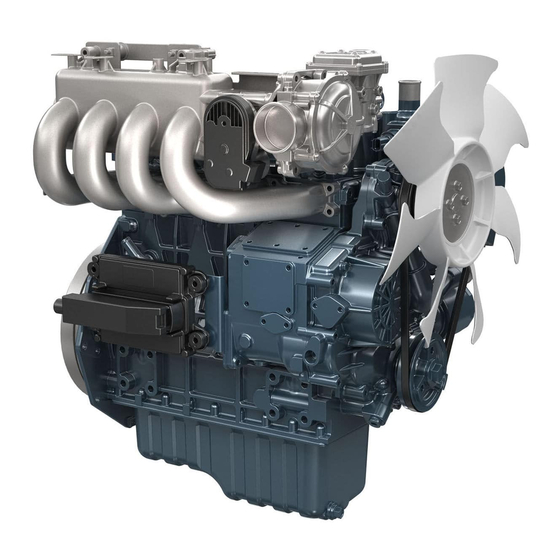

Kubota WG1605-G-E3 Workshop Manual

Gasoline,lpg natural gas engine

Hide thumbs

Also See for WG1605-G-E3:

- Workshop manual (140 pages) ,

- Operator's manual (72 pages) ,

- Operator's manual (71 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Kubota WG1605-G-E3

- Page 1 WORKSHOP MANUAL GASOLINE,LPG, NATURAL GAS ENGINE WG1605-E3 KiSC issued 05, 2014 A...

- Page 2 All illustrations, photographs and specifications contained in this manual are of the newest information available at the time of publication. KUBOTA reserves the right to change all information at any time without notice. Since this manual includes many models, information or illustrations and photographs can show more than one model.

- Page 3 Record of Revisions For pdf, use search function {Search word} to find all the revised locations. Last digit Issue Reference of the Main Revised Point and Corrective Measures {Search word} month Page Code No. 2014.05 Added the models – (WG1605-N-E3, WG1605-LN-E3, WG1605-GLN-E3) KiSC issued 05, 2014 A...

- Page 4 INFORMATION KiSC issued 05, 2014 A...

-

Page 5: Table Of Contents

INFORMATION CONTENTS 1. SAFETY FIRST ..........................I-1 2. SPECIFICATIONS.......................... I-4 3. IMPORTANT ITEMS OF EXHAUST EMISSION REGULATION............ I-8 [1] THREE-WAY CATALYST ......................I-9 [2] VAPORIZER AND LOCK OFF VALVE (WG1605-L-E3, WG1605-N, WG1605-GL-E3, WG1605-LN-E3, WG1605-GLN-E3)....I-9 [3] LENGTH OF THE VAPOR HOSE (WG1605-L-E3, WG1605-N, WG1605-GL-E3, WG1605-LN-E3, WG1605-GLN-E3).... -

Page 6: Safety First

INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 1. SAFETY FIRST SAFETY FIRST • This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on the machine itself to warn of the possibility of personal injury. Read these instructions carefully. - Page 7 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM OPERATE SAFELY • Do not use the machine after you consume alcohol or medication or when you are tired. • Put on applicable clothing and safety equipment. • Use applicable tools only. Do not use alternative tools or parts.

- Page 8 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM DISCARD FLUIDS CORRECTLY • Do not discard fluids on the ground, down the drain, into a stream, pond, or lake. Obey related environmental protection regulations when you discard oil, fuel, coolant, electrolyte and other dangerous waste. WSM000001INI0007US0 PREVENT ACID BURNS •...

-

Page 9: Specifications

*The specification described above is of the standard engine of each model. *Conversion Formula: HP = 0.746 kW, PS = 0.7355 kW *KUBOTA RECOMMENDED LPG FUEL SPECIFICATIONS • Commercial Propane gas only. • Equivalent to Propanes H-D-5 of GPA* standards. - Page 10 *The specification described above is of the standard engine of each model. *Conversion Formula: HP = 0.746 kW, PS = 0.7355 kW *KUBOTA RECOMMENDED LPG FUEL SPECIFICATIONS • Commercial Propane gas only. • Equivalent to Propanes H-D-5 of GPA* standards.

- Page 11 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM WG1605-N-E3 WG1605-LN-E3 Model Natural gas fuel Natural gas fuel LPG fuel Number of Cylinder Vertical, water cooled, Type Vertical, water cooled, 4-cycle natural gas engine 4-cycle LPG gas engine Bore × Stroke 79.0 × 78.4 mm (3.11 × 3.09 in.) Total Displacement 1.537 L (93.79 cu.in.)

- Page 12 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM WG1605-GLN-E3 Model Gasoline Natural gas fuel LPG fuel Number of Cylinder Vertical, water cooled, Vertical, water cooled, Vertical, water cooled, Type 4-cycle gasoline engine 4-cycle natural gas engine 4-cycle LPG gas engine Bore × Stroke 79.0 × 78.4 mm (3.11 × 3.09 in.) Total Displacement 1.537 L (93.79 cu.in.)

