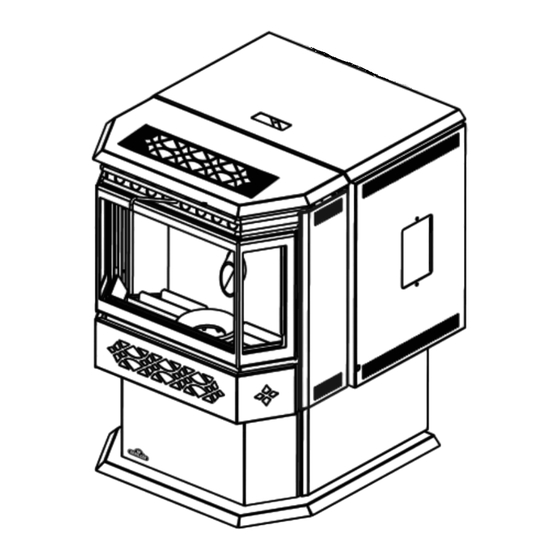

Napoleon NPS40 Installation And Operating Instructions Manual

Pellet stove & insert heater

Hide thumbs

Also See for NPS40:

- Installation and operating insctructions (48 pages) ,

- Installation and operating instruction (36 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Napoleon NPS40

- Page 1 W415-0616 / C / 06.04.08 $10.00 W415-0616 / C / 06.04.08...

-

Page 2: Table Of Contents

NPI40 FINISHING 12-13 GENERAL VENTING Flashing Installation Type of Vent Trivet NPI40 Installing Pellet Vent Installing the viewing door NPS40 and NPI40 Venting the Pellet Heater OPERATING INSTRUCTIONS Pellet Vent Termination Start up Alcove Installation (NPS40 Only) Shut down Minimum Air Terminal Installations... -

Page 3: Warranty

NAPOLEON ® Pellet Heaters are manufactured under the strict Standard of the World Recognized ISO 9001 : 2000 Quality Assurance Certifi cate. NAPOLEON ® products are designed with superior components and materials, assembled by trained craftsmen who take great pride in their work. The complete fi replace is thoroughly inspected by a qualifi ed technician before packaging to ensure that you, the customer, receives the quality product that you expect from NAPOLEON ®. -

Page 4: Warnings And Safety Precautions

WARNINGS AND SAFETY PRECAUTIONS W415-0616 / C / 06.04.08... - Page 5 WARNINGS AND SAFETY PRECAUTIONS W415-0616 / C / 06.04.08...

-

Page 6: General Introduction

Burn Rate (Pounds per Hour)** 1.0 to 5.0 Maximum Burn Time on Low Burn** 55 Hours (NPS40), 45 Hours (NPI40) Hopper Capacity 55 Pounds (NPS40), 45 Pounds (NPI40) * Heating capacity will vary depending on the home's fl oor plan, degree of insulation, and the outside temperature. It is also affected by the fuel size, quality, and moisture level. -

Page 7: Dimensions

DIMENSIONS Figures 1a-b NPS40 NPI40 with NI800 Flashing Shown Figures 2a-c W415-0616 / C / 06.04.08... - Page 8 DIMENSIONS CONTINUED NPI40 with AK9 Adapter and CISK Flashing Shown Figures 3a-c W415-0616 / C / 06.04.08...

- Page 9 DIMENSIONS CONTINUED Figures 4a-c NPI40 with AK8 Adapter and GICSK Flashing Shown W415-0616 / C / 06.04.08...

-

Page 10: Specifi Cations

30 1/2" NPS40 Depth 26 5/8" Weight 210 Pounds Exhaust Collar 3" Intake Collar 2" NPS40 Hopper Cap. 55 Pounds NPI40 Hopper Cap. 45 Pounds Exempt Burn Rate** 1.0 to 5.0 (Pounds Per Hour) BTU/h** 8500 to 42500 Minimum Fireplace Opening Size... -

Page 11: Installation Options

INSTALLATION OPTIONS NPS40: To install in a Residential or Mobile Home see the section "Mobile Home Requirements". For alcove installations see the section "Alcove Installation Requirements". For horizontal vent or vertical vent see the section "General Venting". See the section "Outside Air" for this option. -

Page 12: Mobile Home

MOBILE HOME Installation into a manufactured home or mobile home should be installed in accordance with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard, CAN/CSA Z240 MH Series, in Canada. The heater must be grounded to the steel chassis of the mobile home (Some states do not require this;... -

Page 13: Venting The Pellet Heater

Horizontal terminations must protrude 12" from the wall, vertical terminations require a minimum 24" above the highest point that it penetrates through the roof. Depending on pellet quality, vent confi guration and air settings, black soot may occur on the terminal wall. ALCOVE INSTALLATION (NPS40 ONLY) Figure 7 Minimum Alcove Dimensions... -

