Table of Contents

Advertisement

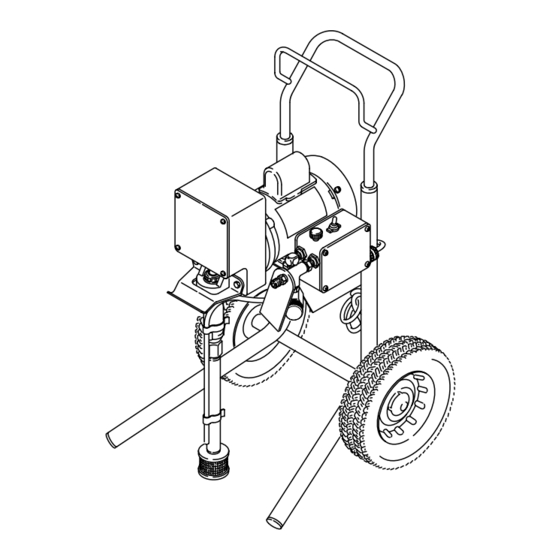

1/2 gpm, Portable, Electric

Model 820-002, Series F

Without hose, gun, or filter

2750 psi (190 bar) MAXIMUM WORKING PRESSURE

INDEX

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

Warranty

. . . . . . . . . . . . . . . .

NOTE: This is an example of the DANGER label on your sprayer.

This label is available in other languages, free of charge.

See page 23 to order.

Spray painting, flushing or cleaning equipment with flammable liq-

uids in confined areas can result in fire or explosion.

Use outdoors or in extremely well ventilated areas. Ground equip-

ment, hoses, containers and objects being sprayed.

Avoid all ignition sources such as static electricity from plastic drop

cloths, open flames such as pilot lights, hot objects such as ciga-

rettes, arcs from connecting or disconnecting power cords or turn-

ing light switches on and off.

Failure to follow this warning can result in death or serious injury.

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

The SHERWIN-WILLIAMS COMPANY, CLEVELAND, OHIO 44115

This manual contains Important

Warnings and Instructions. Read the

manual and keep it for reference.

S

UPER

2

4

6

8

9

10

10

11

12

14-19

14

. . . . . . .

16

16

17

17

.

18

. .

19

20

23

Back Cover

Back Cover

FIRE AND

EXPLOSION HAZARD

OWNER'S MANUAL

820-008 Rev. M

SUPERSEDES Rev. L

N

OVA

AIRLESS PAINT SPRAYER

Liquids can be injected into the body by high pressure airless spray

or leaks - especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body. Drain all pressure before removing parts.Avoid accidental trig-

gering of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In

case

of

accidental

"Surgical Treatment".

Failure to follow this warning can result in amputation or serious

injury.

PATENT NO. 4,323,741

SKIN INJECTION

HAZARD

skin

injection,

seek

immediate

Advertisement

Table of Contents

Summary of Contents for Sherwin-Williams SUPERNOVA 820–002

-

Page 1: Table Of Contents

OWNER’S MANUAL 820–008 Rev. M This manual contains Important Warnings and Instructions. Read the SUPERSEDES Rev. L manual and keep it for reference. UPER 1/2 gpm, Portable, Electric AIRLESS PAINT SPRAYER PATENT NO. 4,323,741 Model 820–002, Series F Without hose, gun, or filter 2750 psi (190 bar) MAXIMUM WORKING PRESSURE INDEX Warnings... -

Page 2: Safety Warnings

SAFETY WARNINGS HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY. FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS. Read and understand all instruction manuals before operating the equipment. FLUID INJECTION HAZARD General Safety Safety Latch This equipment generates very high fluid pressure. Spray from Whenever you stop spraying, even for a moment, always set the the gun, leaks or ruptured components can inject fluid through gun safety latch in the closed or “safe”... - Page 3 MOVING PARTS HAZARD HOSE SAFETY Moving parts can pinch or amputate your fingers or other body High pressure fluid in the hoses can be very dangerous. If the parts. KEEP CLEAR of moving parts when starting or operating hose develops a leak, split or rupture due to any kind of wear, the sprayer.