-

Page 13: Important Items Of Exhaust Emission Regulation

INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 3. IMPORTANT ITEMS OF EXHAUST EMISSION REGULATION WG1605 is available and unavailable in those countries. North kW, Disp. Model Type Europe Japan America WG1605-G-E3, WG1605-L-E3, 19 < P, 1.0 < L WG1605-N-E3, WG1605-GL-E3, Available Available Non-available WG1605-LN-E3, WG1605-GLN-E3 Current and future emission regulations. -

Page 14: Three-Way Catalyst

Vaporizer requires a normally-closed electrically controlled fuel lock off valve that is close coupled to the vaporizer and off when ignition switch is off or when the engine is not running normally (supplied from KUBOTA). In operation without a lock off upstream the vaporizer will flow fuel with the engine off. The vaporizer is not a fuel shut-off safety device. -

Page 15: Gaseous Fuel System

INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (5) Gaseous Fuel System FEA must use only the vaporizer and the lock off valve KUBOTA offers and assemble the LPG fuel system parts according to the instructions. 9Y1210661INI0023US0 (6) Engine Control Unit (ECU) Installation must use all 4 of the vibration mounts. -

Page 16: Performance Curves

INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 4. PERFORMANCE CURVES WG1605-G/L/GL/N-E3 (1) Brake Horsepower (4) Torque (6) Gross Intermittent Brake (a) Gasoline Use (2) Engine Speed (5) Gross Intermittent Torque Horsepower (b) LP Gas Use (3) Specific Fuel Consumption (7) Gross Intermittent Specific (c) Natural Gas Use... -

Page 17: Dimensions

INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 5. DIMENSIONS WG1605-G-E3 9Y1210661INI0009US0 WG1605-L-E3, WG1605-N-E3, WG1605-LN-E3 9Y1210661INI0010US0 I-12 KiSC issued 05, 2014 A... - Page 18 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM WG1605-GL-E3, WG1605-GLN-E3 9Y1210661INI0011US0 I-13 KiSC issued 05, 2014 A...

-

Page 19: Wiring Diagram

INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 6. WIRING DIAGRAM WG1605-G-E3 I-14 KiSC issued 05, 2014 A... - Page 20 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM WG1605-L-E3, WG1605-N-E3, WG1605-LN-E3 I-15 KiSC issued 05, 2014 A...

- Page 21 INFORMATION WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM WG1605-GL-E3, WG1605-GLN-E3 I-16 KiSC issued 05, 2014 A...

- Page 22 GENERAL KiSC issued 05, 2014 A...

- Page 23 GENERAL CONTENTS 1. ENGINE IDENTIFICATION ......................G-1 [1] ENGINE MODEL NAME, CODE NUMBER AND ENGINE SERIAL NUMBER ...... G-1 [2] E3 ENGINE ..........................G-3 [3] CYLINDER NUMBER ......................G-4 [4] CATALYTIC MUFFLER / CONVERTER ................G-5 2. GENERAL PRECAUTIONS......................G-6 3.

-

Page 24: Engine Identification

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 1. ENGINE IDENTIFICATION [1] ENGINE MODEL NAME, CODE NUMBER AND ENGINE SERIAL NUMBER When contacting the manufacture, always specify your engine model name, code number and serial number. The engine model, code number and its serial number need to be identified before the engine can be serviced or parts replaced. - Page 25 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (Continued) Production Month and Lot Number Month Engine Lot Number January A0001 ~ A9999 B0001 ~ February C0001 ~ C9999 D0001 ~ March E0001 ~ E9999 F0001 ~ April G0001 ~ G9999 H0001 ~ J0001 ~ J9999...

-

Page 26: E3 Engine

Non-Road Emission regulations depends on the engine displacement and output classification. Over the past several years, KUBOTA has been supplying SI engines that comply with regulations in the respective countries affected by Non-Road Emission regulations. For KUBOTA Engines, E3 will be the designation that identifies engine models affected by the next emission phase (See the table below). -

Page 27: Cylinder Number

[F] WG1605-GLN-E3 9Y1210661GEG0037US0 [3] CYLINDER NUMBER The cylinder numbers of KUBOTA gasoline, gasoline / LPG and natural gas engine are designated as shown in the figure. The sequence of cylinder numbers is given as No.1, No.2, No.3 and No.4 starting from the gear case side. -

Page 28: Catalytic Muffler / Converter

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [4] CATALYTIC MUFFLER / CONVERTER KUBOTA provides the catalytic muffler and converter as the catalyst parts. The parts number, the manufacturing date and the catalyst lot number are marked on surfaces of the catalyst parts as the catalyst identification. -

Page 29: General Precautions

• Remove oil and dirt from parts before measuring. • Use only KUBOTA genuine parts for parts replacement to keep engine performance and to ensure safety. • Gaskets and O-rings must be replaced during reassembly. -

Page 30: Maintenance Check List

Change engine oil and replace oil filter cartridge after the first 50 hours of operation. *: Change more often when operating under dusty conditions. **: If you do not have the proper tools and / or are not mechanically proficient, contact your local KUBOTA dealer. CAUTION •... -

Page 31: Check And Maintenance

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 4. CHECK AND MAINTENANCE [1] DAILY CHECK POINTS Checking Engine Oil Level 1. Level the engine. 2. To check the oil level, draw out the dipstick (1), wipe it clean, reinsert it, and draw it out again. - Page 32 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Checking and Fill Coolant 1. Without recovery tank: Remove the radiator cap (1) and check to see that the coolant level is just below the port. With recovery tank (2): Check to see that the coolant level lies between FULL"A" and LOW "B".

- Page 33 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Checking Air Cleaner Element (If necessary) 1. Remove the dust cup in the air cleaner. 2. Check the dust in the dust cup and the element. (When reassembling) • Install the air cleaner dust cup with "TOP" indicated on the rear of the cup.

