Table of Contents

Advertisement

Installation and Maintenance Manual

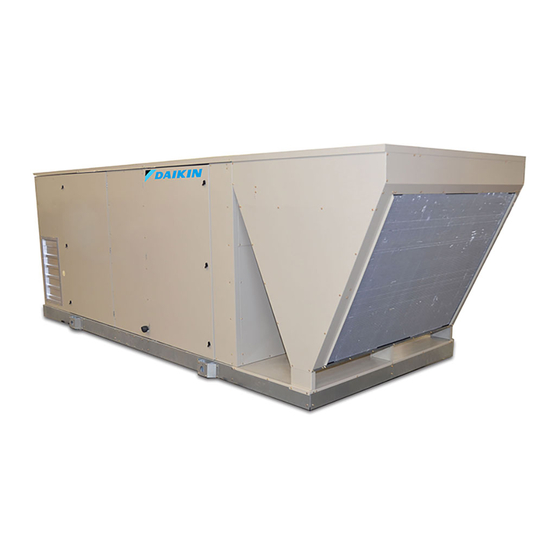

Rebel

Commercial Packaged

™

Rooftop Systems

Heating and Cooling

Models DPS003 – 028A

R-410A Refrigerant

MicroTech

III Unit Controller

®

Energy Recovery Wheel

3–6 tons

16–28 tons

Shown with Energy Recovery

IM 1125-7

Group: Applied Air Systems

Part Number: IM 1125

Date: November 2015

7–15 tons

Shown with Energy Recovery

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Daikin DPS005

- Page 1 Installation and Maintenance Manual IM 1125-7 Group: Applied Air Systems Part Number: IM 1125 Date: November 2015 Rebel Commercial Packaged ™ Rooftop Systems Heating and Cooling Models DPS003 – 028A R-410A Refrigerant MicroTech III Unit Controller ® Energy Recovery Wheel 3–6 tons 7–15 tons Shown with Energy Recovery...

-

Page 2: Table Of Contents

Daikin Tubular Heater Series . . . . . . . . . . . . . . . . . . -

Page 3: Introduction

This manual provides general information about the “A” The unit nameplate is located on the outside of the main vintage Daikin Rebel Commercial Packaged Rooftop Unit, control box door. It includes the unit model number, serial model DPS. In addition to an overall description of the unit, number, electrical characteristics, and refrigerant charge. -

Page 4: Mechanical Installation

Allow service clearances as approximately indicated in Figure 1. Also, Daikin recommends providing a roof walkway to the The installation of this equipment shall be in accordance rooftop unit as well as along each side of the unit that provides access to most controls and serviceable components. - Page 5 eChanICal nsTallaTIon Figure 1: Service Clearances Small Cabinet Medium Cabinet 003—006 007—015 Exhaust Exhaust 50 .00 50 .00 Fan Access Fan Access (1270 mm) (1270 mm) Outdoor Air Outdoor Air 17.00 (431 mm) 21.00 (533 mm) Hood Hood Filter Filter Access Access 60 .00...

-

Page 6: Overhead Clearance

eChanICal nsTallaTIon Overhead Clearance Roof Curb Assembly and Installation 1 . Unit(s) surrounded by screens or solid walls must have WARNING no overhead obstructions over any part of the unit. For Mold can cause personal injury . Some materials such heat pump models overhead obstructions could allow the as gypsum wall board can promote mold growth when formation of dangerous ice cycles. - Page 7 eChanICal nsTallaTIon Figure 2: Roof Curb Assembly (DPS 003—006) LEFT SIDE BACK SIDE 28.69 INSIDE 9.84 INSIDE 28.76 INSIDE 9.64 INSIDE 44.24 61.50 RIGHT SIDE FRONT SIDE NOTE: 1. Check submittal drawing for gas/water/electrical/supply/return air opening DPS 003–006 Roofcurb with ERW Certifi ed Drawing Horizontal above the roof gas connection only Model: DPS McQuay International certifi es that its equipment will conform to this drawing and McQuay’s...

- Page 8 eChanICal nsTallaTIon Figure 3: Roof Curb Assembly (DPS 007–015) BACK SIDE LEFT SIDE SUPPLY RETURN RIGHT SIDE FRONT SIDE DPS 007–012 Roofcurb with ERW Certifi ed Drawing Model: DPS McQuay International certifi es that its equipment will conform to this drawing and McQuay’s published specifi cations, subject to its published warranty.

- Page 9 eChanICal nsTallaTIon Figure 4: Roof Curb Assembly (DPS 016–028) BACK SIDE LEFT SIDE SUPPLY RETURN RIGHT SIDE FRONT SIDE NOTE: 1. Check submittal drawing for gas/water/electrical/supply/return air opening 2. Horizontal above the roof gas connection only 3. All dimensions in inches Standard Roof Curb –...

-

Page 10: Rigging And Handling

eChanICal nsTallaTIon Rigging and Handling Figure 5: Rigging Label 003–015 WARNING LIFT ONLY AS SHOWN Only trained and qualified personnel should be allowed to rig loads or operate load rated cranes and/or hoist USE SPREADER BAR assemblies. Do not use a forklift to lift or maneuver the unit. - Page 11 eChanICal nsTallaTIon Table 2: Physical Data—Unit Weights DPS 003 through 028 Small Cabinet Medium Cabinet Model Weight (lbs .) Base Weight 1000 1000 1025 1058 1600 1600 1600 1763 Heat pump 1030 1030 1058 1058 1660 1660 1660 1823 Electric Heat Hot Water 2 Row 16 .5 Hot Water 1 Row...