-

Page 4: Avertissement

AVERTISSEMENT La pulvérisation à haute pression peut causer de blessures très graves. Réservé exclusivement à l’usage professionnel. Observer toutes les consignes de sécurité. Bien lire et bien comprendre tous les manuels d’instructions avant d’utiliser le matériel. RISQUES D’INJECTION Consignes générales de sécurité Verrou de sécurité... - Page 5 RISQUES EN CAS DE MAUVAISE UTILISATION DU MATERIAL Consignes générales de sécurité TOUS LES TUYAUX FLEXIBLES DOIVENT AVOIR DES RES- SORTS SPIRALE DE PROTECTION AUX 2 BOUTS! Les spira- toute utilisation anormale de l’appareil du pulvérisation ou des les de protection contribuent à éviter la formation de pliures, de accessoires comme, par exemple, la mise sous une pression boucles ou de nœuds sur les tuyaux qui pourraient entraîner la excessive, les modifications de pièces, l’utilisation de produits...

-

Page 6: Advertencia

ADVERTENCIA EL ROCIADO A ALTA PRESION PUEDE CAUSAR GRAVES LESIONES. SOLO PARA USO PROFESIONAL. RESPECTE LOS AVISOS DE ADVERTENCIA. Lea y entienda todo el manual de instrucciones antes de manejar el equipo. PELIGRO DE INYECCION DE FLUIDO Seguridad general Aparatos de seguridad de la pistola pulverizadora Este equipo general un fluido a una presión muy alta. - Page 7 PELIGRO POR MAL USO DEL EQUIPO Seguridad general Presión del sistema Cualquier mal uso del equipo pulverizador o los accesorios, tal Esta pulverizadora puede desarrollar 190 barías (2750 psi) de como sobre presurización, modificación de piezas, uso de ma- PRESION DE TRABAJO MAXIMA. Asegurar que todo el equipo teriales y productos químicos incompatibles, o utilización de pie- pulverizador y sus accesorios tienen la capacidad para aguan- zas dañadas o desgastadas, puede hacen que se rompan y...

-

Page 8: Setup

SETUP Connect Hose and Gun Remove the plastic cap from the outlet tee, and connect a 50 ft. (15 m) (minimum length) fluid hose to it. Connect the other end of the hose to the spray gun. Don’t use thread sealant, and don’t install the spray tip yet! PRESSURE CONTROL CAUTION KNOB... -

Page 9: Flushing Guidelines

FLUSHING GUIDELINES When To Flush WARNING To reduce the risk of static sparking and splashing, 1. Before using your new sprayer. Your new sprayer always remove the spray tip from the gun, and hold was factory tested with motor oil and the oil was left. a metal part of the gun firmly to the side of a in it to protect the pump parts. -

Page 10: Adjust The Spray Pattern

ADJUST THE SPRAY PATTERN Increase the pressure adjusting knob setting just until Cleaning and Clearing the Spray Tip spray from the gun is completely atomized. Use the low- WARNING est pressure necessary to get the desired results, which To reduce the risk of injection injury, DO NOT hold helps prolong the life of your sprayer and minimizes paint your hand, body, or a rag in front of the spray tip lost by overspray. -

Page 11: Shutdown And Care

For interior corners , such as on a bookcase or inside a cabinet, aim the gun toward the center of the corner to spray. By dividing the spray pattern this way, the edges on both sides are sprayed evenly. If there is a wind , angle the spray pattern into the wind to minimize drifting. -

Page 12: Troubleshooting Guide

TROUBLESHOOTING GUIDE This guide will help you identify the causes and solutions to sprayer problems. If you cannot identify and resolve the problem, or if “Return for repair” is indicated, contact your nearest authorized service agency for instructions on where and how to return the sprayer for repair. -

Page 13: Service

TROUBLESHOOTING GUIDE PROBLEM CAUSE SOLUTION Electric motor hums but will not Circuit board failure Replace circuit board, see page 18. Low voltage Never use more than 200 ft. (61 m) of 12 gauge extension cord; use a long fluid hose instead; check power supply which should be 110 Volt minimum. -

Page 14: Displacement Pump

DISPLACEMENT PUMP WARNING To reduce the risk of serious bodily injury, including fluid injection; splashing in the eyes or on the skin; injury from moving parts or electric shock, always follow the Pressure Relief Procedure Warning on page 12 before continuing. Removing the Pump Flush the sprayer if possible. - Page 15 Unscrew and remove the packing nut (38). Using a rub- When reassembling the piston, install the new glands ber mallet, tap the piston rod (47) down and pull it out and packings in the correct order, alternating the leather through the bottom of the cylinder (46). See Fig 3 and 4. and plastic packings.

