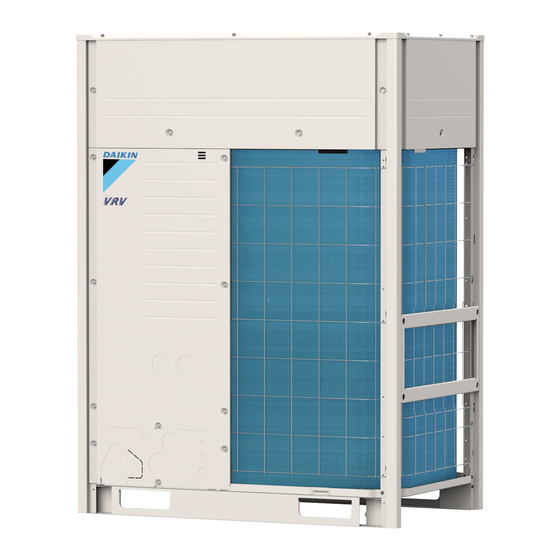

Daikin VRV System Installation Manual

Hide thumbs

Also See for VRV System:

- Service manual (255 pages) ,

- Reference manual (68 pages) ,

- Operation manual (14 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Daikin VRV System

-

Page 1: Technical Data

technical data Systems Installation... -

Page 2: Table Of Contents

• Installation Installation Table of contents Introduction Precautions on installation..........................2 Procedure and tools for refrigerant piping work ................3 Installation of outdoor units ........................6 Field refrigerant piping Inverter heat pump series..........................9 Field wiring cooling only / heat pump..........................10 Inverter cooling only / heat pump series ..................16 Heat recovery series............................21 VRV plus .................................24 •... -

Page 3: Precautions On Installation

• Installation Introduction Precautions on installation R-407C applies higher pressure than R-22 and uses refrigeration oil R-22 R-407C different from R-22. Therefore, piping works and tools are also different Refrigerant (Single-component refrigerant) (Multiple-component refrigerant) from those for R-22 refrigerants. Refrigeration oil Mineral oil (Suniso) Synthetic (ether) oil Condensing pressure... -

Page 4: Procedure And Tools For Refrigerant Piping Work

• Installation Introduction Procedure and tools for refrigerant piping work Procedure • Piping work for R-407C models partially differs from R-22 models in items and procedures of piping work and refrigerant charging due to different component and higher pressure for R-407C. The chart below shows general work procedure for R-407C models. Work items and precautions Determination of work item Confirm the refrigerant is R-407C or R-22... - Page 5 • Installation Introduction Procedure and tools for refrigerant piping work Tools • Several dedicated tools are required for the installation work of R-407C models. Some conventional tools can be used except tools actually used to install R-22 models. Representative tools and devices and interchangeability Tool name Work process / Usage Interchangeability with conventional tool...

- Page 6 • Installation Introduction Procedure and tools for refrigerant piping work Refrigerant charging • Charge R-407C from service port at liquid side stop value of outdoor unit in liquid phase. At that time, conduct vacuum drying using vacuum pump. Air-tightness test •...

-

Page 7: Installation Of Outdoor Units

• Installation Introduction Installation of outdoor units Determination of the Installation Location Selection of location • This unit, both indoor and outdoor, is suitable for installation in a commercial and light industrial environment. If installed as a household appliance it could cause electromagnetic interference. •... - Page 8 • Installation Introduction Installation of outdoor units 5, 8, 10HP H ≤ 1500 ⇒ A ≥ 500 h ≤ 500 ⇒ B1 ≥ 300 H = 1500+X ⇒ A ≥ 500+X/2 ⇒ B1 ≥ 300+Y/2 h = 500+Y ≥20 ≥20 ≥10 ≥10 ≥10...

- Page 9 • Installation Introduction Installation of outdoor units Caution when installing 1. Remove the crate from the unit. 4. Fasten the unit in place using four anchor bolts M12. 2. Remove the four screws fixing the unit to the pallet. 5. Remove the upper and lower service plate. 6.

-

Page 10: Inverter Heat Pump Series

• Installation Field refrigerant piping Inverter heat pump series (1) The following materials should be used for all refrigerant piping. • Materials: Deoxidized phosphorous seamless copper pipe (for external diameters of 25.4mm or more, C1220T-0 for the rest) or equivalent (2) Tips for insulation •... -

Page 11: Cooling Only / Heat Pump

• Installation Field wiring cooling only / heat pump • Up to 3 units can be connected by crossover power source wiring between outdoor units. However, units of smaller capacity must be connected downstream. For details, refer to the equipment design data and technical data. •... - Page 12 • Installation Field wiring cooling only / heat pump 2-1-1 Field line connection • L1, L2, L3, N-phase of the power cord should be clamped to the safety catch using the included clamp material. • The green and yellow striped wrapped wires should be used for grounding. Heat Pump Spring washer Flat washer...

- Page 13 • Installation Field wiring cooling only / heat pump 2-1-2 Field line connection: transmission wiring (cool/heat selection) Heating/cooling switching remote control (Indoor –Outdoor) (Outdoor –Outdoor) Heating/cooling switching remote Secure to the lock plate using control cord (when a heating/ the included cramping material. cooling switch remote control Wiring between the units (Sold separately) is connected)

- Page 14 • Installation Field wiring cooling only / heat pump 2-1-3 Example of performing cool/heat setting of two or more outdoor units in block with cool/heat selector • For the wiring shown in front figure, be sure to use 0.75-1.25 mm vinyl cords with sheath or cables (two-core).