-

Page 34: Check Points Of Intial 50 Hours

Then, fill the engine oil up to the specified level. IMPORTANT • To prevent serious damage to the engine, replacement element must be highly efficient. Use only a KUBOTA genuine filter or its equivalent. (1) Engine Oil Filter Cartridge... -

Page 35: Check Points Of Every 50 Hours

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [3] CHECK POINTS OF EVERY 50 HOURS CAUTION • Stop the engine when trying the check and replace prescribed below. • Make sure to check the fuel line periodically. The fuel line is subject to wear and aging, fuel may leak out onto the running engine, causing a fire. -

Page 36: Check Points Of Every 100 Hours

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [4] CHECK POINTS OF EVERY 100 HOURS Cleaning Air Cleaner Element 1. Remove the air cleaner element. 2. Use clean dry compressed air on the inside of the element. Pressure of compressed air must be under 205 kPa (2.1 kgf/cm... - Page 37 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Fan Belt Tension 1. Measure the deflection (A), depressing the belt halfway between the fan drive pulley and alternator pulley at specified force 98 N (10 kgf, 22 lbf). 2. If the measurement is not within the factory specifications, loosen the alternator mounting screws and relocate the alternator to adjust.

-

Page 38: Check Points Of Every 200 Hours

Then, fill the engine oil up to the specified level. IMPORTANT • To prevent serious damage to the engine, replacement element must be highly efficient. Use only a KUBOTA genuine filter or its equivalent. (1) Engine Oil Filter Cartridge... -

Page 39: Check Points Of Every 1000 Hours

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Checking Radiator Hoses and Clamp Bands 1. Check to see if the radiator hoses are properly fixed every 200 hours of operation or every six months, whichever comes first. 2. If the clamp is loose, apply oil to the threads and retighten it securely. - Page 40 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Checking Valve Clearance IMPORTANT • The valve clearance must be checked and adjusted when engine is cold. 1. Remove the cylinder head cover. 2. Align the "1TC" mark (1) on the flywheel and alignment mark (2) on the rear end plate so that the No. 1 piston comes to the compression top dead center.

-

Page 41: Check Points Of Every 2000 Hours

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [7] CHECK POINTS OF EVERY 2000 HOURS Replacing Spark Plug 1. Disconnect the ignition coil. 2. Remove the spark plug. 3. Replace the new spark plug. 4. Tighten the spark plug with a plug wrench. IMPORTANT (When reassembling) •... - Page 42 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Cleaning Water Jacket and Radiator Interior CAUTION • Do not remove the radiator cap when the engine is hot. Then loosen cap slightly to the stop to relieve any excess pressure before removing cap completely. 1. Stop the engine and let cool down.

- Page 43 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Anti-Freeze • There are two types of anti-freeze available: use the permanent type (PT) for this engine. • Before adding anti-freeze for the first time, clean the radiator interior by pouring fresh, soft water and draining it a few times.

-

Page 44: Check Points Of Every 2 Years

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [9] CHECK POINTS OF EVERY 2 YEARS Replacing Intake Air Line 1. Replace the intake hose and the clamps between the air cleaner and the electronic throttle body or gas mixer. 9Y1210661GEG0047US0 Replacing Breather Hose 1. Replace the breather hose and the clamps between the head cover and the intake manifold. - Page 45 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Changing Radiator Coolant (L.L.C.) CAUTION • Do not remove the radiator cap when the engine is hot. Then loosen cap slightly to the stop to relieve any excess pressure before removing cap completely. 1. Stop the engine and let cool down.

- Page 46 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (Continued) (Anti-freeze) • There are two types of anti-freeze available; use the permanent type (PT) for this engine. • Before adding anti-freeze for the first time, clean the radiator interior by pouring fresh, soft water and drain it a few times.

- Page 47 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Replacing Battery CAUTION • When the battery is being activated, hydrogen and oxygen gases in the battery are extremely explosive. Keep open sparks and flames away from the battery at all times, especially when charging the battery.

-

Page 48: Special Tools

GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 5. SPECIAL TOOLS Compression Tester Code No. • 07909-30251 Application • Use to measure gasoline engine compression and diagnose the engine for a major overhaul. WSM000001GEG0088US0 Oil Pressure Tester Code No. • 07916-32032 Application • Use to measure lubricating oil pressure. - Page 49 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Bushing Replacing Tool Application • Use to press out and press fit the bushing. [For small end bushing] 157 mm (6.18 in.) 24 mm (0.94 in.) 120 mm (4.72 in.) 21.8 to 21.9 mm dia. (0.859 to 0.862 in. dia.) 24.8 to 24.9 mm dia.

- Page 50 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Crankshaft Bearing 1 Replacing Tool Application • Use to press out and press fit the crankshaft bearing 1. [Press out] 135 mm (5.31 in.) 72 mm (2.8 in.) 40 mm radius (1.6 in. radius) 10 mm (0.39 in.) 24 mm (0.94 in.)

- Page 51 GENERAL WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Crank Sleeve Setter Application • Use to fix the crankshaft sleeve. (1) Auxiliary socket for pushing 130 mm (5.12 in.) 112 mm (4.41 in.) 107 mm (4.21 in.) 82 mm (3.2 in.) 72 mm (2.8 in.) 67 mm (2.6 in.) 47 mm (1.8 in.)

- Page 52 ENGINE KiSC issued 05, 2014 A...

- Page 53 [4] RADIATOR ......................... 1-M10 [5] RADIATOR CAP......................... 1-M11 4. FUEL SYSTEM......................... 1-M12 [1] GENERAL .......................... 1-M12 [2] FUEL FILTER (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3)........ 1-M13 [3] ELECTRONIC THROTTLE BODY (ETB) ................1-M13 [4] FUEL PUMP (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3)........1-M14 [5] INJECTORS AND DELIVERY PIPE (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3) ............

- Page 54 (4) Starter Safety System....................1-M23 [2] CHARGING SYSTEM......................1-M23 (1) General ......................... 1-M23 (2) IC Regulator Built-in Type Alternator ................1-M23 [3] ENGINE CONTROL UNIT (ECU) ..................1-M26 [4] WATER TEMPERATURE SENSOR .................. 1-M26 [5] TEMPERATURE AND MANIFOLD ABSOLUTE PRESSURE SENSOR (TMAP SENSOR) ...........................