-

Page 16: Connecting Rod & Bearing

CONNECTING ROD AND BEARING WARNING NOTE: After every 100 hours of operation, or whenever servicing the pump (whichever comes first), fill To reduce the risk of serious bodily injury, including the cavity in connecting rod (64) with SAE 10 fluid injection; splashing in the eyes or on the skin; non–detergent motor oil. -

Page 17: Capacitor

Remove the pump, connecting rod and bearing as de- Clean and inspect the gear (69) for wear or damage. Re- scribed on pages 14 and 16. place it if necessary. To remove the gear, drive out the pin (70), and pull it off the motor shaft. Apply molybdenum Remove the capscrews (25 &... -

Page 18: Pressure Control & Circuit Board

PRESSURE CONTROL AND CIRCUIT BOARD WARNING WARNING Adjust the pressure control whenever a new or To reduce the risk of serious bodily injury, including used pressure control or circuit board is installed, fluid injection; splashing in the eyes or on the skin; to reduce the risk of overpressurization which can injury from moving parts or electric shock, always result in component rupture, fire or explosion. -

Page 19: Calibrating The Pressure Control

PRESSURE CONTROL CALIBRATION WARNING USE EXTREME CAUTION WHEN PERFORMING THIS CALIBRATION PROCEDURE to reduce the risk of an injection injury or other serious bodily injury which can result from component rupture, electric shock, fire, explo- sion, or moving parts. This procedure sets the sprayer to 2750 psi (190 bar) NEVER try to increase the fluid outlet pressure by per- MAXIMUM WORKING PRESSURE. -

Page 20: Parts List

PARTS LIST Model 820–002, Series F Includes items 1–125 NO. PART NO. DESCRIPTION NO. PART NO. DESCRIPTION 820-621 MOTOR, electric, 0.75 HP: includes 820–318 items 5, 7, 81, 104, 105,119 820–319 TAG, Caution 820–252 LOCKWASHER 820–006 LABEL, identification 820–339 CAPACITOR 820–321 PRESSURE CONTROL ASSEMBLY 185–952*... -

Page 21: Parts Drawing & Lists

PARTS DRAWING (located under the cover) DANGER LABEL, ENGLISH DANGER LABEL, FRENCH Part of 65 LABEL LABEL Ref 77 LABEL (OUTSIDE) LABEL (INSIDE) Ref 20 Ref 90 121 19... - Page 22 PARTS DRAWING AND LIST Part No. 820–337 Ref No. 74 NOTES: Pressure Control Assembly Numbers with “Ref” preceeding Includes replaceable items them correspond with the parts listed below Ref 1 list on page 20. See wire colors in Fig 10. Ref 75 85 Ref 76 LABEL...

-

Page 23: Accessories

PARTS DRAWING AND LIST Part No. 820–377 Ref No. 26 Displacement Pump Includes items 27–49 NO. PART NO. DESCRIPTION 820–276* .BALL, stainless steel, 0.3125” 820–277* .BALL, stainless steel, 0.5” 820–278* .SEAL, u–cup, polyurethane 820–463* .GLAND, female 820–280* .V–PACKING, leather 820–281* .GLAND, male 820–282 .NUT, hex, 1/2–20... -

Page 24: Technical Data

THE SHERWIN-WILLIAMS WARRANTY AND DISCLAIMERS The Sherwin-Williams Company warrants this sprayer to be free from defects in material and workmanship on the date of sale to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, The Sherwin-... - Page 25 Pump Packing Material ..UHMW polyethylene, leather TO PLACE AN ORDER , call SHERWIN-WILLIAMS COMPANY 1–800–367–4023 Toll Free CLEVELAND, OHIO 44115 FOR TECHNICAL ASSIST ANCE , call COPYRIGHT 1990, GRACO INC. 1–800–543–0339 Toll Free...

- Page 26 82Z–008 Rev B Supplement to instruction manual 820–008. Super Nova Airless Paint Sprayer WARNING INJECTION HAZARD This is only a quick reference to the fea- tures and frequently ordered parts of this INSTRUCTIONS sprayer. To reduce the risk of serious injury, including fluid injection, while operating or UNDER THIS COVER repairing this sprayer, follow the warnings and in-...