellow) when the electric gripper control board is functioning normally. Lights up (red) when an alarm occurs. -

Page 17: Handling Procedures And Cautions

Handling Procedures and Cautions 4.1. Installation and Connection with External Equipment Refer to the basic flowchart showing the process that contains identification, installation, wiring, trial operation, and actual operation of the purchased product. In this chapter, the procedure flow from identification to installation and wiring of the product is described. Flow from wiring procedure to operation Product check Electric gripper installation... -

Page 18: Handling The Packed Controller

4.1.1. Handling the Packed Controller CAUTION • Do not apply excessive impact on the package by dropping or hitting. • When setting down the package, keep it horizontal • Do not step onto the package. Do not place a heavy object that can deform the package on the package or article of •... -

Page 19: Storage Environment

4.1.5. Installation If the electric gripper control board is purchased individually, the customer is responsible for installing it in the robot controller. Refer to “Expansion Board Attachment” in the “RC8 Controller Optional Device Operation Manual” for details of the installation method. -

Page 20: Electric Gripper And Wiring To Control Board

4.1.6. Electric Gripper and Wiring to Control Board Use the electric gripper connection cables provided to wire the electric gripper and electric gripper control board. The wiring will differ depending on the robot controller connection type. WARNING Do not turn on the power while wiring the controller. •... - Page 21 B connection Connect as shown in the diagram below. Electric gripper connection cable (B connection) Electric gripper ENC CN21 connector MOT To CN21 Electric gripper connector Connection wires prepared by customer ENC Refer “Recommended Green: SLD Arrangement” for details of the pin Yellow-green:0V...

- Page 22 C connection Connect as shown in the diagram below. Electric gripper connection cable (C connection) To signal wiring connector Electric gripper (Open cover and connector connect.) Electric gripper Signal wiring connector (inside cover) Connection wires prepared by customer Refer to the guidelines of each robot for details on how to connect wires to connectors.

- Page 23 Electric gripper connection cable FG wire connection Connect as shown in the diagram below. Tightening torque: 0.6 N⋅m Electric gripper control board Electric gripper connection cable Robot controller front panel...

-

Page 24: Connecting To Power Supply

4.1.7. Connecting to Power Supply Power-supply voltage is as shown in the table below: Specification Power 24V DC±10 1A MAX Supply (motor power supply) Disconnect the connector from the electric gripper control board and connect the power supply wire. ■Power supply connector No. -

Page 25: Grounding Work

CAUTION • Take care not to connect the power supply incorrectly. Incorrect connection may result in a serious incident such as fire. There is no power switch on the electric gripper control board, and therefore a suitable shut-off device (insulated) capable of cutting the power to the entire unit must be installed. -

Page 26: Prevention Of Malfunction By Noise

4.1.10. Prevention of Malfunction by Noise CAUTION • Be sure to install a serge absorber circuit to a coil such as a relay, electromagnetic contacting machine, induction motor, and break solenoid. • Do not bundle the power supply line, motor line, and signal lines together or do not lay them in the same duct. - Page 27 Attaching a ferrite core to the B, C connection cable Attach the ferrite core as shown in the diagram below. Attach the ferrite core (small) provided as close as possible to the connector connected to the robot without trapping the cable, and then secure it with one of the tie bands (small) provided.

-

Page 28: Other Notice On Wiring

4.1.11. Other Notice on Wiring ① Wrong wiring Wrong connection to the electric gripper control board and the electric gripper may cause product damage. Thoroughly check for proper connection. ② Fuse There is a fuse in the electric gripper control board. The fuse is not for protecting the electric gripper control board itself but for preventing a secondary disaster in the case where the electric gripper control board damage was caused by earth fault. -

Page 29: Troubleshooting

4.2. Troubleshooting 4.2.1. If You Have a Problem with the Controller When you contact us for a problem with the controller, please provide the following information as exactly as possible. Item Details Model of electric gripper What has the problem? Number of electric gripper Date purchased When the problem occurred? - Page 30 Register the license. If the to the electric gripper not been done yet. registration has completed license is not provided, please screen contact to Denso Wave. Impossible to The electric gripper Confirm whether the electric Connect appropriate electric operate the electric...

-

Page 31: Specifications

Specifications Item Specification Number of 1 axis control axes Position detection Optical rotary encoder method Axis control Minimum 0.01mm setting distance Speed setting Set to 10 – 100% of parameter maximum speed. Gripping force Set to 30 – 100% at point data. setting Protective function (alarm) See “Alarm Messages”, “Error Messages”. - Page 32 Please feel free to send your comments regarding any errors or omissions you may have found, or any suggestions you may have for generally improving the manual. In no event will DENSO WAVE INCORPORATED be liable for any direct or indirect damages resulting from the application of the information in this manual.