-

Page 12: Unit Piping - Condensate Drain Connection

eChanICal nsTallaTIon Unit Piping - Condensate Drain Connection Damper Assemblies The optional damper assemblies described in this section WARNING are ordered with factory-installed actuators and linkages. The following sections describe the operation and linkage Drain pans must be cleaned periodically . Material in adjustment of the factory option. -

Page 13: Cabinet Weather Protection

5 . Use a static pressure tip (Dwyer A302 or equivalent) or On vertical-supply/vertical-return units, if a Daikin roof curb the bare end of the plastic tubing for the duct tap. (If the is not used, the installing contractor should make an airtight duct is lined inside, use a static pressure tip device.) - Page 14 eChanICal nsTallaTIon Figure 10: Duct Static Pressure Sensing Tubing Installation 3 . Locate the building tap so it is not influenced by any source of moving air (velocity pressure). These sources Main Control Panel Condenser Section may include air diffusers or outside doors. 4 .

-

Page 15: Electrical Installation

leCTrICal nsTallaTIon leCTrICal nsTallaTIon Pre-Construction DANGER The Rebel unit comes equipped with a Microtech III controller Hazardous voltage . Can cause severe injury or and can be used for sites that are still under construction. The death . following conditions must be met. Disconnect electric power before servicing equipment. -

Page 16: All Units

leCTrICal nsTallaTIon Electrostatic Discharge (ESD) All Units Disconnect Power to the Rebel Rooftop Unit prior to Wiring must comply with all applicable codes and ordinances. inspecting and/or repairing . The warranty is voided if wiring is not in accordance with these specifications. -

Page 17: Field Control Wiring

. Turn off the manual gas valve to the appliance before performed by Daikin trained technicians who are familiar with shutting off the electrical supply. working on live equipment. A representative of the owner or the... - Page 18 leCTrICal nsTallaTIon Table 6: 003–015 Electric Heat Data Table 7: DPS 016–028 Electric Heat Data Voltage Amps Voltage Amps Voltage Amps Voltage Amps 16 .7 99 .9 83 .4 250 .1 15 .1 90 .4 75 .4 226 .2 7 .3 43 .8 37 .7 113 .1...

-

Page 19: Refrigeration System

efrIgeraTIon ysTeM efrIgeraTIon ysTeM Piping System The Rebel piping system varies significantly between the multiple possible configurations; heat pump, cooling only, and modulating hot gas reheat. In spite of this multiplicity there are some consistent characteristics. All units have a single circuit with a single or tandem compressor. - Page 20 efrIgeraTIon ysTeM Figure 13: Typical Refrigeration Circuit for Heat Pump Unit with Modulating Hot Gas Reheat (DPS 007–015 shown) Item Description Indoor coil electronic expansion valve Outdoor coil electronic expansion valve Check Valve, size 3-15 only Refrigerant Receiver Indoor fan Outdoor fan COMP1 Inverter compressor...

-

Page 21: Dps 003-015 Component Description

efrIgeraTIon ysTeM DPS 003–015 Component Description Variable Speed Compressor Receiver A variable speed compressor (COMP1) is used on all DPS(H) Only Rebel Heat Pump units will have a receiver. Different 003–015. On small cabinet units (3–6 Tons) the variable speed volumes of refrigerant are required inside the system during compressor will be the only one present. - Page 22 efrIgeraTIon ysTeM Oil Separator Check Valve All DPS(H) 003–015 units will have an oil separator on the All DPS 003–015 will have check valves on each of the discharge line of the compressor. This device will remove compressor discharge lines. On medium cabinet units oil from the compressor discharge gas and return it to the (7–15 Tons), two valves, one on each compressor, prevent compressor suction line.

- Page 23 efrIgeraTIon ysTeM High Pressure Switch Four-Way Valve All Rebel Units will have a high pressure switch on each The Four-Way Valve (4WV) also known as a Reversing Valve compressor. Medium cabinet units (7–15 Tons) will have an is a component only used on Heat Pumps. This device is HP1 switch on the variable speed compressor (COMP1) and a used to direct the discharge gas from the compressor into the HP3 on the fixed speed compressor (COMP3).

- Page 24 efrIgeraTIon ysTeM By-Pass Solenoid Valve Indoor Expansion Valve The By-Pass Solenoid Valve (SVB) is used to “short-circuit” The Indoor Expansion Valve (EVI) is a 12 VDC stepper motor the high pressure compressor discharge to the low pressure driven valve, used in heating and cooling mode. In cooling suction side during start-up.

- Page 25 efrIgeraTIon ysTeM Suction Pressure Transducer Outdoor Refrigerant Temperature The Suction Pressure Transducer (PTS) is a refrigerant Only Rebel Heat Pumps units will have an Outdoor Refrigerant pressure sensor that screws onto a Schrader fitting on the Temperature Sensor (ORT). This sensor is used in Cooling suction line of the compressor deck.

- Page 26 It will always be Daikin's meeting the building load the variable speed compressor will recommendation that unit’s suspected of being over/under...

-

Page 27: Dps 016-028 Ton Component Description

efrIgeraTIon ysTeM DPS 016–028 Ton Component Description Variable Speed Compressor Figure 28: High Pressure Switch A variable speed compressor (COMP1) is used on all DPS 016-028. On DPS 16–20 ton units, the variable speed compressor will be the only one present, and be on the right. The discharge of the variable speed compressor is located on the top and the suction is located on the side. - Page 28 efrIgeraTIon ysTeM Indoor Expansion Valve Suction Pressure Transducer The Indoor Expansion Valve (EVI) is a 12 VDC stepper motor The Suction Pressure Transducer (PTS) is a refrigerant driven valve. In cooling mode EVI is used to control the pressure sensor that screws onto a Schrader fitting on the superheat and expand the refrigerant entering the Indoor Coil, suction line of the compressor deck.

