Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Husqvarna GTH2248XP

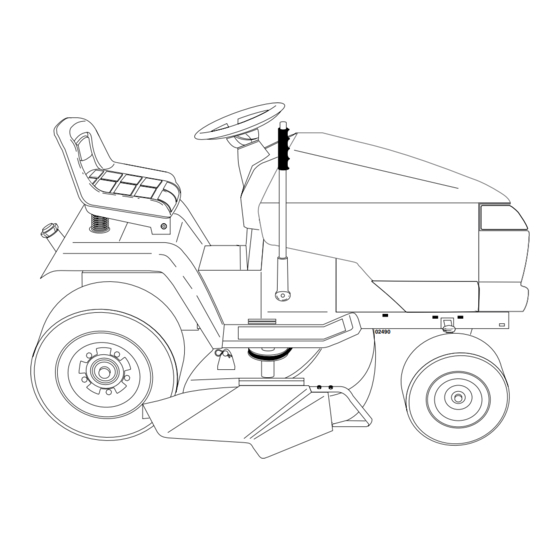

- Page 1 02578_husqvarna 02490 GTH2248XP Owner's Manual...

-

Page 2: Safety Rules

SAFE OPERATION PRACTICES FOR RIDE-ON MOWERS IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROW ING OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH. I. GENERAL OPERATION • Read, understand, and follow all instructions in the manual and on the machine before starting. - Page 3 SAFE OPERATION PRACTICES FOR RIDE-ON MOWERS • Be sure the area is clear of other people before mowing. Stop machine if anyone enters the area. • Never carry passengers or children even with the blades off. • Do not mow in reverse unless absolutely necessary. Al ways look down and behind before and while backing.

-

Page 4: Table Of Contents

PRODUCT SPECIFICATIONS Gasoline Capacity 5.0 Gallons and type: Unleaded Regular Oil Type (API-SF-SJ): SAE 30 (above 32°F) SAE 5W-30 (below 32°F) Oil Capacity: W/ Filter: W/O Filter: 3.5 Pints Spark Plug: Champion (Gap: .040") RCJ8Y Ground Speed (MPH): Forward: Reverse: Tire Pressure: Front: Rear:... -

Page 5: Unassembled Parts

UNASSEMBLED PARTS Steering Wheel Steering Wheel Insert Seat (4) Hex Bolts 5/16-18 x 3/4 (4) Lockwasher Mower (2) Retainer Springs (single loop) (2)Flanged Pins (1)Front Plate Assembly Steering Wheel Adapter (4) Retainer Springs Steering Sleeve Steering Sleeve Extension (4) Retainer Springs (double loop) Gauge Wheel (4) Adjusting Bar... -

Page 6: Assembly

Your new tractor has been assembled at the factory with exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tractor all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper tightness. TOOLS REQUIRED FOR ASSEMBLY A socket wrench set will make assembly easier. - Page 7 INSTALL SEAT (See Fig. 3) Seat position should be adjusted forward or backward so that the operator can comfortably reach clutch/brake pedal and safely operate the tractor. • Remove the two (2) bolts and fl at washers securing the seat to cardboard packing. Keep the two (2) bolts only and place them with the two (2) identical bolts and four (4) washers in the parts bag.

-

Page 8: Install Mower And Drive Belt

TO ATTACH NOSE ROLLER (See Fig. 5) • Assemble brackets "A" and "B" to the inside of mower mounting brack ets as shown. Tighten securely. NOTE: Be sure bracket tabs are po si tioned in tab holes in mower brackets. •... -

Page 9: Assembly

• Connect anti-sway bar to chassis bracket under left foot rest and retain with double loop retainer spring. • If equipped, turn height adjustment knob clock wise to remove slack from mower sus pen sion. • Raise deck to highest position. •... -

Page 10: Operation

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their mean- ing. REVERSE NEUTRAL LIGHTS ON ENGINE ON ENGINE OFF OIL PRESSURE FUEL OVER TEMP LIGHT ATTACHMENT ATTACHMENT CLUTCH ENGAGED CLUTCH DISENGAGED FREE WHEEL (Automatic Models only) Failure to follow instructions... - Page 11 KNOW YOUR TRACTOR READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR. Compare the illustrations with your tractor to familiarize yourself with the location of various controls and adjustments. Save this man ual for future reference. THROTTLE CONTROL BRAKE PEDAL MOTION DRIVE BELT TENSION...

