Advertisement

Quick Links

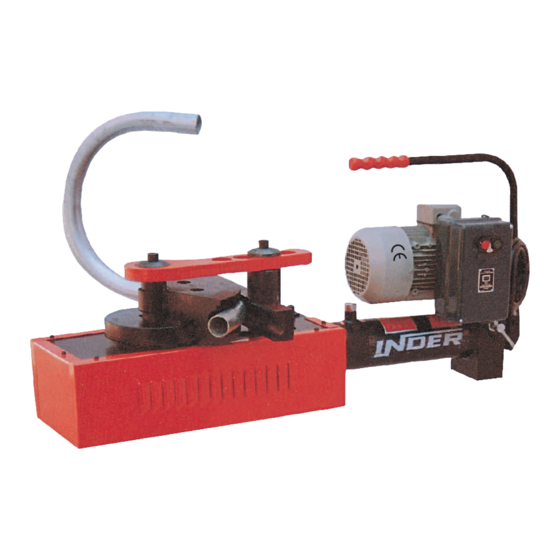

PARTS DIAGRAM

5

1

6

4

56

53

30

7

20

57

54

19

55

58

22

15

31

18

14

54

17

57

56

53

32

21

13

16

ITEM#

DESCRIPTION

QTY.

1

Main Cylinder

1

2

Upper Plate

1

3

Lower Plate

1

4

Side cover

1

5

Die/Formers 3/8" to 2"

7

6

Sliding bar

7

7

Side plate

2

8

Ram/Main Piston

1

9

Bucket For Piston

1

10

Piston Disc Small

1

11

L-Key Bolt

1

12

Spring For Piston

1

13

Piston Nut

1

14

O-Ring

1

15

Rubber Packing For Nut

1

16

Ball For Release Value

1

17

Washer

1

18

O-Ring For Release Valve

1

19

Release Plug

1

20

Release valve

1

21

Air valve washer

1

22

Air valve

1

23

Washer

1

24

Filter

1

25

Drain Plug

1

26

Ball (Small)

1

27

Weight pin

1

28

Ball (Big)

1

29

L - Key screw

1

30

Clamp

1

31

Washer

1

32

Bolt

1

35

Hex b

olt

1

36

Hex Nut

1

Page # 7 - M:222

52

8

12

47

50

48

3

46

45D

45B

45C

2

45

51

61

45A

29

60

62

9

28

44

25

27

10

26

43

24

59

42

11

23

41

PARTS LIST

66

67

65

ITEM#

DESCRIPTION

37

Handle

41

Ball

42

Surfacer

43

Nylon washer

44

Double spring

45

Plunger shaft

45B

Pump plunger

45C

Plunger outer ring

45D

Plunger oil seal

46

Flenge

47

L - Key bolt for flenge

47A

Plunger washer

48

Tripod

48A

Leg

50

Lock

51

Bolt For Upper & Lower Plate

52

Oil Seal Kit

53

L - Key bolt

54

Washer

55

Dolly block

56

L - Key bolt

57

Washer

58

Former holder

59

Base plate of former

60

L - Key bolt for former holding

61

Guide

62

Washer

63

L - Key bolt

65

Motor

66

Hex bolt

67

Bearing kem

68

Circlip lock

69

Switch box

®

48A

63

62

63

37

36

35

68

69

QTY.

1

1

1

1

1

1

1

1

1

1

4

1

1

3

1

8

1

2

2

1

2

2

1

1

Note:Before using this Pipe Bending Tool, carefully read through this

4

INSTRUCTIONS MANUAL to ensure efficient, safe operation. It is recommended

1

that these INSTRUCTIONS be kept readily available as an important reference

2

when using this Pipe Bending Tool.

2

1

4

1

1

1

S I N C E 1 9 5 8

PROD. 222

INSTRUCTION MANUAL

®

Advertisement

Summary of Contents for Inder 222

- Page 1 L - Key bolt L - Key screw Motor Clamp Hex bolt Washer Bearing kem ® Bolt Circlip lock Hex b Switch box Hex Nut ® S I N C E 1 9 5 8 Page # 7 - M:222...

- Page 2 FEATURES DEFECT AND REMEDY DEFECT : Dust particles in filter portion. "INDER" HYDRAULIC MOTORISED PIPE BENDERS WITH DOUBLE FRAME OPEN REMEDY: Open complete drain plug (#25) as shown in the figure 8 and clean filter (#24) BENDING is specially self designed for short radius heavy & thin wall thickness bending throughly as shown in the figure 9 3/8"...

- Page 3 MODEL 222 Step Switch on the machine to create hydraulic pressure as shown in figure 6 “INDER" HYDRAULIC MOTORISED PIPE BENDERS WITH DOUBLE FRAME OPEN BENDING are supplied in wooden cases with export worthy packing and contains following accessories as shown in figure 1...

- Page 4 Figure 4 Pipe Figure 3 Figure 5 Step 4 : Insert pipe into the former (#5) dolly block (#55) & put sliding bar (#6) as shown in figure 5 Page # 3 - M:222 ® Page # 4 - M:222 ®...