-

Page 29: Vfd Compressor Operation - Dps 016-028

efrIgeraTIon ysTeM VFD Compressor Operation – DPS 016–028 DPS Size 025 & 028, Two Compressor Units VFD compressor modulation is controlled by a Mobus signal ® from the unit controller. The minimum VFD compressor speed If the VFD compressor were to become inoperative, the is 25 rps (1500 rpm) and the maximum VFD compressor speed unit can continue to operate on the remaining fixed speed is 100 rps (6000 rpm), but the minimum and maximum limits... - Page 30 efrIgeraTIon ysTeM VFD Compressor Control Dehumidification Transition During Cooling State Control of the VFD compressor is accomplished with a digital When dehumidification operation becomes active while the output enable signal and a 0-10VDC analog modulating unit is in the Cooling operating state, The VFD compressor control signal.

- Page 31 efrIgeraTIon ysTeM If the oil balance mode fails to resolve the low oil condition, VFD Compressor Protection Unloading Control or the fixed speed compressor was not running when the low There are several modulating control functions that adjust the oil indication occurred, or the VFD compressor was not part speed control range of the VFD compressor to protect it from of a tandemized compressor set, when the low oil indication damage under abnormal operating conditions.

- Page 32 efrIgeraTIon ysTeM High Discharge Line Temperature Unloading Control High Superheat A compressor discharge temperature sensor (Thermistor) is If the VFD compressor discharge superheat rises to 75F for 10 installed on the VFD compressor as standard. The temperature consecutive minutes, the VFD compressor speed is reduced is used to measure discharge temperature and superheat by 10 rps increments down to a 40 rps operating speed.

-

Page 33: Variable Speed Scroll Compressor

Guidelines. Under all circumstances, the EN378 (or other applicable local safety regulations) requirements must be fulfilled . Daikin units with variable speed inverter compressor are engineered with fixed speed compressor in such a way that the unit delivers only the required energy to satisfy space conditions and provides you with exceptional energy savings. - Page 34 efrIgeraTIon ysTeM Oil Injection Control Optical Oil Level Sensor The VFD compressor contains an oil injection valve and An optical oil sensor is used to monitor oil level in VFD solenoid (SV11) as standard. The oil injection valve provides compressor sump. The sensor is mounted directly to a fitting lubrication to the scroll set under low speed/low refrigerant on the VFD compressor shell and can be removed without velocity situations.

- Page 35 efrIgeraTIon ysTeM Variable Frequency Drive for VFD Compressor Basic Operation of Compressor Drive: WARNING Start= Connect terminals 12 & 18 for minimum of 5 secs, Never bypass the compressor drive or directly connect connect terminals 12 &27 and terminals 13 &37 the VFD compressor to the main power supply.

-

Page 36: Optional Modulating Hot Gas Reheat

pTIonal odulaTIng eheaT pTIonal odulaTIng eheaT Modulating Hot Gas Reheat The reheat coil option comes complete with an aluminum micro channel coil and modulating hot gas valves for leaving air temperature control. On a call for dehumidification, the unit will enable the supply to be over-cooled by the DX coil. Hot gas from the unit condenser will be routed to an indoor coil downstream of the DX coil to reheat the air. - Page 37 pTIonal odulaTIng eheaT Figure 38: Ideal for Neutral Air Ventilation Control • The rooftop mainly dehumidifies the required ventilation air • Terminal units provide additional sensible cooling as required Dehumidification Initiation Dehumidification Termination An analog sensor is mounted in the return duct, the space, or Dehumidification is terminated if the selected variable, Relative outdoors to sense Relative Humidity.

- Page 38 pTIonal odulaTIng eheaT Control & Arrangement In conjunction with dehumidification, MHGRH is used to raise • In the reheat mode, the minimum position for the reheat the temperature of the cooled air to a desirable value. MHGRH valves is 1% (1.0 Vdc). The controller will modulate the is comprised of a parallel coil arrangement, with dual reheat reheat valves from this starting position.

-

Page 39: Optional Electric Heat

pTIonal leCTrIC pTIonal leCTrIC Electric Heater Design If the 10th digit in the model number is an “E”, the rooftop unit was furnished with a factory installed electric furnace (Example, DPS010AHCE). The Rebel rooftop units are available with 4-stage heat output (see capacities in Table 23 . -

Page 40: Optional Gas Heat

Daikin Tubular Heater Series Hooded and screened openings for combustion air have been provided in the furnace(s) access door. The air opening provides Package Heater Module unrestricted combustion air to the burners and sized such that a minimum free area is maintained. The minimum free area is ANSI Z83.8-2013/CSA 2.6-2013... -

Page 41: Gas Heating Capacity Data

pTIonal Gas Heating Capacity Data Table 14: DPS 003-015 Gas Heating Capacities Unit Size Data 003 - 006 007 - 015 Low Heat Med Heat High Heat Low Heat Med Heat High Heat Heating Input (MBh) Heating Output (MBh) Steady State Efficiency Number of Stages Turndown 10:1... - Page 42 pTIonal Figure 41: Typical Modulating Furnace Assembly (016–028 shown) Item Description Furnace Inducer Combustion Blower Plate-Inducer Orifice Transformer – 40 VA Spark Igniter (2) Ignition Control #1 Ignition Control #2 Gas Safety Valve #1 Gas Safety Valve #2 Gas Modulating Valve Gas Modulating Control Burner In-Shot (Typ) Flame Roll-Out Switch (2)

- Page 43 Electrical Gas Pressure Requirements The Daikin burner receives its electrical power from the main unit The pressure furnished to the main gas valve must not exceed control panel. No additional power wiring must be routed to the 13.9" wc. When the supply pressure is above 13.9" wc, a high burner.

