Advertisement

Quick Links

HM-381 & HM-381F Standard Pneumatic Direct

INTRODUCTION

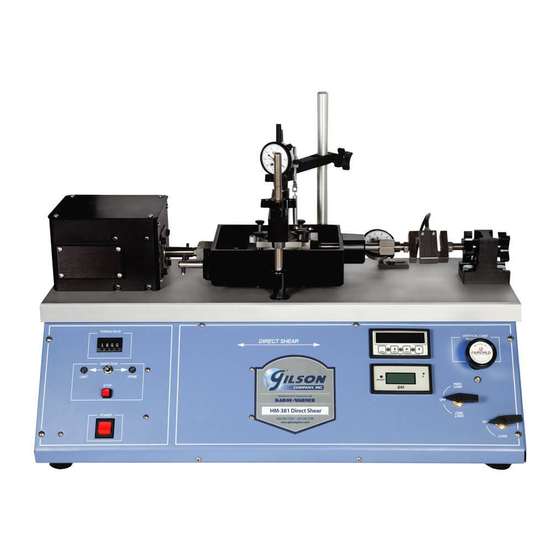

The Gilson HM-381 Standard Pneumatic Direct Shear

Machine is a tabletop unit that provides direct or di-

rect/residual shear values for evaluating the strength

and stability of soils. Manufactured in cooperation with

Karol-Warner, this device utilizes a pneumatic loading

piston for applying the vertical load to the sample. A

calibration chart is included for setting the high load or

the low load via the Fairchild Regulator while a built-in

digital readout displays the vertical load in psi.

This Direct Shear Unit has a strain rate of 0.0001 –

0.3 in/min (0.0025 – 7.62 mm/min) with a maximum

shear displacement of 0.8in (20.3mm) and the travel

speed is set with the thumbwheels on the left side of

the unit. The residual shear force is determined by a

load cell while real time load settings and peak load

are displayed on the digital readout. Consolidation and

shear displacement are measured with analog dial in-

dicators.

FEATURES

•

Total shear capacity of 1,500lbf (6.67kN)

•

Stepper motor controls strain rates to +/- 1% from

0.0001 – 0.3in/min (0.0025 – 7.62mm/min

• T eflon coated anodized aluminum water chamber

with drainage port included.

•

Meets requirements for ASTM D3080 and

AASHTO T 236

REQUIRED ACCESSORIES (purchased separately)

•

Direct shear boxes are sold separately and are

available in a wide range of inch and metric sizes

with round or square shapes. See all options at

www.globalgilson.com and in chart below.

–

Direct Shear Boxes and Accessories

PHONE: 800-444-1508

740-548-7298

Shear Machine

P.O. Box 200, Lewis Center, Ohio 43035-0200

E-mail: customerservice@gilsonco.com Product Web Page:

OPERATING MANUAL

Direct Shear Boxes & Accessories

Description

Shear Box

Round Direct Shear Boxes

50mm (1.97in) Diameter

HMA-733M

2.0in (50.8mm) Diameter

HMA-733

60mm (2.36in) Diameter

HMA-734M

2.42in (61.4mm) Diameter

HMA-734

2.5in (63.5mm) Diameter

HMA-735

100mm (3.94in) Diameter

HMA-737

4in (101.6mm) Diameter

HMA-736

Square Direct Shear Boxes

50mm (1.97in) Square

HMA-733MS

2.0in (50.8mm) Square

HMA-733S

60mm (2.36in) Square

HMA-734MS

2.42in (61.4mm) Square

HMA-734SA

2.5in (63.5mm) Square

HMA-735S

100mm (3.94in) Square

HMA-737S

4in (101.6mm) Square

HMA-736S

•

A constant supply of compressed air at 90psi (6.2

bar) is required for use.

UNPACKING & SETUP

•

Inspect your HM-381 for damage, remove from the

pallet.

•

Place Direct Shear Machine on a sturdy, level sur-

face, such as a bench top or HMA-95 Pneumatic

Shear Machine Rolling Cart.

•

Review the Connections section and install neces-

sary components.

www.globalgilson.com

1

HM-381

Cutters

Extruders

HMA-743M

HMA-763M

HMA-743

HMA-763

HMA-744M

HMA-764M

HMA-744

HMA-764

HMA-745

HMA-765

HMA-747

HMA-767

HMA-746

HMA-766

HMA-743MS

HMA-763MS

HMA-743S

HMA-763S

HMA-744MS

HMA-764MS

HMA-744SA

HMA-764SA

HMA-745S

HMA-765S

HMA-747S

HMA-767S

HMA-746S

HMA-766S

FAX: 800-255-5314

740-548-5314

Porous

Stones

GSA-208

GSA-210

GSA-213

GSA-217

GSA-219

GSA-231

GSA-232

GSA-208S

GSA-210S

GSA-213S

GSA-217S

GSA-219S

GSA-231S

GSA-232S

Rev: 05/2020

Advertisement

Summary of Contents for Gilson HM-381

- Page 1 • Meets requirements for ASTM D3080 and AASHTO T 236 UNPACKING & SETUP • Inspect your HM-381 for damage, remove from the REQUIRED ACCESSORIES (purchased separately) pallet. • Direct shear boxes are sold separately and are •...

- Page 2 CONNECTIONS must be plugged in to a properly wired ground- ed receptable with appropriate electrical current. Vertical Displacement Rod – Screws into the top plat- form to the right of the rear pull-down rod. PANEL CONTROLS — LOAD SETTING Vertical Displacement Clamping Arm – Attach to the above rod.

- Page 3 Stop Switch – Momentary push button to stop the 3. Turn the “LOAD” knob to “OFF” and adjust the Pres- motor. sure Regulator to the desired normal load based on the load calibration chart. If reading from the Direction Switch – Momentary (spring loaded) switch. “LOW”...

- Page 4 MAINTENANCE Special care should be taken to see that the four roll- er bearings between the water chamber and the base slide track are properly cleaned and contain a slight amount of oil during and after use. It is recommended to cover the Direct Shear machine when not in use to prevent dust buildup.