Advertisement

Quick Links

Read this instruction manual before using this product. Failure to do so can result in serious injury or death.

This instruction manual must be kept in the vicinity of the machine at all times so that it is accessible to the operator.

Features

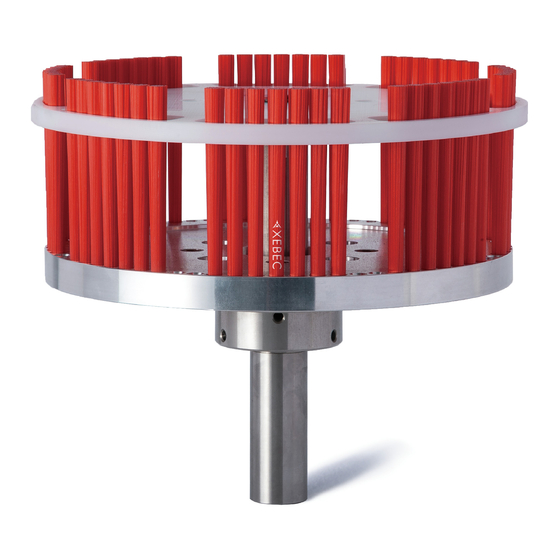

After cutting process, this product removes burrs with the burr root thickness of about 0.2 mm.

It is also ideal for cutter mark removal and surface polishing.

The tip of the bristle removes burrs and finishes the edges.

CNC deburring and cutter mark removal can be achieved by installing onto a machining

center, robot, drilling machine, or other machining equipment. (Can be installed on machining

equipment with a collet chuck, milling chuck, drill chuck, or similar means.)

The original brush material (ceramic fibers) enables consistent deburring and polishing

capability without changes to the cutting performance and brush shape.

The abrasive material is ceramic fiber that contains no abrasive grains at all.

SAFETY PRECAUTIONS

Be sure to observe the methods described in this manual.

Using the product in ways inconsistent with the methods described in this manual may result in serious injury or death.

WARNING

There is the risk of operator loss of sight or injury resulting

from this product detaching from the machining equipments,

bristles breaking off, workpieces breaking, etc.

Fragments, cutting particles,

processing with this product, and these can pierce the

eyes or skin of operators causing loss of sight and injury.

Dust occurring as a result of processing with this product can

cause lung damage, irritate skin, and bring on allergic reactions.

Even if there is no problem at the pre-work check, if

vibration or other abnormality occurs during use,

discontinue use immediately. Continuing to use the

product when there is an abnormality presents the risk of

operator loss of sight or injury resulting from this product

detaching from the machining equipments, bristles

breaking off, workpieces breaking, etc.

NOTICE

As a result of the above, there is also the risk of damage to machines, jigs, and workpieces.

Operator Safety Protection

Use of protective equipment

Wear personal protective gear including goggles, masks, gloves, and earmuffs to

prevent loss of sight, injury, or lung damage caused by damaged parts flying off

the product. Wear clothing with long sleeves or other clothing that does not

expose the skin, and fasten the cuffs and hems tightly.

Attention to the work area

Install an enclosure so that persons other than the operator do not enter the

work area, and ensure that all persons, if any, in the work area are wearing

protective equipment.

Keep the floor of the work area clean at all times to prevent the risk of slipping

or tripping on dust, cutting particles, oil, water, or other substance.

There is the risk of fire caused by heating, sparks, or other factor resulting from

use of the product. Do not use the product close to a flammable liquid or in an

explosive atmosphere.

Also be sure to enact fire prevention measures.

Precaution regarding cutting particles

Fragments, cutting particles, and other substances generated during work will be

scattered into the surrounding area. Be sure to use a dust collector or other means

to collect them.

Pre-Work Check

Perform test operation for 1 minute or more before starting work, and for

3 minutes or more after the machine tool or product was changed, and

check that there is no looseness, vibration, or other abnormality of the

machine and the part where the product is installed.

XEBEC TECHNOLOGY CO.,LTD.

Fuerte Kojimachi 1・7 Building, 1-7-25,

Koujimachi, Chiyoda-ku, Tokyo, 102-0083, Japan

TEL. +81-3-6893-0810 FAX. +81-3-5211-8964

© 2019 XEBEC TECHNOLOGY CO.,LTD.

XEBEC Brush

Instruction Manual

burrs, etc., occur due to

TM

Surface Extra-Large

This document may also be viewed at

the below website:

https://www.xebec-

tech.com/instruction_manual/

Do not use the product while exceeding the maximum rotational

speed, depth of cut, or brush projection, as there is the risk of

operator loss of sight or injury resulting from this product

detaching from the machining equipment, bristles breaking off,

workpieces breaking, etc.

Machining at a constant point for a prolonged time causes

the tip of the tool to become hot which presents the risk of

operator loss of sight or injury resulting from bristles coming

loose or breaking off. Adjust the processing times for the

same locations being processed so that they do not become

hot. Also be careful not to touch the locations being

processed directly with bare hands after use.

Use the slide ring (shank, base holder, ring) for XEBEC Brush

Surface suitable to the applicable brush diameter. There is the

risk of operator loss of sight or injury resulting from bristles

breaking off, parts breaking, etc., if a slide ring not suitable to

the applicable brush diameter is used.

Precautions for Use

Installation onto a machining center or other

machine

WARNING: When chucking, slide the shank onto the

chuck of the machining equipment securely all the way to

the base.

If not inserted all the way to the base when chucked, vibration

during machining may cause this product to fall from the

machining equipment.

There is the risk that this may cause operator loss of sight or injury.

When installing, use a chuck that is correct for the shank diameter.

Install and use on machining equipment that can control the rotational speed.

When the product is used with precision machining equipment, there is the risk

that cutting particles may have an adverse effect on the equipment sliding parts.

Be sure to properly collect cutting particles and wash thoroughly.

How to Use

Truing, dressing

If the brush shape deforms as a result of use, rotate the brush while gently pressing it onto

a diamond disc blade to form the shape.

A-CB 20190906E

Created in September 2019

1/3 Page

Advertisement

Summary of Contents for Xebec Brush Surface Extra-Large

- Page 1 Use the slide ring (shank, base holder, ring) for XEBEC Brush operator loss of sight or injury resulting from this product Surface suitable to the applicable brush diameter. There is the...

- Page 2 Process with reverse rotation of the brush on the return path (Refer to are removed but the brush TEL. +81-3-6893-0810 FAX. +81-3-5211-8964 the figure at right) is worn unevenly © 2019 XEBEC TECHNOLOGY CO.,LTD. A-CB 20190906E Created in September 2019 2/3 Page...

- Page 3 As shown in the below figure, after fixing position A, fix position B and C. Ⓐ Ⓒ Ⓑ XEBEC TECHNOLOGY CO.,LTD. Fuerte Kojimachi 1・7 Building, 1-7-25, Koujimachi, Chiyoda-ku, Tokyo, 102-0083, Japan 3/3 Page TEL. +81-3-6893-0810 FAX. +81-3-5211-8964 © 2019 XEBEC TECHNOLOGY CO.,LTD. A-CB 20190906E Created in September 2019 3/3 Page...