Table of Contents

Advertisement

Quick Links

How to Use This Manual

This manual provides detailed instructions on installation and

maintenance of gear drives and couplings. Use the table of

contents below to locate required information.

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE

FREE SERVICE.

Table of Contents

Installation Instructions . . . . . . . . . . . . . . . . . . . . . Pages 1 & 2

Shaft Connections . . . . . . . . . . . . . . . . . . . . . . . . Pages 2 & 3

Tightening Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Lubrication Recommendations. . . . . . . . . . . . . . Pages 3 thru 7

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Stored and Inactive Gear Drives . . . . . . . . . . . . . . . . . . Page 8

Introduction

Credit for long service and dependable operation of a gear

drive is often given to the engineers who designed it, or the

craftsmen who constructed it, or the sales engineer who

recommended the type and size. Ultimate credit belongs to the

mechanic on the job who worked to make the foundation rigid

and level, who accurately aligned the shafts and carefully

installed the accessories, and who made sure that the drive

received regular lubrication. The details of this important job are

the subject of this manual.

NAMEPLATE — Operate Falk gear drives only at horsepower, speed

and ratio shown on nameplate. Before changing any one of these,

submit complete nameplate data and new application conditions to

the Factory for correct oil level, parts and application approval.

DISASSEMBLY AND ASSEMBLY — Disassembly & assembly

instructions and parts guides are available from the Factory or

Falk Representatives. When requesting information, please give

complete data from the nameplate on the gear drive; Model,

M.O.Number, Date, RPM, and Ratio.

WARNING: Consult applicable local and national safety codes

for proper guarding of rotating members. Lock out power source

and remove all external loads from drive before servicing drive

or accessories.

Warranty

The Falk Corporation (the "Company") warrants that, for a

period of one year from the date of shipment, the product

described herein will deliver successfully its rated output as

indicated on the nameplate, provided, it is properly installed

and maintained, correctly lubricated, and operated in the

environment and within the limits of speed, torque or other load

conditions for which it was sold. Such product is expressly not

warranted against failure or unsatisfactory operation resulting

from dynamic vibrations imposed upon it by the drive system in

which it is installed unless the nature of such vibrations has been

fully defined and expressly accepted in writing by the Company

as a condition of operation.

The Falk Corporation, a Sundstrand Company, P .O. Box 492, Zip 53201-0492

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

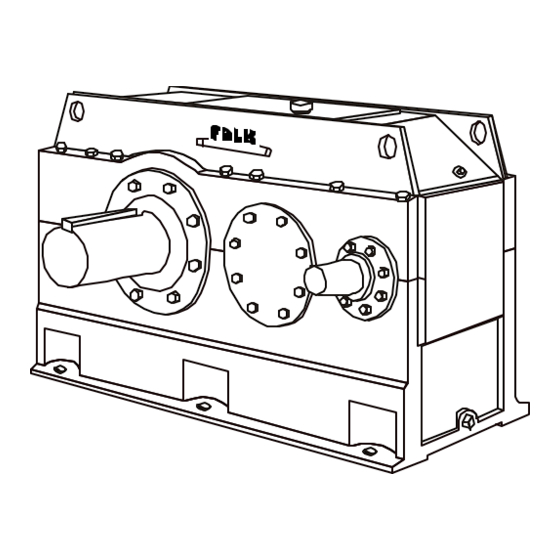

Enclosed Gear Drives

Types GHB, Y, YB & YBX

Type Y

Type YB

Installation Instructions

The following instructions apply to standard Falk Type GHB, Y,

YB & YBX drives shown above. If a drive is furnished with special

features, refer to the supplementary instructions shipped with the

drive.

WELDING — Do not weld on the gear drive or accessories

without prior approval from The Falk Corporation. Welding on

the drive may cause distortion of the housing or damage to the

bearings and gear teeth. Welding without prior approval could

void the warranty.

EFFECTS OF SOLAR ENERGY — If the gear drive operates in

the sun at ambient temperatures over 100°F(38°C), then special

measures should be taken to protect the drive from solar energy.

This protection can consist of a canopy over the drive or reflective

paint on the drive. If neither is possible, a heat exchanger or other

cooling device may be required to prevent the sump temperature

from exceeding the allowable maximum.

HORIZONTAL MOUNTING — Mount gear drive with base

horizontal, unless it has been specifically ordered for mounting

in another position. If it is necessary to mount the drive in a

different position from that for which it was ordered, consult The

Falk Corporation for changes necessary to provide

proper lubrication.

NON-HORIZONTAL MOUNTING — For gear drives with

non-horizontal mounting, including tilted, vertical and wall

mounted, refer to instructions provided with the drive for oil

levels and bearing lubrication.

Installation & Maintenance Instructions

•

Sizes 1080–1195 & 2050–2235 (Page 1 of 8)

•

Type YBX

Type GHB

148-050

April 1999

Supersedes 4-89

Advertisement

Table of Contents

Summary of Contents for FALK GHB Series

- Page 1 Company as a condition of operation. 148-050 The Falk Corporation, a Sundstrand Company, P .O. Box 492, Zip 53201-0492 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 April 1999 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com...

- Page 2 Types GHB, Y, YB & YBX • FOUNDATION, GENERAL — To facilitate oil drainage, elevate If equipment is received from Falk mounted on a bedplate, the the gear drive foundation above the surrounding floor level. If components were accurately aligned at Falk with the bedplate desired, replace the drive oil mounted on a large, flat assembly plate.

-

Page 3: Fastener Tightening Torques

Synthetic lubricants can also be used in normal climates. 148-050 The Falk Corporation, a Sundstrand Company, P .O. Box 492, Zip 53201-0492 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 April 1999 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com... -

Page 4: Synthetic Lubricants

Lubricants in Table 3 do contain several of these additives. 148-050 The Falk Corporation, a Sundstrand Company, P.O. Box 492, Zip 53201-0492 April 1999 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 Supersedes 4-89... - Page 5 Valvoline AW ISO 320 ..148-050 The Falk Corporation, P .O. Box 492, Zip 53201-0492 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 (.pdf revision) April 1999 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com...

-

Page 6: Lubrication Systems

A grease that meets the USDA “H1” classification is suitable for food processing applications. 148-050 The Falk Corporation, a Sundstrand Company, P.O. Box 492, Zip 53201-0492 April 1999 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 Supersedes 4-89... - Page 7 ‡ Consult Factory before substituting higher viscosity grades from those indicated in Table 7 above. 148-050 The Falk Corporation, a Sundstrand Company, P .O. Box 492, Zip 53201-0492 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 April 1999 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com...

-

Page 8: Preventive Maintenance

Refer to Page 4. BEARING & SEAL GREASES — Refer to Page 6. 148-050 The Falk Corporation, a Sundstrand Company, P.O. Box 492, Zip 53201-0492 April 1999 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 Supersedes 4-89...