-

Page 55: Engine Body

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 1. ENGINE BODY [1] CYLINDER BLOCK The engine has a high durability tunnel-type cylinder block in which the crank bearing component is a constructed body. Furthermore, liner less type, allow effective cooling, less distortion, and greater wear resistance. -

Page 56: Cylinder Head

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [4] CYLINDER HEAD Intake and Exhaust Port The cross-flow type intake / exhaust ports, which lower the heat conduction from the exhaust port to the intake port. The low heat conduction keeps the intake air from being heated and expanded by the exhaust gas. -

Page 57: Piston And Piston Ring

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [6] PISTON AND PISTON RING Piston and Piston Ring The piston has a slightly oval shape when cold (in consideration of thermal expansion) and a concave head. Top Ring: The top ring is of plain barrel face type. The barrel... -

Page 58: Gear Shaft

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [9] GEAR SHAFT The gear shaft is a shaft that was changed from the fuel camshaft for 05-E3B engine to the shaft with no cam. (1) Injection Pump Gear (4) Feather key (2) Stopper (5) Gear shaft... -

Page 59: Inlet And Exhaust Valves

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [12] INLET AND EXHAUST VALVES The valve and its guide for the inlet are different from those for the exhaust. Other parts, such as the spring (4), spring retainer (3), collet (2), stem seal (5), and cap (1) are the same for both the inlet and exhaust. -

Page 60: Lubricating System

• Full pressure feed type • Pressure feed and splash type KUBOTA engines have lubricating system of full pressure feed type. This system consists of an oil strainer (11), oil pump (12), relief valve (10), oil filter cartridge (9) and oil pressure switch (2). -

Page 61: Oil Pump

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [2] OIL PUMP This oil pump has an inner rotor (1) and an outer rotor (2). The inner rotor (1), which is driven by crankshaft, rotates the outer rotor (2) in the same direction. The inner rotor (1) has one less lobe than the outer rotor (2), and they are eccentrically engaged with each other. -

Page 62: Oil Pressure Switch

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [5] OIL PRESSURE SWITCH The oil pressure switch is mounted on the cylinder block and is led to the lubricating oil passage. When the oil pressure falls below the specified value, the oil pressure warning lamp lights. -

Page 63: Cooling System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 3. COOLING SYSTEM [1] GENERAL (1) Radiator (2) Water Pump (3) Cooling Fan (4) Thermostat (5) Cylinder Head (6) Cylinder Block The cooling system consists of a radiator (1), a centrifugal water pump (2), a cooling fan (3) and a thermostat (4). -

Page 64: Water Pump

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [2] WATER PUMP The water pump is driven by the crankshaft and a V belt. The rotating impeller (4) in the water pump sucks the coolant from the radiator and sends it into the water jacket in the cylinder block. -

Page 65: Radiator Cap

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [5] RADIATOR CAP The pressure type radiator cap prevents differences in pressure between the inside and the outside of the radiator from deforming the radiator. When the coolant temperature rises and the pressure in the radiator increases above the specified pressure, the pressure valve (1) opens to reduce the internal pressure. -

Page 66: Fuel System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 4. FUEL SYSTEM [1] GENERAL (1) Delivery Pipe (8) Vapor Hose* [A] Gasoline Fuel (d) Liquid Propane or Natural (2) Fuel Pressure Manifold (FPM) (9) Vaporizer (DSR) [B] LPG / Natural Gas Fuel Gas Line* (3) Fuel Pump... -

Page 67: Fuel Filter (Wg1605-G-E3, Wg1605-Gl-E3, Wg1605-Gln-E3)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [2] FUEL FILTER (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3) The fuel filter is installed in the fuel line between the fuel tank and the feed pump. As the fuel flows from the inlet "A" through the filter element (1), the dirt and impurities in the fuel are filtered, allowing only clean fuel to penetrate the inside of the filter element. -

Page 68: Fuel Pump (Wg1605-G-E3, Wg1605-Gl-E3, Wg1605-Gln-E3)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [4] FUEL PUMP (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3) The gasoline system will use an external electric gasoline fuel pump. The pump will be mounted in the chassis of the vehicle, or equipment near the fuel tank. Gasoline rated fuel hose and securing devices supplied by the OEM, will be used to transfer the pumped fuel to the Gasoline Fuel Pressure Manifold assembly. -

Page 69: Injectors And Delivery Pipe (Wg1605-G-E3, Wg1605-Gl-E3, Wg1605-Gln-E3)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [5] INJECTORS AND DELIVERY PIPE (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3) The gasoline fuel delivery system, uses a delivery pipe (1) mounted with injectors (2), for each cylinder. The Engine Control Unit (ECU) will use the gasoline fuel delivery calibrations, to pulse width modulate each injector (2), to deliver the correct amount of gasoline, for optimized performance and emission control. -

Page 70: Vaporizer (Dual Stage Regulator (Dsr)) (Wg1605-L-E3, Wg1605-L-E3, Wg1605-N-E3, Wg1605-Ln-E3, Wg1605-Gln-E3)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [6] VAPORIZER (DUAL STAGE REGULATOR (DSR)) (WG1605-L-E3, WG1605-L-E3, WG1605-N-E3, WG1605-LN-E3, WG1605-GLN-E3) When evaporating by primary chamber of vaporizer liquid propane or natural gas needs the evaporation heat. This vaporizer installs the water jacket, throws the coolant of engine, heats primary chamber, promotes evaporation. -