-

Page 12: To Move Forward And Backward

The operation of any tractor can result in foreign objects thrown into the eyes, which can result in severe eye dam age. Always wear safety glass es or eye shields while op- erating your tractor or per form ing any adjustments or repairs. We rec om mend a wide vision safety mask over spectacles or stan dard safety glasses. -

Page 13: To Operate On Hills

TO ADJUST GAUGE WHEELS (See Fig. 9) Gauge wheels are properly adjusted when they are slightly off the ground when mower is at the desired cutting height in operating position. Gauge wheels then keep the deck in proper position to help prevent scalping in most terrain conditions. -

Page 14: Before Starting The Engine

NOTE: To protect hood from damage when transporting your tractor on a truck or a trailer, be sure hood is closed and secured to tractor. Use an appropriate means of tying hood to tractor (rope, cord, etc.). TOWING CARTS AND OTHER AT TACH - MENTS Tow only the attachments that are recommended by and comply with specifi... - Page 15 AUTOMATIC TRANSMISSION WARM UP • Before driving the unit in cold weather, the trans mis sion should be warmed up as follows: • Be sure the trac tor is on level ground. • Place the motion control lever in neu tral. Release the parking brake and let the brake slowly return to operating position.

-

Page 16: Maintenance Schedule

MAINTENANCE SCHEDULE FILL IN DATES AS YOU COMPLETE REGULAR SERVICE Check Brake Operation Check Tire Pressure Check Operator Presence and Interlock Systems Check for Loose Fasteners Sharpen/Replace Mower Blades Lubrication Chart Check Battery Level Clean Battery and Terminals Check Transaxle Cooling Check V-Belts Check Engine Oil Level Change Engine Oil (with oil filter) -

Page 17: Maintenance

TRACTOR Always observe safety rules when performing any main- te nance. BRAKE OPERATION If tractor requires more than six (6) feet stopping distance at high speed in highest gear, then brake must be adjusted. (See “TO ADJUST BRAKE” in the Service and Ad just ments section of this manual). -

Page 18: Clean Air Screen

TO CLEAN BATTERY AND TERMINALS Corrosion and dirt on the battery and terminals can cause the battery to “leak” power. • Remove terminal guard. • Disconnect BLACK battery cable fi rst then RED bat- tery cable and remove battery from tractor. •... - Page 19 CLEAN AIR INTAKE/COOLING AREAS To insure proper cooling, make sure the grass screen, cooling fi ns, and other external surfaces of the engine are kept clean at all times. Every 100 hours of operation (more often under extremely dusty, dirty conditions), remove the blower housing and other cooling shrouds.

-

Page 20: Service And Adjustments

SERVICE AND ADJUSTMENTS WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY SER VICE OR AD JUSTMENTS: • Depress brake pedal fully and set parking brake. • Place attachment clutch in “DISENGAGED” position. • Turn ignition key to “STOP” and remove key. •... -

Page 21: To Level Mower Housing

SERVICE AND ADJUSTMENTS • Position front plate assembly between front mower brackets. Raise deck and plate assembly to align holes and insert fl anged pins. Secure pins with double loop retainer springs between the plate assembly and mower brack ets. NOTE: To assist in locating hole in fl... -

Page 22: To Replace Mower Drive Belt

SERVICE AND ADJUSTMENTS TO REPLACE MOWER DRIVE BELT MOWER DRIVE BELT REMOVAL (See Fig. 23) • Park tractor on a level surface. En gage parking brake. • Lower mower to its lowest position. • Disengage belt tention rod from lock bracket. CAUTION: Rod is spring loaded. - Page 23 SERVICE AND ADJUSTMENTS TO ADJUST ATTACHMENT CLUTCH (See Fig. 25) The electric clutch should provide years of service. The clutch has a built-in brake that stops the pulley within 5 seconds. Eventually, the internal brake will wear which may cause the mower blades to not engage, or, to not stop as required.

- Page 24 SERVICE AND ADJUSTMENTS TO AD JUST STEER ING WHEEL ALIGN- MENT If steering wheel crossbars are not horizontal (left to right) when wheels are positioned straight forward, remove steer- ing wheel and reassemble per instructions in the Assembly section of this manual. FRONT WHEEL TOE-IN/CAMBER The front wheel toe-in and camber are not adjustable on your tractor.

- Page 25 SERVICE AND ADJUSTMENTS KEPS NUT TERMINAL ACCESS DOOR TERMINAL GUARD FIG. 32 TO REPLACE HEADLIGHT BULB • Raise hood. • Pull bulb holder out of the hole in the backside of the grill. • Replace bulb in holder and push bulb holder securely back into the hole in the backside of the grill.