Page 14: Minimum Air Terminal Installations

MINIMUM AIR TERMINAL INSTALLATIONS Figure 8 Illustration dimensions are to the center and the exhaust exit point of the vent. CLEARANCE Clearance above grade, veranda porch, deck or balcony. 24 INCHES (Including Vegetation and Mulch) 48 INCHES Clearance beside or below any windows or doors that open. 12 INCHES* Clearance above any window or door that opens. -

Page 15: Nps40 Installations

NPS40 INSTALLATION MINIMUM CLEARANCE TO COMBUSTIBLES STRAIGHT INSTALLATION Through the Wall Installations Interior Vertical Vents Figure 10 Figure 9 CORNER INSTALLATION Through the Wall Vents Interior Vertical Vents Figure 11 Figure 12 NOTE: If interior vertical pellet vent is used, the clearance to the back wall is determined by the upward-turning elbow or "Tee". -

Page 16: Horizontal Exhaust Through Wall Installation

VENTING INSTALLATION EXAMPLES HORIZONTAL EXHAUST THROUGH WALL INSTALLATION Figure 13 THROUGH WALL WITH VERTICAL RISE AND HORIZONTAL TERMINATION INSTALLATION Figure 14 W415-0616 / C / 06.04.08... -

Page 17: Minimum Inside Vertical Clearance

MINIMUM INSIDE VERTICAL CLEARANCES Vertical Cap Storm Collar Roof Flashing Vent must maintain 3” Ceiling Support clearance to combus- tibles. Figure 15 3” 2” Floor Protection Outside air (Recommended) (Installation showing inlet of out- side air in ventilated crawl space) CLASS A CHIMNEY RETROFIT Vertical Cap Storm Collar... -

Page 18: Hearth Mount Installation

HEARTH MOUNT INSTALLATION Vertical Cap Storm Collar Chimney Cap Figure 17 Pellet Liner Flue Cover Pellet Clean-out Vent 6” Floor Protection Bring outside air to the stove Outside Air (Recommended) PRIOR TO INSTALLATION Clean all ashes out of the inside of the fi replace. Make sure that the chimney and fi replace are free of cracks, loose mortar, cresote deposits, blockage or other signs of deterioration. - Page 19 NPI40 INSTALLATION MINIMUM CLEARANCES TO COMBUSTIBLES Side wall to unit 8" Maximum mantel depth 10" Mantel to top of unit 8" Top facing to unit 6 3/8" Side facing to unit 6" Floor protection* 6"* Figure 18 * Floor Protection: Minimum 6" in front of door and to either side.

- Page 20 NPI40 INSTALLATION OVERVIEW Figure 21 See the section “INSTALLATION - MINIMUM MANTEL CLEARANCES” Drywall (or other combustible material) See the section “MINIMUM FRAM- ING DIMENSIONS” See the sections “GENERAL VENTING” and “INSTALLATION” See the section “MINIMUM Side CLEARANCES TO Wall COMBUSTIBLES”...

-

Page 21: Prior To Installation

INSTALLATION INTO A MASONRY FIREPLACE PRIOR TO INSTALLATION Stand-offs (See Dimensions on page 7) may be removed to fi t Figure 22 the insert into the fi replace. When installing the insert into a masonry fi replace, do not remove any bricks or masonry. If necessary, the damper plate may be removed from the smoke shelf, to accommodate the chimney liner. -

Page 22: Liner Installation

INSTALLATION INTO A FACTORY BUILT (METAL) FIREPLACE PRIOR TO INSTALLATION Stand-offs (See Dimensions on page 7) may be removed to fi t the insert Figure 23 into the fi replace. When installing the insert into a factory built fi replace, you must not modify any part that would alter the integrity in any way. -

Page 23: Installation Into A Combustible Built In Enclosure

INSTALLATION INTO A COMBUSTIBLE BUILT-IN ENCLOSURE MINIMUM FRAMING DIMENSIONS When installing the insert as a "Built-in" heater, it is important to maintain the "Clearances to Combustibles" as illustrated in Figure 24a-b. A non-combustible heart must cover the fl ooring underneath, as well as, a minimum of six inches in front and to both sides of the heater. -

Page 24: Minimum Enclosure Clearances

MINIMUM ENCLOSURE CLEARANCES Figure 25 NPI40 FINISHING FLASHING INSTALLATION 1. Secure the Right Flashing to the right side of the unit using two of the FIGURE 26 #8 x 1/2" screws. NOTE: Feed the Air Control Rod into the Air Control Slot on the Right Flashing before securing. -

Page 25: Trivet Npi40

The trivet for the NPI40 is attached by two set screws on the inside of the hopper lid. Figure 32 INSTALL VIEWING DOOR NPS40 AND NPI40 The main viewing door has been boxed separate from the heater, but MUST be installed before burning the heater. -