Page 71: Lock Off Valve (Wg1605-L-E3, Wg1605-L-E3, Wg1605-N-E3, Wg1605-Ln-E3, Wg1605-Gln-E3)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [7] LOCK OFF VALVE (WG1605-L-E3, WG1605-L-E3, WG1605-N-E3, WG1605-LN-E3, WG1605-GLN-E3) Vaporizer requires a normally-closed electrically controlled fuel lock off valve that is close coupled to the vaporizer and off when ignition switch is off or when the engine is not running normally. In operation without a lock off upstream the vaporizer will flow fuel with the engine off. -

Page 72: Exhaust System

KUBOTA engines have two kinds of catalytic devices, catalytic muffler and catalytic converter. (1) Catalytic Muffler (2) Catalytic Converter... -

Page 73: Oxygen Sensor

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [2] OXYGEN SENSOR An Oxygen sensor is an essential element of a feedback control of air-fuel ratio. The sensor has a mechanism in which a zirconia tube, which is a solid electrolyte, is exposed into the exhaust gas and the... -

Page 74: Electrical System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 6. ELECTRICAL SYSTEM [1] STARTING SYSTEM (1) General The starting device consists of the starter, starter switch, fuse, battery etc., and the outline of the basic operation is as the followings; 1. Voltage from battery is added to the B terminal of starter switch through the fuse. - Page 75 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM When the Pinion Gear Engages with the Ring Gear without Collision When the pinion gear engages with the ring gear at a certain position, the magnetic switch main contact closes, and a large current flows through the main contact to the armature.

-

Page 76: Starter Switch

As the standard part of KUBOTA engine, the starter switch in below figure is recommended. [Connection Diagram] 9Y1210661ENM0046US0... -

Page 77: Starter Safety System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (4) Starter Safety System The ECU can be configured for either auto cranking (crank until starting) or crank limiting (maximum crank time and disabling of starter if frequency and number of tries is too high). 9Y1210661ENM0047US0 [2] CHARGING SYSTEM (1) General The function of the charging device is to charge batteries. - Page 78 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM D2 Type Regulator (1) Alternator Assembly (2) IC Regulator (3) Key Switch IC regulator has a special feature that makes it possible to interrupt field current by using the transistor or IC instead of the contact-point-type regulator.

- Page 79 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Total Wave Rectification In case of the generator for mobile equipment of which purpose is to charge the batteries, alternating current cannot be used as it is. Because of this, it is required to conduct the action called rectification so that the alternating current can be changed to direct current.

-

Page 80: Engine Control Unit (Ecu)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Surge voltage waveform with any charging cable disconnection. • May be VHmin = 6.5 V in high electric load shedding or unloaded condition with the battery fully charged. (1) Voltage (a) VH max (2) Angle of Rotation (°) -

Page 81: Temperature And Manifold Absolute Pressure Sensor (Tmap Sensor)

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [5] TEMPERATURE AND MANIFOLD ABSOLUTE PRESSURE SENSOR (TMAP SENSOR) TMAP sensor is mounted in the intake manifold and measures the absolute pressure as well as the temperature of the air / fuel stream. MAP data is used by... -

Page 82: Knock Sensor

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [8] KNOCK SENSOR The knock sensor is used to detect detonation through mechanical vibration in the engine block and / or cylinder heads and provide feedback for the ignition system to retard spark to reduce knock intensity. In most... - Page 83 SERVICING CONTENTS 1. TROUBLESHOOTING.........................1-S1 [1] FOR GENERAL ........................1-S1 [2] FOR GASOLINE FUEL ......................1-S2 [3] FOR LPG / NATURAL GAS FUEL ..................1-S2 2. SERVICING SPECIFICATIONS ....................1-S3 3. TIGHTENING TORQUES......................1-S10 [1] TIGHTENING TORQUES FOR GENERAL USE SCREWS, BOLTS AND NUTS....1-S10 [2] TIGHTENING TORQUES FOR GENERAL USE SCREWS, BOLTS ........1-S11 4.

-

Page 84: Troubleshooting

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 1. TROUBLESHOOTING [1] FOR GENERAL Reference Symptom Probable Cause Solution Page Engine Will Not Turn Engine jammed Check engine to find – Over the problem and repair it Battery discharged Charge – Starter malfunctioning Repair or replace... -

Page 85: For Gasoline Fuel

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Reference Symptom Probable Cause Solution Page Exhaust Flames Damaged ignition coil Replace 1-S20 Damaged spark plug Adjust spark plug or G-13 replace Wires disconnected or damaged wire Reconnect / replace – Bad connection of ignition coil and spark plug Reconnect –... -

Page 86: Servicing Specifications

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 2. SERVICING SPECIFICATIONS ENGINE BODY Item Factory Specification Allowable Limit Valve Clearance (Cold) 0.145 to 0.185 mm – 0.00571 to 0.00728 in. Compression Pressure – 1.27 MPa 0.88 MPa 13.0 kgf/cm 9.0 kgf/cm 185 psi 130 psi Variance Among –... - Page 87 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Item Factory Specification Allowable Limit Valve Spring Free Length 35.1 to 35.6 mm 34.8 mm 1.39 to 1.40 in. 1.37 in. Tilt – 1.0 mm 0.039 in. Setting Load / 74 N / 31.0 mm 63 N / 31.0 mm Setting Length 7.5 kgf / 31.0 mm...

- Page 88 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Item Factory Specification Allowable Limit Cam Height Intake 28.80 mm 28.75 mm 1.134 in. 1.132 in. Exhaust 29.00 mm 28.95 mm 1.142 in. 1.140 in. Camshaft Journal to Cylinder Block Bore Oil Clearance 0.050 to 0.091 mm 0.15 mm...

