Summary of Contents for Apollo 7200ETL

- Page 1 APOLLO Gate Operators, Inc. Model 7200ETL Post Mounted Residential & Heavy Duty Commercial Slide Gate Operator INSTALLATION MANUAL 04/11...

-

Page 2: Table Of Contents

CONTENTS IMPORTANT SAFETY INSTRUCTIONS ............Applications ....................Pre-Installation Checklist ................Parts Identification ..................Operator Installation ..................Chain Bracket Installation ................Chain & Chain Bolt Installation ............... Internal Limits ……………................10-11 Quick Release Operation .................. Programming Current Sensing …………………………………………………… 835/836 Control Board ..................14-18 Siren Connection ……………………………………………………………………... -

Page 3: Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS WARNING - To reduce the risk of injury or death: READ AND FOLLOW ALL INSTRUCTIONS. Installation should be performed by a professional installer. Required welding should be performed by a qualified welder. Should electricity be required, use a certified electrician only. Any device that requires 120 Volts AC should be U.L. -

Page 4: Applications

APPLICATIONS The Apollo Model 7200ETL Slide Gate Operator is designed to handle a slide gate up to 32 feet in total length (accomodates a 30 foot drive) and 1,000 Lbs. A professional fence or gate dealer is recommended to assure proper installation. -

Page 5: Pre-Installation Checklist

PRE-INSTALLATION CHECKLIST The following checklist should be used before beginning installation: Verify that the proper operator has been selected for this application. Verify proper installation and operation of the gate. 1. Are all rollers covered with a protective housing? 2. Are the rollers servicable? 3. -

Page 6: Parts Identification

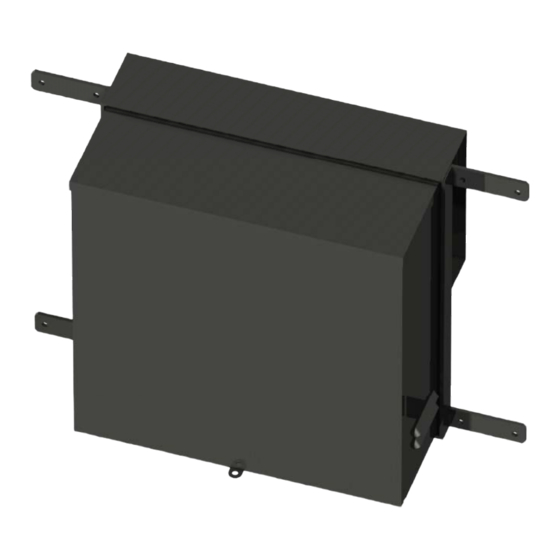

PARTS IDENTIFICATION 5/16 Washers, Lock Washers, & Nuts (16 each) Chain Brackets (2) Operator Chain Bolts with hardware (2 each) 5/16” x 2” U Bolts (4 each) 5/16” x 3” U Bolts (4 each) Tie Wraps (4 each) Master Chain Links (2 each) #40 Roller Chain (35 feet) #273G CAUTION Signs (2 each) -

Page 7: Operator Installation

OPERATOR INSTALLATION STEP 1. Install two 3” dia. Posts parallel to the gate as shown. Posts height depends on height preference of operator. Gate F e n c e 5” 6” 24” Inside posts D r i v e w a y STEP 2. -

Page 8: Chain Bracket Installation

STEP 3. Install one of the gate brackets and chain bolts on right side of gate using the supplied 2” U-bolts. Do not tighten at this time. STEP 4. Attach the chain to the chain bolt using the master chain link. Adjust the chain bolt to allow for maximum tightening Note: The height of... - Page 9 STEP 5. Thread chain on the sprockets as shown. Chain should be level with about a 1 inch lag per 10 feet. T O P Chain should be aligned with all sprockets. STEP 6. (Refer to page 8) Install the other gate bracket and chain bolt on the left side of the gate. Determine the required length of chain needed to attach to the chain bolt and still allow adjustment.