- Page 44 pTIonal Auxiliary Limit Switch Function The auxiliary limit switch is a manually resetable switch and is Figure 42: 3–6 Ton—Auxiliary Limit Switch designed to trip in the event of a supply fan failure. It should not View of supply fan trip during any other conditions.

- Page 45 pTIonal Figure 45: Capacity of Pipe Natural Gas (CFH) With Pressure Drop of 0 .3" Wc & Specific Gravity Of 0.60 Pipe Size-inches (Ips) Pipe Length (ft .) ½ ¾ 1¼ 1½ 2½ 1050 1600 2050 4800 8500 17500 1100 2100 3300 5900...

- Page 46 pTIonal Gas Piping Routing Into Unit On-The-Roof Piping 1 . Remove knockout on upright (refer to Figure Figure Figure 48: Rebel C Cabinet 016–028 Gas Piping 47 or Figure 48). Field Piping . Piping to 2 . Route gas supply pipe through hole. Carefully plan pipe be supported such that route and fitting locations to avoid interference with if does not generate...

- Page 47 pTIonal DPS 016–028 Gas Pipe Manifold Pressure Adjustment For Two Stage Furnace For Modulating Furnace: 1 . Read gas pressure at the Inlet Pressure Tap of the 1 . Read gas pressure at the Inlet Pressure Tap of the Honeywell VR8305Q Gas Safety Control Valve (Figure Honeywell VR8305Q Gas Safety Control Valve (Figure...

-

Page 48: Dps 003-015 Sequence Of Operation

This unit is equipped at the factory for use with natural gas only. Conversion to LP gas requires a special kit Table 18: Furnace Identification for LP Conversion supplies by Daikin Parts. Failure to use the proper Unit Size Staged Furnace conversion kit can cause fire, carbon monoxide 3 –... -

Page 49: Dps 016-028 Sequence Of Operation

Conversion to LP gas requires a special kit 5 . 30 second pre-purge cycle starts. supplies by Daikin Parts. Failure to use the proper conversion kit can cause fire, carbon monoxide 6 . Spark ignitor is activated for 3 seconds. -

Page 50: Start-Up Procedures

Start-Up Procedures Altitude Conversion Start-Up Responsibility For elevations up to 2000 feet, rating plate input ratings apply. For high altitudes (elevations over 2000 ft) contact Daikin Applied Parts. See Table 20 for part numbers. Or contact local DANGER gas supplier to confirm gas heating value has been devalued Overheating or failure of the gas supply to shut for applicable elevations. -

Page 51: Operating Procedures

pTIonal Operating Procedures Turning OFF Gas to the Appliance DANGER 1 . Set the controller to the lowest setting. If you do not follow these instructions exactly, a fire 2 . Turn OFF all electrical power to the appliance if service or explosion may result causing property damage, personal injury, or loss of life . -

Page 52: Staged Gas Furnace

pTIonal DPS 003–015 (only) Ignition Control Module for Staged Gas Furnace Figure 52: Typical Staged Gas Furnace Electrical Schematic with Sensor Ignition Control Module LED Diagnostics The following LED indicators can be used to diagnose faults associated with the staged gas furnace. Table 21: LED Indicator and Fault Conditions Figure 53: Ignition Control Wiring Indicator... -

Page 53: Modulating Gas Furnace

pTIonal DPS 003–015 (only) Ignition Control Module for Modulating Gas Furnace Figure 54: Typical Modulating Gas Furnace Electrical Schematic with Sensor www.DaikinApplied.com IM 1125-7 • REBEL ROOFTOPS... -

Page 54: Dps 003-015 (Only) Gas Furnace Ignition And Control

DPS 003–015 (only) Gas Furnace Ignition and Control Troubleshooting Variable Furnace Controller Modulating Furnace Diagnostics Daikin’s furnace controller is an electronic device that delivers The Rebel furnace control that operates the furnace has full control of the modulating furnace. Control includes built-in, self-diagnostic capability. - Page 55 pTIonal Table 24: Functional Alerts — DPS 003–015 only Display Information Alert Description Possible Cause Solution The flame could not be established during the trial for ignition period. Failed ignition attempt This alert indicates the See “01” in the See “01” in the maximum number of LOCKOUT ERRORS LOCKOUT ERRORS...

- Page 56 pTIonal Table 24 continued: Functional Alerts Display Information Alert Description Possible Cause Solution 1. Insure gas supply is connected to furnace A. Low gas line pressure and check for proper line pressure . 1. Check for faulty gas valve wiring. 2.

- Page 57 pTIonal Table 25: Lockout Errors — DPS 003–015 only Display Information Alert Description Possible Cause Solution 1. Check 24-volt transformer for correct output . 2. Check connections and A. Faulty transformer wiring to control board and other components connected to the 24 volt source.

- Page 58 pTIonal Table 25 continued: Lockout Errors Display Information Alert Description Possible Cause Solution 1. Check filter / replace if dirty. 2. Check for improperly sized duct system. A. Improper circulating airflow 3. Check for faulty blower motor . 4. Check for faulty blower motor wiring.