- Page 89 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Item Factory Specification Allowable Limit Piston Ring to Piston Ring Groove Top Ring 0.040 to 0.080 mm 0.2 mm (Clearance) 0.0016 to 0.0031 in. 0.008 in. Second Ring 0.030 to 0.070 mm 0.2 mm (Clearance) 0.0012 to 0.0027 in.

- Page 90 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM LUBRICATING SYSTEM Item Factory Specification Allowable Limit Engine Oil Pressure At Idle Speed 49 kPa – 0.50 kgf/cm 7.1 psi At Rated Speed 196 to 441 kPa 147 kPa 2.00 to 4.49 kgf/cm 1.50 kgf/cm 28.5 to 63.9 psi 21.3 psi...

- Page 91 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM IGNITION SYSTEM Item Factory Specification Allowable Limit Ignition Timing Gasoline fuel 0.45 rad (26 °) – before T.D.C. / 3000 min (rpm) 0.17 rad (10 °) – before T.D.C. / 800 min (rpm) LPG / natural gas 0.35 rad (20 °)

- Page 92 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM ELECTRICAL SYSTEM Item Factory Specification Allowable Limit Starter Commutator 28.0 mm 27.0 mm (O.D.) 1.10 in. 1.06 in. Difference Less than 0.4 mm (O.D.) 0.05 mm 0.02 in. 0.002 in. Mica 0.50 to 0.80 mm 0.20 mm (Undercut) 0.020 to 0.031 in.

-

Page 93: Tightening Torques

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 3. TIGHTENING TORQUES Screws, bolts and nuts must be tightened to the specified torque using a torque wrench, several screws, bolts and nuts such as those used on the cylinder head must be tightened in proper sequence and the proper torque. -

Page 94: Tightening Torques For General Use Screws, Bolts

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [2] TIGHTENING TORQUES FOR GENERAL USE SCREWS, BOLTS If the tightening torque is not specified, refer to the table below for the none specified torques values. Indication on No-grade or 4T top of bolt Unit N·m kgf·m lbf·ft... -

Page 95: Checking, Disassembling And Servicing

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM 4. CHECKING, DISASSEMBLING AND SERVICING [1] CHECKING AND ADJUSTING (1) Engine Body Compression Pressure 1. Run the engine until it is warmed up. 2. Stop the engine. 3. Remove the air cleaner, the catalytic muffler / converter and all spark plugs. - Page 96 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Adjusting Valve Clearance IMPORTANT • The clearance must be checked and adjusted when engine is cold. 1. Remove the cylinder head cover and the spark plugs. 2. Align the "1TC" mark (1) on the flywheel and alignment mark (2) on the rear end plate so that the No.

-

Page 97: Lubricating System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (2) Lubricating System Engine Oil Pressure 1. Remove the engine oil pressure switch, and set an oil pressure tester. 2. Start the engine. After warming up, measure the oil pressure of both idling and rated speeds. 3. If the oil pressure is less than the allowable limit, check the following. - Page 98 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Fan Belt Damage and Wear 1. Check the fan belt for damage. 2. If the fan belt is damaged, replace it. 3. Check if the fan belt is worn and sunk in the pulley groove. 4. If the fan belt is nearly worn out and deeply sunk in the pulley groove, replace it.

-

Page 99: Fuel System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Radiator Water Leakage 1. Pour a specified amount of water into the radiator. 2. Set a radiator tester (1) and an adaptor (2) and raise the water pressure to the specified pressure (210 kPa, 2.14 kgf/cm 30.5 psi). - Page 100 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Resistance of Fuel Pressure Manifold (FPM) 1. Disconnect the connector. 2. Measure the resistance between terminal 1 and terminal 2 with an ohmmeter. 3. If the resistance is not with in the factory specifications, replace Factory Terminal 1 –...

-

Page 101: Ignition System

NOTE • The LPG / natural gas in joint (fitting) to the vaporizer / regulator is not provided in the KIT by KUBOTA, due to the many different connection requirements by the OEM. • Vapor hose length must not exceed 700 mm (27.6 in), shorter is generally considered better. - Page 102 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Spark Test (For gasoline) 1. Disconnect all injector connector. 2. Remove the spark plug, put it inside the ignition coil firmly, and then ground the threaded section to the engine body (not to painted or resin parts).

- Page 103 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Spark Plug Gap 1. Remove the spark plug, and remove carbon from the electrode with a wire brush or other tools. 2. Measure the spark plug gap with a feeler gauge, and repair or replace the plug if the measured gap differs from the factory specification.

-

Page 104: Electrical System

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (6) Electrical System CAUTION • To avoid accidental short circuit, be sure to attach the positive cable to the positive terminal before the negative cable is attached to the negative terminal. • Never remove the battery cap while the engine is running. - Page 105 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Battery Specific Gravity CAUTION • If battery acid (dilute sulfuric acid) gets on you it could cause blindness or burns, or could cause corrosion of machinery and tools so please be careful when handling. • Wear safety glasses and rubber gloves when performing battery maintenance and inspection (measuring specific gravity, replenishing water, or charging).

- Page 106 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Motor Test CAUTION • Secure the starter to prevent it from jumping up and down while testing the motor. 1. Disconnect the battery negative cable from the battery. 2. Disconnect the battery positive cable from the battery.

- Page 107 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Alternator on Unit Test (Before testing) • Before alternator on unit test, check the battery terminal connections, circuit connection, fan belt tension, charging indicator lamp, fuses on the circuit, and abnormal noise from the alternator. • Prepare full charged battery for the test.