Page 26: Operating Instructions

OPERATING INSTRUCTIONS The pellet heater can be operated with or without the ring in place over the burn pot. With the ring in place, a more ef- fi cient burn will occur, however more fi ner fl y ash will be experienced. It may be necessary to clean the burn pot of ash more frequently. -

Page 27: General Maintenance Nps40 And Npi40

GENERAL MAINTENANCE NPS40 AND NPI40 DAILY (WHENEVER USING THE HEATER) OPEN MAIN VIEWING DOOR WARNING The front of the heater becomes very hot during operation. Let the heater cool completely before conducting service. 1. Open the side doors on either side of the heater. - Page 28 CLEANING THE HEAT EXCHANGE TUBES WARNING The front edge of the hopper lid becomes very hot, do not touch the area below the handle. Figure 38 WARNING This rod becomes very hot during operation. Wait till heater has cooled completely or you MUSt wear heat resistant gloves when cleaning or handling this heater.

- Page 29 CLEANING THE BURN POT WARNING Make certain the heater has fully cooled (approximately 25 minutes) before opening the door and conducting service. To clean the burn pot, open the door and knock away any debris on the burn Figure 40 pot.

- Page 30 NOTE: The heater becomes very hot during operation. Let the heater cool completely and disconnect the power cord prior to conducting service. VACUUM HOPPER NPS40: Run the heater until the pellets run out, then open the hopper and vacuum out the entire hopper. The dust and any other debris near the bottom should be removed to Figure 44 prevent excessive build-up.

- Page 31 CLEAN THE VERTICAL EXHAUST DUCT If the PRPP40 or the brick kit NP841KT is in place, remove that accessory fi rst. Figure 45 1. Open side door, release the latch and pivot the viewing door wide open. See Figure 35 and 36. 2.

- Page 32 CHECK ALL SEALS Check for air leaks around the door, glass, and ash pan and replace gaskets as required. Air leaks into the fi rebox will decrease the heater's performance greatly, leading to excessive soot, ineffi cient burning, and may even cause a malfunction. Test the door seal by shutting the door on a piece of paper in various locations.

-

Page 33: Normal Operating Sounds

NORMAL OPERATING SOUNDS Figure 49 W415-0616 / C / 06.04.08... -

Page 34: Wiring Diagram

WIRING DIAGRAM Figure 51 W415-0616 / C / 06.04.08... - Page 35 W010-1685 LEFT LOUVRE ASSEMBLY W660-0053 OVER-RIDE SWITCH 160°F (71°C) W010-1567 AIR CONTROL W660-0054 IGNITION SWITCH 120°F (60°C) W660-0055 HIGH LIMIT SWITCH 200°F (93°C) NPS40 COMPONENTS W660-0056 VACUUM SWITCH W380-0020 CONTROL KNOB W010-1508 WELDED TOP ASSEMBLY W195-0004 POWER CORD W010-1527 SIDE DOOR ASSEMBLY...

- Page 36 COMMON REPLACEMENTS PARTS W415-0616 / C / 06.04.08...

- Page 37 NPS40 REPLACEMENTS PARTS W415-0616 / C / 06.04.08...

- Page 38 NPI40 REPLACEMENTS PARTS W415-0616 / C / 06.04.08...

- Page 39 COMMON ACCESSORY PARTS PARTS NPI40 ACCESSORY W415-0616 / C / 06.04.08...

-

Page 40: Troubleshooting

TROUBLESHOOTING *NOTE: All troubleshooting procedures should be carried out by qualifi ed technicians or installers. CAUTION: When checking connections, installing jumper wires (for test purposes only) or replacing components, unplug heater from the receptacle to prevent electrical shock or dampage to the compo- nent. - Page 41 TROUBLESHOOTING CONTINUED SYMPTOM TEST SOLUTION Feed rate dial has - Secure all connections to the power control module. no effect on the - Perform a resistance test to the potentiometer by placing the two test leads fi re (timer control from a multi meter into the leads of the potentiometer.

- Page 42 TROUBLESHOOTING CONTINUED SYMPTOM TEST SOLUTION The 200°F (93°) - Reset the sensor and determine whether it was the convection blower or 160°F (71°C) high limit tem- temperature sensor failure. Bypass the 160°F (71°C) sensor. Does the convection perature sensor blower not come on high? If no than replace the blower. has tripped The heater will - Disconnect one of the brown wires from the exhaust temperature sensor and if the unit...

- Page 43 SERVICE AND MAINTENANCE LOG OWNERSHIP RECORDS Dealer's Name: Dealer's Address: City: State/Province: Zip Code/Postal Code: Serial Number: Date of Purchase: Date Installed: Notes: SERVICE DATE SERVICE TECHNICIAN SERVICE DESCRIPTION W415-0616 / C / 06.04.08...

- Page 44 NOTES W415-0616 / C / 06.04.08...