- Page 15 • Installation Field wiring cooling only / heat pump 2-1-6 Picking power line and transmission line • Pick the power line from the upper hole on the left side plate, from the front position of the main unit (Through the conduit hole of the wiring mounting plate - optional parts) or from a knock out hole to be made in the unit’s bottom plate.

- Page 16 • Installation Field wiring cooling only / heat pump 2-1-6 Picking power line and transmission line When the power goes from outdoor unit to outdoor unit • Pass the power wiring which goes between the outdoor units through the bottom after securing it to the power wiring using cramping material so that it does not come into contact with the shut-off valve and the piping.

-

Page 17: Inverter Cooling Only / Heat Pump Series

• Installation Field Wiring Inverter cooling only / heat pump series 2-2-1 General instructions • All wiring components, parts which will be obtained locally and materials must comply with the applicable standards of the country and the region. • Use copper conductors only. •... - Page 18 • Installation Field Wiring Inverter cooling only / heat pump series 2-2-3 Gist of field line connection W1 Type See the figure 4 and 5 Power supply field Electric parts box Electric parts box of outdoor unit Earth terminal To indoor unit Clamp the anchor Figure 4...

- Page 19 • Installation Field Wiring Inverter cooling only / heat pump series 2-2-5 Example of performing cool/heat setting with cool/heat selector (heat pump unit only) Cool/Heat selector (Option) Heat pump unit only A B C F1 F2 F1 F2 A B C To In/D unit To Out/D unit C/H Selector...

- Page 20 • Installation Field Wiring Inverter cooling only / heat pump series 2-2-6 Setting gist of cool/heat operation (heat pump unit only) • When performing cool/heat setting with remote controller connecting indoor unit. Keep the cool/heat selector switch (SS1) on the outdoor unit PC board (A1P) at the factory setting position (set the IN/D unit). To IN/D IN/D OUT/D...

- Page 21 • Installation Field Wiring Inverter cooling only / heat pump series 2-2-7 Gist of picking power line and transmission line • Be sure to let the power supply wiring and the transmission wiring pass trough the conduit tube as shown in the figure. •...

-

Page 22: Heat Recovery Series

• Installation Field Wiring Heat recovery series 2-3-1 General instructions • All wiring components, parts which will be obtained locally and materials must comply with the applicable standards of the country and the region. • Use copper conductors only. • Follw the schematic attached to the unit for details on wiring. - Page 23 • Installation Field Wiring Heat recovery series 2-3-4 Gist of field line connection Power supply 3N ~50Hz (See the figure 4.) 380 ~415V (See the figure 5.) Electric parts box of Electric parts box (left) outdoor unit (right) IN/D UNIT OUT/D UNIT Electric parts box (right)

- Page 24 • Installation Field Wiring Heat recovery series 2-3-6 Gist of picking power line and transmission line • Be sure to let the power supply wiring and the transmission wiring pass through the conduit tube as shown in the right figure. •...

-

Page 25: Vrv Plus

• Installation Field Wiring VRV plus 2-4-1 General instructions • All field wiring and components must be installed and maintenanced by a licensed electrician and must comply with relevant local and national regulations. • The field wiring must be carried out in accordance with the wiring diagrams and instructions given below. •... - Page 26 • Installation Field Wiring VRV plus 2-4-2 System Example 1. Field power supply 2. Main switch 3. Earth leak detector 4. Fuse 5. Cool/heat selector 6. Remote control RSXYP16,18,20 RXYP8,10 RXEP8,10 Power supply wiring (sheathed cable) Transmission wiring (sheathed cable) RSXYP24,26,28,30 RXYP16,20 RXEP8,10...

- Page 27 • Installation Field Wiring VRV plus 2-4-4 Field line connection between main unit (RXYP-) and sub unit (RXEP-) NOTES In the event that the main unit and the sub unit are separated by 1000 mm or more, the attached cables cannot be used. The wiring between the outdoor units should be connected by extending the attached cable using the included connectors.

- Page 28 • Installation Field Wiring VRV plus 2-4-4 Field line connection between main unit (RXYP-) and sub unit (RXEP-) RSXYP24,26,28,30 1. RXYP16,20 (main unit) 11. cable (low voltage) 2. RXEP8,10 (sub unit) 12. RXYP (main unit) Switch Box 3. Power supply 13.

- Page 29 • Installation Field Wiring VRV plus 2-4-5 Field line connection: transmission wiring and cool/heat selection 1. Switch box (main unit) 2. Fix to the safety catch using the attached clamp material 3. Attached cable (between main and sub units) RXYP 8, 10, 16, 20 fig 21 2-4-6 Example of performing cool/heat with cool/heat selector...

- Page 30 • Installation Field Wiring VRV plus 2-4-7 Example of performing cool/heat setting of two or more outdoor units in block with cool/heat selector • For the wiring shown in figure 22, be sure to use 0.75-1.25 mm vinyl cords with sheath or cables (two-core). (Three-core cables can be used only for the cool/heat selector.) (Insulated thickness: 1mm or more) •...

- Page 31 • Installation Field Wiring VRV plus 2-4-9 Picking power line and transmission line • Be sure to let the power line and the transmission line pass through a conduit hole. • Pick the power line from the upper hole on the left side plate, from the front position of the main unit (through the conduit hole of the wiring mounting plate - optional parts) or from a knock out hole to be made in the unit’s bottom plate.

- Page 32 Daikin Europe N.V. is approved by LRQA for its Quality VRV products are not within the scope Management System in accordance with the ISO9001 of the Eurovent certification programme.