-

Page 108: Disassembling And Assembling

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [2] DISASSEMBLING AND ASSEMBLING IMPORTANT • When reassembling, replace all of the O-rings and gaskets by new ones. • When disassembling the LPG / natural gas engine after completely consuming the fuel in piping. • In order to reduce the fuel pressure, do not remove the fuel hose at least 3 minutes after stopping the engine. -

Page 109: External Components

57.2 to 66.5 lbf·ft (1) Cooling Fan (2) Fan Belt 9Y1210661ENS0102US0 Fuel Line (WG1605-G-E3, WG1605-GL-E3, WG1605-GLN-E3) 1. Disconnect the gasoline hose from the connector (1). CAUTION • In order to reduce the fuel pressure, do not remove the fuel hose at least 3 minutes after stopping the engine. - Page 110 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Vapor Hose and Coolant Hose (WG1605-N-E3, WG1605-GL-E3, WG1605-LN-E3, WG1605-GLN-E3) CAUTION • Close the LPG / natural gas tank valve. • In order to reduce the fuel pressure, do not remove the fuel hose at least 3 minutes after stopping the engine.

-

Page 111: Cylinder Head, Valves And Oil Pan

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (3) Cylinder Head, Valves and Oil Pan Cylinder Head Cover 1. Remove the cylinder head cover cap nut (1). 2. Remove the cylinder head cover (2). 3. Remove the intake manifold (3). (When reassembling) • Check to see if the cylinder head cover gasket is not damaged. - Page 112 (1). 2. Remove the cylinder head screw in the order of (r) to (a). 3. Remove the spark plug. 4. Remove the injector flange (WG1605-G-E3, WG1605-GL-E3) / ignition coil flange (WG1605-L-E3). 5. Lift up the cylinder head to remove. 6. Remove the cylinder head gasket.

- Page 113 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Valves 1. Remove the valve caps (2). 2. Remove the valve spring collet (3), pushing the valve spring retainer (4) with valve spring replacer (1). 3. Remove the valve spring retainer (4), valve spring (5) and valve stem seal (6).

-

Page 114: Thermostat

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Oil Pan and Oil Strainer 1. Remove the oil pan mounting screws (2). 2. Remove the oil pan (1) by lightly tapping the rim of the pan with a wooden hammer. 3. Remove the oil strainer (3). -

Page 115: Timing Gear, Camshaft, Gear Shaft And Pto Shaft

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (5) Timing Gear, Camshaft, Gear Shaft and PTO Shaft Fan Drive Pulley 1. Secure the flywheel to keep it from turning. 2. Remove the fan drive pulley screw. 3. Draw out the fan drive pulley with a puller. - Page 116 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Cam Gear, Idle Gear 1, 2 and Governor Gear 1. Remove the idle gear 2 (7) / idle gear 1 (4). 2. Remove the fuel camshaft stopper (8). 3. Draw out the injection pump gear (1) with fuel gear shaft (9).

-

Page 117: Piston And Connecting Rod

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (6) Piston and Connecting Rod Connecting Rod Cap 1. Remove the connecting rod caps (1) using a hexagonal 8 mm socket. (When reassembling) • Align the marks (a) with each other. (Face the marks toward the intake manifold.) •... -

Page 118: Crankshaft

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Piston Ring and Connecting Rod 1. Remove the piston rings using a piston ring tool. 2. Remove the piston pin (10), and separate the connecting rod (8) from the piston (7). (When reassembling) • When installing the second ring (2), assemble the rings so that the manufacturer's mark (11) near the gap faces the top of the piston. - Page 119 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Bearing Case Cover 1. Remove the bearing case cover mounting screws. First, remove inside screws (1) and then outside screws (2). 2. Remove the bearing case cover (6). (When reassembling) • Fit the bearing case gasket (3) and the bearing case cover gasket (4) with correct directions.

- Page 120 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Main Bearing Case Assembly 1. Remove the two main bearing case screws 1 (5), and remove the main bearing case assembly 1 (1), being careful with crankshaft bearing 3 (7). 2. Remove the main bearing case assembly 2 (2), the main bearing case assembly 3 (3) and the main bearing case assembly (4) as above.

-

Page 121: Starter

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (8) Starter (1) Solenoid Switch Mounting (2) Starter Drive Housing (3) Drive Lever (4) Gasket (5) Solenoid Switch (6) B Terminal Nut (7) C Terminal Nut (8) Snap Ring (9) Overrunning Clutch (10) Armature (11) Brush Spring... -

Page 122: Alternator

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (9) Alternator (1) Pulley (2) Drive End Frame (3) Stator (4) Bearing (5) Retainer Plate (6) Rotor (7) Bearing (8) Rear End Frame (9) Rectifier (10) IC Regulator (11) Brush Holder (12) Rear End Cover 1. Remove the pulley (1). -

Page 123: Servicing

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM [3] SERVICING (1) Cylinder Head and Valves Top Clearance 1. Remove the cylinder head. 2. With the piston at TDC, use grease to affix three or four plastigauges (1) of a diameter 1.5 mm (0.059 in.) × 5.0 to 7.0 mm (0.20 to 0.27 in.) long to the crown of the piston;... - Page 124 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Cylinder Head Flaw 1. Prepare an air spray red check. 2. Clean the surface of the cylinder head with the detergent (2). 3. Spray the cylinder head surface with the red permeative liquid (1). Leave it five to ten minutes after spraying.

- Page 125 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Valve Lapping 1. Apply compound evenly to the valve lapping surface. 2. Insert the valve into the valve guide. Lap the valve onto its seat with a valve flapper or screwdriver. 3. After lapping the valve, wash the compound away and apply oil, then repeat valve lapping with oil.