- Page 59 pTIonal Table 25 continued: Lockout Errors Display Information Alert Description Possible Cause Solution 1. Perform Modulating System A. Modulating actuator / ball Gas Valve Alignment valve not properly aligned procedure as defined in the service manual. 1 . Insure line pressure is properly adjusted for the B.

-

Page 60: Dps 016-028 Gas Furnace Ignition Troubleshooting

pTIonal DPS 016–028 Gas Furnace Ignition Troubleshooting Table 26: 300/450/600 MBH Staged Ignition Control Troubleshooting Guide (UTEC 1016 Ignition Board) LED Indicator System Status Fault Description Possible Causes and Corrective Action Steady ON System Normal 1. Check 120V is being supplied to heater transformer. LED OFF Lockout LED is OFF... - Page 61 Switch Switch Spark Igniter TS02 TS01 SI01 620A 620D 620B 620C (Daikin P/N 910172859; includes ignitor and wire) remotely mounted Inducer Fan Motor IFM01 602C 623A 602D LED Diagnostic Information Steady Off: No power or Control hardware fault Steady On: Power applied, Control OK...

- Page 62 Switch Switch Spark Igniter TS02 TS01 SI01 620D 620A 620B 620C (Daikin P/N 910172859; includes ignitor and wire) remotely mounted Inducer Fan Motor IFM01 602C 623A 602D LED Diagnostic Information Steady Off: No power or Control hardware fault Steady On: Power applied, Control OK...

- Page 63 616A Flame Sensor FS01 619A 619B Spark Igniter 1R-1 S101 622A 622B 622C (Daikin P/N 910172859; includes ignitor and wire) Inducer Fan Motor IFM01 602C 625A 602D Ignition Module #2 Gas Safety Shutoff Valve #2 IM02 GSSV02 UTEC 1016-578 610D...

- Page 64 616B 618A 618E TB10 2R-1 Flame Sensor FS01 621A 621B 621C Spark Igniter S101 624A 624B (Daikin P/N 910172859; includes ignitor and wire) Inducer Fan Motor 1R-1 (Hi speed) IFM01 627B 627A 627C 603C 1R-2 629A 618A TB10 633B (Low speed)

-

Page 65: Optional Hot Water Heat

The freezing of coils is not the responsibility of Daikin Applied. If the 10th digit of the model number is a “W”, the rooftop unit was furnished with a factory installed hot water coil (Example: Field Installed Freeze Stats DPS010AHCW). -

Page 66: Optional Energy Recovery Wheel

Wheel Construction Enthalpy wheel - A generic name for an energy conservation Your Daikin enthalpy wheel is delivered completely assembled wheel. The term “enthalpy” refers to an air stream’s total and ready to run. The wheel is built to provide many years of energy (temperature and humidity level). - Page 67 Figure 60: Wheel Construction (Side-by-Side) (1) Currently, only the Over-Under configuration is offered on Daikin rooftop systems and air handlers. Purge and Pressurization Drive Motor Pressurization is critical to minimize crossover from exhaust to The enthalpy wheel comes standard with a constant speed drive supply and to allow the purge to operate.

- Page 68 pTIonal nergy eCovery heel Constant Speed Frost Prevention Variable Speed Frequency Control When there is a threat of frost on the enthalpy wheel, the wheel A variable frequency drive is included with the frost protection is jogged so that less enthalpy transfer occurs and frosting option and it controls the speed of the enthalpy wheel.

-

Page 69: Optional Outdoor Air Monitor

pTIonal uTdoor onITor pTIonal uTdoor onITor Thermal Dispersion Airflow Measurement Technology Connecting to MicroTech III Controllers Thermal dispersion technology relates the velocity of the air to the power and rise in temperature of a heated element in a Wiring moving airstream. A precise bead-in glass thermistor probes 1 . - Page 70 pTIonal uTdoor onITor Figure 67: MicroTech III Controller Figure 68: Transmitter and Connector Detail Transmitter Connector IM 1125-7 • REBEL ROOFTOPS www.DaikinApplied.com...

- Page 71 (for example cfm) the transmitter is operating in the Field death if not avoided. Calibration Wizard mode.Daikin McQuay users do not need to use this function. LCD Blinks ** LOW ALARM **, ** HIGH ALARM ** or **...

- Page 72 pTIonal uTdoor onITor Table 30: General Troubleshooting Problem Possible Cause Remedy Power switch not in the "ON" position. Move the power switch to the "ON" position. Ensure that 24VAC power is connected to L1 and L2 Improper supply voltage to the power input terminal of the POWER terminal block and that the voltage No LCD display indication and the green Transmitter block.

- Page 73 Differential pressure is only available from transmitters If a differential pressure measurement is required, There is no value for the differential pressure point that have a Bi-directional Bleed Airflow Sensors contact your local Daikin Representative about a Bi- connected. directional Bleed Airflow Sensor. www.DaikinApplied.com...

-

Page 74: Ecm Motor

eCM M oTor Addressing Return Or Exhaust ECM eCM M oTor Rebel (size 003–015) SAFs and all EAFs utilize ECM [electronically commutated external rotor] motors. ECM motor 1 . Close the MMP or shut the circuit breakers to the speed is controlled by unit mounted, MicroTech III, static supply and energy recovery drives to keep modbus pressure and temperature controls to reliably maintain comfort communication enabled only at the return/exhaust ECM. - Page 75 eCM M oTor 12 . Click on the “Modbus ECM Smoke Purge or Ventilation Override Status” menu Microtech III has been configured via modbus to perform a ventilation override if terminals Din2 and GND at Terminal strip 3 on the ECM are made. Install an isolation relay that would make a dry NO contact across the return/exhaust fan Din2 and GND per Detail A on page...