-

Page 26: Storage

Immediately prepare your tractor for storage at the end of the season or if the tractor will not be used for 30 days or more. WARNING: Never store the trac tor with gas o line in the tank inside a building where fumes may reach an open fl... -

Page 27: Trou Ble Shoot Ing

TROUBLESHOOTING POINTS PROBLEM CAUSE Will not start Out of fuel. Engine not “CHOKED” properly. Engine fl ooded. Bad spark plug. Dirty air fi lter. Dirty fuel fi lter. 7. Water in fuel. Loose or damaged wiring. Carburetor out of adjustment. Engine valves out of adjustment. -

Page 28: Trou Ble Shoot Ing

TROUBLESHOOTING POINTS PROBLEM CAUSE Engine continues to run Faulty operator-safety presence control system. when operator leaves seat with attachment clutch engaged Poor cut - uneven 1. Worn, bent or loose blade. Mower deck not level. Buildup of grass, leaves, and trash under mower. Bent blade mandrel. - Page 29 TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 SCHEMATIC AMMETER (OPTIONAL) IGNITION SWITCH IGNITION SWITCH POSITION CIRCUIT “MAKE” M + G + A1 NONE ON + LIGHTS B + A1 L + A2 B + A1 NONE...

-

Page 30: Repair Parts - Tractor

REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 ELECTRICAL... -

Page 31: Repair Parts

REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 ELECTRICAL KEY PART DESCRIPTION 532 14 49-27 Battery 874 76 04-12 Bolt Hex Head 1/4-20 x 3/4 532 12 48-86 Tray, Battery 532 14 52-11 Bolt, Battery Front 1/4-20 x 7.5 Zinc... - Page 32 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 CHASSIS AND ENCLOSURES chassis-stealth_20-vgt...

- Page 33 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 CHASSIS AND ENCLOSURES KEY PART DESCRIPTION 532 18 03-75 Rail, Frame RH 532 17 52-82 Drawbar, Gt 532 18 56-04 Dash, Plastic 532 15 78-82 Dash, 1PCS, Lower...

- Page 34 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 GROUND DRIVE drive_6-vgt 135 137...

- Page 35 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 GROUND DRIVE KEY PART DESCRIPTION - - - - - - - Transaxle Hydro Gear 331-3000 (Order Parts From Transaxle Manufacturer) 532 00 70-70 Key Sq. 1/4 x 2.5...

- Page 36 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 STEERING ASSEMBLY steering_12-vgt...

- Page 37 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 STEERING ASSEMBLY KEY PART DESCRIPTION 532 16 66-27 Wheel, Steering 532 17 85-57 Axle Asm., Front 532 12 48-36 Fitting, Grease 532 16 18-49 Spindle Asm, LH 532 16 18-48 Spindle Asm., RH...

- Page 38 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 ENGINE engine-kawasaki_1 vgt SPARK ARRESTER KIT...

- Page 39 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 ENGINE KEY PART DESCRIPTION - - - - - - - Engine Kawasaki, Model No. FH641V (Order parts from engine manufacturer) 532 14 97-23 Muffl er Side...

- Page 40 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 LIFT ASSEMBLY 35 73 lift_rh_11...

- Page 41 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 LIFT ASSEMBLY KEY PART DESCRIPTION 532 12 10-06 Rod Asm., Lever 532 18 00-45 Shaft Asm., Lift Vgt 532 15 91-89 Lever Asm., Lift Rh 812 00 00-22...

- Page 42 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 SEAT ASSEMBLY KEY PART DESCRIPTION 532 18 49-95 Seat 532 14 05-51 Bracket, Pivot Seat 532 14 50-06 Clip, Push In Hinged 873 80 06-00 Nut, Crownlock 3/8-16...

- Page 43 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 DECALS KEY PART DESCRIPTION 532 18 10-63 Decal, Final 532 18 00-94 Decal, Engine 532 17 96-29 Decal, Hood, RH 532 17 96-30 Decal, Hood, LH 532 18 00-91...

- Page 44 REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 MOWER DECB mower_deck.48prem_2...

-

Page 45: Repair Parts - Tractor

REPAIR PARTS TRACTOR - MODEL NO. GTH2248XP (GTH2248XPB), PRODUCT NO. 954 56 78-88 MOWER DECK KEY PART DESCRIPTION 532 18 18-48 Deck Weldment Mower 48 532 17 89-15 Bracket Asm., Sway Bar 532 12 46-70 Retainer Spring 532 17 80-24... - Page 46 SUGGESTED GUIDE FOR SIGHTING SLOPES FOR SAFE OPERATION WARNING: To avoid serious injury, operate your tractor up and down the face of slopes, never across the face. Do not mow slopes greater than 15 degrees. Make turns gradually to prevent tipping or loss of control.

- Page 48 02578_husqvarna 532 18 47-58 Rev. 2 05.21.03 RD/TR Printed in U.S.A.