- Page 126 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Clearance between Valve Stem and Valve Guide 1. Remove carbon from the valve guide section. 2. Measure the valve stem O.D. with an outside micrometer. 3. Measure the valve guide I.D. with a small hole gauge, and calculate the clearance.

- Page 127 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Free Length and Tilt of Valve Spring 1. Measure the free length (B) of valve spring with vernier calipers. If the measurement is less than the allowable limit, replace it. 2. Put the spring on a surface plate, place a square on the side of the spring.

- Page 128 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Push Rod Alignment 1. Place the push rod on V blocks. 2. Measure the push rod alignment. 3. If the measurement exceeds the allowable limit, replace the push rod. 0.25 mm Push rod alignment Allowable limit 0.0098 in.

-

Page 129: Timing Gear And Camshaft

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (2) Timing Gear and Camshaft Timing Gear Backlash 1. Set a dial indicator (lever type) with its tip on the gear tooth. 2. Move the gear to measure the backlash, holding its mating gear. 3. If the backlash exceeds the allowable limit, check the oil clearance of the shafts and the gear. - Page 130 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Camshaft Side Clearance 1. Set a dial indicator with its tip on the camshaft. 2. Measure the side clearance by moving the cam gear to the front and rear. 3. If the measurement exceeds the allowable limit, replace the camshaft stopper.

- Page 131 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Oil Clearance between Idle Gear Shaft 1 and 2 and Idle Gear Bushing 1. Measure the idle gear shaft O.D. with an outside micrometer. 2. Measure the idle gear bushings I.D. with an inside micrometer, and calculate the oil clearance.

-

Page 132: Piston And Connecting Rod

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (3) Piston and Connecting Rod Piston Pin Bore I.D. 1. Measure the piston pin bore I.D. in both the horizontal and vertical directions with a cylinder gauge. 2. If the measurement exceeds the allowable limit, replace the piston. - Page 133 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Piston Ring Gap 1. Insert the piston ring into the lower part of the cylinder (the least worn out part) with a piston ring compressor and piston. 2. Measure the ring gap with a feeler gauge. 3. If the measurement exceeds the allowable limit, replace the piston ring.

-

Page 134: Crankshaft

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Connecting Rod Alignment 1. Remove the crankpin bearing, and install the connecting rod cap. 2. Install the piston pin in the connecting rod. 3. Install the connecting rod on the connecting rod alignment tool. 4. Put a gauge over the piston pin, and move it against the face plate. - Page 135 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Oil Clearance between Crankpin and Crankpin Bearing 1. Clean the crankpin and crankpin bearing. 2. Put a strip of plastigauge on the center of the crankpin. 3. Install the connecting rod cap and tighten the connecting rod screws to the specified torque, and remove the cap again.

- Page 136 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Oil Clearance between Crankshaft Journal and Crankshaft Bearing 1 1. Measure the O.D. of the crankshaft front journal with an outside micrometer. 2. Measure the I.D. of the crankshaft bearing 1 with an inside micrometer, and calculate the oil clearance.

- Page 137 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Oil Clearance between Crankshaft Journal and Crankshaft Bearing 2 (Crankshaft Bearing 3) 1. Put a strip of plastigauge on the center of the journal. 2. Install the bearing case and tighten the bearing case screws 1 to the specified torque, and remove the bearing case again.

- Page 138 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Replacing Crankshaft Sleeve 1. Remove the used crankshaft sleeve. 2. Set the sleeve guide (2) to the crankshaft. 3. Heat a new sleeve to a temperature between 150 and 200 °C (302 and 392 °F), and fix the sleeve to the crankshaft as shown in figure.

-

Page 139: Cylinder

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (5) Cylinder Cylinder Wear 1. Measure the I.D. of the cylinder at the six positions (see figure) with a cylinder gauge to find the maximum and minimum I.D.'s. 2. Get the difference (Maximum wear) between the maximum and the minimum I.D.'s. -

Page 140: Oil Pump

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (6) Oil Pump Rotor Lobe Clearance 1. Measure the clearance between lobes of the inner rotor and the outer rotor with a feeler gauge. 2. If the clearance exceeds the factory specifications, replace the oil pump rotor assembly. -

Page 141: Starter

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (7) Starter Overrunning Clutch 1. Inspect the pinion for wear or damage. 2. If there is any defect, replace the overrunning clutch assembly. 3. Check that the pinion turns freely and smoothly in the overrunning direction and does not slip in the cranking direction. - Page 142 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Brush Holder 1. Check the continuity across the brush holder and the holder support with an ohmmeter. 2. If it conducts, replace the brush holder. 9Y1210318ENS0128US0 Armature Coil 1. Check the continuity across the commutator and armature coil core with an ohmmeter.

-

Page 143: Alternator

ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM (8) Alternator Bearing 1. Check the bearing for smooth rotation. 2. If it does not rotate smoothly, replace it. 9Y1210318ENS0131US0 Stator 1. Measure the resistance across each lead of the stator coil with resistance range of circuit tester. - Page 144 ENGINE WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, WSM Rectifier 1. Check the continuity across each diode of rectifier with resistance range of circuit tester. 2. The rectifier is normal if the diode in the rectifier conducts in one direction and does not conduct in the reverse direction.

- Page 145 EDITOR : KUBOTA FARM & INDUSTRIAL MACHINERY SERVICE, LTD. 64, ISHIZU-KITAMACHI, SAKAI-KU, SAKAI-CITY, OSAKA, 590-0823, JAPAN PHONE : ( 81 ) 72-241-1129 : ( 81 ) 72-245-2484 E-mail : ks_g.ksos-pub@kubota.com Printed in Japan 2014. 05, S, EI, EI, engusa Code No.9Y111-06612 2012.