-

Page 76: Unit Options

pTIons pTIons Economizer Enthalpy Control Figure 70: Pressure Tubing Diagram TO ENTERING The economizer can be ordered with the optional differential AIR SIDE OF enthalpy control. With this option a solid-state humidity and THE FILTERS temperature sensing device is located in the return and outdoor airstreams. -

Page 77: Convenience Receptacle (Field Powered)

pTIons Convenience Receptacle (Field Powered) Convenience Receptacle (Unit Powered) A Ground Fault Circuit Interrupter (GFCI) convenience A Ground Fault Circuit Interrupter (GFCI) convenience receptacle is provided in the main control box on all units. To receptacle is provided in the main control box on all units. The use this receptacle, connect a separate field-supplied 115 V receptacle shall be powered by a factory installed and wired power wiring circuit to the outlet. -

Page 78: Wiring Diagrams

IrIng IagraMs IrIng IagraMs Figure 72: Typical CAV_VAV 208-230 VAC Wiring (1 of 4) — DPS 003–006 shown 208V, 3 Phase, 60Hz 208V, 3 Phase, 60Hz 208V, 3 Phase, 60Hz 208V, 3 Phase, 60Hz 103B CUSTOMER 104B SUPPLIED POWER 105A Wire for CW phase monitor MMP1... - Page 79 IrIng IagraMs Figure 72 continued: Typical CAV_VAV 208-230 VAC Wiring (2 of 4) — DPS 003–006 shown (160) (160) 120V_H 120V_N 159A 155B 120V CLASS 2 75VA 207A 207B 207B 207A G-24V 207B GO-24C TIME CLOCK OR TENNANT OVERIDE 207B R3-4 T_CLOCK 207A...

- Page 80 IrIng IagraMs Figure 72 continued: Typical CAV_VAV 208-230 VAC Wiring (3 of 4) — DPS 003–006 shown (160) (160) 120V_H 120V_N R-HP1 HP1-I HP1-I 155B 159A 303A R-CCH1 DO1B 159A 305A 155B R-HP1 HP3-I HP3-I DO2B 159A 307A 307B 307C 155B (303) R5-6...

- Page 81 IrIng IagraMs Figure 72 continued: Typical CAV_VAV 208-230 VAC Wiring (4 of 4) — DPS 003–006 shown www.DaikinApplied.com IM 1125-7 • REBEL ROOFTOPS...

- Page 82 IrIng IagraMs Figure 73: Typical CAV_VAV 460 VAC Wiring (1 of 4) — DPS 003–006 shown 460V, 3 Phase, 60Hz 460V, 3 Phase, 60Hz 460V, 3 Phase, 60Hz 460V, 3 Phase, 60Hz 103B CUSTOMER 104B SUPPLIED POWER 105A Wire for CW phase monitor MMP1 T4-I...

- Page 83 IrIng IagraMs Figure 73 continued: Typical CAV_VAV 460 VAC Wiring (2 of 4) — DPS 003–006 shown (160) (160) 120V_H 120V_N 159A 155B 120V CLASS 2 75VA 207A 207B 207B 207A G-24V 207B GO-24C TIME CLOCK OR TENNANT OVERIDE 207B R3-4 T_CLOCK 207A...

- Page 84 IrIng IagraMs Figure 73 continued: Typical CAV_VAV 460 VAC Wiring (3 of 4) — DPS 003–006 shown (160) (160) 120V_H 120V_N R-HP1 HP1-I HP1-I 155B 159A 303A R-CCH1 DO1B 159A 305A 155B R-HP1 HP3-I HP3-I DO2B 159A 307A 307B 307C 155B (303) R5-6...

- Page 85 IrIng IagraMs Figure 73 continued: Typical CAV_VAV 460 VAC Wiring (4 of 4) — DPS 003–006 shown www.DaikinApplied.com IM 1125-7 • REBEL ROOFTOPS...

- Page 86 IrIng IagraMs Figure 74: Typical 575 Volt Wiring (1 of 4) — DPS 007–015 shown with 460 to 575 Transformer (106) 22kVA T12-1I HEAT1575-PI T12-2E T12-2E T12-1I 347/575V, 3 Phase, 60Hz 347/575V, 3 Phase, 60Hz 347/575V, 3 Phase, 60Hz 347/575V, 3 Phase, 60Hz F12A F13A HEAT1...

- Page 87 IrIng IagraMs Figure 74 continued: Typical 575 Volt Wiring (2 of 4) — DPS 007–015 shown with 460 to 575 Transformer (160) (160) 120V_H 120V_N PVM1 160A 204A 155A (123) 120V CLASS 2 75VA GF1-I GF1-I GFR1 207A 207B (117) 209A 207B T1-G...

- Page 88 IrIng IagraMs Figure 74 continued: Typical 575 Volt Wiring (3 of 4) — DPS 007–015 shown with 460 to 575 Transformer (160) (160) 120V_H 120V_N R-HP1 HP1-I HP1-I 155A 160A 303A R-CCH1 DO1B 160A 305A 155A R-HP1 HP3-I HP3-I DO2B 160A 307A 307B...

- Page 89 IrIng IagraMs Figure 74 continued: Typical 575 Volt Wiring (4 of 4) — DPS 007–015 shown with 460 to 575 Transformer www.DaikinApplied.com IM 1125-7 • REBEL ROOFTOPS...