-

Page 10: Internal Limits

Internal Limit Adjustment Step 1. Press LED Enable once on the right side of the circuit board. The STOP LED should illuminate. This is a standard condition. Step 2. Turn switch #1 OFF on the control board Step 3. Activate the gate until the CLOSED LIMIT LED is illuminated Step 4. -

Page 11: Wiring Instructions

Left or Right Hand Operation Wiring Instructions STEP 1. Determine which side of driveway operator will be installed on. The factory units are plugged into INPUT B for right side installation as shown in Fig. 1. For left side installation, disconnect from INPUT B and plug into INPUT A on the surge board as shown in Fig. -

Page 12: Quick Release Operation

QUICK RELEASE OPERATION Engaged Engaged Pull & turn 1/2 inch to disengage... -

Page 13: Programming Current Sensing

STEP 7 Programming Current Sensing The 835/836 control boards incorporate a safety feature that will put the op- erator into a hard shutdown mode if the control board detects a current sense two consecutive times during a cycle. This hard shutdown condition can only be reset by shorting the FIREBOX or UL connectors on the left side of the control board to ground. -

Page 14: 835/836 Control Board

835/836 Control Board Parts Identification Timer To Close - GateLink Connector Microprocessor Dual Gate Delay - Current Sensitivity - Adjustments Program Switches Hard Shutdown Reset Operate Push Button Remote Monitor Outputs and Photo Eye Optional Device Inputs LED Enable & Learn Mode Push Button Stop Circuit Jumper Control Board Reset... - Page 15 Actuator Connector Board Actuator Function Cable Pin 1 Orange Open Limit Pin 2 White Close Limit Pin 3 Black Motor (positive on open, negative on close) Pin 4 Motor (negative on open, positive on close) Pin 5 Green Common for both limit switches Pin 6 Yellow Feedback from intelligent actuator(816E/816EX)

- Page 16 Adjustments TIMER TO CLOSE Adjusts time before gate automatically closes Adjustable 5 to 70 seconds. DUAL GATE DELAY Adjusts delay between master and slave op- eration 0-4 seconds (836 only for use with magnetic, solenoid, and other locking de vices) CURRENT SENSITIVITY Increases or decreases the Auto Reverse sensitivity.

-

Page 17: Program Switches

Program Switches 1 TIMER TO CLOSE Gate does not automatically close. Gate automatically closes. 2 TIMER TO CLOSE OPT. Gate automatically closes from Gate automatically closes only when completely any position after opening. open (open limit engaged). 3 SLAVE DISABLE Enables slave side (dual gate use). -

Page 18: Optional Device Inputs

Optional Device Inputs Supplied Battery Ground Activate Gate (Push button activation when momentarily shorted to ground) Supplied Battery Voltage (Protected with 3 Amp fuse) Supplied Battery Ground Activate Gate (Push button activation when momentarily shorted to ground) Supplied Battery Voltage (Protected with 3 Amp fuse) EDGE Reverse edge input. -

Page 19: Siren Connection

Gate Operators, Inc. 911 Siren The 911 Siren is included with all Apollo ETL Gate Operators. Mount siren in an area that will produce maximum performance (additional wire may be required). Connect the red wire to the SIREN connector on the Remote Monitor Output Connector block. -

Page 20: Radio Receiver Options

APOLLO RECEIVER OPTIONS Gate Operators Do not confuse the receiver code switches with the red program switches on the gate control board. Never set all code switches to the same position. Transmitters must match code switches for proper operation. If power is taken directly from battery or connected as shown below, receiver should be configured for 12VDC... -

Page 21: Troubleshooting

TROUBLESHOOTING The Apollo 835/836 board is the standard board in all ETL compliant Apollo Gate Opera- tors. Single gate systems use the 835 board (distinguished by MASTER and EMER- GENCY BYPASS modular receptacles) and DUAL gate systems use the 836 board (distinguished by MASTER, SLAVE and EMERGENCY BYPASS receptacles). - Page 22 “HARD SHUTDOWN RE- SET” button to restart the system. Left Hand / Right Hand Operation: All APOLLO Slide Gates are shipped from the fac- tory wired to close to the left (when looking out of the property). It is suggested to in- stall and adjust the operator as it comes from the factory –...

-

Page 23: Warranty

Ga t e Ope ra t ors, I nc . LIMITED TWO-YEAR WARRANTY Apollo Gate Operators are warranted against defects for a period of 24 months from the date of purchase, providing recommended installation procedures are followed. This warranty is in lieu of all other warranties...