-

Page 90: Sequence Of Operation

equenCe of peraTIon equenCe of peraTIon Operating States Fan Only The transition from any operating state to another is graphically represented in Figure 75 . The outside air damper will modulate to the minimum position and based upon the sensor inputs, the unit will go into one of Figure 75: Operating State Diagram the four running states - “Heating,”... -

Page 91: Mechanical Cooling

equenCe of peraTIon Mechanical Cooling The unit goes into the cooling mode of operation when the control temperature (return temperature) is above the change- Constant Volume (Space Comfort Controller) over setpoint by more than ½ the deadband. The control temperature for a CAV unit is typically the space Example - If the change over temperature is 70.0°F and the temperature. -

Page 92: Preparing The Unit For Start Up

During operation all fans should ride level. Level the fan Daikin Applied. assembly by performing the following: A representative of the owner or the operator of the equipment 1 . -

Page 93: Servicing Control Panel Components

reparIng The nIT for TarT Servicing Control Panel Components Power-Up 1 . Close the unit disconnect switch. DANGER 2 . Power should now be supplied to the control panel. Hazardous voltage . May cause severe injury or death . Phasing the Rebel Unit Disconnect electric power before servicing equipment The supply and return fans, inverter compressor, and condenser fans are all inverter driven and are DC voltage... -

Page 94: Check, Test And Start Procedures

heCk esT and TarT roCedures heCk esT and TarT roCedures Economizer Start-Up Perform the Following Procedure: 1 . Check whether the outdoor air is suitable for free cooling. NOTICE 2 . At the keypad, set the cooling setpoint low enough so the controller calls for cooling. -

Page 95: Set Up For Optimum Control

heCk esT and TarT roCedures Set Up for Optimum Control Air Balancing The Outdoor air sensor must be calibrated. WARNING • Compare the MicroTech III OAT reading to an external Moving machinery hazard . cause severe temperature measuring device . See Appendix, Figure personal injury or death . -

Page 96: Energy Recovery Wheel

heCk esT and TarT roCedures Energy Recovery Wheel Prestartup Checks Diameter Seal Adjustment 1 . By hand, turn wheel clockwise (as viewed from the pulley WARNING side) to verify wheel turns freely through 360° rotation. Keep hands away from rotating wheel! Contact with 2 . -

Page 97: Final Control Settings

Final Control Settings Maintaining Control Parameter Records Daikin recommends that the MicroTech III controller’s setpoints Controller Settings for Normal Operation and parameters be recorded and saved for future reference. When all start-up procedures are completed, set the controls If the microprocessor control board requires replacement, this and program the MicroTech III controller for normal operation. -

Page 98: Maintenance

aInTenanCe aInTenanCe Performing Service Maintenance Planned Maintenance Installation and maintenance must be performed only by Preventive maintenance is the best way to avoid unnecessary qualified personnel who are experienced with this type of expense and inconvenience. Have this system inspected at equipment and familiar with local codes and regulations. -

Page 99: Periodic Service And Maintenance

Once a month, open a door on each section and verify that no moisture or debris is accumulating in the unit. Control Compartment 1 . Daikin Applied recommends that the electronic control equipment in the unit be stored in a 5% to 95% RH (non- condensing) environment. -

Page 100: Refrigerant Charge

aInTenanCe Refrigerant Charge MicroTech III keypad instructions for charging and/ The Rebel unit has many configurable options that can affect or evacuation the refrigerant charge. Actual unit charge is given on the unit’s data plate found on the inside of the control panel. The Rebel Evacuating the charge: unit uses electronic expansion valves that maintain peak •... -

Page 101: Servicing Refrigerant Sensors Or Switches

aInTenanCe Servicing Refrigerant Sensors or Switches Phase Voltage Monitor (PVM) The phase voltage monitor (Figure 80) is designed to protect CAUTION three-phase loads from damaging power conditions. A microprocessor-based voltage and phase sensing circuit Severe loss of charge may occur if the high constantly monitors the three-phase voltages to detect harmful refrigerant pressure switch is replaced before power line conditions. -

Page 102: Cleaning Option E Coated Coils

aInTenanCe Cleaning Option E Coated Coils Routine Quarterly Cleaning of Option E Coated Coil WARNING Surfaces Quarterly cleaning is essential to extend the life of an Option Prior to cleaning the unit, turn off and lock out the main E Coated Coil and is required to maintain warranty coverage. power switch to the unit and open all access panels. -

Page 103: Service And Warranty Procedures

For questions regarding wiring diagrams, provide 2 . Send a completed parts order form to the Daikin Parts the number on the specific diagram. If replacement parts are Department . -

Page 104: Warranty Registration Form

Equipment Warranty Registration Form To comply with the terms of Daikin Applied Warranty, complete and return this form within 10 days to the Warranty Department of Daikin Applied. Check, test, and start procedure for Rooftop roof mounted air conditioners with or without heat recovery and roof mounted air handlers. - Page 105 arranTy egIsTraTIon Rebel Equipment Warranty Registration Form (continued) Select Yes or No. If not applicable to the type of unit, select N/A. I. INITIAL CHECK A. Is any shipping damage visible? ........Yes B.

- Page 106 arranTy egIsTraTIon Rebel Equipment Warranty Registration Form (continued) Select Yes or No. If not applicable to the type of unit, select N/A. IV. PERFORMANCE DATA (Unit to run at steady state for 15 minutes) A. Discharge pressure, one compressor: ........Circuit 1 _____ psig B.

- Page 107 AAH.Wty_WAR_forms@daikinapplied.com Please fill out the Daikin Applied “Quality Assurance Survey Report” and list any additional comments that could affect the operation of this unit; e.g., shipping damage, failed components, adverse installation applications, etc. If additional comment space is needed, write the comment(s) on a separate sheet, attach it to the Survey Report and return it to the Warranty Department of Daikin Applied with the completed Equipment Warranty Registration form.

-

Page 108: Quality Assurance Survey Report

Poor 10. How would you rate the overall quality of the product? Excellent Good Fair Poor 11. How does the quality of Daikin Applied products rank in relation to competitive products? Excellent Good Fair Poor Comments _______________________________________________________________________________________ Please list any additional comments which could affect the operation of this unit; i.e., shipping damage, failed components, adverse installation applications, etc. If additional comment space is needed, write the comment(s) on a separate sheet, attach the sheet to this completed Quality Assurance Survey Report, and return it to the Warranty Department with the completed preceding “Equipment Warranty Registration Form”. - Page 109 Addendum follows IM 1125-7...

-

Page 110: Appendix - Keypad/Display Menu Structure

– k ppendIx eypad Isplay TruCTure The following is a description of the MicroTech III menu structure. These menus and items can all be displayed with the keypad/ display. Menu items displayed will change based on the selected unit configuration. Figure 81: Main Menu –... - Page 111 – k ppendIx eypad Isplay TruCTure Commission Unit Manual Control Service Menus Trending Unit Maintenance BMS Communications ► ► ► Unit Set-Up Manual Control= Normal Timer Settings Trending Ena= No Operating Hours LON Set-Up ► ► ► Timer Settings Supply Fan= Off Operating Hours Apply Chgs= No BACnet MSTP Set-Up...

- Page 112 – k ppendIx eypad Isplay TruCTure Figure 82: View/Set Unit – Keypad/Display Menu Structure View/Set Unit ► Unit Status/Settings ► Occupancy ► Temperatures ► Flow Status ► SAF Spd Control ► RF/EF Control ► Cooling ► Economizer ► Min OA Damper ►...

- Page 113 – k ppendIx eypad Isplay TruCTure Date/Time/Schedules Cooling Economizer Min OA Damper Heating Dehumidification Time= hh:mm:ss Occ Clg Spt= 72.0°F OAD/Econo Pos= XXX% Min OA Pos= XXX% Occ Htg Spt= 68.0°F Dehum Status= ________ Date= MM/DD/YY Unocc Clg Spt= 85.0°F DAT Clg Spt= 55.0°F Vent Limit= 20% Unocc Htg Spt= 55.0°F...

- Page 114 – k ppendIx eypad Isplay TruCTure Figure 83: Commission Unit – Keypad/Display Menu Structure Commission Unit ► Unit Set-Up ► Timer Settings ► SAF Set-Up ► RF/EF Set-Up ► Htg/Clg ChgOvr Set-Up ► Cooling Set-Up ► Unit Set-Up Timer Settings SAF Set-Up INV Cmp Set-Up ►...

- Page 115 – k ppendIx eypad Isplay TruCTure 1, 2 See Figure 84, page 117 for the expansion information INV Cmp Set-Up RF/EF Set-Up Htg/Clg ChgOvr Set-Up Cooling Set-Up COMPRESSOR STATUS COMPRESSOR SETUP RF/EF Ctrl= None Ctlr Temp Src= RAT Clg Stage Time= 5min Clg State= ____________ Clg Lo OAT Lk= 55°F SPEED CONTROL...

- Page 116 – k ppendIx eypad Isplay TruCTure Figure 84: Service Menu – Keypad/Display Menu Structure Service Menus ► Timer Settings ► Operating Hours ► Save/Restore Settings ► Active Alarms ► Alarm Log ► Alarm Configuration ► Analog Input Status ► Universal I/O Status ►...

- Page 117 – k ppendIx eypad Isplay TruCTure Alarm Log Alarm/Event Analog Input Status Universal I/O Status Digital Input Status Digital Output Status ► Configuration Log Count: xx Clr Log= No MCB Al1= XXXXXXXX MCB X1= XXXXXXXX MCB DI1= ____________ MCB DO1= __________ ►...

- Page 118 – k ppendIx eypad Isplay TruCTure Figure 85: BMS Communications – Keypad/Display Menu Structure BMS Communications ► LON Set-Up ► BACnet MSTP Set-Up ► BACnet IP Set-Up ► D-Net Set-Up ► Network Unit Set-Up IM 918 IM 917 IM 916 LON Set-Up BACnet MSTP Set-Up BACnet IP Set-Up...

- Page 119 – k ppendIx eypad Isplay TruCTure Figure 87: Optional Outdoor Air Monitor – Changing the System of Units Press and release ↑/↓ during normal operation to select Enter ↑/↓ (Select) Enter (Move →) Enter (Move →) (Action, Move →→) During Esc (Move ←) Esc (Move ←) Normal Operation...

- Page 120 – k ppendIx eypad Isplay TruCTure Figure 88: Optional Outdoor Air Monitor – Set Up Menu Press and release ↑/↓ during normal operation to select Enter (Move →) Enter (Move →) Enter (Move →) Enter (Action, Move →→) Esc (Normal Operation) Esc (Move ←) Esc (Move ←) Esc (Move ←←)

- Page 121 – k ppendIx eypad Isplay TruCTure 1 . Factory default/current setting 2 . If a selection is made that requires SW1 to be set, the LCD displays “Set SW1 on Board”. 3 . If a selection is made that requires SW2 to be set, the LCD displays “Set SW2 on Board”.

- Page 122 Daikin Applied Training and Development Now that you have made an investment in modern, efficient Daikin equipment, its care should be a high priority. For training information on all Daikin HVAC products, please visit us at www.DaikinApplied.com and click on Training, or call 540-248-9646 and ask for the Training Department.